So Im subscribed to indy-mogul on youtube, and they recently did a tutorial on how to build wolverine-claw-props simular to the ones used in the movies:

I imediatly started building my own claws, and here they are!!!

I modified the design a bit with my own. Instead of plexi-glas, I used PVC pipe, heated and warped flat. Once flat, the material is ALOT easier to cut and sand than plexi-glass, so you dont have to be so delicate with it while cutting and drilling. I also illiminated the armature wire and handle by extending the claws to a single mounting bolt. This can be done with pvc, and not plexi-glass, because you can heat and warp the PVC to give the claws the 'tapered' effect (wider at the tip than at the base) Anyways, here are some progress pictures:

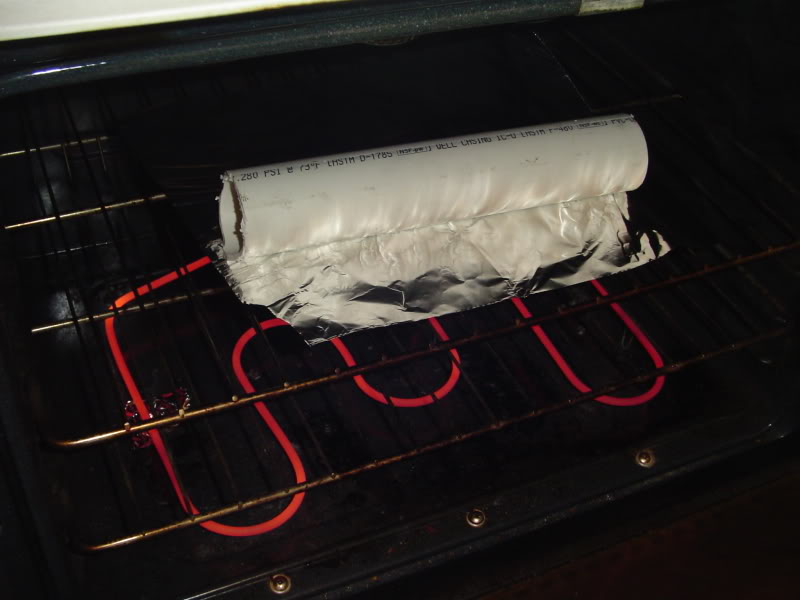

heating the pvc. (I cut a slit accross the top before sticking it in the oven)

after 20 minuts at 300 degrees, the plastic has the consistancy of thick tire rubber.

you only have about a 2-minut 'working time' before the plastic cools and sets. It will lock whatever shape its in at the time.

I used floor tile to compress and flatten the peice while it cooled. The tile also allows it to cool slower than it would if it was open to the air, which helps the plastic to not be brittle later.

TADA!!! Cheap sheets of plastic!!! A sheet of plexiglass this size would be around $10. A 10' peice of PVC will make about 8 of these for a dollar each.

Once done, you know the drill. Trace a card-board cut-out of your desired claw shape, and cut them out!

Strait claws after being bolted together.

This is after the outer claws were heated at the base with a lighter and 'warped' outward while still pliable. You can see the burn marks.

So far, they are un-painted. I still have a bit of sanding work to be done, and I might have to re-make one of the claws, as the first claw I attempted got shorter than the rest from lack of practice. There is also a slight 'moon' on one of the edges... I hope to have them finished in time for the X-men Origins premere. Hope you enjoyed! And happy forging!!!

I imediatly started building my own claws, and here they are!!!

I modified the design a bit with my own. Instead of plexi-glas, I used PVC pipe, heated and warped flat. Once flat, the material is ALOT easier to cut and sand than plexi-glass, so you dont have to be so delicate with it while cutting and drilling. I also illiminated the armature wire and handle by extending the claws to a single mounting bolt. This can be done with pvc, and not plexi-glass, because you can heat and warp the PVC to give the claws the 'tapered' effect (wider at the tip than at the base) Anyways, here are some progress pictures:

heating the pvc. (I cut a slit accross the top before sticking it in the oven)

after 20 minuts at 300 degrees, the plastic has the consistancy of thick tire rubber.

you only have about a 2-minut 'working time' before the plastic cools and sets. It will lock whatever shape its in at the time.

I used floor tile to compress and flatten the peice while it cooled. The tile also allows it to cool slower than it would if it was open to the air, which helps the plastic to not be brittle later.

TADA!!! Cheap sheets of plastic!!! A sheet of plexiglass this size would be around $10. A 10' peice of PVC will make about 8 of these for a dollar each.

Once done, you know the drill. Trace a card-board cut-out of your desired claw shape, and cut them out!

Strait claws after being bolted together.

This is after the outer claws were heated at the base with a lighter and 'warped' outward while still pliable. You can see the burn marks.

So far, they are un-painted. I still have a bit of sanding work to be done, and I might have to re-make one of the claws, as the first claw I attempted got shorter than the rest from lack of practice. There is also a slight 'moon' on one of the edges... I hope to have them finished in time for the X-men Origins premere. Hope you enjoyed! And happy forging!!!

Last edited by a moderator: