Hey everybody! My previous thread was for my first attempt at making a set of scout armor, but I encountered some problems, got frustrated, and got a night shift job, so it went without any update for at least three weeks. Since then, I have completed peps of a new EOD helmet, Noble Six Helmet, and Scout helmet, each for a separate build the three of us are doing. I have been trying to bondo my practice helmet (MK V) but have been having trouble, as when I sand, lots of divots and holes appear in the finish. I layer again, fill those holes, then sand and it happens all over again. Posting progress pictures as well as a link to my previous thread. Any help or suggestions are appreciated, the first issue being what I should do with the bondo situation. I have been dry sanding with 100 grit sandpaper, and can post more pictures of the MK V if need be. I decided to start a new thread because the old one didn't really explain my plans or my situation, and I'll try to do a better job of posting/elaborating in this one.

Link to previous thread: http://www.405th.com/showthread.php/41239-zdruck07-s-Halo-4-Scout-build-(and-problems-along-the-way)

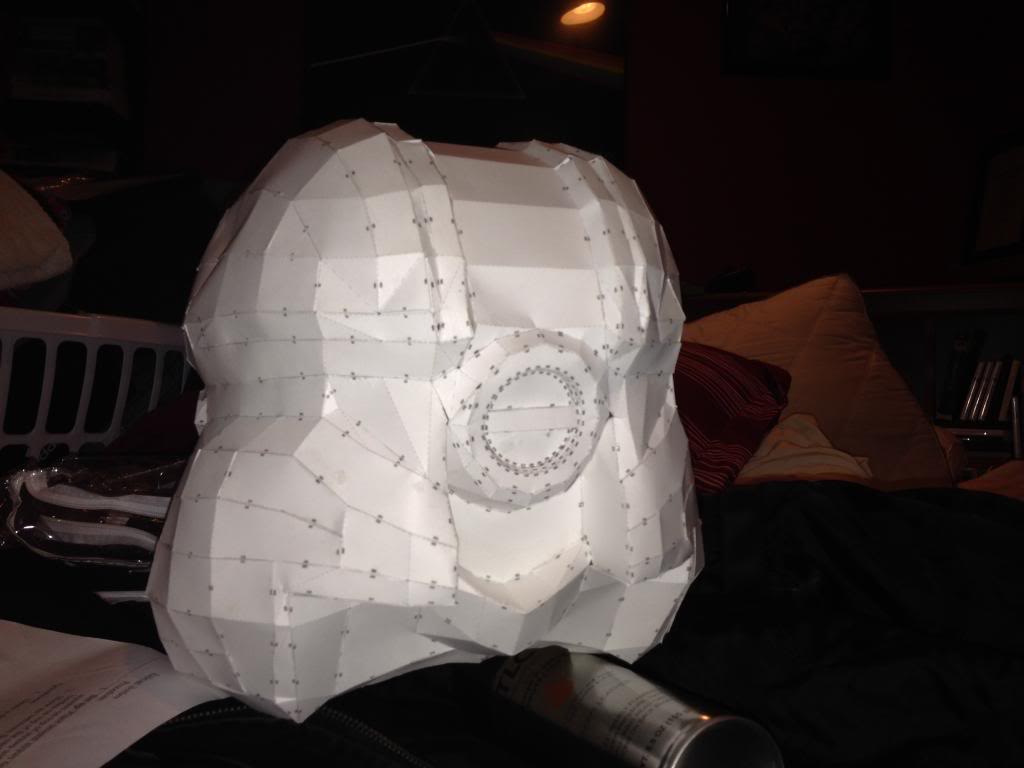

Scout helmet pictures:

Noble Six:

EOD (adding resin, though may be using it too thickly)

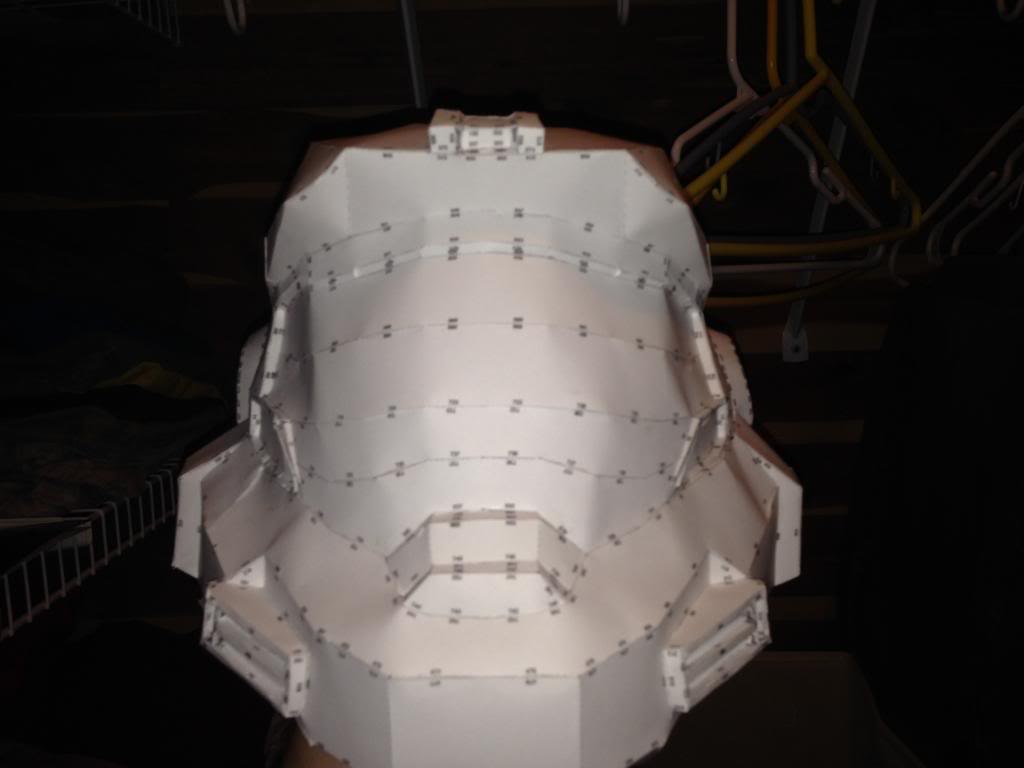

MK V

Link to previous thread: http://www.405th.com/showthread.php/41239-zdruck07-s-Halo-4-Scout-build-(and-problems-along-the-way)

Scout helmet pictures:

Noble Six:

EOD (adding resin, though may be using it too thickly)

MK V

Attachments

-

F2EF588B-4666-4C0D-B6A1-15AB729641F4_zpsrfue6vlv.jpg43 KB · Views: 112

F2EF588B-4666-4C0D-B6A1-15AB729641F4_zpsrfue6vlv.jpg43 KB · Views: 112 -

077ACB82-2CB6-4BF5-BD41-E502ABA238A4_zpsjdftzzpd.jpg42.1 KB · Views: 125

077ACB82-2CB6-4BF5-BD41-E502ABA238A4_zpsjdftzzpd.jpg42.1 KB · Views: 125 -

E97AD13B-5B04-4EA5-AC3F-F9889040AA5E_zpsj2ayplbg.jpg67.4 KB · Views: 125

E97AD13B-5B04-4EA5-AC3F-F9889040AA5E_zpsj2ayplbg.jpg67.4 KB · Views: 125 -

0C877439-A453-43BD-9739-1273425BE272_zpsopqnlyeg.jpg14 KB · Views: 135

0C877439-A453-43BD-9739-1273425BE272_zpsopqnlyeg.jpg14 KB · Views: 135 -

D16AD6F2-F5FB-478B-8FF0-F4521E15D157_zpsdq1mscji.jpg34.4 KB · Views: 123

D16AD6F2-F5FB-478B-8FF0-F4521E15D157_zpsdq1mscji.jpg34.4 KB · Views: 123 -

A79A93B0-5AAD-4D50-94A5-C853F21D4FA2_zps4jveuhyk.jpg14 KB · Views: 133

A79A93B0-5AAD-4D50-94A5-C853F21D4FA2_zps4jveuhyk.jpg14 KB · Views: 133