RCSRex

New Member

SYNOPSIS

Welp, it was bound to happen. Hello 405th peeps! You can probably already assume why this thread exists. I'm building my MP Spartan suit, specifically my Halo Reach Spartan (with a little extras here and there hopefully)! This is something that I have always dreamed of doing since I was a little kid back in the Halo 2 days, but lacked the time, patience, skill, yadda yadda excuses excuses... you get the gist. I actually remember printing like 100 pages of Pepakura cutout templates as a kid and not knowing what to do with them, lol.

Anyhow, let's get into the fun stuff. First, a rough idea of what I want my Spartan to look like. I whipped this up in Blender a while ago for VRChat use, but never got around to actually doing that. Maybe another time, but it is still mostly accurate for what I would like for my cosplay to look like.

THE PRINTER AND FILAMENT

I actually initially started off with an Ender 3 V2 and a couple spools of Sunlu PLA+ when I began this journey. It was an learning experience to say the least. I constantly battled the bed leveling, belt tension, filament stringing, (which I later learned that filaments need to be dry!), instances of heat creep, clogs... yeah. No fun. After a couple months of getting a couple of successful prints here and there, I took a very long break from printing before boxing the printer back up.

One day, I was doing a little window shopping on Micro Center's website when I came across this futuristic looking printer from some company called Bambu Lab, and it's X1 Carbon printer. It advertised itself as: "It just works right out of the box. You don't have to mess with it, just simply hit print, and the printer will handle all the calibrations (Auto-Bed Leveling, Vibration compensation) for you". Safe to say, I was intrigued. That's when I decided to check out a YouTube review on it.

I was sold. It hurt my wallet big time, but I felt that it was a justified investment.

Timeskip to today. Let me talk about filament. PLA and it's many subcategories are relatively easy to print. My big concern for it personally is it's heat resistance. It can begin to soften at temperatures of 55–65 °C. I live in Southern California, and more than likely would have to store this cosplay in a sturdy box outside due to the space inside the house. I tried PETG for a while, but it was a stringing NIGHTMARE for me, even after being dried extensively, so I decided to skip on it. Lots of YouTube videos regarding filaments later... I came across a filament called ASA. It was ABS's little brother, but it was bigger in every way. It had the same mechanical properties as ABS (a heat resistance of 95–100 °C!), but had high UV resistance, and generally better weather and chemical resistance off the bat. PLUS, it can be smoothed with acetone, which could in theory cut down on post-processing time significantly when it comes to sanding. I find it to print just as easily as PLA, albeit a little slower, but not by much. The only minus is that it LOVES to warp during a print, especially on large parts. It is extremely highly recommended that your printer has an enclosure if you want to print this filament. I have found a mostly stable way of preventing warping, as long as I keep the temperature inside the printer at a stable 45-50 °C.

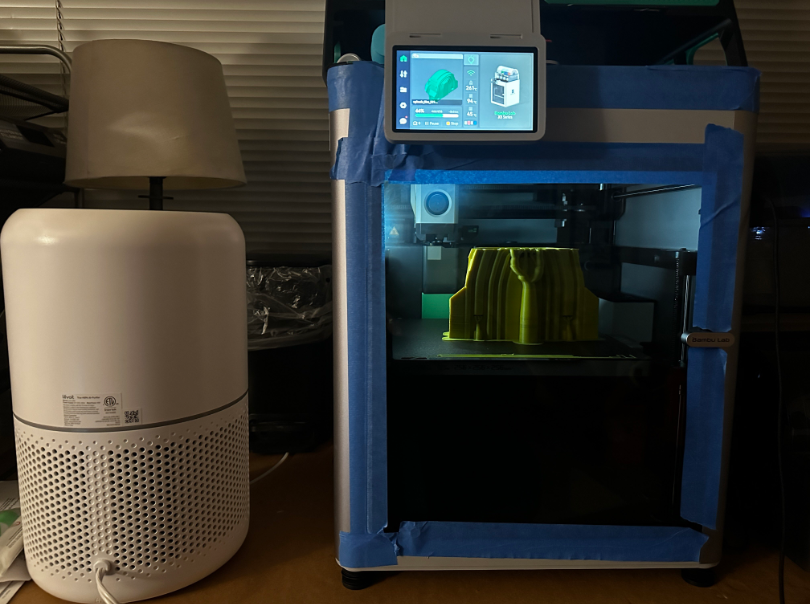

One thing to note is ASA, like ABS, emits toxic VOCs while it is printing. You need to invest in a filter system if you want to print this filament. For my use case, I purchased a VOXEL Bento Box 2 Stage Filter that could be installed inside the printer enclosure. It scrubs the air inside the printer enclosure, minimizing the fumes that escape, while keeping the temperature inside the printer nice and hot. As a precaution, I also invested in and staged a LEVOIT Air Purifier with a activated carbon filter next to the printer.

The reason for the masking tape on the front of the printer is to try and cover all the gaps in the door to keep all the hot air inside. You can see the Bento Box filter inside the printer on the right hand side.

THE MODELS

The majority of my models will be sourced from NerdForgeDesign and TitlewaveDesigns' files. I've also outsourced some parts, mainly the helmet from Branfuhr Studios, and the undersuit from 850 Armor Works.

Welp, it was bound to happen. Hello 405th peeps! You can probably already assume why this thread exists. I'm building my MP Spartan suit, specifically my Halo Reach Spartan (with a little extras here and there hopefully)! This is something that I have always dreamed of doing since I was a little kid back in the Halo 2 days, but lacked the time, patience, skill, yadda yadda excuses excuses... you get the gist. I actually remember printing like 100 pages of Pepakura cutout templates as a kid and not knowing what to do with them, lol.

Anyhow, let's get into the fun stuff. First, a rough idea of what I want my Spartan to look like. I whipped this up in Blender a while ago for VRChat use, but never got around to actually doing that. Maybe another time, but it is still mostly accurate for what I would like for my cosplay to look like.

THE PRINTER AND FILAMENT

I actually initially started off with an Ender 3 V2 and a couple spools of Sunlu PLA+ when I began this journey. It was an learning experience to say the least. I constantly battled the bed leveling, belt tension, filament stringing, (which I later learned that filaments need to be dry!), instances of heat creep, clogs... yeah. No fun. After a couple months of getting a couple of successful prints here and there, I took a very long break from printing before boxing the printer back up.

One day, I was doing a little window shopping on Micro Center's website when I came across this futuristic looking printer from some company called Bambu Lab, and it's X1 Carbon printer. It advertised itself as: "It just works right out of the box. You don't have to mess with it, just simply hit print, and the printer will handle all the calibrations (Auto-Bed Leveling, Vibration compensation) for you". Safe to say, I was intrigued. That's when I decided to check out a YouTube review on it.

I was sold. It hurt my wallet big time, but I felt that it was a justified investment.

Timeskip to today. Let me talk about filament. PLA and it's many subcategories are relatively easy to print. My big concern for it personally is it's heat resistance. It can begin to soften at temperatures of 55–65 °C. I live in Southern California, and more than likely would have to store this cosplay in a sturdy box outside due to the space inside the house. I tried PETG for a while, but it was a stringing NIGHTMARE for me, even after being dried extensively, so I decided to skip on it. Lots of YouTube videos regarding filaments later... I came across a filament called ASA. It was ABS's little brother, but it was bigger in every way. It had the same mechanical properties as ABS (a heat resistance of 95–100 °C!), but had high UV resistance, and generally better weather and chemical resistance off the bat. PLUS, it can be smoothed with acetone, which could in theory cut down on post-processing time significantly when it comes to sanding. I find it to print just as easily as PLA, albeit a little slower, but not by much. The only minus is that it LOVES to warp during a print, especially on large parts. It is extremely highly recommended that your printer has an enclosure if you want to print this filament. I have found a mostly stable way of preventing warping, as long as I keep the temperature inside the printer at a stable 45-50 °C.

One thing to note is ASA, like ABS, emits toxic VOCs while it is printing. You need to invest in a filter system if you want to print this filament. For my use case, I purchased a VOXEL Bento Box 2 Stage Filter that could be installed inside the printer enclosure. It scrubs the air inside the printer enclosure, minimizing the fumes that escape, while keeping the temperature inside the printer nice and hot. As a precaution, I also invested in and staged a LEVOIT Air Purifier with a activated carbon filter next to the printer.

The reason for the masking tape on the front of the printer is to try and cover all the gaps in the door to keep all the hot air inside. You can see the Bento Box filter inside the printer on the right hand side.

THE MODELS

The majority of my models will be sourced from NerdForgeDesign and TitlewaveDesigns' files. I've also outsourced some parts, mainly the helmet from Branfuhr Studios, and the undersuit from 850 Armor Works.

Last edited: