mitch35542

Member

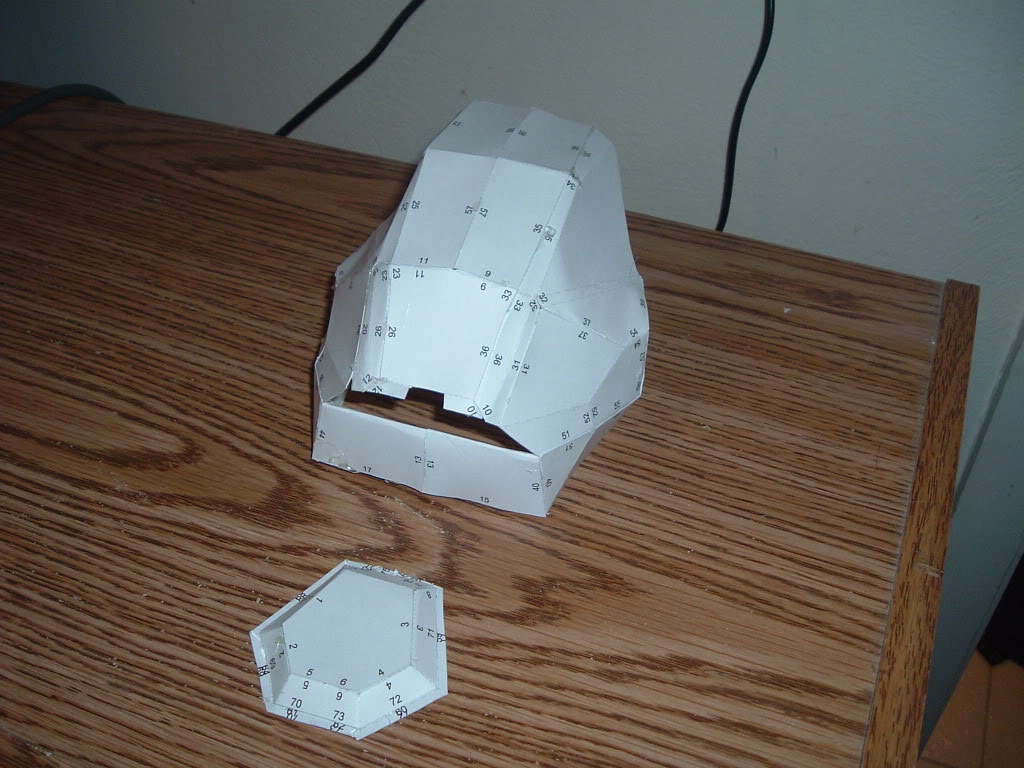

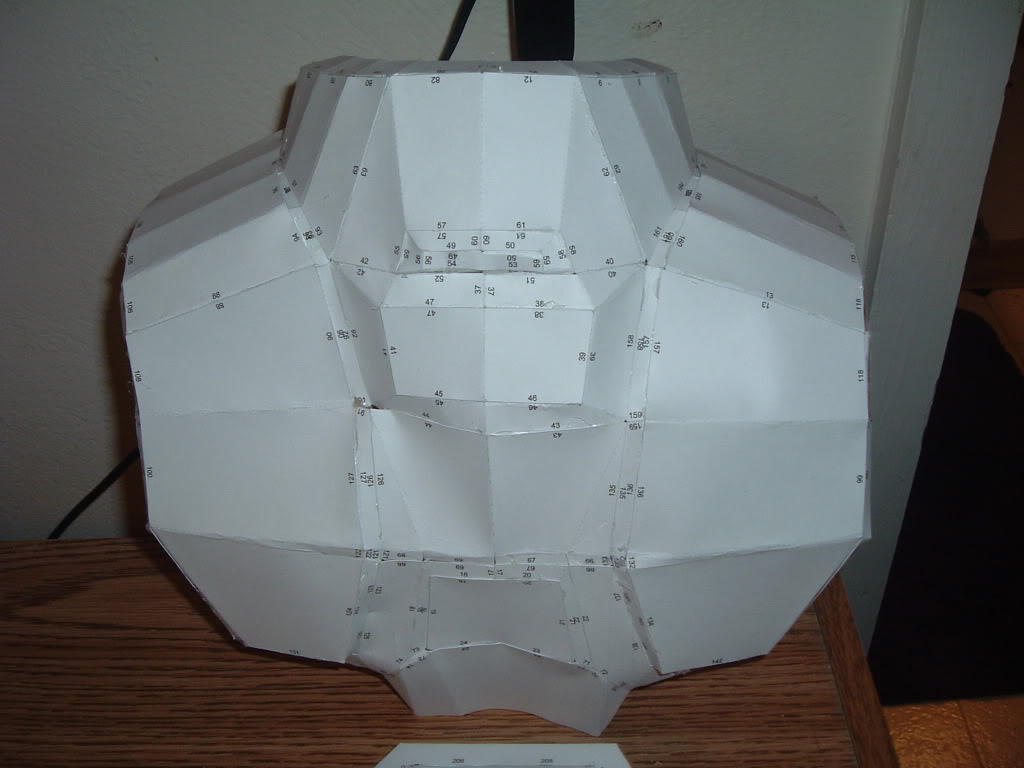

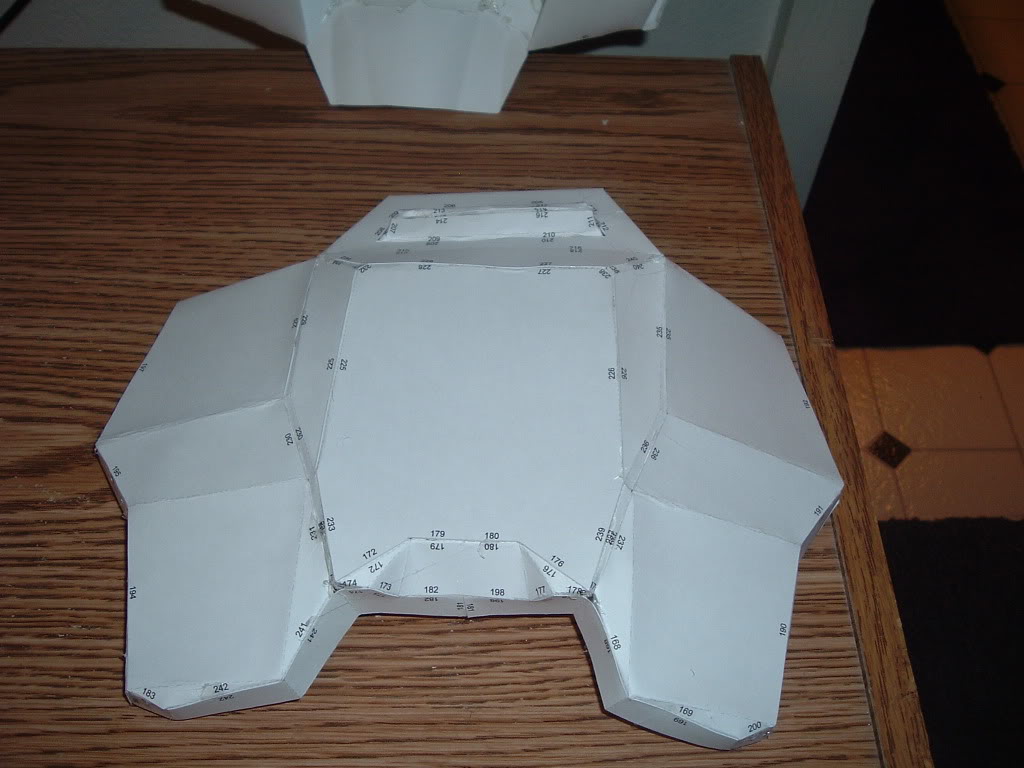

So here I am posting what I have of my suit so far at 12:17 AM. I've posted two threads about the helmet before, the second was because I lost the first thread but I was stupid and didn't make it a WIP thread, I don't think I knew what it even stood for back then. OH WELL! My helmet was originally a test piece to see if I had what it takes to make a suit and after I joined a group of 405th members in Ohio I decided to make a full suit, so heres what I have done. My helmet only needs to be sanded then painted, the shoulders and chest piece are pepped and ready for the other stages. Heres the pics of the pieces.