I mean, it's ur call but that doesn't look too ridiculously big from the pic. EOD is kind of a chonky helmet to begin with and you do want a little room if your gonna do fans or anything... Just one amateur's opinion but it looks about right to me.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1st Build 3d print reach build

- Thread starter cursedzeba

- Start date

- Status

- Not open for further replies.

cursedzeba

New Member

I mean it feels really wide for what it is there is like 3cm each side of my head and popping into armoursmith for a better look it seems bigI mean, it's ur call but that doesn't look too ridiculously big from the pic. EOD is kind of a chonky helmet to begin with and you do want a little room if your gonna do fans or anything... Just one amateur's opinion but it looks about right to me.

Fair enough. Don't hop over to my thread ur gonna hate how too big my ODST bucket is . Ultimately what matters is how you feel about it-so resize away!

Just out of curiosity, what are it's general dimensions?

Just out of curiosity, what are it's general dimensions?

cursedzeba

New Member

dimensions are about X=30 Y=33 Z=34 in centimeters. Taking it down about 13%Fair enough. Don't hop over to my thread ur gonna hate how too big my ODST bucket is . Ultimately what matters is how you feel about it-so resize away!

Just out of curiosity, what are it's general dimensions?

cursedzeba

New Member

Okay after investing in Armoursmith and using that to size the helmet I now have a MUCH better fit for my head, took a good few centimeters off all directions which is great because if that failed I was going to go for a whole different helmet like ODST or Commando (Or gunginir since I plan on going crazy with electronics)

Hey! Are you still having trouble getting good prints? I'm really experienced with 3d printing, if you have any questions HMU. Also, I'd recommend not printing in petg for a project like this. Instead, I'd suggest Esun PLA+! I've been using it for my build and it's super strong (as strong as PETG) while being super easy to print. I'm my experience PETG is really difficult to get good prints out of. Check out my thread if you want to see my printed build so far, im also using an EOD helmet, and let me know if you have any questions!

cursedzeba

New Member

As strong as PETG? I thought it was weaker than it, but if it is jsut as strong then I would probably use it instead for easy prints. What kind of settings do you use?Hey! Are you still having trouble getting good prints? I'm really experienced with 3d printing, if you have any questions HMU. Also, I'd recommend not printing in petg for a project like this. Instead, I'd suggest Esun PLA+! I've been using it for my build and it's super strong (as strong as PETG) while being super easy to print. I'm my experience PETG is really difficult to get good prints out of. Check out my thread if you want to see my printed build so far, im also using an EOD helmet, and let me know if you have any questions!

My armor I'm making out of the pla+ is super strong, in not afraid of anything breaking whatsoever. For my ender 3, I'm printing it at 210. For my lulzbot Taz 5 I'm printing it at 190.As strong as PETG? I thought it was weaker than it, but if it is jsut as strong then I would probably use it instead for easy prints. What kind of settings do you use?

cursedzeba

New Member

Well I will probably start using pla+, not going to redo what I already have but for the rest I want an easier print than what this has been

Good luck! Esun pla + is what I recommend

cursedzeba

New Member

Alright helmet attempt 2 almost done! going to smooth it out with resin and woodfiller before getting started with the painting.

How do you smooth prints with resin?

- Member DIN

- S068

Very carefully.How do you smooth prints with resin?

You can use a brush on polyester resin like XTC-3D to create a glossy coat that fills gaps. The downside there is that fine detail gets rounded over and recessed detail gets filled in as well.

cursedzeba

New Member

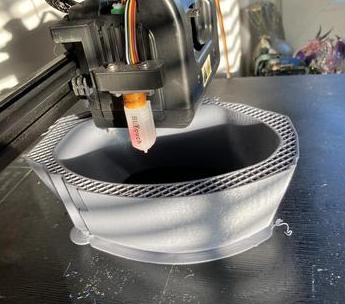

So with the helmet printed I can start printing other components starting with the shoulder area using eSun PLA+ at 210 and a nice small leyer hight of 0.1 mm, though that gives this bicep section a nice long print time of 2 days

looks good, I find that 0.2 layer height is usually a good medium between speed and quality. Also, you don't need that much infill actually, as it doesn't contribute that much to strength. The infill mostly just acts as a surface to build internal overhangs on. I usually stick to 5% infill with 3 outer perimeters if I'm using pla+. I lower infill percentage will drastically decrease your printing time and costs.

cursedzeba

New Member

only 5%? wow I usually never go below 10 but I will give it a try, thanks for the tip

cursedzeba

New Member

Okay I may have made it just a Little too big

In fact I can almost put both my arms though it, I need to work out more to get that Spartan look

In fact I can almost put both my arms though it, I need to work out more to get that Spartan look

cursedzeba

New Member

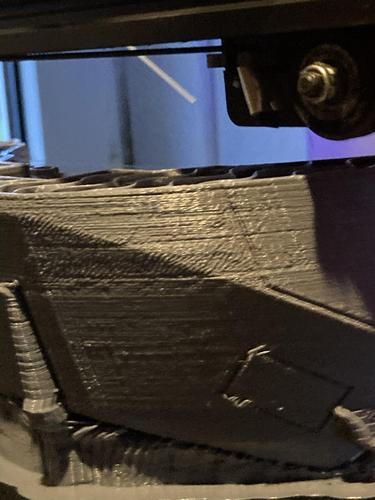

Okay I am going to need to ask for opinions here, what the heck is wrong with this print? its Esun pla at 210C and somehow it is comming out like this. any thoughts? I am hearing randon stuttering at times but it flows fine whenever I test it

Okay I am going to need to ask for opinions here, what the heck is wrong with this print? its Esun pla at 210C and somehow it is comming out like this. any thoughts? I am hearing randon stuttering at times but it flows fine whenever I test it

View attachment 297376

View attachment 297377

That looks like either temps are too high, your filament has absorbed moisture, or there is a partial clog in your hotend. Id start out by trying lowering your temperature by 10 degrees incrementally and see if anything changes. Are you hearing pops from the nozzle when it prints? If that doesn't help it, dry out your filament and do a few cold pulls to check if your extruder is clogged. If you don't know what a cold pull is there are tons of tutorials online

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 1,316

- Replies

- 6

- Views

- 1,298

Similar threads

- Replies

- 6

- Views

- 1,298