cursedzeba

New Member

Alright so the title is rather self explanitory, I did start a recon build years ago with pepakura but I never got far with it.

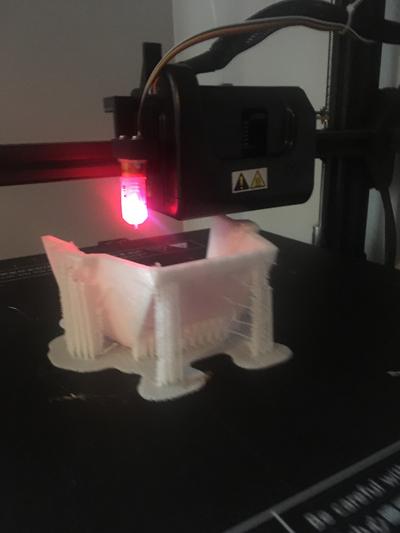

Now I have a 3d printer I thought I could try again so here I am, I attempted to start with a EOD helmet but Somehow I could not get the parts to print right with the petg I have and decided to order some other materials to try out. I have however had success with the simpler parts like the hand plates so I at least have them.

I decided on the EOD helmet it has a small visor and plenty of room for me to experiment with electronincs though the Gunginir helmet is VERY tempting to try however for a first helmet it is probably too ambitious.

Now I have a 3d printer I thought I could try again so here I am, I attempted to start with a EOD helmet but Somehow I could not get the parts to print right with the petg I have and decided to order some other materials to try out. I have however had success with the simpler parts like the hand plates so I at least have them.

I decided on the EOD helmet it has a small visor and plenty of room for me to experiment with electronincs though the Gunginir helmet is VERY tempting to try however for a first helmet it is probably too ambitious.