Citruspers

Member

Update: if anyone doesn't want to scroll all the way to the end, here's a little update how things are going:

-----

Hi everyone,

I'm Citruspers from The Netherlands, 31 years old and been a Halo fan for a long time (I'm no stranger to hauling CRT TV's for a system link LAN party, lol). I've obviously played the games and have read most of the books. Favourite game is a toss-up between Halo 3 (finale) and Reach (storytelling/presentation), favourite books are probably the Karen Traviss series.

I've been dabbling with making a Mjolnir costume for years now, starting out years ago with a paper/pepakura model and a massive amount of filler putty. After that, the project had been on ice for a few years until the Halo TV show came around. Disregarding the flaws, their depiction of spartan armor got the itch going again and I found myself low-key 3D printing some parts of Moe Sizzlac's mkVI armor set.

Then Castlefest came around again (finally!) where I walked around in my first (and last-minute) Skyrim cosplay and the reactions I got really motivated me to pursue my Mjolnir armor further.

So that's where I'm at now, my printer (a Voron 2.4 300mm) is busy cranking out more parts as I type this. I'll update this post to become a proper build log, but for now I'm excited to join the community, have a chat and share experiences.

Links to files used:

www.thingiverse.com

www.thingiverse.com

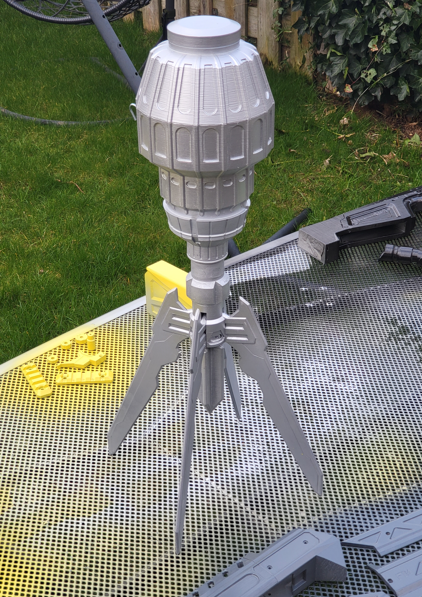

Plasma grenade, Cortana chip, BR75: Get more from OddWorks on Patreon

-----

Hi everyone,

I'm Citruspers from The Netherlands, 31 years old and been a Halo fan for a long time (I'm no stranger to hauling CRT TV's for a system link LAN party, lol). I've obviously played the games and have read most of the books. Favourite game is a toss-up between Halo 3 (finale) and Reach (storytelling/presentation), favourite books are probably the Karen Traviss series.

I've been dabbling with making a Mjolnir costume for years now, starting out years ago with a paper/pepakura model and a massive amount of filler putty. After that, the project had been on ice for a few years until the Halo TV show came around. Disregarding the flaws, their depiction of spartan armor got the itch going again and I found myself low-key 3D printing some parts of Moe Sizzlac's mkVI armor set.

Then Castlefest came around again (finally!) where I walked around in my first (and last-minute) Skyrim cosplay and the reactions I got really motivated me to pursue my Mjolnir armor further.

So that's where I'm at now, my printer (a Voron 2.4 300mm) is busy cranking out more parts as I type this. I'll update this post to become a proper build log, but for now I'm excited to join the community, have a chat and share experiences.

Links to files used:

Halo 3 - Mark 6 - Master Chief Armor Set - No Helmet by moesizzlac

Update 11-18-21: Added a 16 piece wrap for the torso. You can individually glue this onto your torso area and it'll look good.Update 08-12-20: Fixed Torso issue.Update 10-02-19: Added Torso details to be printed using TPU Filament (Ninjaflex). Need to give a nod to Phil Shinner and his work...

Plasma grenade, Cortana chip, BR75: Get more from OddWorks on Patreon

Attachments

Last edited: