I intend to use this thread to ask specific questions as I learn my way to 3D printer excellence.

I did a ton of trouble shooting, trial and error, and watching of youtube videos and thought I had my settings dialed in pretty well. Then, today, three hours into a print it failed and spaghettid all over the place. Now when I try to get it going again, the filament won't stick to the plate. When I start a print, I get this:

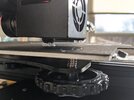

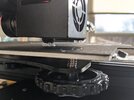

idk how clearly you can see but instead of touching and sticking to the plate, the filament has decided to curl up and stick to the nozzel/ itself. It then just makes a bigger and bigger tangled ball of filament as it goes. I didn't change anything and I was getting decent prints last night.

idk how clearly you can see but instead of touching and sticking to the plate, the filament has decided to curl up and stick to the nozzel/ itself. It then just makes a bigger and bigger tangled ball of filament as it goes. I didn't change anything and I was getting decent prints last night.

Does anyone know what happened? Or how to fix it?

EDIT: to clarify, I have an ender 3 pro and am currently printing 1.75 PLA.

I did a ton of trouble shooting, trial and error, and watching of youtube videos and thought I had my settings dialed in pretty well. Then, today, three hours into a print it failed and spaghettid all over the place. Now when I try to get it going again, the filament won't stick to the plate. When I start a print, I get this:

idk how clearly you can see but instead of touching and sticking to the plate, the filament has decided to curl up and stick to the nozzel/ itself. It then just makes a bigger and bigger tangled ball of filament as it goes. I didn't change anything and I was getting decent prints last night.

idk how clearly you can see but instead of touching and sticking to the plate, the filament has decided to curl up and stick to the nozzel/ itself. It then just makes a bigger and bigger tangled ball of filament as it goes. I didn't change anything and I was getting decent prints last night.Does anyone know what happened? Or how to fix it?

EDIT: to clarify, I have an ender 3 pro and am currently printing 1.75 PLA.