EDIT: This thread details the creation of two builds. The first was a commission on a 4 day deadline for a friend of mine. The second was a commission from Bethesda Softworks to re-create the gun again for display in their offices.

This is the final "V1" (4 day build)

This is the final "V2" (Bethesda's replica)

———————————

A friend of mine came to me on August 1st and said he was planning on going to DragonCon as a Vault Dweller from Fallout 3. He wanted a Pip-Boy 3000 and a Laser Rifle done in time for the convention on September 4th.

Of course, that's insane. I told him one or the other, and I could give it about 30 hours total for the build. He picked the AER9 Laser Rifle.

I started by making a blueprint of the gun, based off several screenshots and some images pulled from a modelviewer. I'm going to be repeating this a lot, but since this is a short build, I didn't take as much time with this as I usually do with some blueprints:

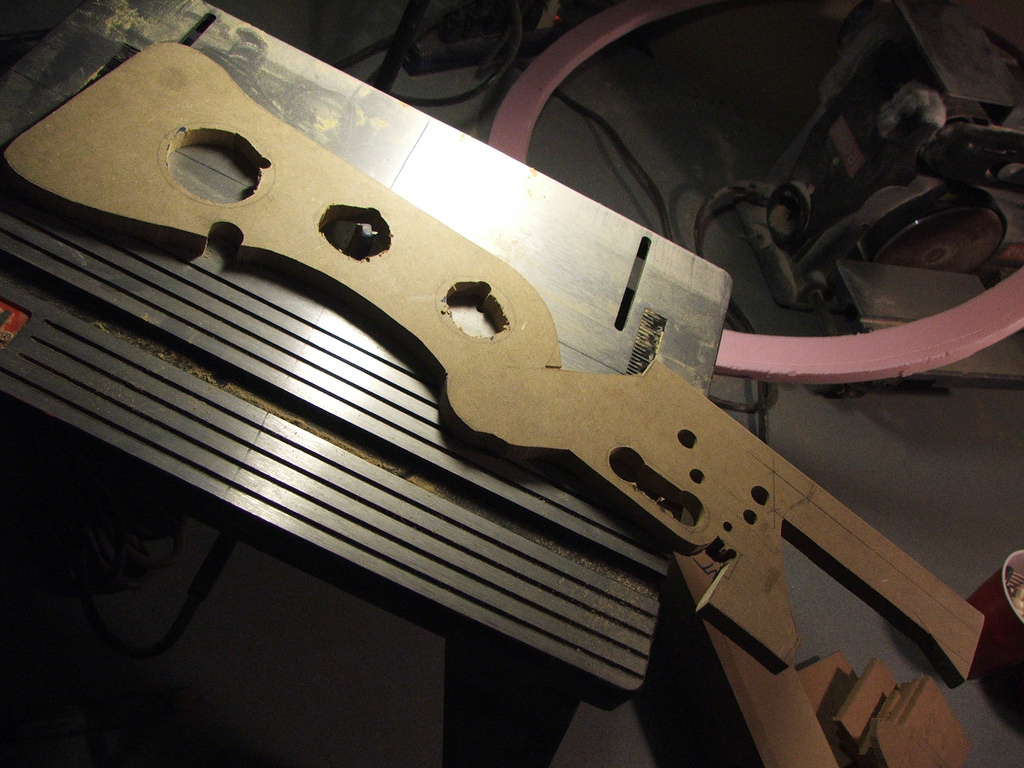

In order to save some time, my friend came by my shop one day while I was working on other projects and rough-cut some shapes for me to refine later. Most of this thing is going to me made out of MDF. I gave him the blueprints, some basic ideas of what I needed, and he went to town with the bandsaw:

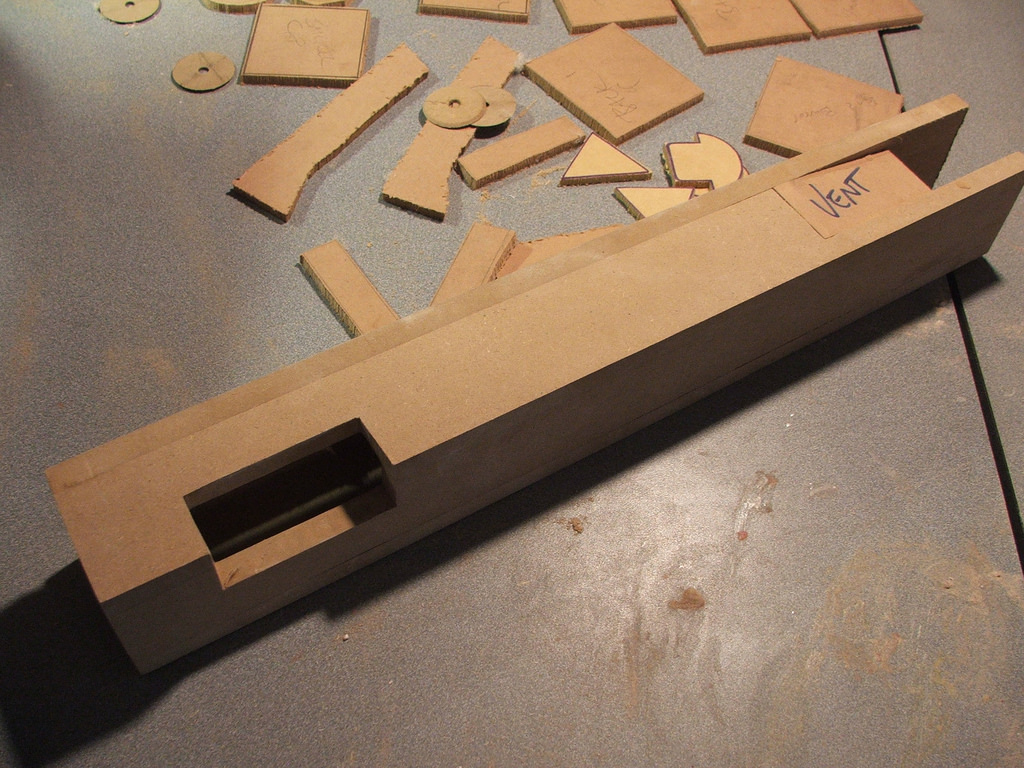

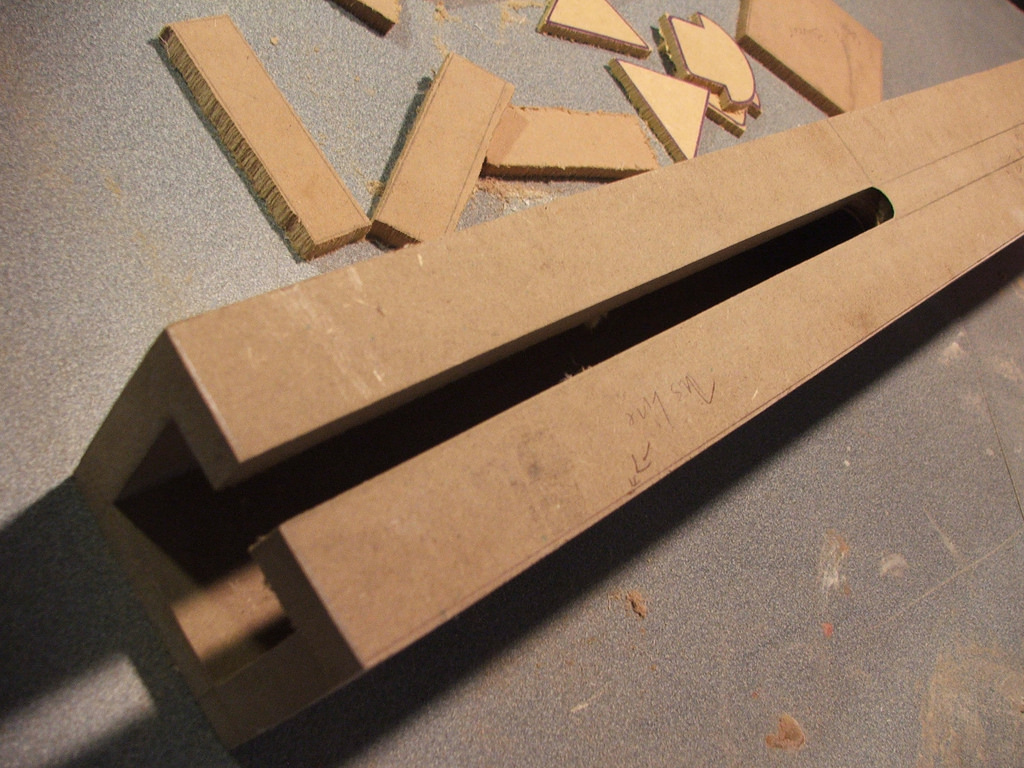

This is the main body/barrel of the gun, a box shaped out of 1/2" MDF. The missing chunk is where the "microfusion cell" lives, which is the ammo for this weapon. The rear stock and trigger assembly fits into the channel routed out of the bottom

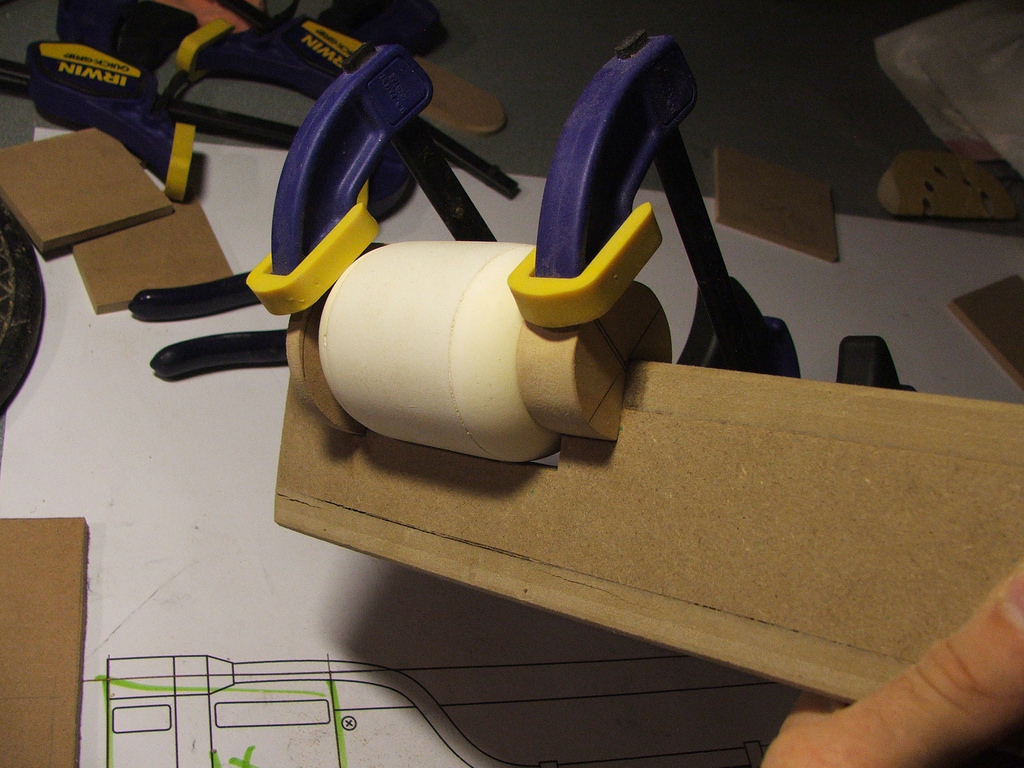

Here is the microfusion cell - I had a dome-shaped mold from another project that happened to be nearly the correct shape. I pulled 2 copies, epoxied it around some PVC, and voila!

Rear stock shaved down on the router table, nearly done shaping it

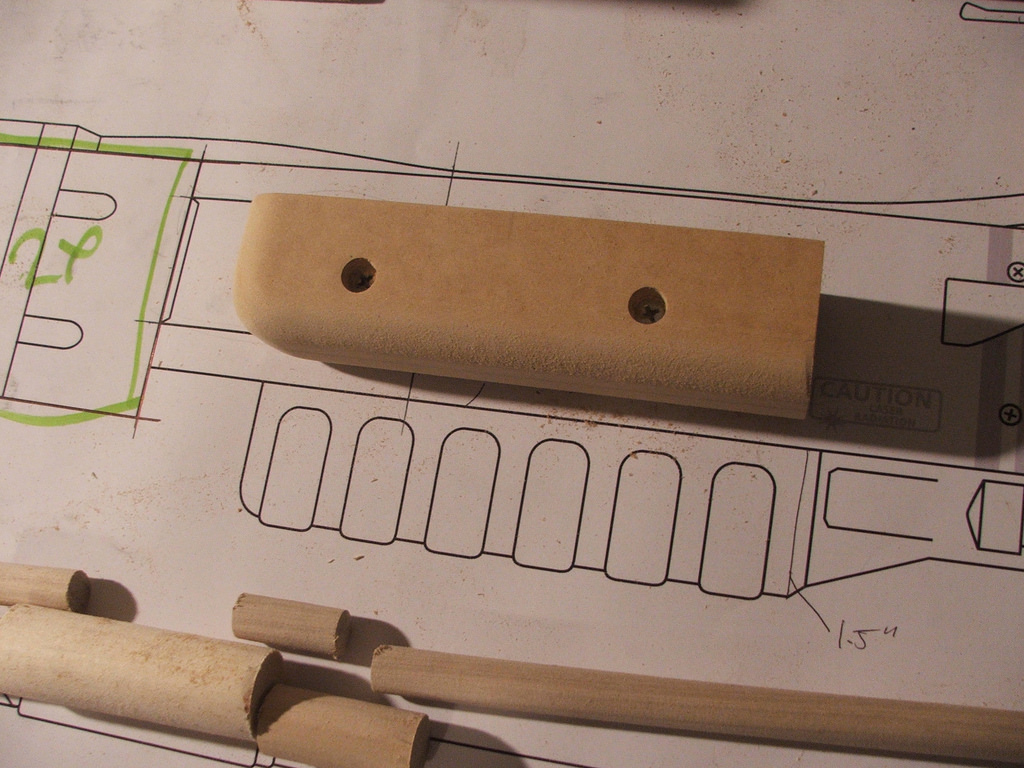

front grip carved from 2 pieces of 3/4" MDF. I'll add the raised sections on later with styrene sheet

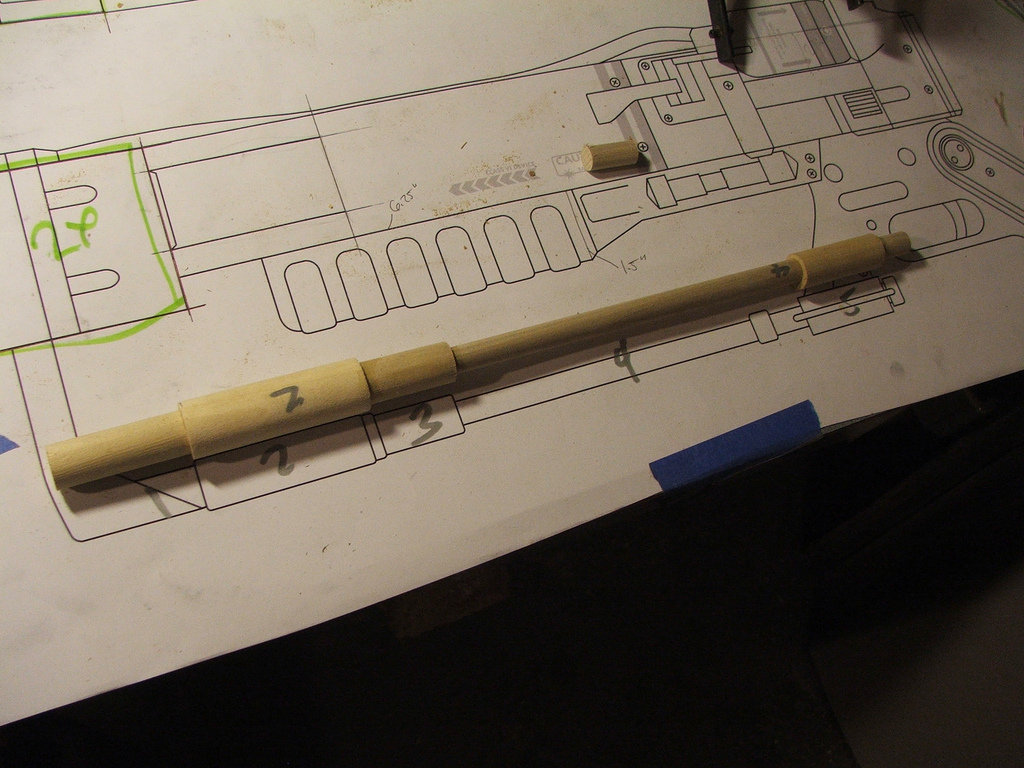

The under-barrel rod... thing. No idea what this is for, but its made out of different diameters of pine dowels joined together. Didn't have time to lathe something more accurate. I'll fill in the chamfered edges later with apoxie sculpt

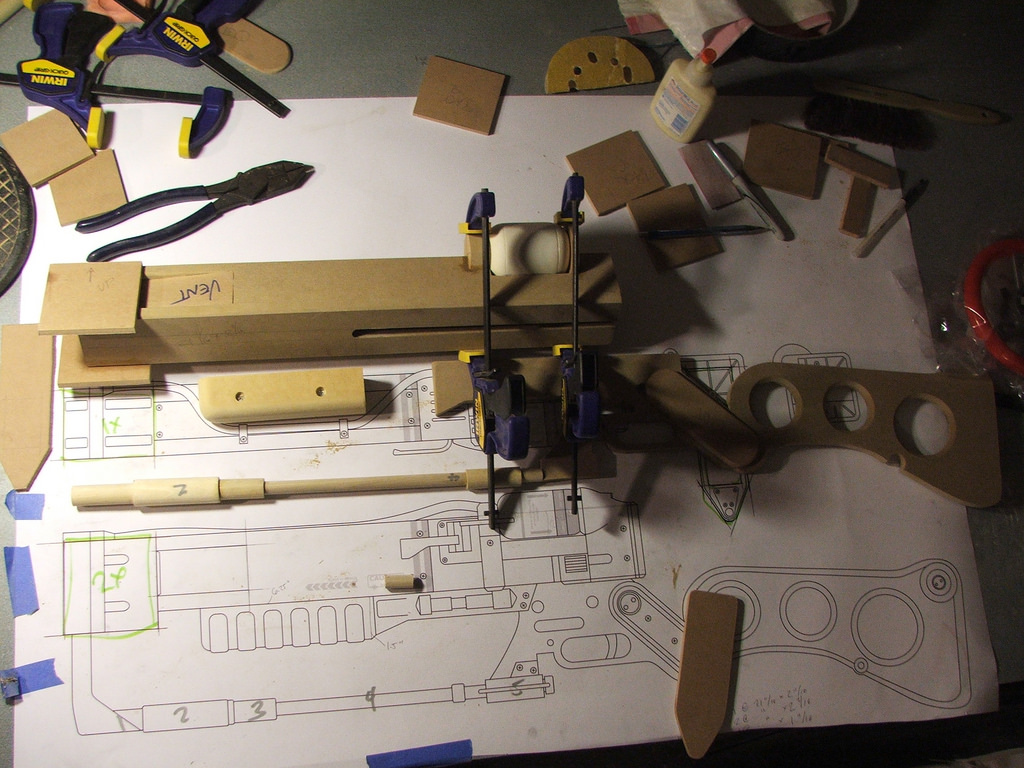

End of day 1, about 8 hours total (not including the schematics)

Stay tuned!

This is the final "V1" (4 day build)

This is the final "V2" (Bethesda's replica)

———————————

A friend of mine came to me on August 1st and said he was planning on going to DragonCon as a Vault Dweller from Fallout 3. He wanted a Pip-Boy 3000 and a Laser Rifle done in time for the convention on September 4th.

Of course, that's insane. I told him one or the other, and I could give it about 30 hours total for the build. He picked the AER9 Laser Rifle.

I started by making a blueprint of the gun, based off several screenshots and some images pulled from a modelviewer. I'm going to be repeating this a lot, but since this is a short build, I didn't take as much time with this as I usually do with some blueprints:

In order to save some time, my friend came by my shop one day while I was working on other projects and rough-cut some shapes for me to refine later. Most of this thing is going to me made out of MDF. I gave him the blueprints, some basic ideas of what I needed, and he went to town with the bandsaw:

This is the main body/barrel of the gun, a box shaped out of 1/2" MDF. The missing chunk is where the "microfusion cell" lives, which is the ammo for this weapon. The rear stock and trigger assembly fits into the channel routed out of the bottom

Here is the microfusion cell - I had a dome-shaped mold from another project that happened to be nearly the correct shape. I pulled 2 copies, epoxied it around some PVC, and voila!

Rear stock shaved down on the router table, nearly done shaping it

front grip carved from 2 pieces of 3/4" MDF. I'll add the raised sections on later with styrene sheet

The under-barrel rod... thing. No idea what this is for, but its made out of different diameters of pine dowels joined together. Didn't have time to lathe something more accurate. I'll fill in the chamfered edges later with apoxie sculpt

End of day 1, about 8 hours total (not including the schematics)

Stay tuned!