MkII Colonial Viper from the 2003 reimagined series of Battlestar Galactica

I first had this idea years ago, along with a couple of other projects I may move onto after it. With all the iron man stuff, photography, astronomy and knife making going on, it didn't look like I was ever going to do it.

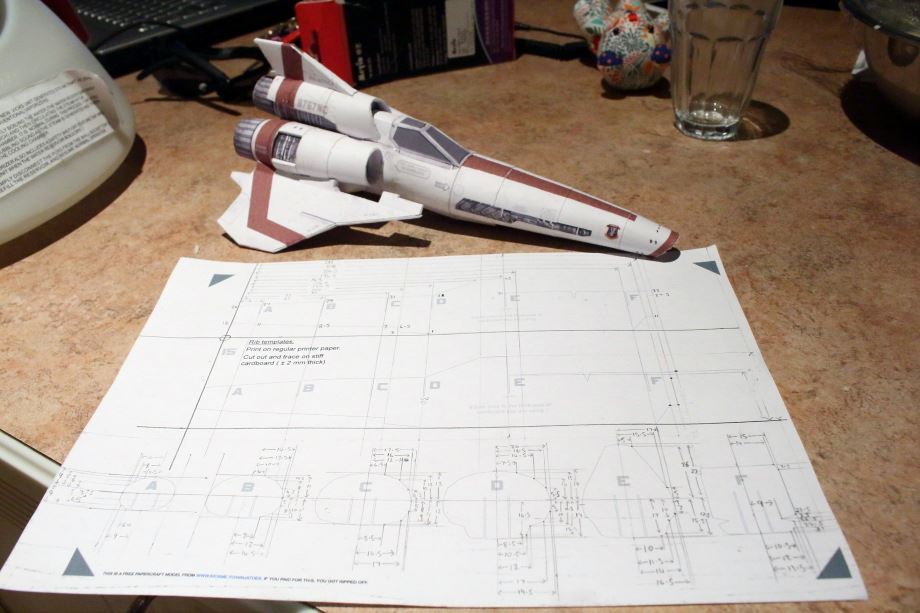

A few years ago, I tried upscaling a paper model from online and started a life-size cardboard version, but didn't like the shape of it. After sitting in my shed for nearly a year taking up space, I destroyed it.

Next, I grabbed a Mobeius kit and took Vernier caliper measurements from the plastic model and multiplied them by the scale factor of about three. I made a concept model three times the size in cardboard and wood, threw some lights in it and worked out how the modular sections might assemble on-site for transport and pull-down.

I only built one side of it so the other side can stay open for future visual planning. I mirrored a couple of photos for fun. (above)

I've been collecting plywood and foam, among other materials for many months. For the last couple of years I've been trying to get shop drawings out of any CAD specialist willing to help, but I understand it's a lot of work for free and it's a big ask to dedicate the time.

Even using verniers and blowing it up three times, brought inaccuracies I can't accept, so I really needed to get dimensions accurate.

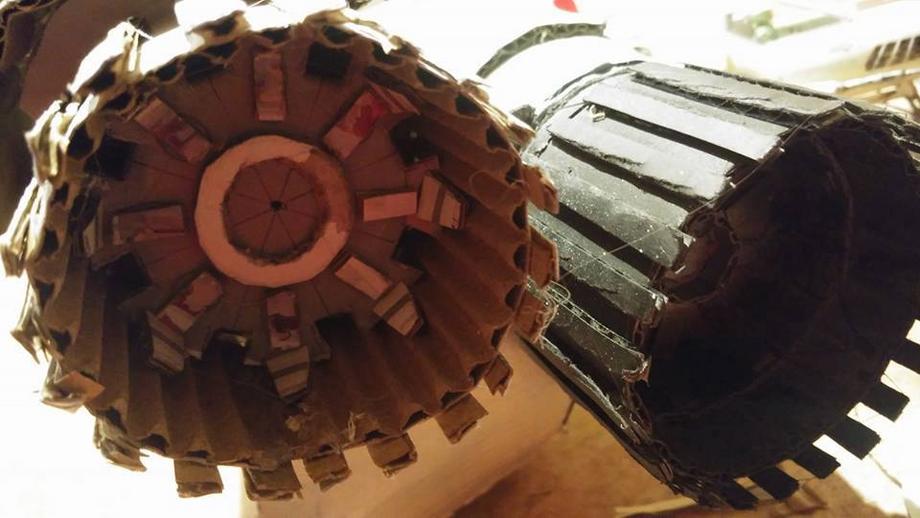

Now that I have a CAD expert helping me, I finally have accurate shop drawings and have started on the first two and a bit metres of the nose.

The craft will use a variety of materials to make it, depending on strength/safety and where it is needed. The majority will be plywood frame, some aluminium longerons etc for strength, polystyrene foam fill for sculpting, then skinned with fibreglass.

The cockpit and undercarriage will be constructed in such a way that it is safe to support and adult's weight and then some.

The entire ship tops out at 8.4 metres in length.

I have big plans for the rest of the ship, but I will tell the story as I go, rather than skip to the last chapter.

Since my first thoughts of this years ago, I was dismayed to go online searching for blueprints, not finding any, but finding at least two other full scale Vipers out there. One is in full aluminium and a little further along than mine, the other is a plywood, completed and recently unveiled in Manchester. I think they are both 1978 versions, where as mine is the reimagined 2003 version.

Just goes to show what can happen if you don't act on your dreams right away. Someone else will!

I first had this idea years ago, along with a couple of other projects I may move onto after it. With all the iron man stuff, photography, astronomy and knife making going on, it didn't look like I was ever going to do it.

A few years ago, I tried upscaling a paper model from online and started a life-size cardboard version, but didn't like the shape of it. After sitting in my shed for nearly a year taking up space, I destroyed it.

Next, I grabbed a Mobeius kit and took Vernier caliper measurements from the plastic model and multiplied them by the scale factor of about three. I made a concept model three times the size in cardboard and wood, threw some lights in it and worked out how the modular sections might assemble on-site for transport and pull-down.

I only built one side of it so the other side can stay open for future visual planning. I mirrored a couple of photos for fun. (above)

I've been collecting plywood and foam, among other materials for many months. For the last couple of years I've been trying to get shop drawings out of any CAD specialist willing to help, but I understand it's a lot of work for free and it's a big ask to dedicate the time.

Even using verniers and blowing it up three times, brought inaccuracies I can't accept, so I really needed to get dimensions accurate.

Now that I have a CAD expert helping me, I finally have accurate shop drawings and have started on the first two and a bit metres of the nose.

The craft will use a variety of materials to make it, depending on strength/safety and where it is needed. The majority will be plywood frame, some aluminium longerons etc for strength, polystyrene foam fill for sculpting, then skinned with fibreglass.

The cockpit and undercarriage will be constructed in such a way that it is safe to support and adult's weight and then some.

The entire ship tops out at 8.4 metres in length.

I have big plans for the rest of the ship, but I will tell the story as I go, rather than skip to the last chapter.

Since my first thoughts of this years ago, I was dismayed to go online searching for blueprints, not finding any, but finding at least two other full scale Vipers out there. One is in full aluminium and a little further along than mine, the other is a plywood, completed and recently unveiled in Manchester. I think they are both 1978 versions, where as mine is the reimagined 2003 version.

Just goes to show what can happen if you don't act on your dreams right away. Someone else will!

Last edited: