Hi, i first want to thank all the people on this forum for all the good tips and tricks, tutorials and resources.

Before i start posting pictures of what i built so far, i want to start different and tell you something about the Tool(s) i built in order to be able to work…

Problem: No Garage, no Workshop, only a small balcony and often wet or muddy weather.

Idea: Build an exhaust duct to be able to work in the living room or kitchen,…

It should be big enough to work on big parts like the torso and it should be foldable in order to be able to store away when not needed

Parts:

- some cheap batten

- offcut kitchen countertop (from hardware store)

- metal fittings and screws

- a strong transparent tarp

- Velcro straps + webbing

- exhaust fan

- flexible air pipe

- optional some lighting

Due to the use of Velcro for the tarp it’s easy to exchange if needed.

Another cool fact: you can heat the inner part up quite easy

Size:

The Base Plate (Kitchen Countertop) is 60cm deep and 80cm wide.

The inner height is between 65 and 75 cm.

Venting:

The Volume of the box is about 0,336 m³

The Fan is capable of an Airflow of about 110m³ /h

So the Air inside the Box is exchanged every 11 sec. should be enough. If I need more I will have to exchange the Fan. But this one is very quiet. We will see...

Keep in mind: This Box is no replacement for propper Protecton Equipment like a respirator!

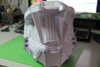

2 Pics of the Box "ready to use"

The Box folded

The other was to be foldable: It fits behind an unused Radiator and is out of view...

The test still has to be done but i'm confident that it works out as expected. And even if not. I can prevent my neighbors from the sanding dust by using it on the balcony.

Alex

Before i start posting pictures of what i built so far, i want to start different and tell you something about the Tool(s) i built in order to be able to work…

Problem: No Garage, no Workshop, only a small balcony and often wet or muddy weather.

Idea: Build an exhaust duct to be able to work in the living room or kitchen,…

It should be big enough to work on big parts like the torso and it should be foldable in order to be able to store away when not needed

Parts:

- some cheap batten

- offcut kitchen countertop (from hardware store)

- metal fittings and screws

- a strong transparent tarp

- Velcro straps + webbing

- exhaust fan

- flexible air pipe

- optional some lighting

Due to the use of Velcro for the tarp it’s easy to exchange if needed.

Another cool fact: you can heat the inner part up quite easy

Size:

The Base Plate (Kitchen Countertop) is 60cm deep and 80cm wide.

The inner height is between 65 and 75 cm.

Venting:

The Volume of the box is about 0,336 m³

The Fan is capable of an Airflow of about 110m³ /h

So the Air inside the Box is exchanged every 11 sec. should be enough. If I need more I will have to exchange the Fan. But this one is very quiet. We will see...

Keep in mind: This Box is no replacement for propper Protecton Equipment like a respirator!

2 Pics of the Box "ready to use"

The Box folded

The other was to be foldable: It fits behind an unused Radiator and is out of view...

The test still has to be done but i'm confident that it works out as expected. And even if not. I can prevent my neighbors from the sanding dust by using it on the balcony.

Alex