You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First Spartan III build (3D print)

- Thread starter Emp Frosty

- Start date

- Status

- Not open for further replies.

I can’t wait to see this finished

Carter7236

New Member

I'm working on Carter 3D print myself, as well as Kat. Nicely done!

- Member DIN

- S144

Progress is slow for a couple reasons but mostly due to how precise I want to be with the scale of each of these parts. The armorsmith designer is great due to its free form deformation but I'd love it if I could be even more accurate with the shape of the body than the initial measurements.

Hopefully I can have the thighs printed up next week though. Also how did everyone else do the boots? The files I have from nerd forge look like they just sit over your foot wear but I was wondering if it was possible to model them to have a treaded bottom and then put inserts in them to use as actual boots?

Hopefully I can have the thighs printed up next week though. Also how did everyone else do the boots? The files I have from nerd forge look like they just sit over your foot wear but I was wondering if it was possible to model them to have a treaded bottom and then put inserts in them to use as actual boots?

- Member DIN

- S144

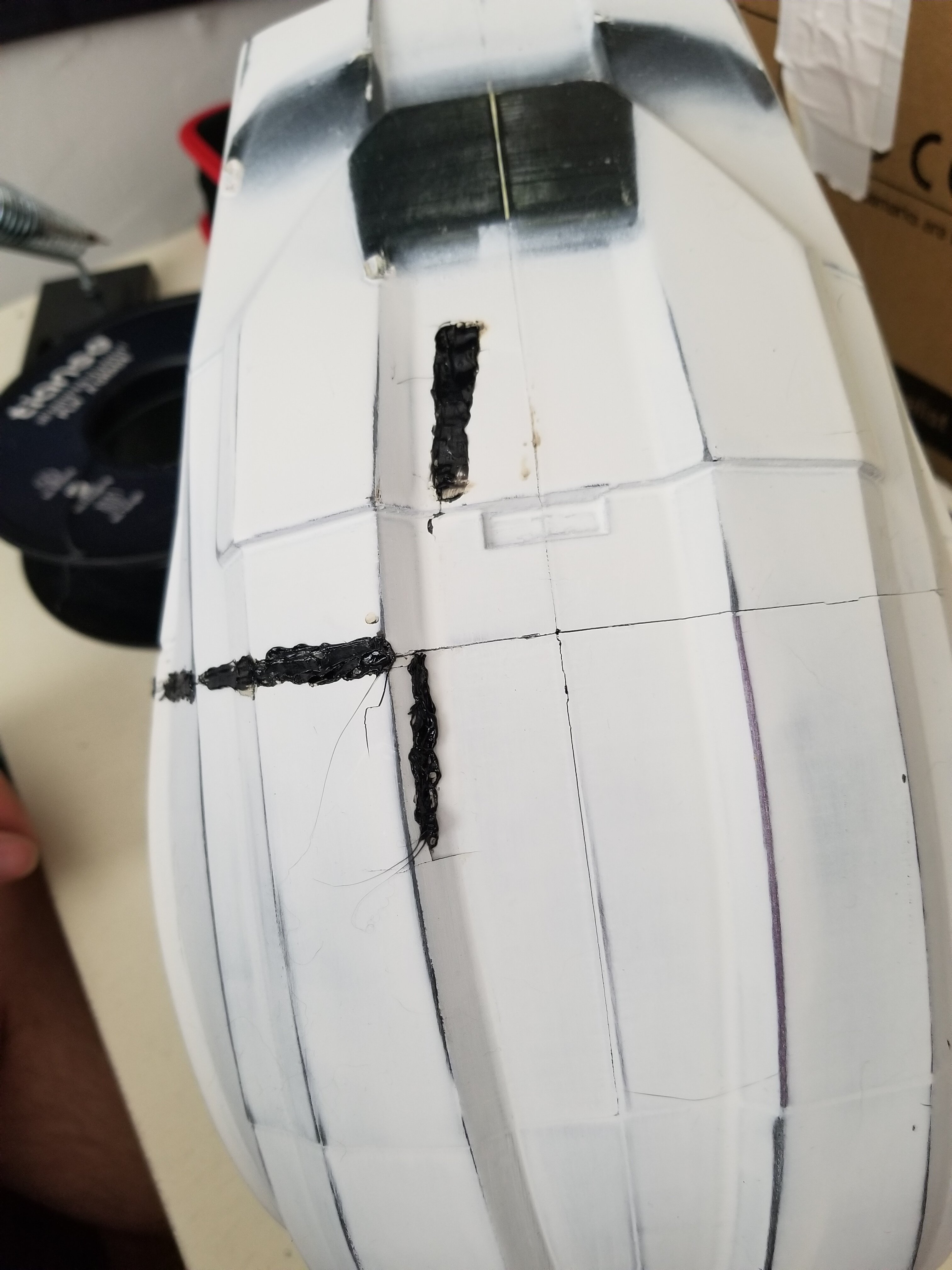

Here's a peek at the current state of the helmet. The visor could have come out better but I'm more or less happy with it for now till I make a buck and vacuum form one.

- Member DIN

- S144

The Helmet (and just about all the files im using) is from NerdForgeDesigns on etsy, only the visor was free handed by me.The helmet looks sick dude. Did you design it yourself?

- Member DIN

- S144

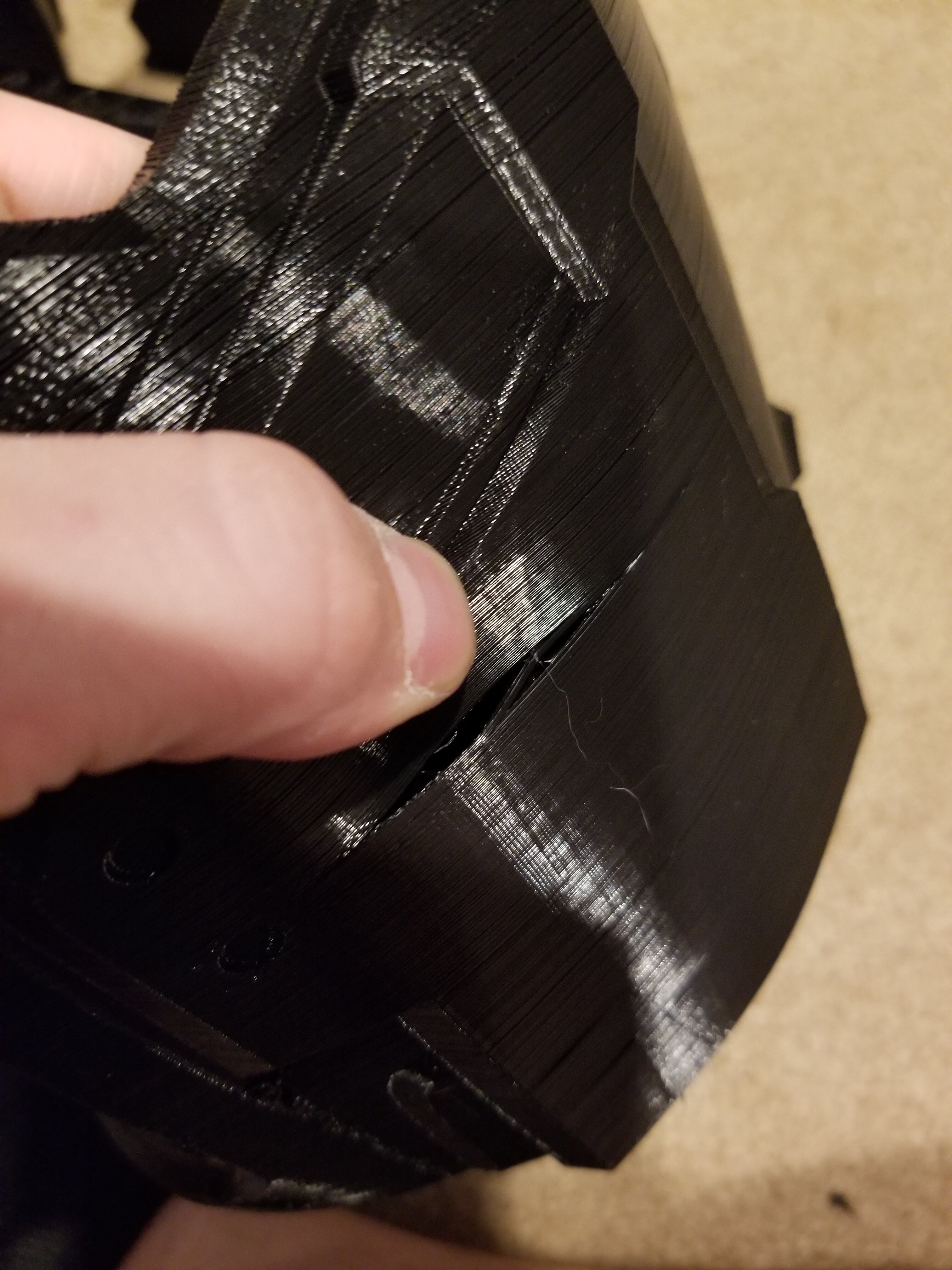

Isnt it always great to learn you've wasted a couple days on some prints?

Managed to print out a whole thigh section without noticing how brittle it was so I ran another file through to see it was the file or a printer problem (after purging and cleaning the nosel of course). Think I just got a really inconsistent spool of pla+ and it kept clogging so I'm gonna run it through my other printer before sacrificing it to the printing gods and getting some new spools.

Managed to print out a whole thigh section without noticing how brittle it was so I ran another file through to see it was the file or a printer problem (after purging and cleaning the nosel of course). Think I just got a really inconsistent spool of pla+ and it kept clogging so I'm gonna run it through my other printer before sacrificing it to the printing gods and getting some new spools.

- Member DIN

- S018

Can you weld the parts together?

- Member DIN

- S144

Definitely a possibility but the whole thing is so brittle that I dont think it's worth the effort to try. Just a little bit of pressure and it starts to buckle then split like shown.Can you weld the parts together?

- Member DIN

- S144

So turns out the filament wasn't the problem. I ran it through my Ender 3 last night and the print came out just fine like it was supposed to which means ill have to spend a day not printing and instead taking apart and deep cleaning my DOGE Machine (Ender 5)

Rock Lobbster

Sr Member

- Member DIN

- S098

Looks great! The scaling is spot on!

- Member DIN

- S144

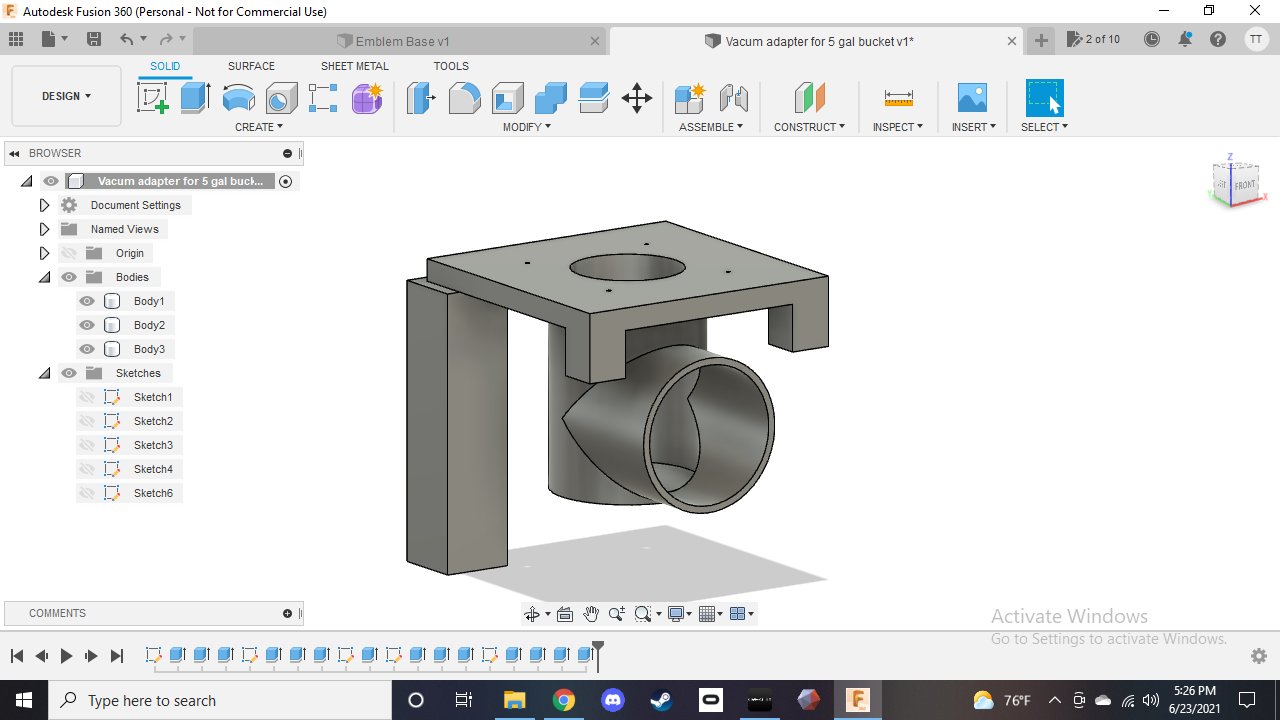

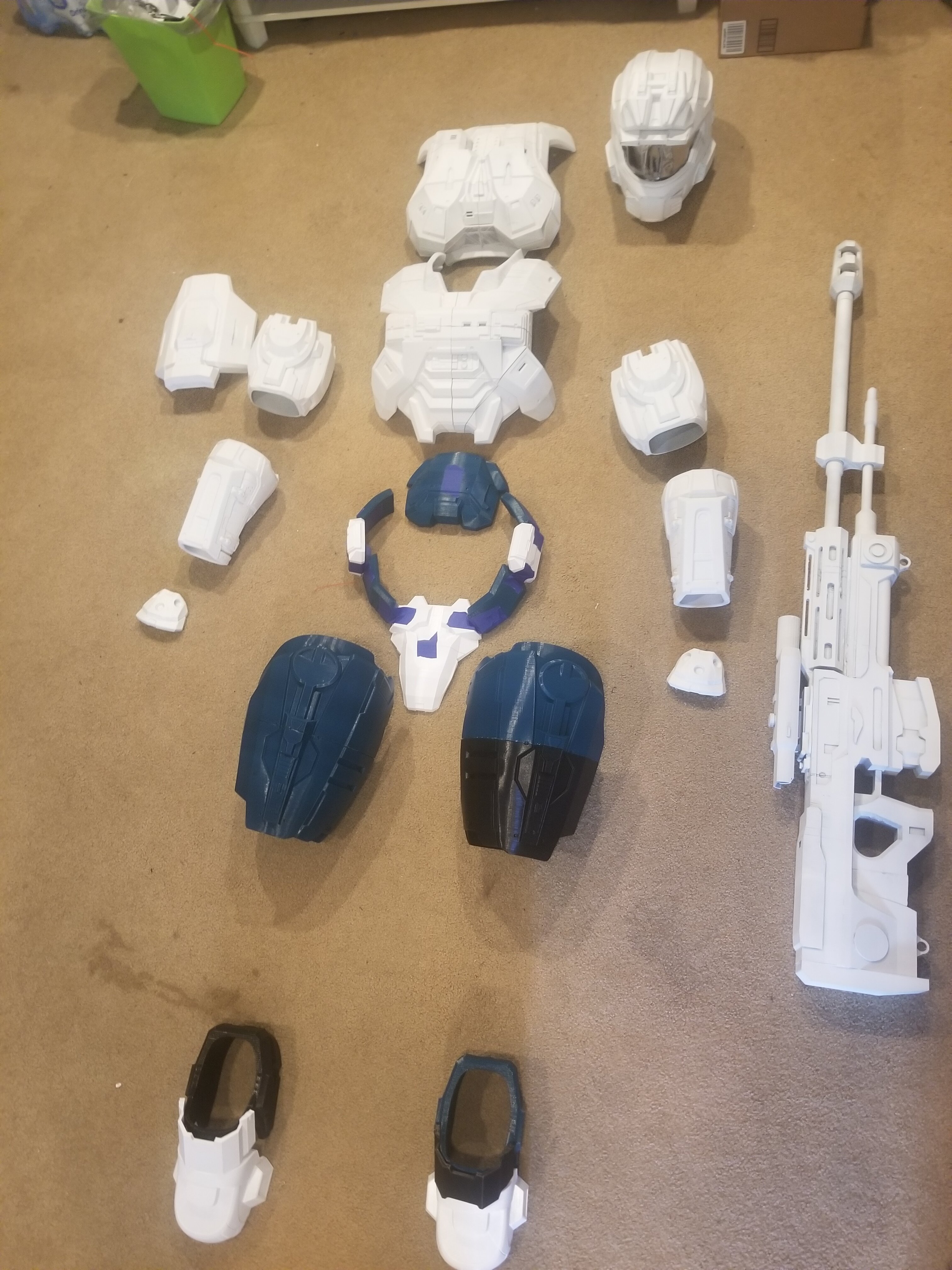

Been slow to update but I've managed to print out both boots and the right thigh (this time without it crumbling in my hands) and have the left thigh on the printer atm. All that's left to print is the shins and knee covers. I'm having trouble finding a way to fit the shins on my legs without having to just split them in half then reconnect with magnets, I want them to be form fitting but also as solid as possible. Have also been working on a pretty lazy way to make a vacuum box that just requires a peg board and a 5gal bucket (picture relevant) and some stencils for the Reach emblems if anyone is interested they will ultimately be linked to the tutorial index.

- Member DIN

- S144

Still in the middle of sanding and filling most of it but it doesnt look like candy anymore does it?

Just gotta get the scale of the shins and knees right and I'm dont printing the main body.

Just gotta get the scale of the shins and knees right and I'm dont printing the main body.

- Member DIN

- S144

Now that I've got my attention split through 4 or projects things are slowing down but I did get around to printing a visor buck and making a (test) vacuum bucket from the adapter I designed. Gotta give it a test run still but should theoretically work.... hopefully.

- Member DIN

- S144

Finally got around to a test of my vacuum bucket! Its not a great way to test it but i put some plastic wrap over the buck and and board and let it do its thing. Gotta do some adjustments to the hose socket but it should be ready for a step up to plastic.

Not sure if its gonna work but here a picture of what my clamps are gonna be

![20210717_095027[1].jpg 20210717_095027[1].jpg](https://www.405th.com/forums/attachments/20210717_095027-1-jpg.307914/)

![20210717_095015[1].jpg 20210717_095015[1].jpg](https://www.405th.com/forums/attachments/20210717_095015-1-jpg.307915/)

I tried to make this whole build as easy as possible for someone with no knowledge of vacuum forming to be able to do with store bought items and without any power tools.

Not sure if its gonna work but here a picture of what my clamps are gonna be

I tried to make this whole build as easy as possible for someone with no knowledge of vacuum forming to be able to do with store bought items and without any power tools.

- Member DIN

- S144

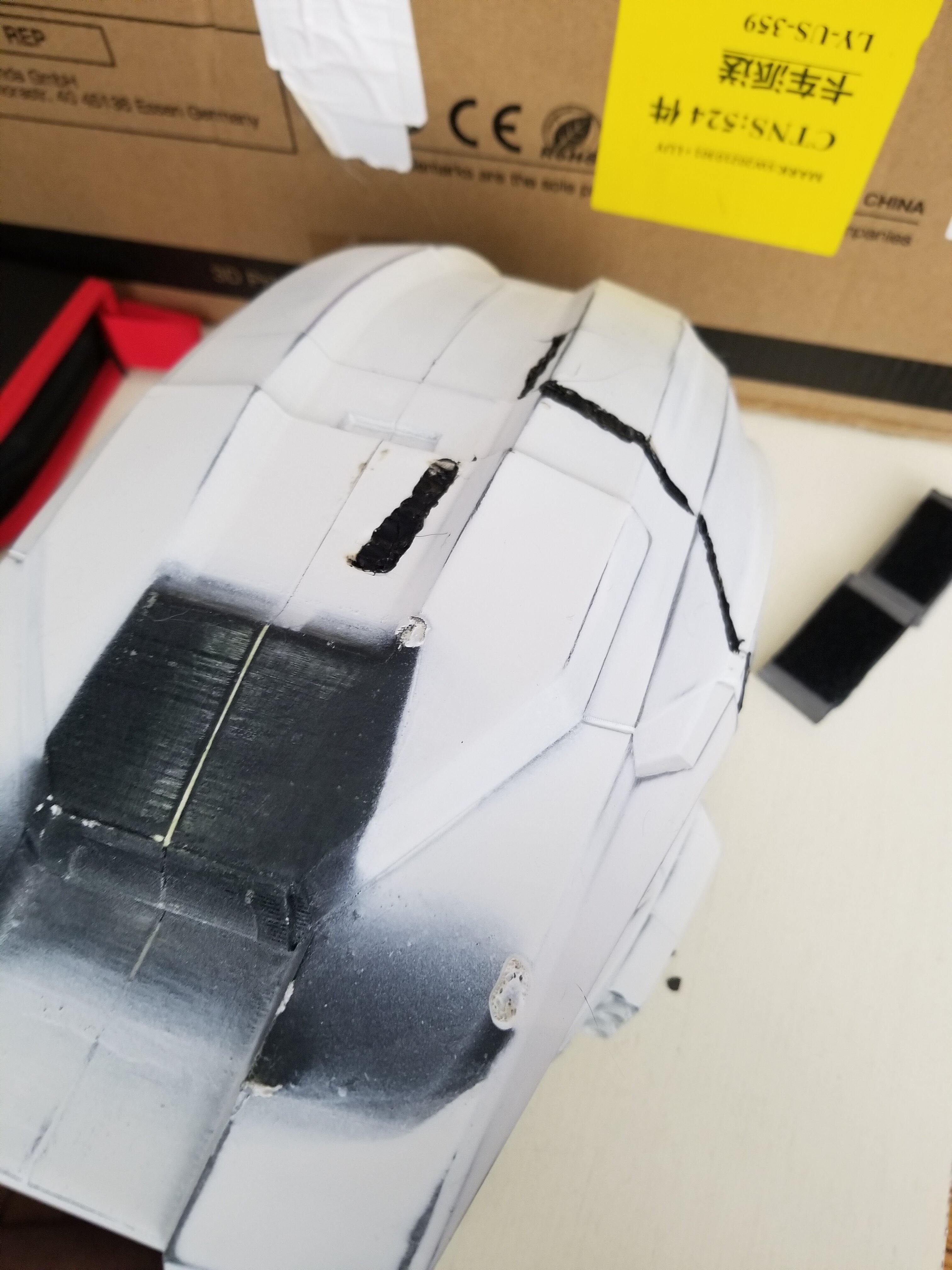

So imagine this:

Be me, spend a couple months on a build.

Makes pretty good progress learning about post processing 3d printed cosplay.

Learns he gets into school program that hes been waiting on for a year.

Has to move to St. Louis for school.

Packs costume extra secure for moving.

Makes it to St. Louis

Surprise nothing broke on drive!

Starts setting up appartment.

Decides to hang up wooden shelf from high school with velcro....

Decides to set really nice looking helmet under said shelf................

Shelf decides to fall a day later...........................

Helmet almost becomes scrap.

Lucky super glue held really well.

I didnt take any pictures before I welded it back together but there was a pretty big dent in it near the front and some pretty bad cracks throughout.

Be me, spend a couple months on a build.

Makes pretty good progress learning about post processing 3d printed cosplay.

Learns he gets into school program that hes been waiting on for a year.

Has to move to St. Louis for school.

Packs costume extra secure for moving.

Makes it to St. Louis

Surprise nothing broke on drive!

Starts setting up appartment.

Decides to hang up wooden shelf from high school with velcro....

Decides to set really nice looking helmet under said shelf................

Shelf decides to fall a day later...........................

Helmet almost becomes scrap.

Lucky super glue held really well.

I didnt take any pictures before I welded it back together but there was a pretty big dent in it near the front and some pretty bad cracks throughout.

Sorry to see that happen..So imagine this:

Be me, spend a couple months on a build.

Makes pretty good progress learning about post processing 3d printed cosplay.

Learns he gets into school program that hes been waiting on for a year.

Has to move to St. Louis for school.

Packs costume extra secure for moving.

Makes it to St. Louis

Surprise nothing broke on drive!

Starts setting up appartment.

Decides to hang up wooden shelf from high school with velcro....

Decides to set really nice looking helmet under said shelf................

Shelf decides to fall a day later...........................

Helmet almost becomes scrap.

Lucky super glue held really well.

View attachment 308971View attachment 308972

I didnt take any pictures before I welded it back together but there was a pretty big dent in it near the front and some pretty bad cracks throughout.

Would a resin help fill in the cracked bits? Might add some weight but you wouldn't need to worry about it breaking further?

Bondo and sanding would hopefully cover bigger dents that you've patched.

- Member DIN

- S144

I done a fair bit of melting and filling with some spare PLA+ for now and am planning to bondo and sand it over again. Wasnt planning to use resin before now but I am definitely considering for the whole armor now that this has happened.Sorry to see that happen..

Would a resin help fill in the cracked bits? Might add some weight but you wouldn't need to worry about it breaking further?

Bondo and sanding would hopefully cover bigger dents that you've patched.

- Status

- Not open for further replies.