You have a pretty common setup there.

This may not have much impact on your plans, but I would make one note.

The single-point attachment of the Thighs has given me a world of better mobility than the older two-point attachment.

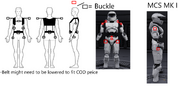

I would also note that my entire lower suit is foam for comfort, and as such, my shins can rest directly on the boots without needing any other supports. And the Thighs just need the one point to clip onto my harness:

View attachment 372034

It looks like you are pretty well on your way to getting the process sorted. And as you noted to Bob. A foam (even if only a 1-3mm Eva craft foam) barrier to parts that may rub or bump into each other with any frequency can help with clicking and clacking as you move about. (foam has a tendency to squeak at times, though if the rub is constant enough.) Not to mention the use of various upholstery foams to maintain fit and positioning while wearing the armor.