Samuelskinny

New Member

Hello! I am quite new around here but I have already been introduced to a couple of the 405th members on the Facebook group. I look forward to becoming a part of this community and doing my part to contribute to the wealth of knowledge that this community crates.

Description

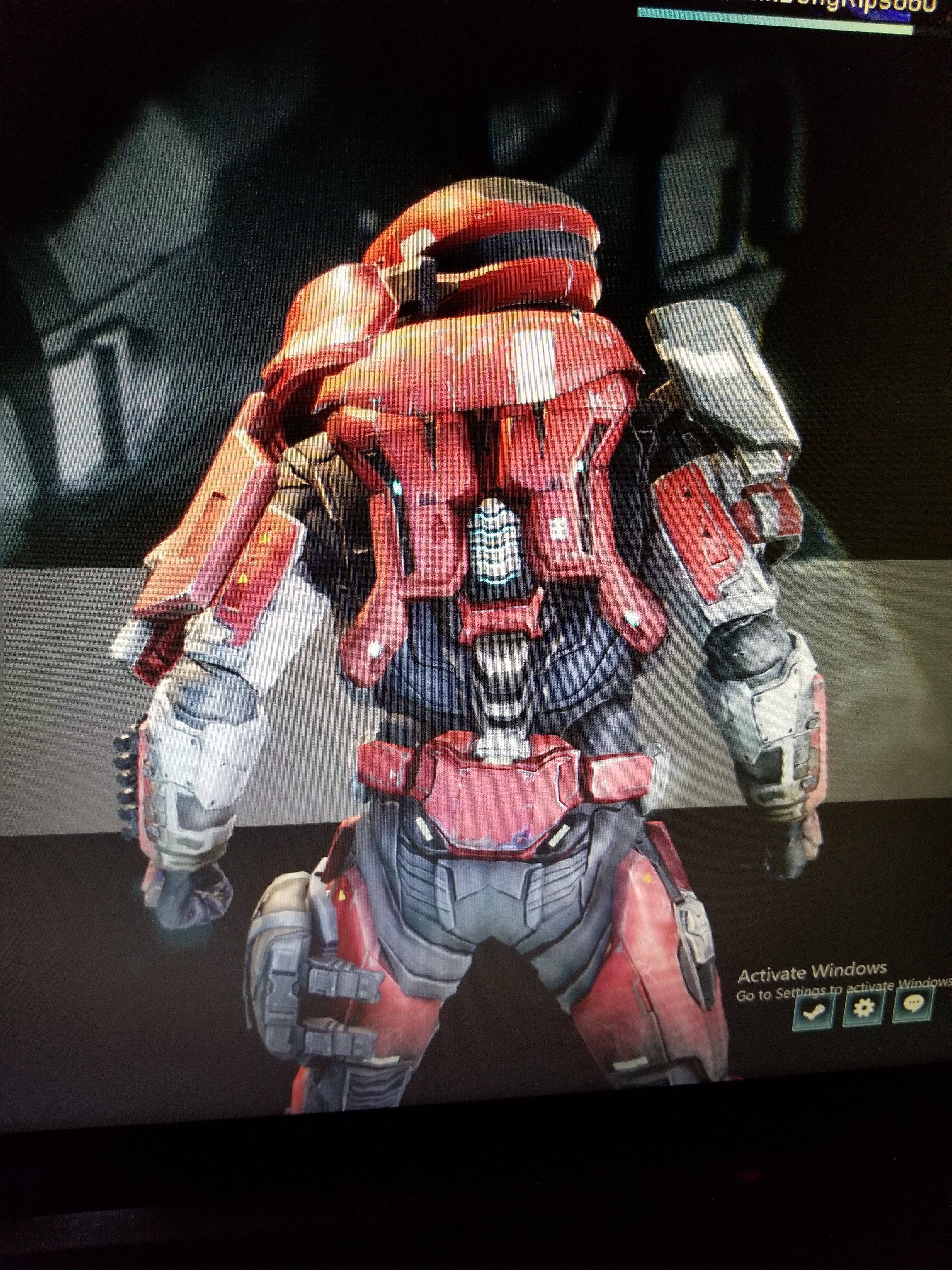

What I plan to do here is create a full Halo Reach armor set that is 3D printed and is as photo-realistic do the in-game model as possible. As a long-term goal I would either want to vacuum form this armor or create different armor using this one as a template out of either carbon fiber or fiberglass. And yes I wany you to be picky about my armor because I am striving for quality not time. So please, if you see anything that is concerning, please post it. Also if you have any questions do not be afraid to ask. I am more active on the Facebook group if you have a time based question, but be sure to post it on here!

Method

As I build and printing armor I will be keeping a log book of pertinent information such as printer settings, issues, thoughts, and general information about the build. I foresee this build requiring 3D printing, and foam work to complete but seeing as I worked and Auto Body I feel I'm qualified to get the specifications down.

Armor loadout and weapons

EOD Mark V helmet

Mark V base armor

Collar/Grenadier [UA] over chest

Left shoulder cqc plate

Right shoulder commando

Soft pack utility

Tactical ugps forearm

Sidearm m6g magnum

Main weapon m41 spankr

Description

What I plan to do here is create a full Halo Reach armor set that is 3D printed and is as photo-realistic do the in-game model as possible. As a long-term goal I would either want to vacuum form this armor or create different armor using this one as a template out of either carbon fiber or fiberglass. And yes I wany you to be picky about my armor because I am striving for quality not time. So please, if you see anything that is concerning, please post it. Also if you have any questions do not be afraid to ask. I am more active on the Facebook group if you have a time based question, but be sure to post it on here!

Method

As I build and printing armor I will be keeping a log book of pertinent information such as printer settings, issues, thoughts, and general information about the build. I foresee this build requiring 3D printing, and foam work to complete but seeing as I worked and Auto Body I feel I'm qualified to get the specifications down.

Armor loadout and weapons

EOD Mark V helmet

Mark V base armor

Collar/Grenadier [UA] over chest

Left shoulder cqc plate

Right shoulder commando

Soft pack utility

Tactical ugps forearm

Sidearm m6g magnum

Main weapon m41 spankr