You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

halo reach custom foam armor wip

- Thread starter Shaymin Sky

- Start date

- Status

- Not open for further replies.

King Ramna

Jr Member

The chest looks good. I hope you are you going to add the spinal detail on the bottom back of the chest because it has a really cool shadow effect and yummy to look at.

Shaymin Sky

Well-Known Member

I like your chest piece. Is that the Dawn Under Heaven chest, because I have been trying to make foam templates out of it, but some parts confuse me. Is it possible if you could share it, if it's the DUH chest file? I did donate if that's a concern.

It's actuallly not the Dawn under haven chest. I made this one out of a combination of pieces between L3x's v3 and v4 foam chest templates. I must mention that I did take certain liberties with pieces.(splitting them up, attaching others, ignoring pieces and adding others). I can send you my unfolds but I doubt they will be useful to you since they are quite a mess( pieces are all over the place and not organized). My advice to you would be to go to l3x's file base and download his foam chest templates and adjust them to your pleasure.

I do plan on unfolding Dawn under haven pieces for foam in the future however. While doing more foam unfolds is low on my list, It is on my list.

Right now my biggest concern is getting the suit done by Halo:CEA release. I still have to decide on a color scheme, experiment with getting paint right on the foam, padding and strapping, and the list goes on.

I also managed to get a pair of the gloves that everybody and their mother on this site owns. I'm talking thses ones.

yes it is a stock image. But it's just the gloves, nothing to really get that excited about.

enjoi.(even though there's really nothing in this post to do so

That armor is looking good. I'm trying to redo parts of my suit with the foam method before the release of Halo:CEA as well. I like that I don't have to work with fiberglass or rely on the weather but I haven't got the hang of cutting the right angles. Any tips because yours look amazing

Shaymin Sky

Well-Known Member

That armor is looking good. I'm trying to redo parts of my suit with the foam method before the release of Halo:CEA as well. I like that I don't have to work with fiberglass or rely on the weather but I haven't got the hang of cutting the right angles. Any tips because yours look amazing

NO CUT ANGLES! CUT ANGLES BAD!!! I Use a Rotary tool tool or a belt sander. I got a very cheap belt sander on sale for around $50 at harbor frieght(warning: it is also cheaply made), and I've always had my dremel. I find that I get more even angles with the sander, but the dremel allows me to get in tight places.

hope it helps.

LOL, ok I'll use my sander or dremel next time Thanks

Shaymin Sky

Well-Known Member

well hallo everyone. It's been quite a while. I really don't have much to update in a physical sense.

The helmet has gotten some love and bondo. It still needs more love and bondo. I'd say she is about 60% done. I still have to smooth out the dome, carve out the top details, and smooth out the rest of the helm, and spot putty. LOTS OF SPOT PUTTY.

Now for the less physical updates. I've been researching lots of under suit and strapping measures. Thanks to a helpful tip from Tim Winn (Timecon), I've learned that cheap black dive skins do the job quite nicely. Here's the one I plan to purchase.

Here it is

Now for strapping. I've done some research(big surpise) on strapping. According to the sticky, too thin strapping will cut into your skin, and too thick does something else bad I forget. I've decided on using 1 inch strapping. Im going to order it from strapworks soon, I just checked out the price and for 20 yards of the stuff its only $3.60. (I don't know if I did something wrong, but that sounds way to good to be true.) I'll have to investigate further.

I'm getting this kind (suggestions would also be helpful)

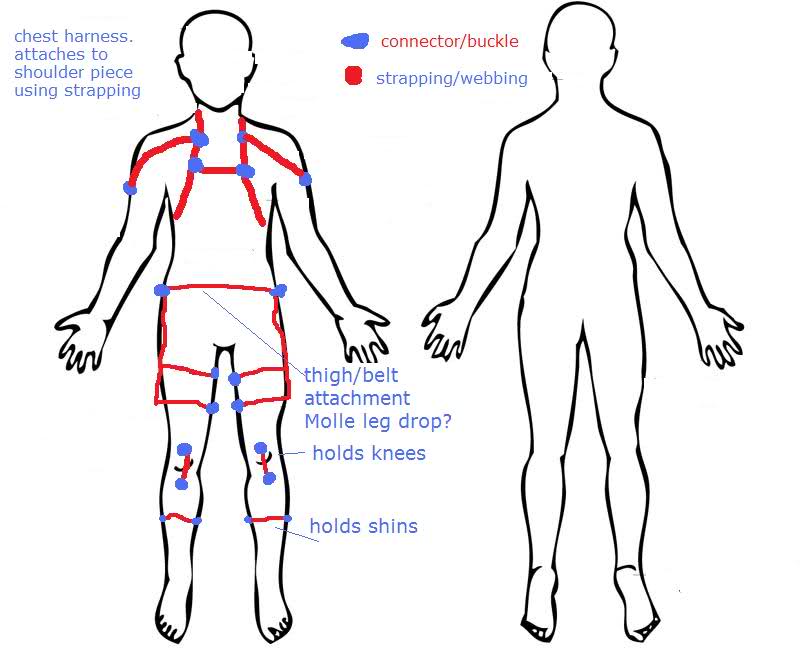

The Chest/shoulder and belt/leg straps are going to be separate for cosmetic purposes. The chest is going to be army suspenders with an attachment to allow for strapping to come down to the shoulder pieces, and hold those in place.

The belt is going to be attached to the Cod piece using Possibly a slider/loop piece, and strapping will come down from the belt to allow for thigh attachment. It would be easiest to buy a molle leg platform, but for $30 for a pair, I think I'm going to try with the strapping first.

The knees are simply going to be strapping sewn on to the suit, with a buckle so they can change (standard, gungir, grenadeer).

The shins are a head scratcher. Should I even strap them at all? or just add enough padding so they stay in place? I'm open to ideas.

The diagram is below.

I'm open to any and all ideas, tips or tricks. Time is starting to run out for me. I would like to have this not go down to the last minute if at all possible. My deadline stands for the Halo:CEA release, but If I can have it done by Halloween, I'd be thankful. School is kind of in the way, but I try to find a moment to work on things.

In parting news, I just finished unfolding the Dawn under Haven Cod for foam and have the templates cut out. Hopefully by this weekend, it will be fully assembled.

Painting experimenting begins today. I'm going to try sealing with Plasti-dip spray, Liquid nails clear seal, and both for good measure.

I've decided on using a Noble six Grey for my armor. However the only grey spray paint that I can find in the stores are gloss ones. no flat. I've been told that you can take out gloss with a satin clear coat, but I don't know how that affects foam. I might just buy a cheap paint gun and spray them all with watered down acrylic paint. I'm open to suggestions on this as well.

back to the armor grind. Thanks for looking and as always,

enjoi

The helmet has gotten some love and bondo. It still needs more love and bondo. I'd say she is about 60% done. I still have to smooth out the dome, carve out the top details, and smooth out the rest of the helm, and spot putty. LOTS OF SPOT PUTTY.

Now for the less physical updates. I've been researching lots of under suit and strapping measures. Thanks to a helpful tip from Tim Winn (Timecon), I've learned that cheap black dive skins do the job quite nicely. Here's the one I plan to purchase.

Here it is

Now for strapping. I've done some research(big surpise) on strapping. According to the sticky, too thin strapping will cut into your skin, and too thick does something else bad I forget. I've decided on using 1 inch strapping. Im going to order it from strapworks soon, I just checked out the price and for 20 yards of the stuff its only $3.60. (I don't know if I did something wrong, but that sounds way to good to be true.) I'll have to investigate further.

I'm getting this kind (suggestions would also be helpful)

The Chest/shoulder and belt/leg straps are going to be separate for cosmetic purposes. The chest is going to be army suspenders with an attachment to allow for strapping to come down to the shoulder pieces, and hold those in place.

The belt is going to be attached to the Cod piece using Possibly a slider/loop piece, and strapping will come down from the belt to allow for thigh attachment. It would be easiest to buy a molle leg platform, but for $30 for a pair, I think I'm going to try with the strapping first.

The knees are simply going to be strapping sewn on to the suit, with a buckle so they can change (standard, gungir, grenadeer).

The shins are a head scratcher. Should I even strap them at all? or just add enough padding so they stay in place? I'm open to ideas.

The diagram is below.

I'm open to any and all ideas, tips or tricks. Time is starting to run out for me. I would like to have this not go down to the last minute if at all possible. My deadline stands for the Halo:CEA release, but If I can have it done by Halloween, I'd be thankful. School is kind of in the way, but I try to find a moment to work on things.

In parting news, I just finished unfolding the Dawn under Haven Cod for foam and have the templates cut out. Hopefully by this weekend, it will be fully assembled.

Painting experimenting begins today. I'm going to try sealing with Plasti-dip spray, Liquid nails clear seal, and both for good measure.

I worry about this. Does this mean that Paint wrinkles if foam is bent before hand, or if it happens afterwords? I'll also look into that upon experimentation.its Clear Seal! Paint DOES NOT flake off of this stuff! However, it does not prevent wrinkles if the foam is bent.

I've decided on using a Noble six Grey for my armor. However the only grey spray paint that I can find in the stores are gloss ones. no flat. I've been told that you can take out gloss with a satin clear coat, but I don't know how that affects foam. I might just buy a cheap paint gun and spray them all with watered down acrylic paint. I'm open to suggestions on this as well.

back to the armor grind. Thanks for looking and as always,

enjoi

Shaymin Sky

Well-Known Member

Your work with foam is amazing. The detail looks sick and I can't wait to see the finished product! What were you planning to do for the color scheme?

I've decided on a noble six grey. I feel that choosing a wild color scheme would only make me want to change it later.

here's an overall progress shot you may enjoy.

This will be added to the chest this weekend along with the neck area to complete it.

So today I experemented with sealing and painting. I used a coat of plasti dip srpay on. Then I made a trip to lowes and purchased Grey gloss valspar spray paint. The ned result was not pretty. The scraps of foam had not been sealed all the way by the plasti dip, meaning that several coats of the stuff is nessecasry( or somethign new altogether), and the gloss paint gave the foam an ugly shiny plastic look, and it even made the small pores of the foam stand out even more.

I also tried the liquid nails clear seal. First, it was really hard to even get it out of the bottle. Then, it began to harden and get hard to spread even before it made contact with the foam. I really don't have the skill or patience to work with the stuff. I'm glad I tired it on scrap first.

at this point i am officially at a loss for painting and sealing the foam effectively. I've sent out PMs, asked questions in threads, and done tons of research from other threads on the site. I haven't gave up yet, and I'm still looking. If you have any Ideas or tactics you've found worked pretty well, feel free to pm me, or post here.

And some painting unrelated news, the helmet is too big. Way to big. Even with the motorcycle liner i had it still not only looked to big, but the size caused it to collide with the back of the chest, and the chest is about a perfect fit for me. It is a sad day. With school, I don't think i'll have time to make another, so I'm stuck with my old one, or, it's time to hit the classifieds.

I apologize if the demeanor of this post is whiny and depressive. Thanks for looking, and enjoi.

My only suggestion is make sure you don't rush anything, you'll be much more proud of your armor if you take the time to make it look good rather than get it done faster!

Other than that, did you get my reply to your question? Never got a follow up on if you were going to go with it

Other than that, did you get my reply to your question? Never got a follow up on if you were going to go with it

Shaymin Sky

Well-Known Member

I just noticed you replied. I guess I got it a little late.

My main curiosity with acrylics is, like you said, "not waterproof". I would not be happy if I was at a con, it started drizzling, and so it my armor. lol. I'm not familiar with any clear sealant for foam armor, and I'm not sure if regular clear seal will work on foam. I could try it, but that's money wasted if it doesn't work, and wasting money is not good right now, especially since i'm looking to replace a helmet.

thanks for the suggestions. If All else fails, I will go acrylic route. I'm more concerned with foam sealing, though, since plasti dip is everyone's go to option, and it didn't work that well for me. I haven't tried multiple layers yet, but the weekend is here, And I have lots of time to play around.

My main curiosity with acrylics is, like you said, "not waterproof". I would not be happy if I was at a con, it started drizzling, and so it my armor. lol. I'm not familiar with any clear sealant for foam armor, and I'm not sure if regular clear seal will work on foam. I could try it, but that's money wasted if it doesn't work, and wasting money is not good right now, especially since i'm looking to replace a helmet.

thanks for the suggestions. If All else fails, I will go acrylic route. I'm more concerned with foam sealing, though, since plasti dip is everyone's go to option, and it didn't work that well for me. I haven't tried multiple layers yet, but the weekend is here, And I have lots of time to play around.

Zat German

Member

at this point i am officially at a loss for painting and sealing the foam effectively. I've sent out PMs, asked questions in threads, and done tons of research from other threads on the site. I haven't gave up yet, and I'm still looking. If you have any Ideas or tactics you've found worked pretty well, feel free to pm me, or post here.

That sucks to hear about the Liquid Nails. What kind of temperature/humidity were you working with it at? I believe you are supposed to work the tube with your hands for a bit to get it to flow better.

Also, I saw you ask Hyperballistik about the Alex Plus stuff and I am almost certain that he is not really "mixing" it with water. He is just adding some water to make the silicone cure faster since that is what it reacts with during curing. It is pretty common when working with silicone caulking, I believe.

I cannot tell from your pictures but did you hit the exterior foam surface with a heat gun? That is supposed to be a necessary step to stop the foam from absorbing whatever you put on it straight into it. It definitely appears smoother and glossier after you do it. I bet Krylon Fusion would take to it pretty well. That technique was not known when I did my paint tests but unheated foam definitely sucked up the paint.

Curious that the plastidip didn't work for you. Do you have pictures of the failed pieces?

I tried using a spray at first but I thought it wasn't very cost effective, so I ended up using brush-on plastidip dilluted eith "industrial machine lubricant" that's supposed to be used in the place of xylene. Because it was diluted, it went on very lightly and it took a few coats, but I think it ended up quite smooth and sealed on my armor. That might be worth a try for you.

I tried using a spray at first but I thought it wasn't very cost effective, so I ended up using brush-on plastidip dilluted eith "industrial machine lubricant" that's supposed to be used in the place of xylene. Because it was diluted, it went on very lightly and it took a few coats, but I think it ended up quite smooth and sealed on my armor. That might be worth a try for you.

Also, I saw you ask Hyperballistik about the Alex Plus stuff and I am almost certain that he is not really "mixing" it with water. He is just adding some water to make the silicone cure faster since that is what it reacts with during curing. It is pretty common when working with silicone caulking, I believe.

Just don't use pure silicone, it will not take paint, the paint will just bead off, make sure if you use caulking to get the stuff that says permantly flexible and paintable, otherwise the non flexible stuff will just crack off

JediStumpy

Well-Known Member

Sky,

Are you saying that you will cut your pieces out to the size you want them OR cut it out leaving a 1/2 inch left on each side to then be "sanded" down to your angles you want them?

I am using the templates are well. if you cut the shaped out prefect it is fine but i am left with no "angle" sides sometimes.

Do you understand the question.

A video tut would be good (or pic)

Thanks!

Are you saying that you will cut your pieces out to the size you want them OR cut it out leaving a 1/2 inch left on each side to then be "sanded" down to your angles you want them?

I am using the templates are well. if you cut the shaped out prefect it is fine but i am left with no "angle" sides sometimes.

Do you understand the question.

A video tut would be good (or pic)

Thanks!

NO CUT ANGLES! CUT ANGLES BAD!!! I Use a Rotary tool tool or a belt sander. I got a very cheap belt sander on sale for around $50 at harbor frieght(warning: it is also cheaply made), and I've always had my dremel. I find that I get more even angles with the sander, but the dremel allows me to get in tight places.

hope it helps.

Shaymin Sky

Well-Known Member

Sorry for the late replies, I was a little tied up with small things and school and home.

time for answers.

While I can't produce a video at this time, I do plan on doing a foam tutorial for the forums. To answer your immediate question, What I do is I cut out the piece of foam exactly as it appears on the template. Then, Using a Dremel I hold the dremel at an angle and apply to the piece, sanding an angle into the foam, making sure that there is no excess and it creates a perfect angle. Failure to do so causes the pieces to not meet together at the edge and creates a bursted look. I have seen this quite a lot on the forums, and I try to avoid it at all times. Using the Belt sander is the same principle, but instead of holding the dremel at an angle(becuase its not being used) I hold the Piece at an angle against the belt, which is a flat surface. As stated before, this will create a more even edge or angle, but cannot be used in hard to reach places. That is where I use the dremel.

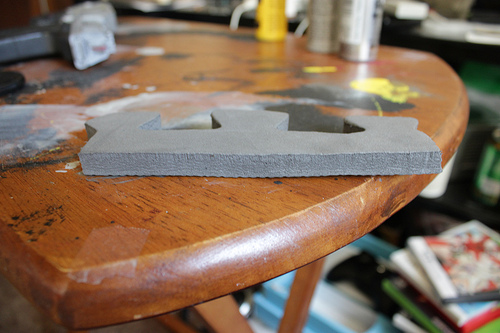

If you don,t feel like reading text, look at these pictures. Say this scrap is a piece of armor. I don't add anything to the template, its cut out as normal. then i use dremle or sander to make an edge.

I hope this helps.

Thanks I appreciate it.:$

unfortunately I threw them away. sorry.

I used it at room temperature at first, then let it sit outside(about 70 degress) for a while, then tried it again. Still not much of a budge.

First off, big thanks to everyone who has offered advice, including those who answered my PMs. After reading through all of it, I realize that i missed one step that would help lots. I need to heat treat the foam pieces. So considering that, here is my plan to seal the foam correctly.

Heat treating(at the lowest setting 250Deg)>a coat of plasti-dip> Alex plus to fill in gaps(applied with closed cell sponge)>water+ Alex plus> paint.

still looking into types of spray paint. I've been told that backwash takes out the gloss in the spray paint, but I want to see If I can find a satin grey first.

time for answers.

Are you saying that you will cut your pieces out to the size you want them OR cut it out leaving a 1/2 inch left on each side to then be "sanded" down to your angles you want them?

I am using the templates are well. if you cut the shaped out prefect it is fine but i am left with no "angle" sides sometimes.

While I can't produce a video at this time, I do plan on doing a foam tutorial for the forums. To answer your immediate question, What I do is I cut out the piece of foam exactly as it appears on the template. Then, Using a Dremel I hold the dremel at an angle and apply to the piece, sanding an angle into the foam, making sure that there is no excess and it creates a perfect angle. Failure to do so causes the pieces to not meet together at the edge and creates a bursted look. I have seen this quite a lot on the forums, and I try to avoid it at all times. Using the Belt sander is the same principle, but instead of holding the dremel at an angle(becuase its not being used) I hold the Piece at an angle against the belt, which is a flat surface. As stated before, this will create a more even edge or angle, but cannot be used in hard to reach places. That is where I use the dremel.

If you don,t feel like reading text, look at these pictures. Say this scrap is a piece of armor. I don't add anything to the template, its cut out as normal. then i use dremle or sander to make an edge.

I hope this helps.

your foam work is so clean and pretty o.o!

Thanks I appreciate it.:$

Curious that the plastidip didn't work for you. Do you have pictures of the failed pieces?

unfortunately I threw them away. sorry.

That sucks to hear about the Liquid Nails. What kind of temperature/humidity were you working with it at? I believe you are supposed to work the tube with your hands for a bit to get it to flow better.

I used it at room temperature at first, then let it sit outside(about 70 degress) for a while, then tried it again. Still not much of a budge.

First off, big thanks to everyone who has offered advice, including those who answered my PMs. After reading through all of it, I realize that i missed one step that would help lots. I need to heat treat the foam pieces. So considering that, here is my plan to seal the foam correctly.

Heat treating(at the lowest setting 250Deg)>a coat of plasti-dip> Alex plus to fill in gaps(applied with closed cell sponge)>water+ Alex plus> paint.

still looking into types of spray paint. I've been told that backwash takes out the gloss in the spray paint, but I want to see If I can find a satin grey first.

I'm loving you foam work here. The amount of detail is great. Now I might not be an expert on Foam but I do know a few things about paint. So if you want to use acrylics on foam they work fine. You just have to hit them with a clear coat to waterproof them. It worked great on my test pieces with out any problems. I hope this info. helps.

Not sure if anyone has mentioned this but the foam you are using is not micro cel, so yes you need to seal it. One way is to use a heat gun to melt the outer layer therefore colapsing the cells. Ther is guy that has made foam armor and used the heat gun technique to seal the foam.

http://www.squidoo.com/how-to-make-halo-armor

Otherwise you can purchase micro cell foam to make your armor then you wont have any problems with the foam absorbing the paint.

Hope this helps.

Renraku

http://www.squidoo.com/how-to-make-halo-armor

Otherwise you can purchase micro cell foam to make your armor then you wont have any problems with the foam absorbing the paint.

Hope this helps.

Renraku

- Status

- Not open for further replies.

Similar threads

- Replies

- 38

- Views

- 1,781