FinnishSpartan

Well-Known Member

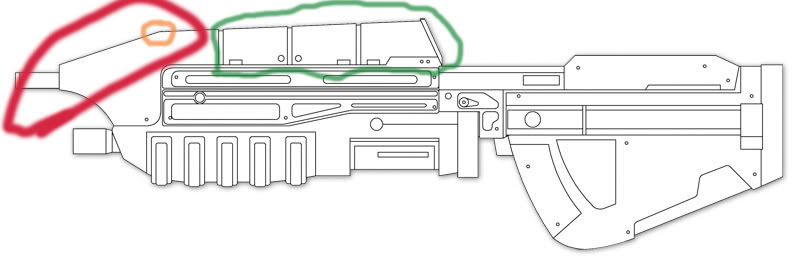

How do i bend this part of aluminium for my AR? (aluminium cannot be welded).

So i highlited more areas so that you can uderstand better.

GREEN: This area has no problems the aluminium is easy to bend to that area.

RED: Highlighted problem area.

ORANGE: this is the specific point of trouble.

As you can see the part curves down but the bottom part of the aluminium doesnt.

The aluminium is supposed to bend over the top of the AR.

I am open to any suggestions.

Thank you.

-Finnish

So i highlited more areas so that you can uderstand better.

GREEN: This area has no problems the aluminium is easy to bend to that area.

RED: Highlighted problem area.

ORANGE: this is the specific point of trouble.

As you can see the part curves down but the bottom part of the aluminium doesnt.

The aluminium is supposed to bend over the top of the AR.

I am open to any suggestions.

Thank you.

-Finnish

Last edited by a moderator: