fc3schick87

New Member

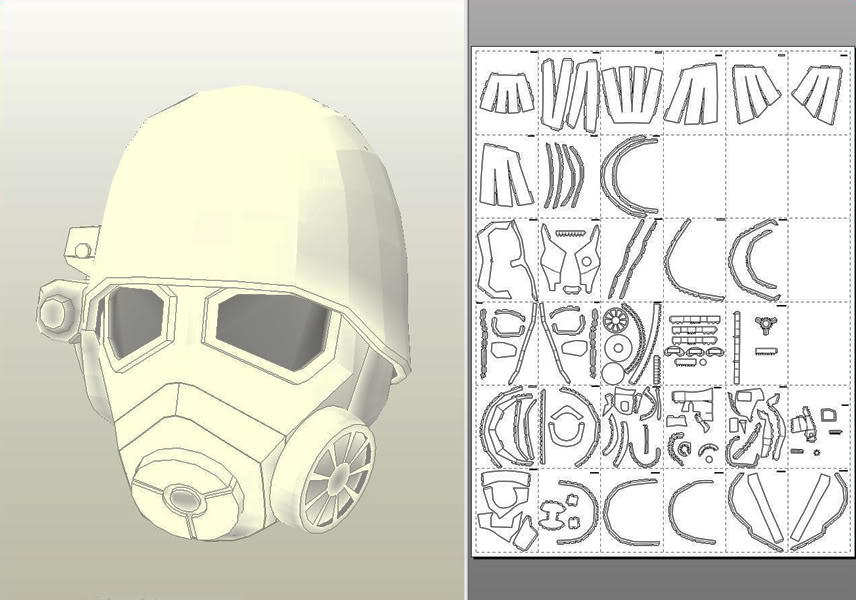

on the fall out mask, and many other files i've seen i've noticed alot of red edges. meaning that they dont join.

i have come across an issue with the fall out mask. the eye pieces as well as the "gas mask" portion of the "nose" dont have any joining tabs

found here, link bellow.

what do i do to join these pieces together? they dont even really match up well either....

i'm using 67w card stock.

so the question is "how do i join these pieces if there are no joining tabs"

i have come across an issue with the fall out mask. the eye pieces as well as the "gas mask" portion of the "nose" dont have any joining tabs

found here, link bellow.

what do i do to join these pieces together? they dont even really match up well either....

i'm using 67w card stock.

so the question is "how do i join these pieces if there are no joining tabs"

Download(I also have the separate .PDO parts in case you like to keep your edge count low.)

NCR Veteran Ranger Helmet

Last edited by a moderator: