Welcome! I’ve been printing for many, many years and while there are decently large 3D printers, none of the ones I can afford are ever big enough. The one I currently use is a resin 3D printer because they capture the most detail and there is a lot less work to finish the print.

The basis of resin printing is that it uses UV light to cure a UV sensitive resin a layer at a time. The resin at this time is not fully cured, and we can use that to our advantage.

I’m working on the Mark V Recon helmet provided here in the Armory section. Here I have two pieces that I was testing quality on and I’m going to show you how to “fuse” them.

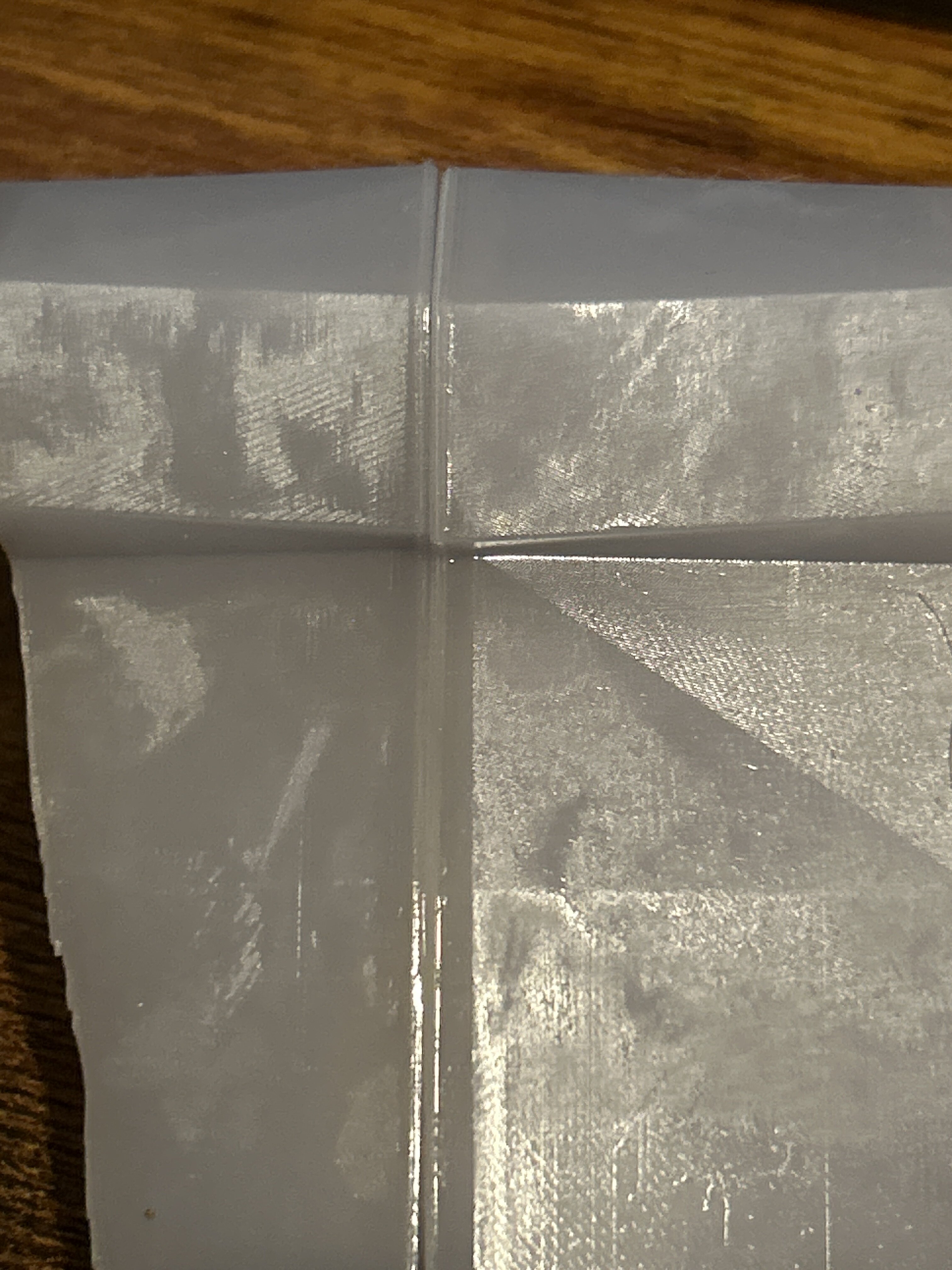

First you have to align them, this has to be exactly how you want them.

First you have to align them, this has to be exactly how you want them.

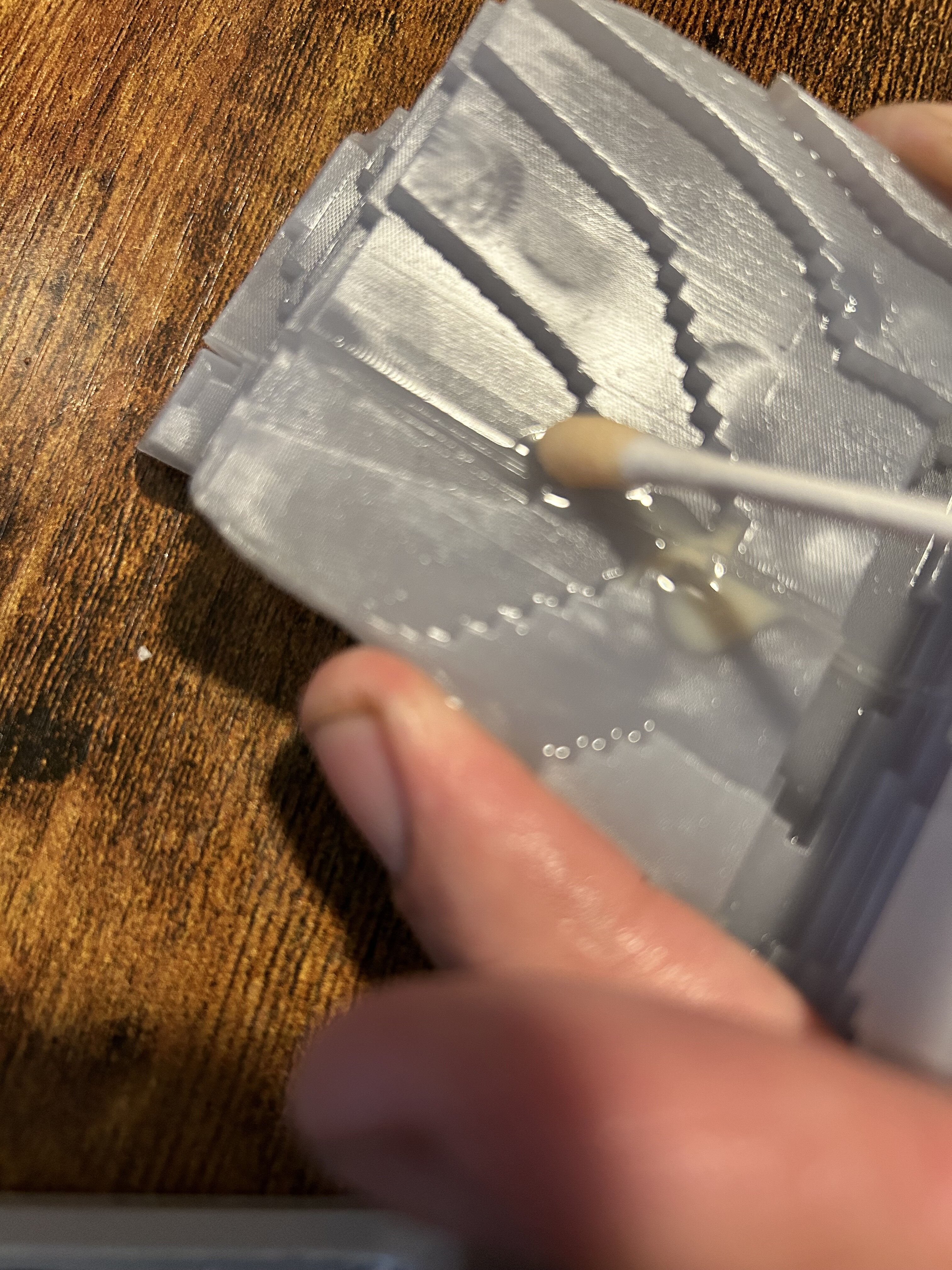

Then take a cotton swab and and end into some of your resin and dab it on the inside of your seam.

I’m using a different color to highlight what I’m doing here.

Then hit it with a UV light source (mine is from Amazon and I use a Christmas light foot switch to turn it on/off hands free)

You can certainly add more for structural integrity, but as long as any gaps are filled it’s going to be a solid piece.

Make sure you cure both sides, oh and don’t be like me and wear gloves when handling resin. After you’ve pieced it all together you can wash it (with my resin I use isopropyl, but there’s water washable stuff too). Once fully cured with UV light the whole thing is one piece.

Now if you just can’t get the alignment right you can always use some sand paper to get rid of any lines you don’t want.

For FDM printers it’s a bit more work, but instead of resin and UV light you can use an acetone/filament slurry, but it takes more time to dry and contact cement is better used.

If you’d like to see how I take a 3D model and split it up into pieces for printing let me know! Or if you have any other questions.

The basis of resin printing is that it uses UV light to cure a UV sensitive resin a layer at a time. The resin at this time is not fully cured, and we can use that to our advantage.

I’m working on the Mark V Recon helmet provided here in the Armory section. Here I have two pieces that I was testing quality on and I’m going to show you how to “fuse” them.

Then take a cotton swab and and end into some of your resin and dab it on the inside of your seam.

I’m using a different color to highlight what I’m doing here.

Then hit it with a UV light source (mine is from Amazon and I use a Christmas light foot switch to turn it on/off hands free)

You can certainly add more for structural integrity, but as long as any gaps are filled it’s going to be a solid piece.

Make sure you cure both sides, oh and don’t be like me and wear gloves when handling resin. After you’ve pieced it all together you can wash it (with my resin I use isopropyl, but there’s water washable stuff too). Once fully cured with UV light the whole thing is one piece.

Now if you just can’t get the alignment right you can always use some sand paper to get rid of any lines you don’t want.

For FDM printers it’s a bit more work, but instead of resin and UV light you can use an acetone/filament slurry, but it takes more time to dry and contact cement is better used.

If you’d like to see how I take a 3D model and split it up into pieces for printing let me know! Or if you have any other questions.