- Member DIN

- S770

So I think it is about time I start this build thread. With the conclusion of ECCC, My bench is finally free to do some long term projects, the first of which is making better armor crates.

I plan on making two of these full sized halo reach armor crates:

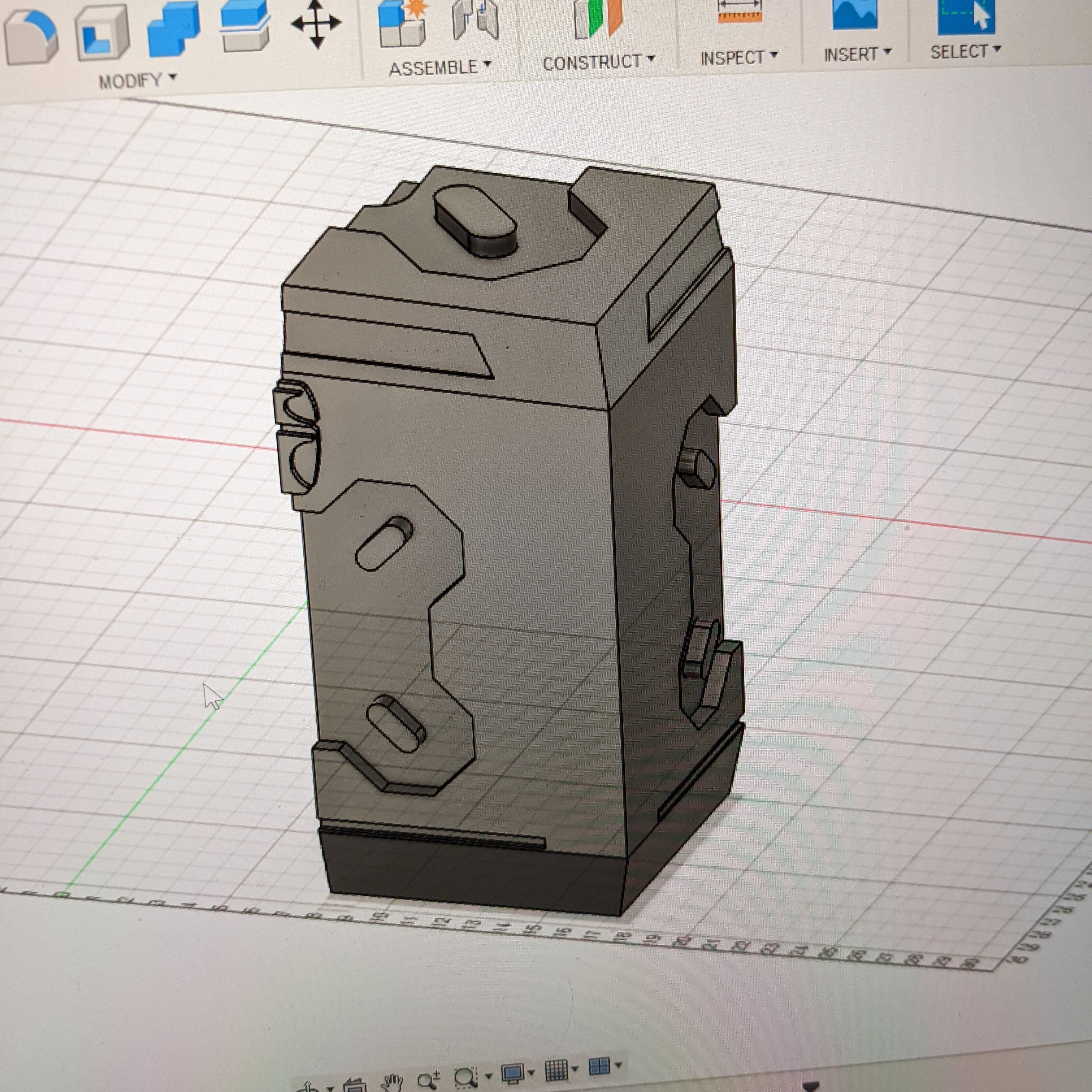

The first steps I took of this process was to learn fusion 360. This is the first time I have ever used fusion 360, and I jumped in head first!

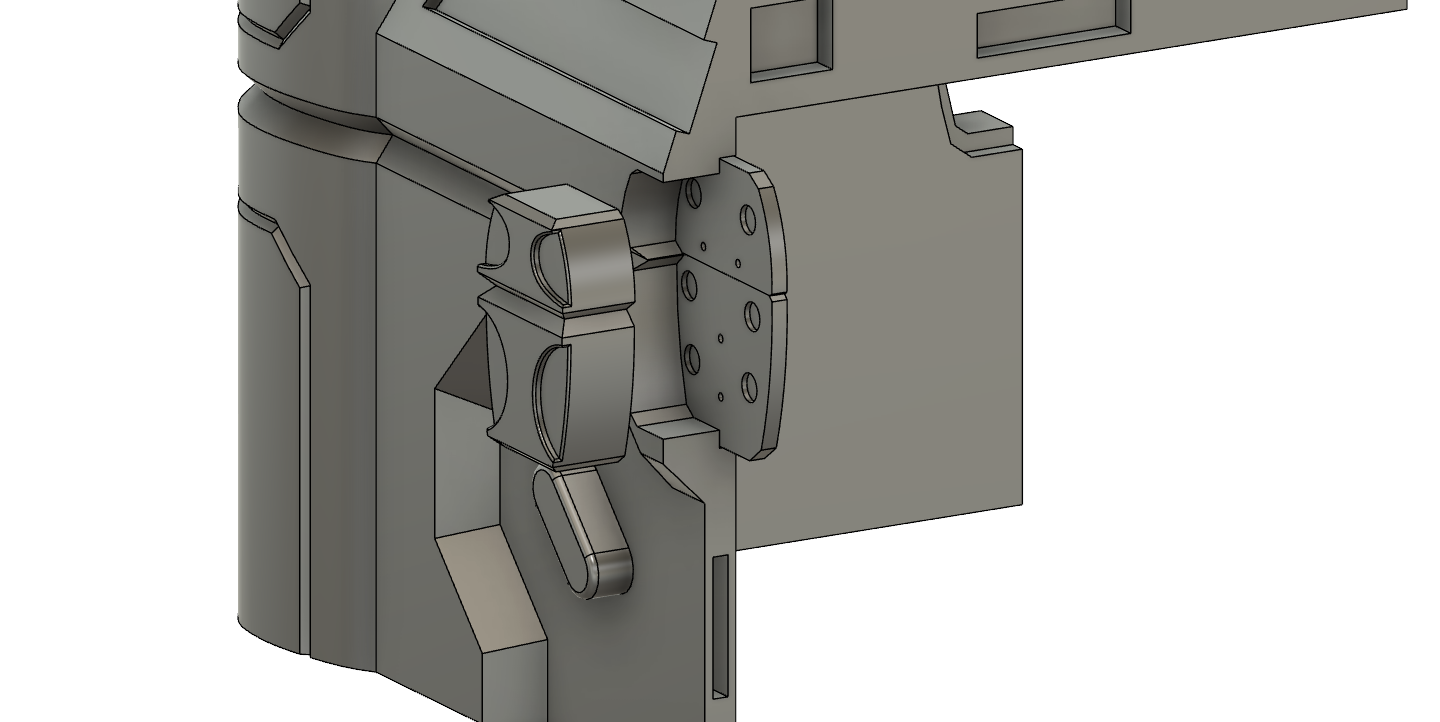

Here is how far I got on the first day:

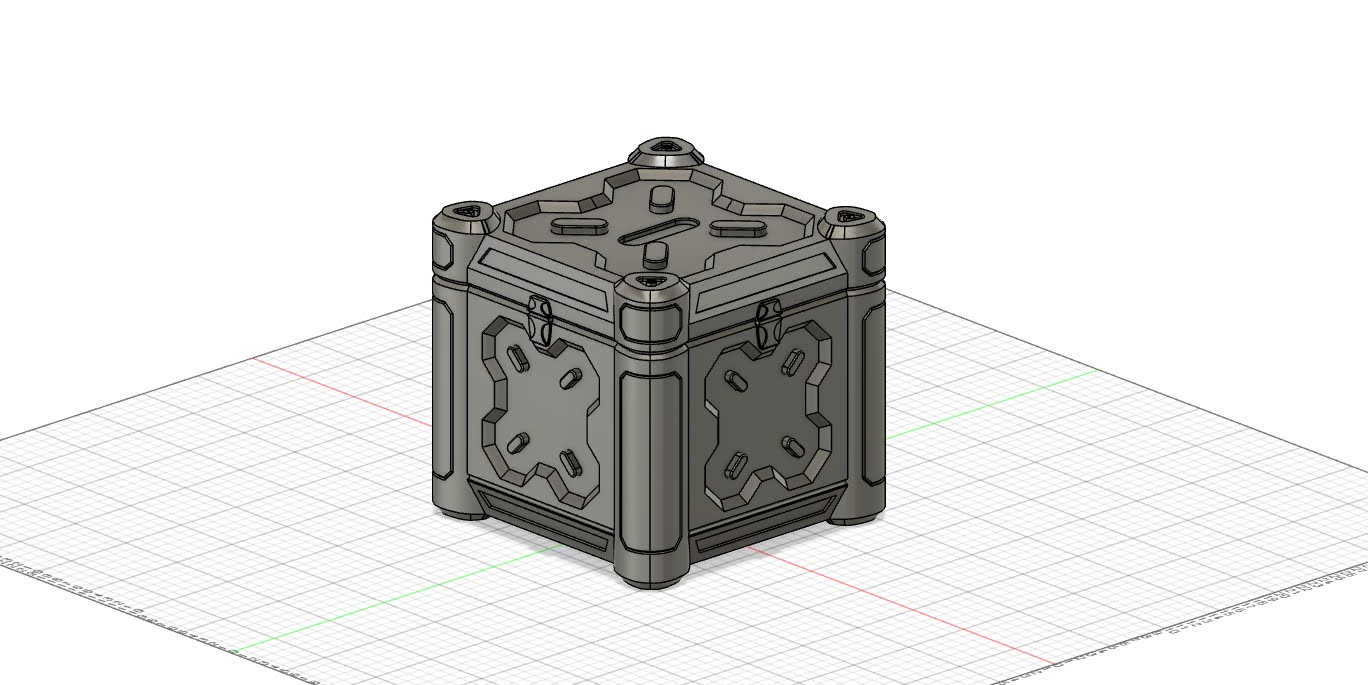

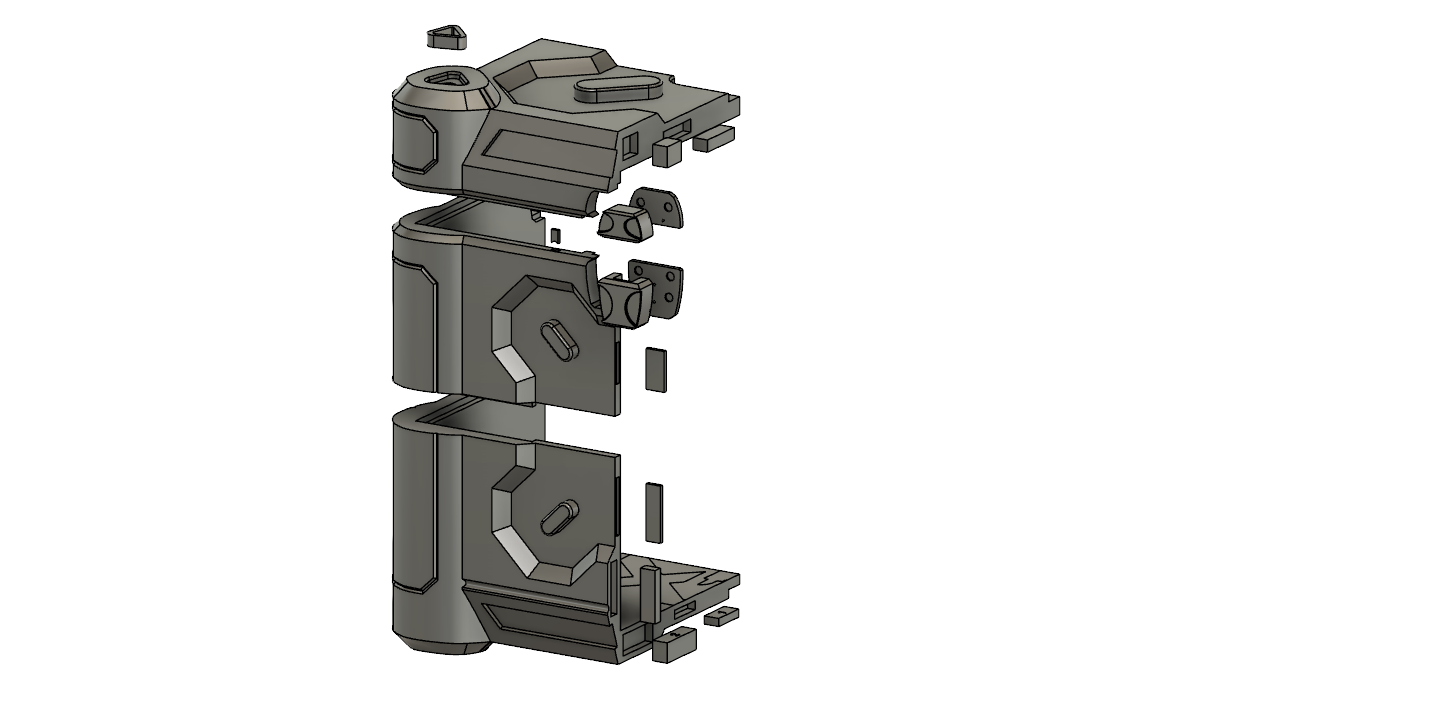

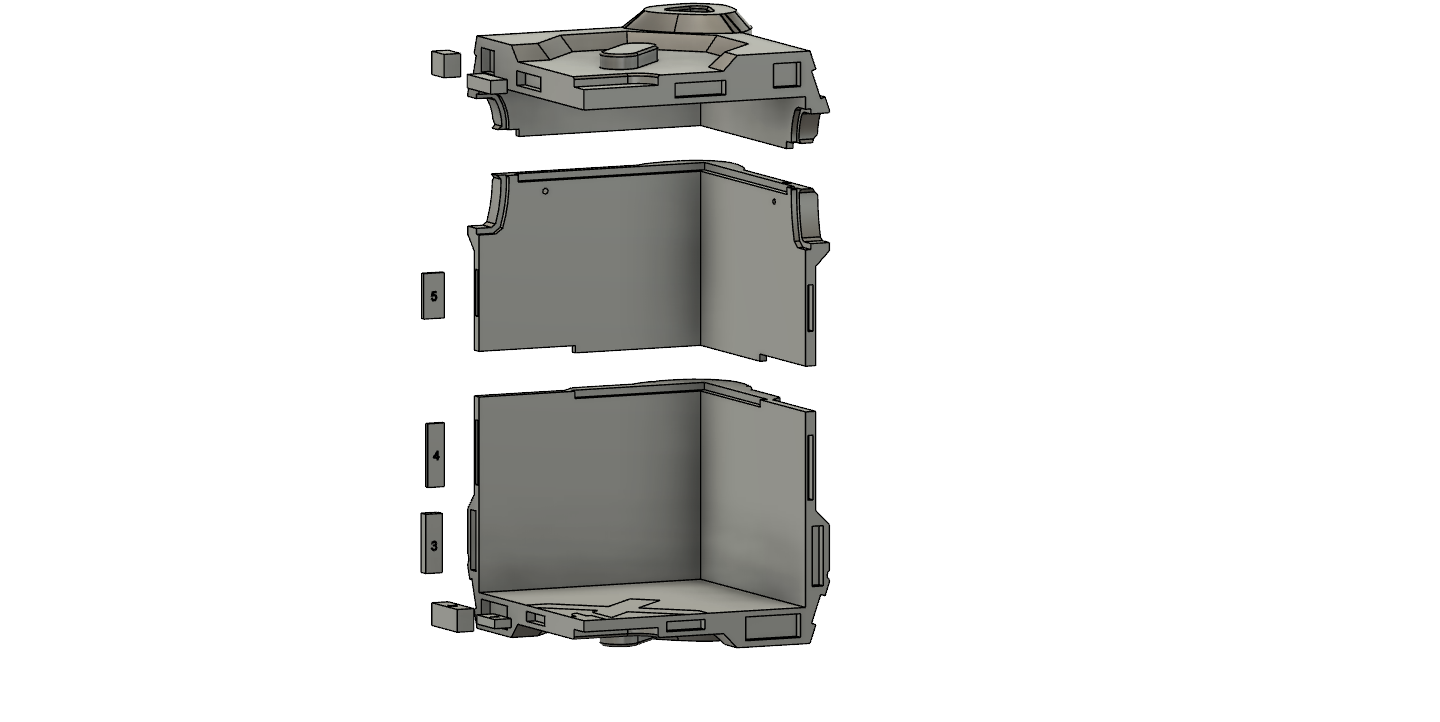

I finished the full model in about 2 days after that:

Now originally the plan was to make these much smaller scale, or out of foam, But after many many hours discussing and arguing with Lukavago , I have finally made a few decisions. First, I plan to make this 24" x 24", and I will be making two. This will allow me to store and transport my armor easily, in an awesome case that we can use as booth props in the future. Second, I finally decided upon how I am going to construct the crate. This part is probably the most discussed part of the build so far. we went back and fourth on molding and casting, or 3d printing, or other methods, but I finally made a decision...

I Plan to fully 3d Print the crate, Harden the outside with resin, and fiberglass the inside of the crate. From there, it was a discussion of features.

So here are the things I wanted from my crate:

-Removable caster wheels on the bottom

-preserve outside look of crate to be as accurate as possible.

-flip out handles from the inside to carry it

-lockable lid

-hidden positive latches to preserve space crate look

-stackable

To Achieve these goals, I had to scale up the crate to full size, and start doing a lot of extra modeling. I had to make registration between the pieces, a way to make the latches, the wheel inserts, and the handle connection points, and the pegs for stacking the crates

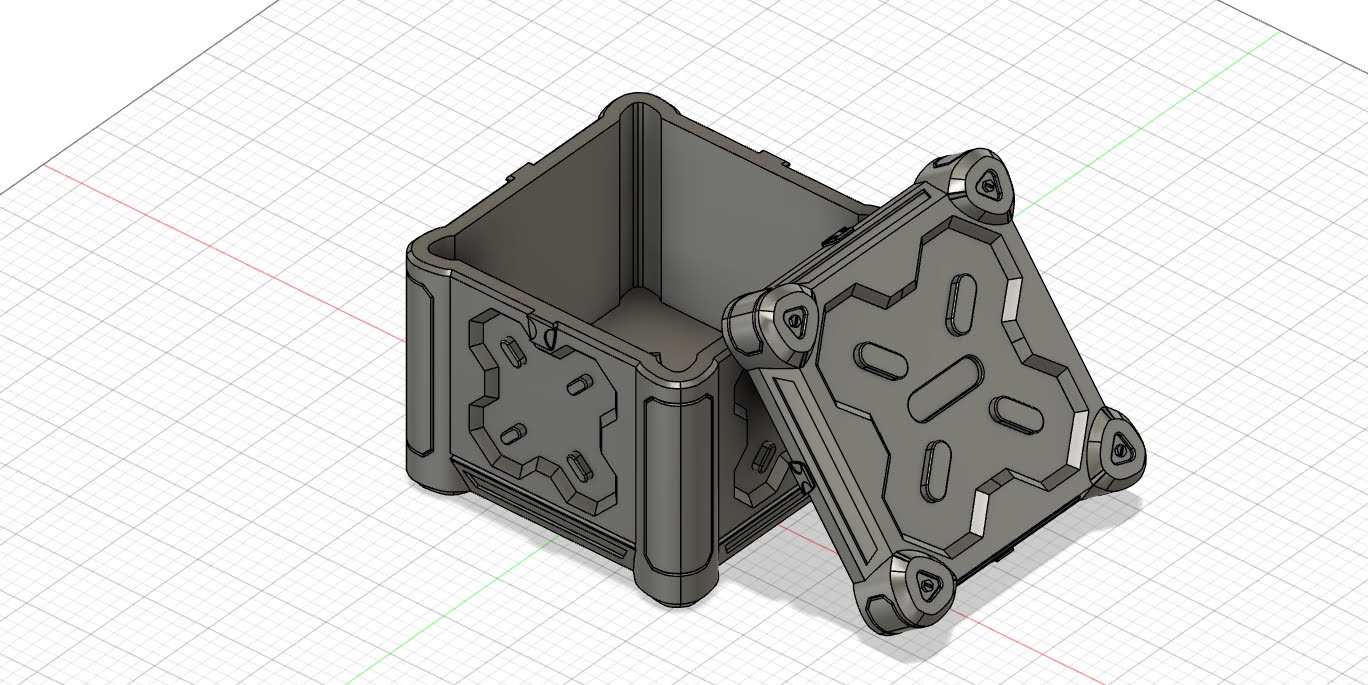

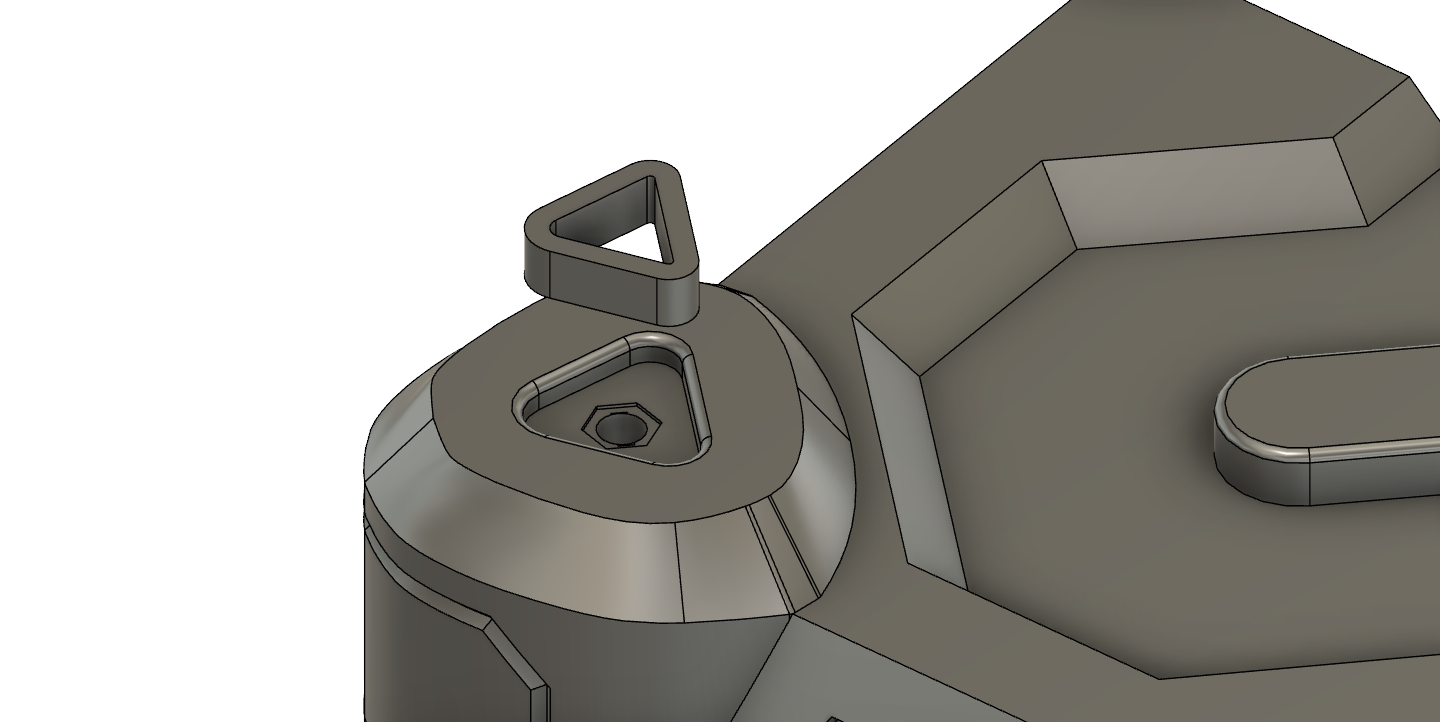

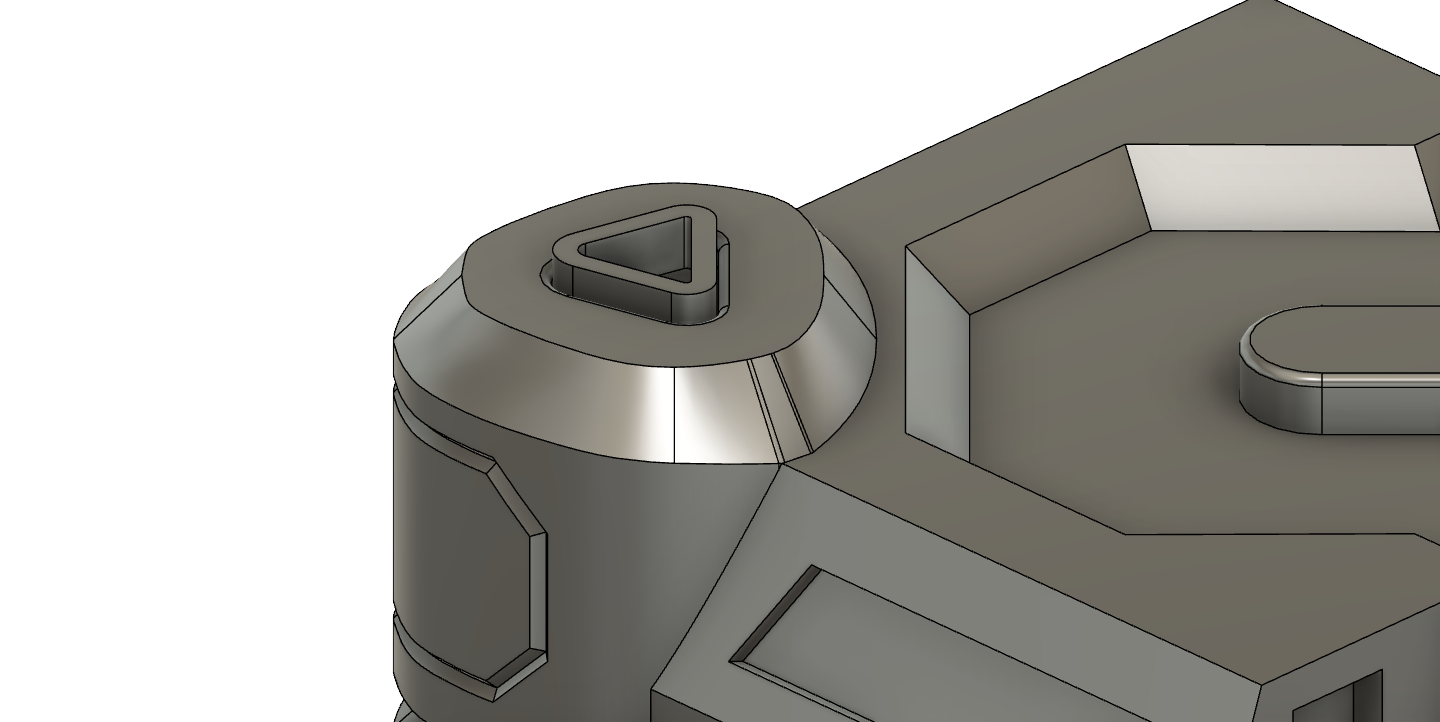

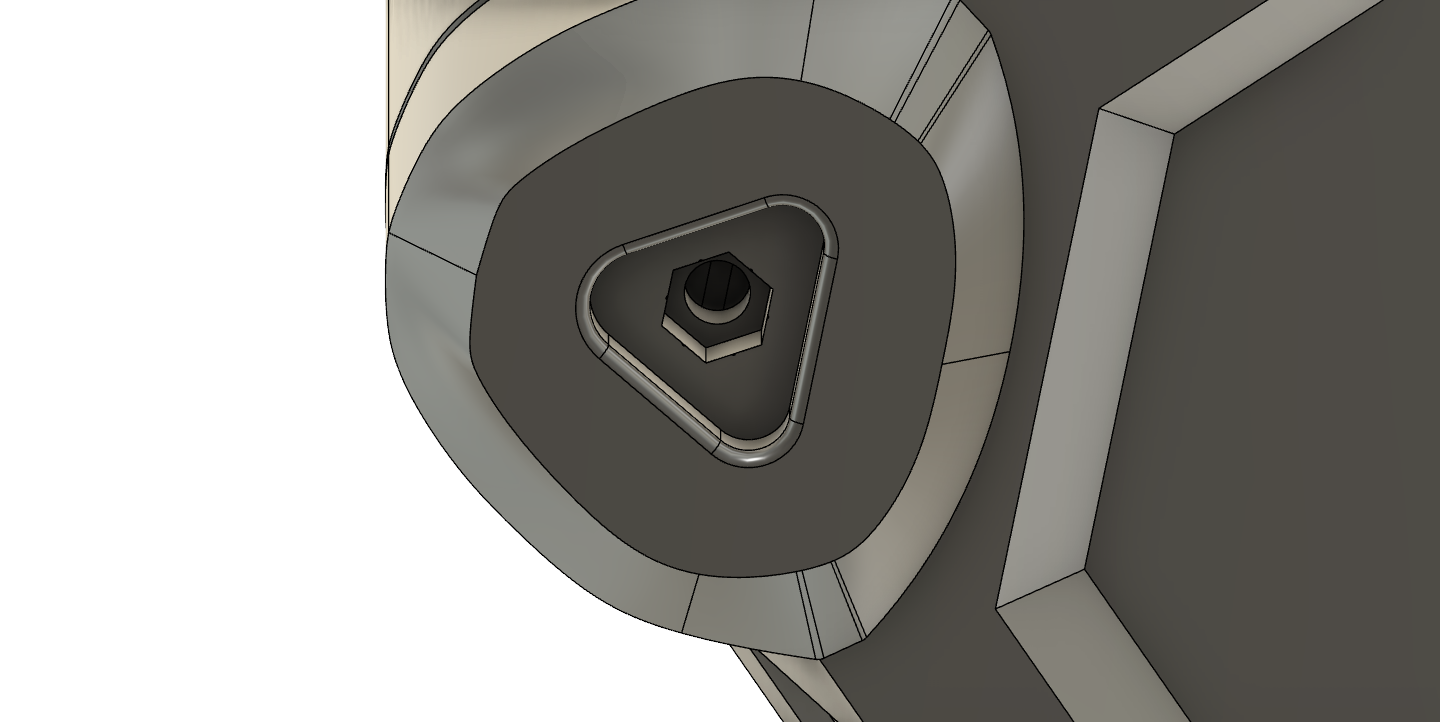

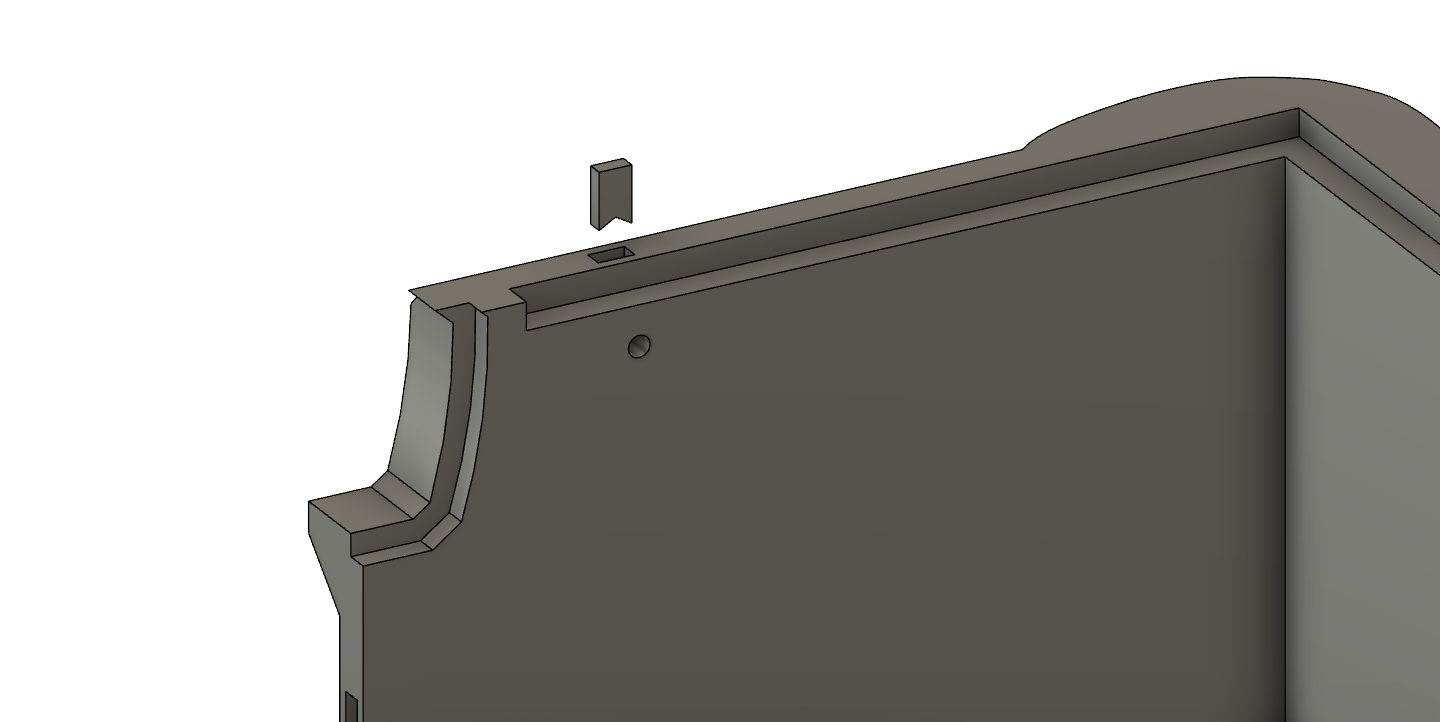

So here is what I came up with:

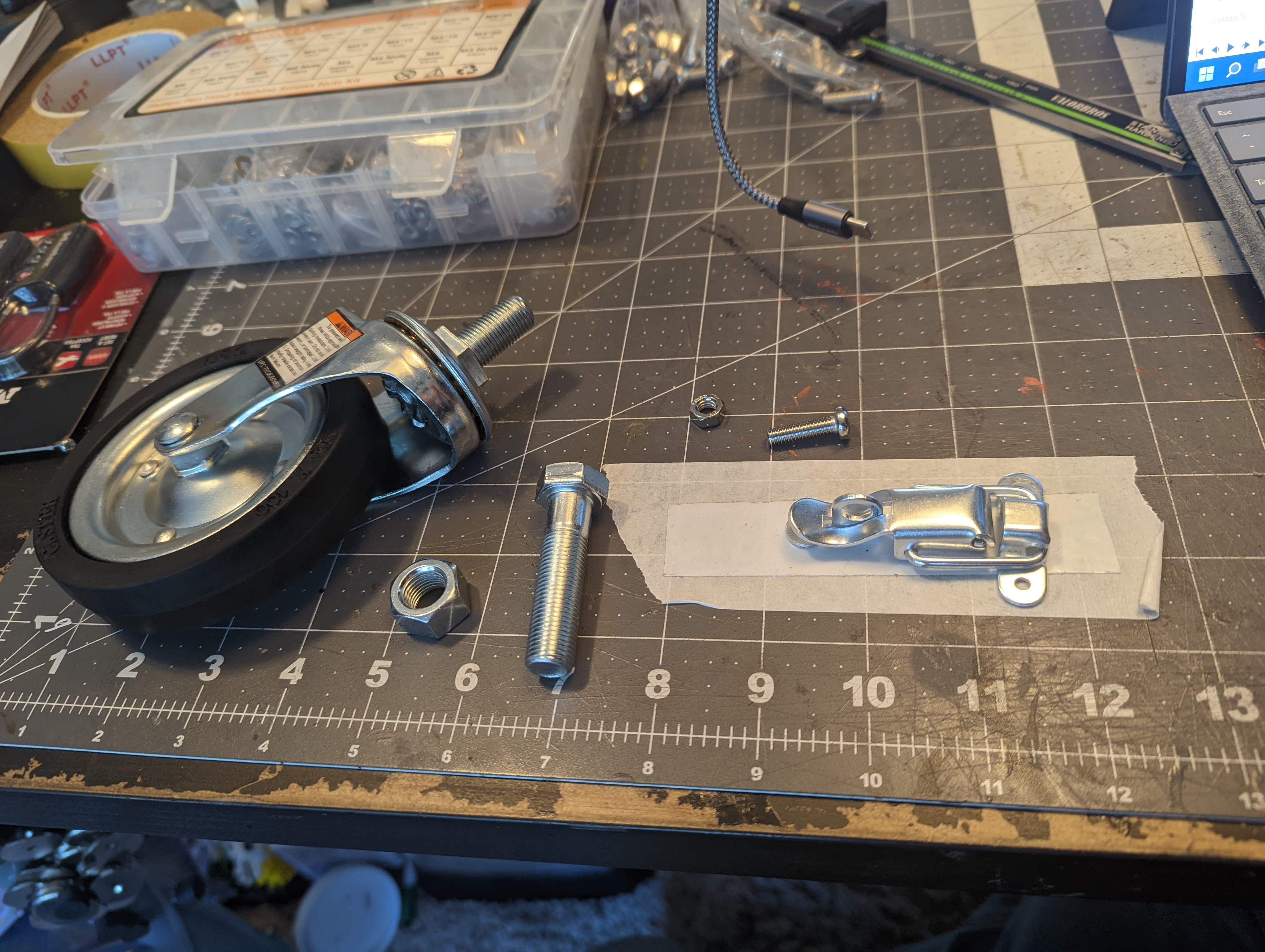

So the first step with this build, once I got my scale right, was the hardware. I had to pick up my hardware so I knew what to model in for those hardware points.

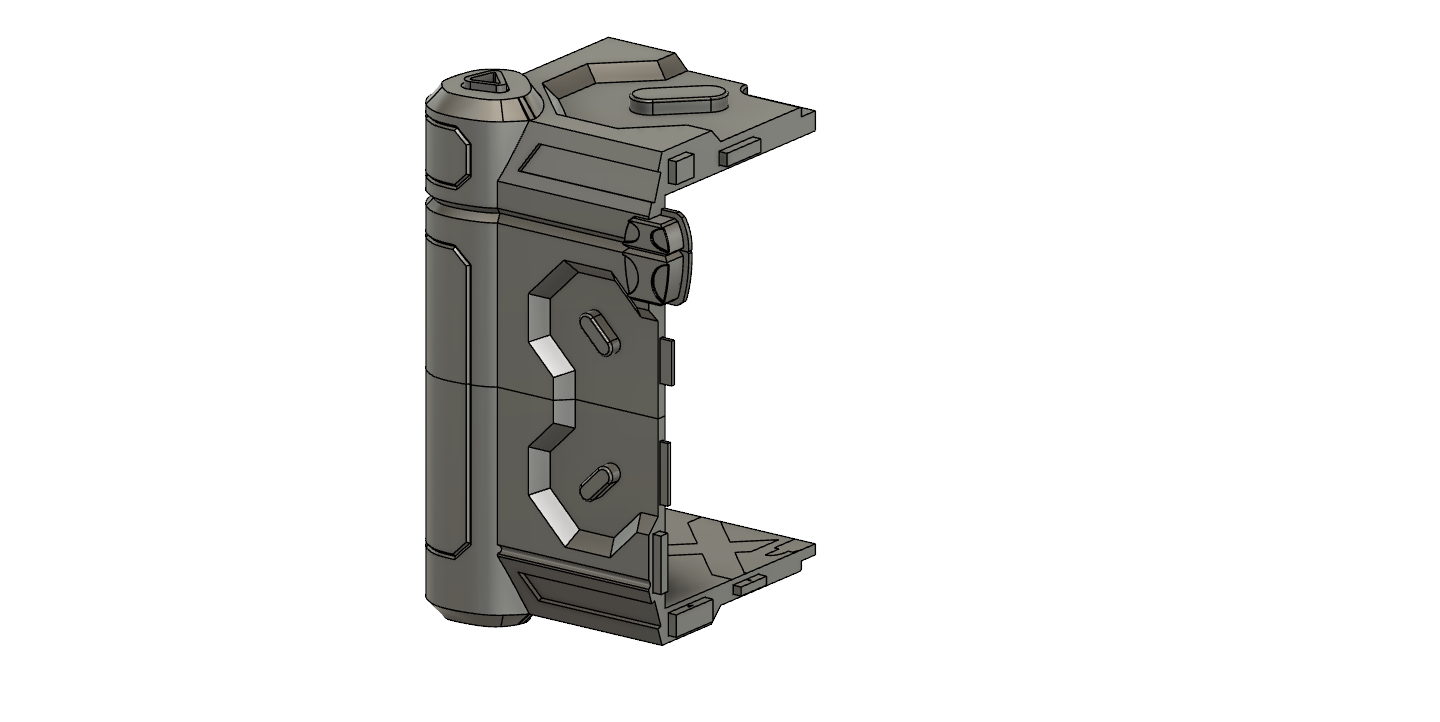

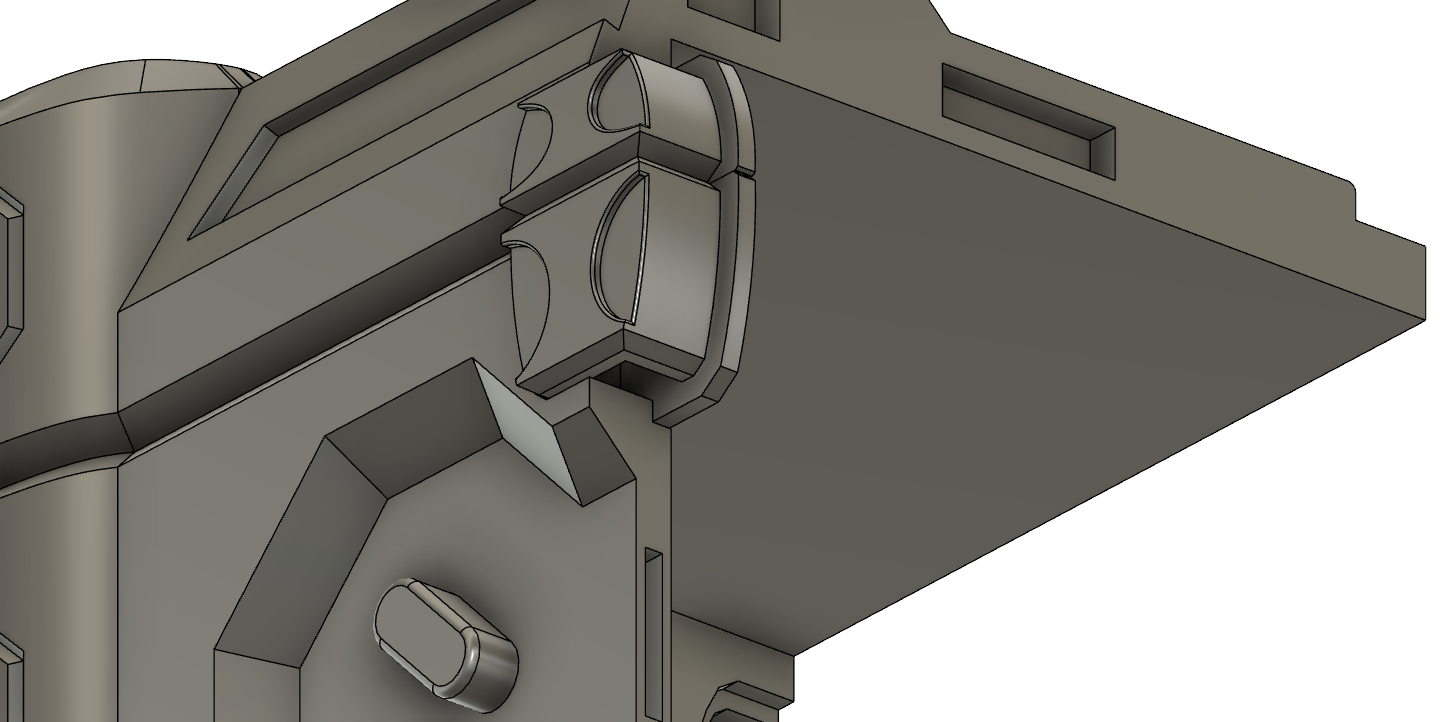

From there, I started with the latch. I decided to have the front space latch magnet over the regular. This would let me either have the crate closed or open, but preserve the look of the space latch. I can also completely remove the space latch, and just have the toggle latch, and be able to put a tsa lock on it for flying

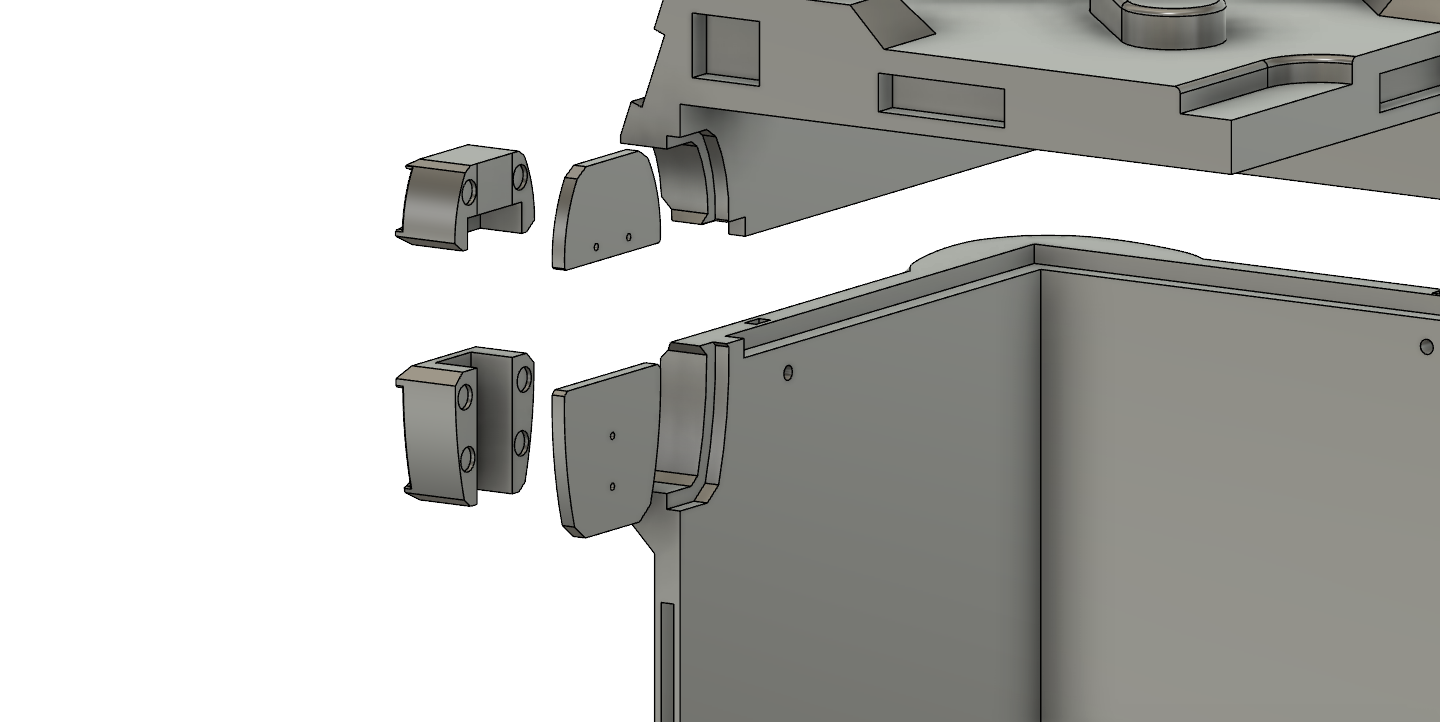

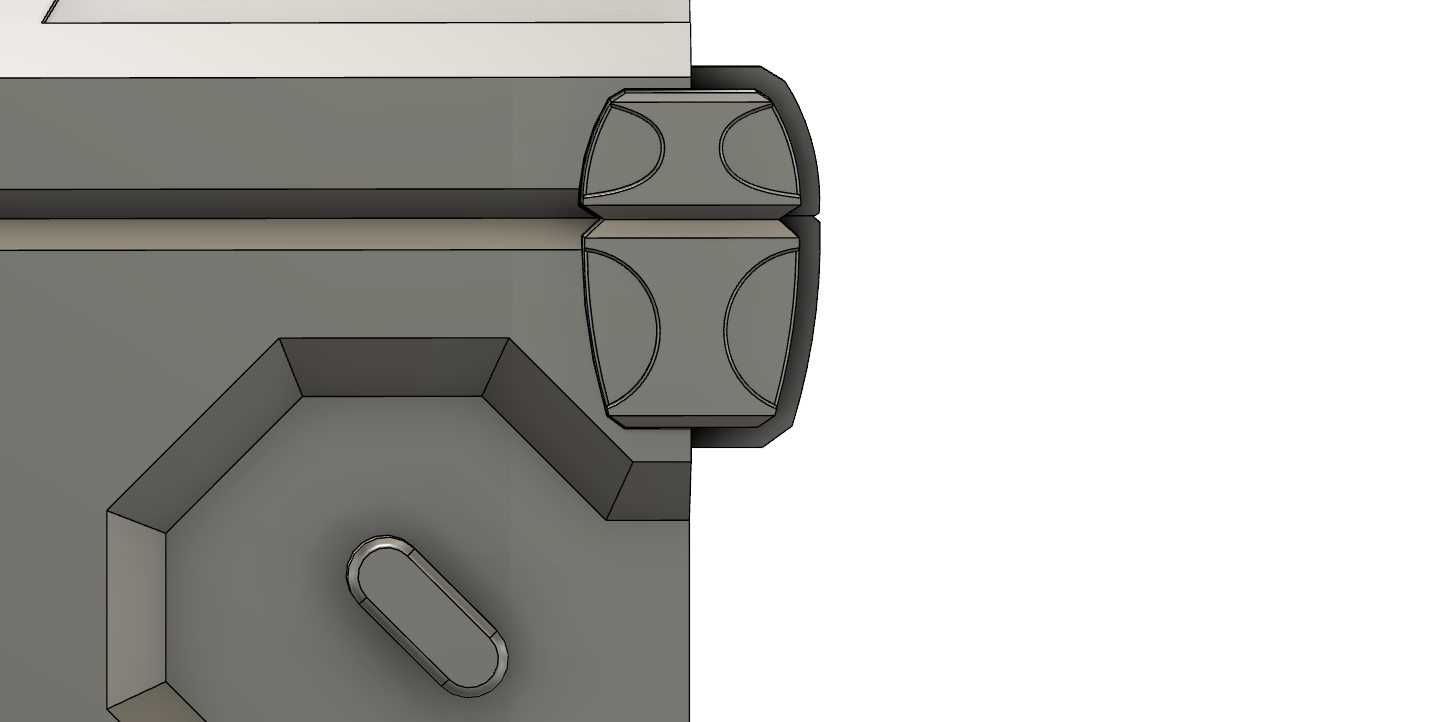

The next thing I decided to tackle, was registration of parts. For the vertical registration, I used notches and grooves, while for the horizontal, I used numbered pegs. I specifically numbered them so I know what direction to print them in, and which goes where. There is also a notch and groove on the lid to the top of the box.

Next problem to tackle, was the bolts and holes for the caster wheels. On the top of the box, there are 4 decorative bolts, where as on the bottom, there is a slot to install a nut that the caster wheel is going to thread through. I also used this section to crate these triangle pegs, to stack two boxes together.

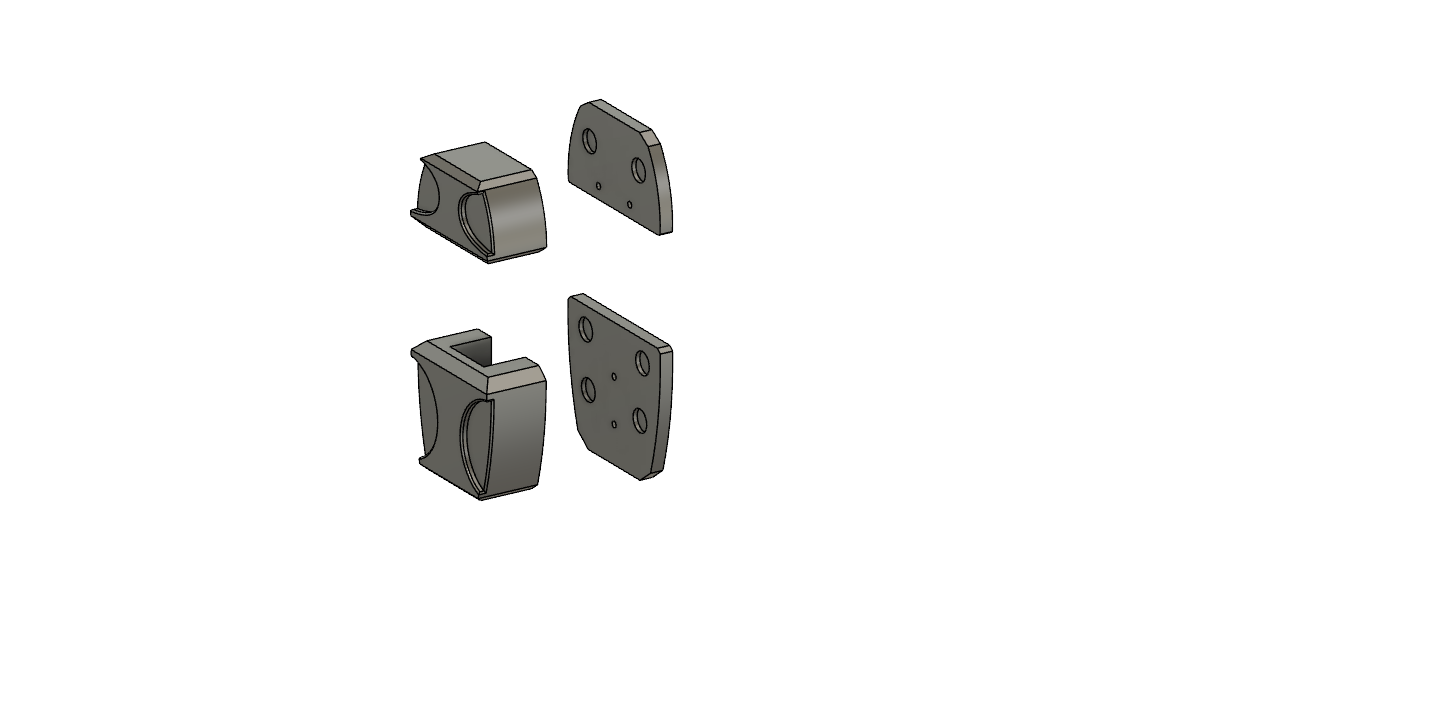

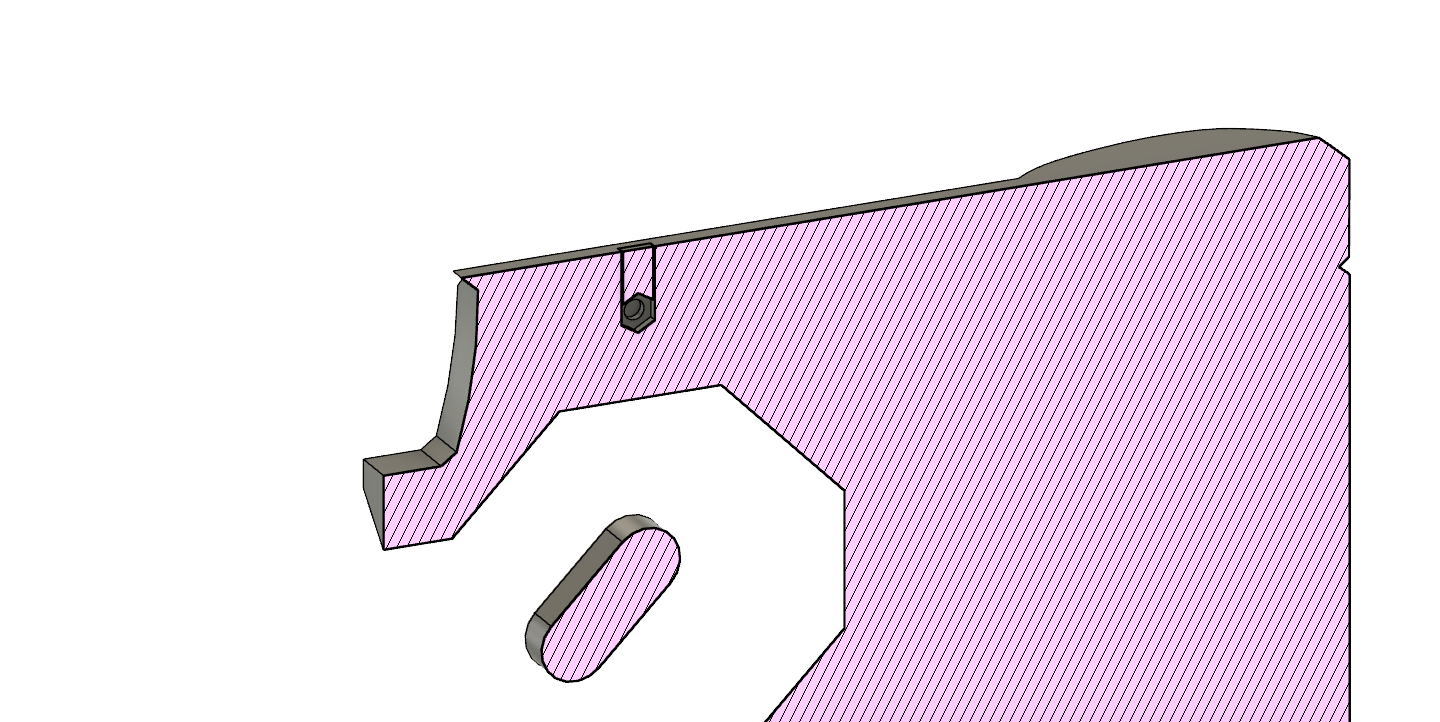

Finally, the last solution was the handles. I needed something that mounted from the inside, that would be strong enough to pull against to hold up the box. I planned on using nylon strapping, and a pvc pipe to make handles for the box. I will use grommets to bolt through the nylon straps into the box. I inset a nut from the top, and capped it off, sealing it into the side, which then I can thread into from the outside.

With all the modeling now done, It is time to start this behemoth. I calculated it, and one crate is going to take a whole 14 rolls of filament!! Each section of the crate is 12" x 12", and just barely fits on my build plate! The first print is now underway.

I plan on making two of these full sized halo reach armor crates:

The first steps I took of this process was to learn fusion 360. This is the first time I have ever used fusion 360, and I jumped in head first!

Here is how far I got on the first day:

I finished the full model in about 2 days after that:

Now originally the plan was to make these much smaller scale, or out of foam, But after many many hours discussing and arguing with Lukavago , I have finally made a few decisions. First, I plan to make this 24" x 24", and I will be making two. This will allow me to store and transport my armor easily, in an awesome case that we can use as booth props in the future. Second, I finally decided upon how I am going to construct the crate. This part is probably the most discussed part of the build so far. we went back and fourth on molding and casting, or 3d printing, or other methods, but I finally made a decision...

I Plan to fully 3d Print the crate, Harden the outside with resin, and fiberglass the inside of the crate. From there, it was a discussion of features.

So here are the things I wanted from my crate:

-Removable caster wheels on the bottom

-preserve outside look of crate to be as accurate as possible.

-flip out handles from the inside to carry it

-lockable lid

-hidden positive latches to preserve space crate look

-stackable

To Achieve these goals, I had to scale up the crate to full size, and start doing a lot of extra modeling. I had to make registration between the pieces, a way to make the latches, the wheel inserts, and the handle connection points, and the pegs for stacking the crates

So here is what I came up with:

So the first step with this build, once I got my scale right, was the hardware. I had to pick up my hardware so I knew what to model in for those hardware points.

From there, I started with the latch. I decided to have the front space latch magnet over the regular. This would let me either have the crate closed or open, but preserve the look of the space latch. I can also completely remove the space latch, and just have the toggle latch, and be able to put a tsa lock on it for flying

The next thing I decided to tackle, was registration of parts. For the vertical registration, I used notches and grooves, while for the horizontal, I used numbered pegs. I specifically numbered them so I know what direction to print them in, and which goes where. There is also a notch and groove on the lid to the top of the box.

Next problem to tackle, was the bolts and holes for the caster wheels. On the top of the box, there are 4 decorative bolts, where as on the bottom, there is a slot to install a nut that the caster wheel is going to thread through. I also used this section to crate these triangle pegs, to stack two boxes together.

Finally, the last solution was the handles. I needed something that mounted from the inside, that would be strong enough to pull against to hold up the box. I planned on using nylon strapping, and a pvc pipe to make handles for the box. I will use grommets to bolt through the nylon straps into the box. I inset a nut from the top, and capped it off, sealing it into the side, which then I can thread into from the outside.

With all the modeling now done, It is time to start this behemoth. I calculated it, and one crate is going to take a whole 14 rolls of filament!! Each section of the crate is 12" x 12", and just barely fits on my build plate! The first print is now underway.