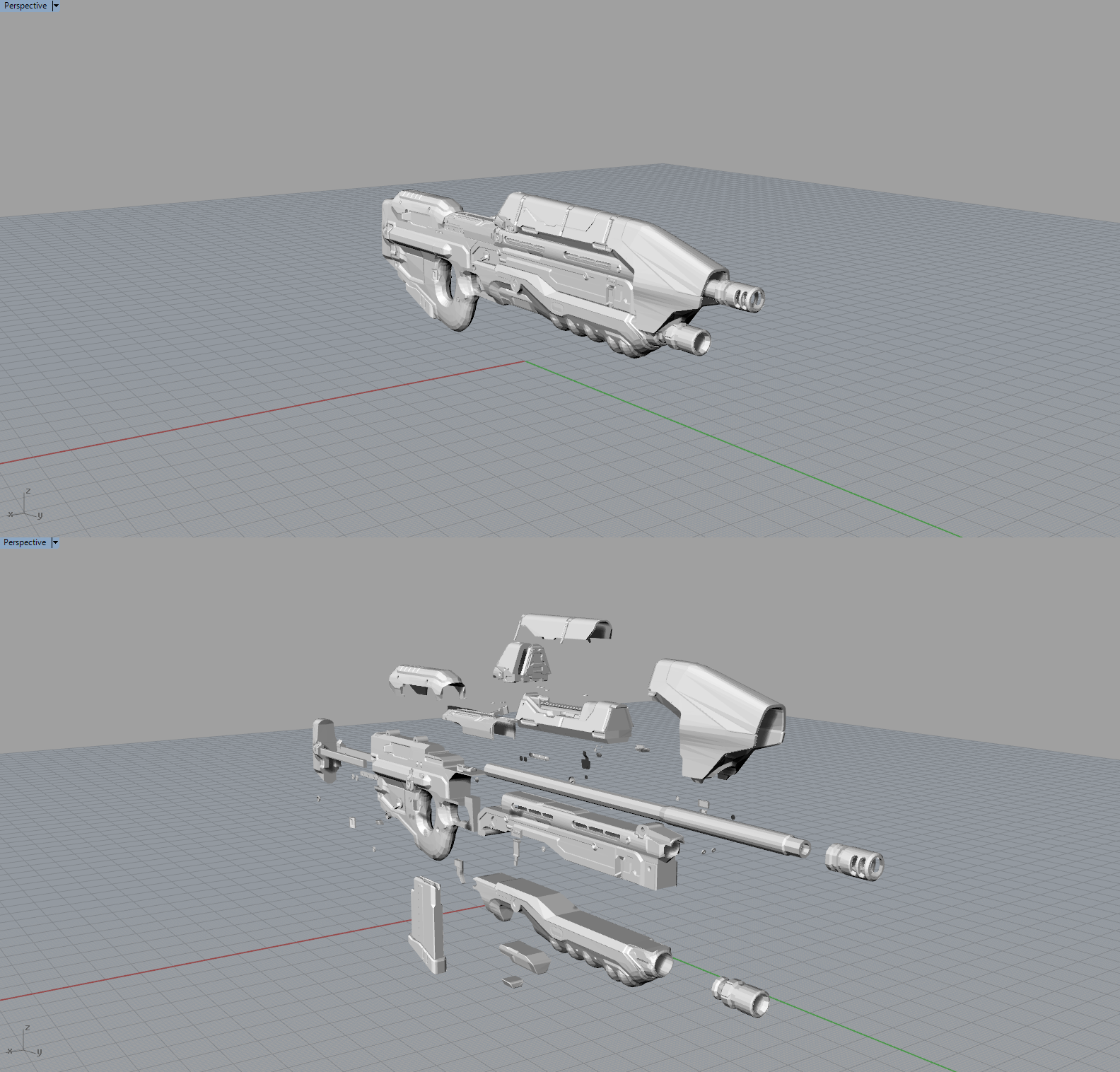

Hey 405th, wanna see an AR Explode?

Now that i have you're attention, allow me to introduce my new project. way back in 2016, I accidentally became the guy who is now responsible for ~99% of the 3D printed halo props in the world. That was absolutely not planned, by the way. i was just trying to teach myself 3D modeling with some game ripped files and you lot REALLY loved it! i'm also known for other hits, such as this failed, abandoned project trying to CNC entire props to mold and cast. and how could anyone forget one of my best talents: completely vanishing off the site and coming back over a year later to a completely new layout that i need to stumble through and relearn like an out of touch 23 year old grandpa.

I'm bringing all this up because this new project is a fusion of these past projects, and is ultimately what i wanted to do with these prop files, but have been waiting for my skills to catch up with the big ideas i had brewing.

THE IDEA:

It's pretty straightforward. I want to take these weapon 3D models, blow them apart into pieces just like the picture above, turn the whole thing into a hollow shell, and fill it up with latches, buttons, lights, and screens to make it the ultimate halo prop weapon. Then i want to take that shell, print it out (i've now moved to the other end of the country from that massive CNC machine), make a mold out of it, and start pumping out copies for you guys to buy. Then i want to do that to as many halo props from as many games as i can, much like how i did the original 3D printable halo props. As for selling them, obviously all my old 3D printable prop models won't be going anywhere. you're all still able to download and print them for free to make your own props. But, if you want some of that real sky-high quality, sci-fi boomstick action with all the bells and whistles, i am more than happy to provide that. It'll work just like any prop kit you've seen before. at the cheapest, just all the parts, straight out of the mold, chucked into a box and thrown at your door for you to assemble and paint. for a little more money, you get it assembled. next highest, i'll slap some paint on it. and for the full price, you get the full english: lights, screens, assembly, paint, hell i'll give it a kiss goodnight and read it a bedtime story before taping the box up and shipping it out.

THE PROBLEM:

Remember how i said i've had this idea for ages and have just been waiting for my skills to catch up? well, they haven't caught up 100%. i'm MILES ahead of where i was when i first made the 3D printable halo props, and as you've already seen i've blown apart the Halo 5 Assault rifle into all its little bits and pieces, but that took me ages with my self taught, intermediate 3D modeling skills. But that's not gonna stop me, especially not when i have such a massive knowledge pool like the 405th sitting around! so, instead of taking forever to go and properly learn these harder 3D modeling skills, i want to turn this project into a collaboration! which leads to...

HELP WANTED [Possibly with pay]

Unfortunately it seems most of the old guard here on the 405th forums have moved on, so the people i usually would go to to ask for help with something like this aren't around anymore. But i'm always up for making new friends! Do you think you have the skills i'm looking for when it comes to 3D modeling? do you ALSO have the skills to possibly answer random questions about Rhino 5 and maybe even teach my dumb ass how to 3D model better while you're doing it? well boy do i have the opportunity for you! To give a more clear picture of what's needed, here's my to-do list so far, for the AR pictured above:

* hollow out the large sections of the model into shells, probably with about a quarter inch wall thickness

* model in screw posts for assembly, and have them line up with the screws and dials already on the model (jesus there are just... so many screws on the AR)

* model in room for wiring, LED lights, and the screen/arduino for the ammo counter

* model in latches, fire switches, dials, etc to give the weapon as much function (besides actually firing bullets, obviously) that it has in the game

* engineering/modeling some kind of charging handle mechanism so the thing can have that nice "KERCHUNK" reload sound (again, without actually racking a cartridge. We're not making actual weapons here, mister ATF agent who might be reading this)

* modeling a battery pack into the existing model's geometry to power all them guts

* loads of other ideas that i'll probably come up with as the project progresses. these are just the main points i can think of off the top of my head.

So if you're a mechanical engineer by trade, stuck inside and bored to tears thanks to this COVID lockdown, and have nothing to do with all your amazing expert 3D modeling skills, then you're basically my dream come true! But, if you're just kinda banging rocks together like me, but know how to bang them together in a way that i don't, then don't hesitate to drop some advice in this thread, or hit me up in DMs.

And like the big bold words say, there could be some fair compensation involved. i know i'm asking for a LOT of time for this project, and i know that, even in lockdown, someone highly skilled can only donate so much of their time. So if you want to go all in on the project with me and tear through everything on that bullet point list, then i'm willing to pay you for your time. You'll also get credit for everything you do when i post on here or elsewhere.

The Project:

Obviously i'm not going to just sit on my ass after making this post and wait for the 3D modelers to come to me and fix all my problems. So regardless of if i get help or not, i'll be posting here regularly with progress updates as i slowly pick apart as many models as i can, and maybe even try to figure out some of the more complex modeling problems myself. I'm sure i'll get plenty of help from you guys along the way as well, so here's to a long and successful project i guess.

Now that i have you're attention, allow me to introduce my new project. way back in 2016, I accidentally became the guy who is now responsible for ~99% of the 3D printed halo props in the world. That was absolutely not planned, by the way. i was just trying to teach myself 3D modeling with some game ripped files and you lot REALLY loved it! i'm also known for other hits, such as this failed, abandoned project trying to CNC entire props to mold and cast. and how could anyone forget one of my best talents: completely vanishing off the site and coming back over a year later to a completely new layout that i need to stumble through and relearn like an out of touch 23 year old grandpa.

I'm bringing all this up because this new project is a fusion of these past projects, and is ultimately what i wanted to do with these prop files, but have been waiting for my skills to catch up with the big ideas i had brewing.

THE IDEA:

It's pretty straightforward. I want to take these weapon 3D models, blow them apart into pieces just like the picture above, turn the whole thing into a hollow shell, and fill it up with latches, buttons, lights, and screens to make it the ultimate halo prop weapon. Then i want to take that shell, print it out (i've now moved to the other end of the country from that massive CNC machine), make a mold out of it, and start pumping out copies for you guys to buy. Then i want to do that to as many halo props from as many games as i can, much like how i did the original 3D printable halo props. As for selling them, obviously all my old 3D printable prop models won't be going anywhere. you're all still able to download and print them for free to make your own props. But, if you want some of that real sky-high quality, sci-fi boomstick action with all the bells and whistles, i am more than happy to provide that. It'll work just like any prop kit you've seen before. at the cheapest, just all the parts, straight out of the mold, chucked into a box and thrown at your door for you to assemble and paint. for a little more money, you get it assembled. next highest, i'll slap some paint on it. and for the full price, you get the full english: lights, screens, assembly, paint, hell i'll give it a kiss goodnight and read it a bedtime story before taping the box up and shipping it out.

THE PROBLEM:

Remember how i said i've had this idea for ages and have just been waiting for my skills to catch up? well, they haven't caught up 100%. i'm MILES ahead of where i was when i first made the 3D printable halo props, and as you've already seen i've blown apart the Halo 5 Assault rifle into all its little bits and pieces, but that took me ages with my self taught, intermediate 3D modeling skills. But that's not gonna stop me, especially not when i have such a massive knowledge pool like the 405th sitting around! so, instead of taking forever to go and properly learn these harder 3D modeling skills, i want to turn this project into a collaboration! which leads to...

HELP WANTED [Possibly with pay]

Unfortunately it seems most of the old guard here on the 405th forums have moved on, so the people i usually would go to to ask for help with something like this aren't around anymore. But i'm always up for making new friends! Do you think you have the skills i'm looking for when it comes to 3D modeling? do you ALSO have the skills to possibly answer random questions about Rhino 5 and maybe even teach my dumb ass how to 3D model better while you're doing it? well boy do i have the opportunity for you! To give a more clear picture of what's needed, here's my to-do list so far, for the AR pictured above:

* hollow out the large sections of the model into shells, probably with about a quarter inch wall thickness

* model in screw posts for assembly, and have them line up with the screws and dials already on the model (jesus there are just... so many screws on the AR)

* model in room for wiring, LED lights, and the screen/arduino for the ammo counter

* model in latches, fire switches, dials, etc to give the weapon as much function (besides actually firing bullets, obviously) that it has in the game

* engineering/modeling some kind of charging handle mechanism so the thing can have that nice "KERCHUNK" reload sound (again, without actually racking a cartridge. We're not making actual weapons here, mister ATF agent who might be reading this)

* modeling a battery pack into the existing model's geometry to power all them guts

* loads of other ideas that i'll probably come up with as the project progresses. these are just the main points i can think of off the top of my head.

So if you're a mechanical engineer by trade, stuck inside and bored to tears thanks to this COVID lockdown, and have nothing to do with all your amazing expert 3D modeling skills, then you're basically my dream come true! But, if you're just kinda banging rocks together like me, but know how to bang them together in a way that i don't, then don't hesitate to drop some advice in this thread, or hit me up in DMs.

And like the big bold words say, there could be some fair compensation involved. i know i'm asking for a LOT of time for this project, and i know that, even in lockdown, someone highly skilled can only donate so much of their time. So if you want to go all in on the project with me and tear through everything on that bullet point list, then i'm willing to pay you for your time. You'll also get credit for everything you do when i post on here or elsewhere.

The Project:

Obviously i'm not going to just sit on my ass after making this post and wait for the 3D modelers to come to me and fix all my problems. So regardless of if i get help or not, i'll be posting here regularly with progress updates as i slowly pick apart as many models as i can, and maybe even try to figure out some of the more complex modeling problems myself. I'm sure i'll get plenty of help from you guys along the way as well, so here's to a long and successful project i guess.