- Member DIN

- S128

I've got to give hats off again to Asgardianhammer . It's people like you that remind me how lazy I am! How I go home after work and just play video games. You're a super active Division Identity Officer, active Regiment Commander, community organizer, scout leader, dad, employed, and you still have time to play video games! I hope you approve of the direction I took with your recruitment booth idea.

We've had the discussion here and on our regiment facebook group about what we want to see in a recruitment booth here in the Pacific. Now it's time to build it!

Drafting

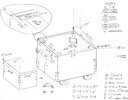

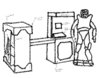

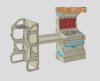

To start off, I'd like to show you a transition of concept sketches.

With the idea in mind now we needed exact measurements to create a cut list.

\

First I had to draw with real 3d effects! By drawing the actual thickness of wood I can see where joints need to be mitered, where dowels or screws or dados need to go, which board sits on which and how does it change the dimensions. I broke down each section and even started the beginning of a supply list on each page.

(not to scale)

(not to scale)

(to scale)

(to scale)

Since the bottom box is the cart that holds all the pieces (except the weapons rack which will hang on the outside). I had to write up all the thicknesses of the pieces used to make sure it fits in the box. Plenty of room to spare!

All in all this took me around 21 hours to doodle.

Cut List

From these dimensions I used MS Paint to lay out a cut list (only the 3/4" material for now).

mblackwell1002 is also doing a CAD drawing so we can cut these pieces on CNC.

(not to scale)

(not to scale)

Materials List

*means still need to purchase

General Materials:

Computer Drafting mblackwell1002

(3) 4' x 8' x 3/4" Birch Plywood|$180

CNC work [Rogers HS]

(1) 4' x 4' x 1/4" Acrylic|$20 donated - Interstate Plastics

(2) 2" x 4" boards|$9

(3) 1/2" wood board scraps|$3

(1) 10" x 80t HiATB Saw Blade|$45

(1) 1/4" Downcut CNC Spiral|$30 [Rogers HS]

(1) 1/16" Roundover Routerbit|$20

(1) 45* x 3/4" Chamfer Routerbit|$25

(2) Grey Primers|$8

(2) Primary Paint|$9

(1) Secondary Spray Paints|$4

(1) Tertiary Spray Paint |$4

(1) PaintersTape|$8

(1) Wood glue|$5

*(1) Wood Putty

(3) Safety Glasses|$3

(5) Dust Masks|$2

Main Terminal:

(4) 5" Caster Wheels with locks|$35

(16) 5/16-18 x 1-1/4" bolts, nuts, washers $10

(1) 28" x 22" Insulation foam to cover inside base of box

(2) 1/4" x 36" Wood Dowel|$2

(34) 2hole L brackets|$30

(8) 1hole seam bracket|$4

(2) 6" x 3" x 1/16" sheet metal strips|$5

(3) 3/4" square hooks|$5

(2) modified 2x4 brackets $2

(1) Tablet|$60

(1) Keyboard|$30

(1) Mouse|$10

(2) Anti Theft Kits|$40

(2) Small Caribiners|$2

(2) 5/8" eyelet bolt|$2

*(1) Custom Aluminum Plaque mblackwell1002

(200) 3/4" deep screws for brackets| $10

(20) 1 1/2" wood screws (just in case)|$2

(1) Power strip|$11

*(1) Extension Chord|$5 used

*(1) UNSC Text Stencil

*(1) UNSC Logo Stencil

*(1) Build Your Character Sticker

*(1) Regiment logos Sticker

*(1) Monitor sticker

Table:

*(1) Custom Aluminum Frame|$?

(1) 16" x 36" Mirror|$8 used

*(1) 16" x 36" x 1/4" Acrylic-donated

(1) 16" x 36" Reflective Window tint|$10

(3) 3' Addressable LEDs|$23

(1) 9' of 1 1/2" x 1 1/2" board

*(1) Particle Photon

*(1) Logic Level Shifter

*(3) 10k Potentionmeter

*(3) Knobs

*(1) 2 and 3 pin terminals

*(1) 5v 10A power supply

(5) 5/16-18 x 1-1/2 bolts, nuts washers|$4

(1) 1-1/2" cabinet hinge|$2

(1) 5/16-18 x 3/4" bolt and nut|$1

*(1) Light-up A.I. Plaque [Kevin Hurd]

(5) Acrylic Business Card Holders|$5

(1) Acrylic Brochure Holder|$7

(1) Acrylic Half Page Holder|$7

(40) Earth Magnets|$10

*Business cards, brochures and booklets| $100

DIY (long stapler $16)

(100) Activity Books |$30

(500) Business Cards |$20

Weapon Rack:

*(1) Caution Stencil| $ [Kevin Hurd]

(3) 1" x 3" x 1/16" Sheet Metal|$5

(10) 1/4" x 2" Lag Bolts|$4

(4) 1/4" x 1 1/2" lag Bolts|$2

(1) 72" x 1 1/4" Wood Dowel|$8

(1) 72" x 3/4" Wood dowel|$5

(100) 11" zip ties|$2

(20) 24" zip ties|$2

Extras:

(1) Mannequin Stand|$100 PerniciousDuke

(1) Flag Pole $18 and Stand DIY PerniciousDuke

*(1) Custom 405th Flag Huntress217

(1) 20' Truck Strap|$6

(2) Eyelet bolts|$2

PerniciousDuke

(2) cloth covers $25 PerniciousDuke

Discounts:

Friend's Military discount @ Lowes

We've had the discussion here and on our regiment facebook group about what we want to see in a recruitment booth here in the Pacific. Now it's time to build it!

Drafting

To start off, I'd like to show you a transition of concept sketches.

With the idea in mind now we needed exact measurements to create a cut list.

\

First I had to draw with real 3d effects! By drawing the actual thickness of wood I can see where joints need to be mitered, where dowels or screws or dados need to go, which board sits on which and how does it change the dimensions. I broke down each section and even started the beginning of a supply list on each page.

(not to scale)

(not to scale)

(to scale)

(to scale)Since the bottom box is the cart that holds all the pieces (except the weapons rack which will hang on the outside). I had to write up all the thicknesses of the pieces used to make sure it fits in the box. Plenty of room to spare!

All in all this took me around 21 hours to doodle.

Cut List

From these dimensions I used MS Paint to lay out a cut list (only the 3/4" material for now).

mblackwell1002 is also doing a CAD drawing so we can cut these pieces on CNC.

(not to scale)

(not to scale)Materials List

*means still need to purchase

General Materials:

Computer Drafting mblackwell1002

(3) 4' x 8' x 3/4" Birch Plywood|$180

CNC work [Rogers HS]

(1) 4' x 4' x 1/4" Acrylic|$20 donated - Interstate Plastics

(2) 2" x 4" boards|$9

(3) 1/2" wood board scraps|$3

(1) 10" x 80t HiATB Saw Blade|$45

(1) 1/4" Downcut CNC Spiral|$30 [Rogers HS]

(1) 1/16" Roundover Routerbit|$20

(1) 45* x 3/4" Chamfer Routerbit|$25

(2) Grey Primers|$8

(2) Primary Paint|$9

(1) Secondary Spray Paints|$4

(1) Tertiary Spray Paint |$4

(1) PaintersTape|$8

(1) Wood glue|$5

*(1) Wood Putty

(3) Safety Glasses|$3

(5) Dust Masks|$2

Main Terminal:

(4) 5" Caster Wheels with locks|$35

(16) 5/16-18 x 1-1/4" bolts, nuts, washers $10

(1) 28" x 22" Insulation foam to cover inside base of box

(2) 1/4" x 36" Wood Dowel|$2

(34) 2hole L brackets|$30

(8) 1hole seam bracket|$4

(2) 6" x 3" x 1/16" sheet metal strips|$5

(3) 3/4" square hooks|$5

(2) modified 2x4 brackets $2

(1) Tablet|$60

(1) Keyboard|$30

(1) Mouse|$10

(2) Anti Theft Kits|$40

(2) Small Caribiners|$2

(2) 5/8" eyelet bolt|$2

*(1) Custom Aluminum Plaque mblackwell1002

(200) 3/4" deep screws for brackets| $10

(20) 1 1/2" wood screws (just in case)|$2

(1) Power strip|$11

*(1) Extension Chord|$5 used

*(1) UNSC Text Stencil

*(1) UNSC Logo Stencil

*(1) Build Your Character Sticker

*(1) Regiment logos Sticker

*(1) Monitor sticker

Table:

*(1) Custom Aluminum Frame|$?

(1) 16" x 36" Mirror|$8 used

*(1) 16" x 36" x 1/4" Acrylic-donated

(1) 16" x 36" Reflective Window tint|$10

(3) 3' Addressable LEDs|$23

(1) 9' of 1 1/2" x 1 1/2" board

*(1) Particle Photon

*(1) Logic Level Shifter

*(3) 10k Potentionmeter

*(3) Knobs

*(1) 2 and 3 pin terminals

*(1) 5v 10A power supply

(5) 5/16-18 x 1-1/2 bolts, nuts washers|$4

(1) 1-1/2" cabinet hinge|$2

(1) 5/16-18 x 3/4" bolt and nut|$1

*(1) Light-up A.I. Plaque [Kevin Hurd]

(5) Acrylic Business Card Holders|$5

(1) Acrylic Brochure Holder|$7

(1) Acrylic Half Page Holder|$7

(40) Earth Magnets|$10

*Business cards, brochures and booklets| $100

DIY (long stapler $16)

(100) Activity Books |$30

(500) Business Cards |$20

Weapon Rack:

*(1) Caution Stencil| $ [Kevin Hurd]

(3) 1" x 3" x 1/16" Sheet Metal|$5

(10) 1/4" x 2" Lag Bolts|$4

(4) 1/4" x 1 1/2" lag Bolts|$2

(1) 72" x 1 1/4" Wood Dowel|$8

(1) 72" x 3/4" Wood dowel|$5

(100) 11" zip ties|$2

(20) 24" zip ties|$2

Extras:

(1) Mannequin Stand|$100 PerniciousDuke

(1) Flag Pole $18 and Stand DIY PerniciousDuke

*(1) Custom 405th Flag Huntress217

(1) 20' Truck Strap|$6

(2) Eyelet bolts|$2

PerniciousDuke

(2) cloth covers $25 PerniciousDuke

Discounts:

Friend's Military discount @ Lowes

Last edited: