I've been messing about with my resin printer for a bit, and I think I have a decent technique down that I'm ready to share.

Let's start at the end, just to give you an idea what's possible:

So let's get started. You're free to model your own lenses, or use the ones I designed: Printables

Modeling:

You probably want to keep these lenses fairly thin, as even "clear" 3D printing resin isn't entirely clear.

Thin lenses will also need less time to cure, which will help us later.

Printing:

I used a resin printer (Mars 2) at 0.02mm layer heights, with Anycubic Clear resin. It's the only clear resin I've used so far, though I've heard good things about Sirayatech Blu Clear as well.

As you can see, the lenses are extremely clear right out of the tank, but unfortunately they're not ready for use yet.

Cleaning:

Wash the lenses in IPA, and wash them well. I use a two-stage process to get rid of any excess resin. First 7 minutes inside a wash&cure stirrer, and then some manual shaking in a pickle jar with very clean IPA.

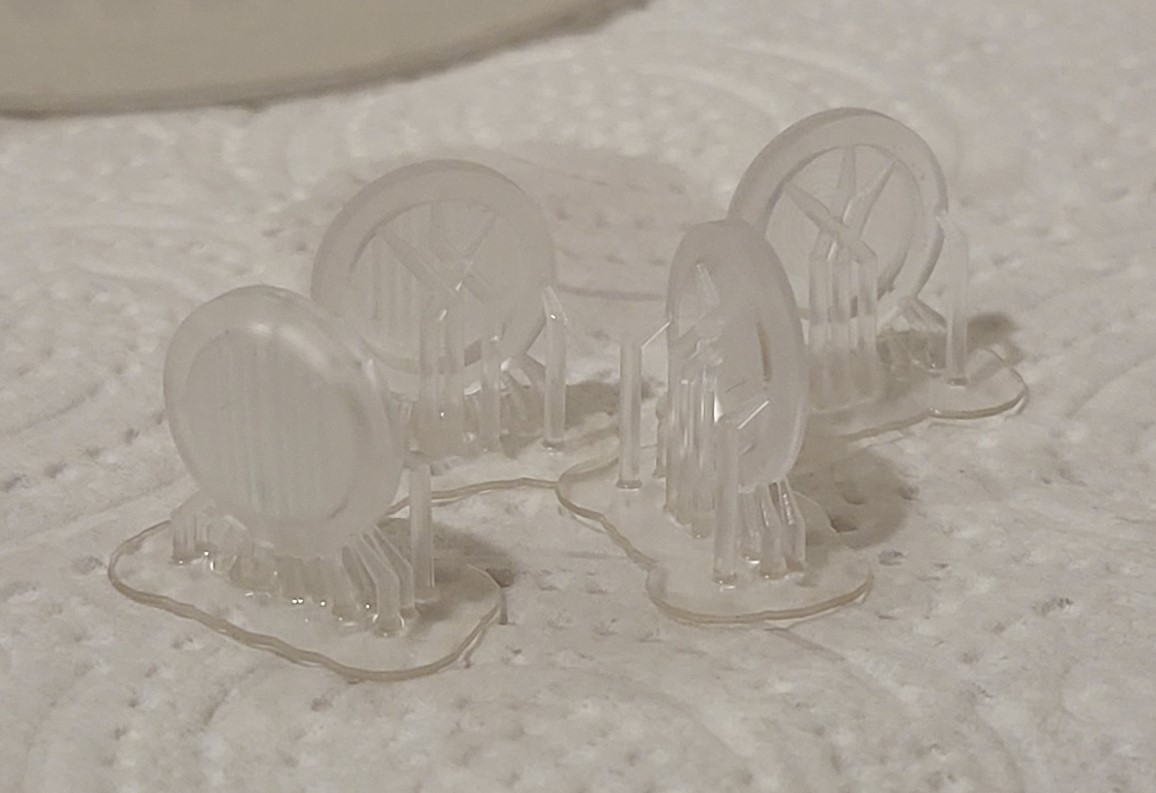

The cleaning process gives the lenses a frosted appearance, this is normal.

Curing:

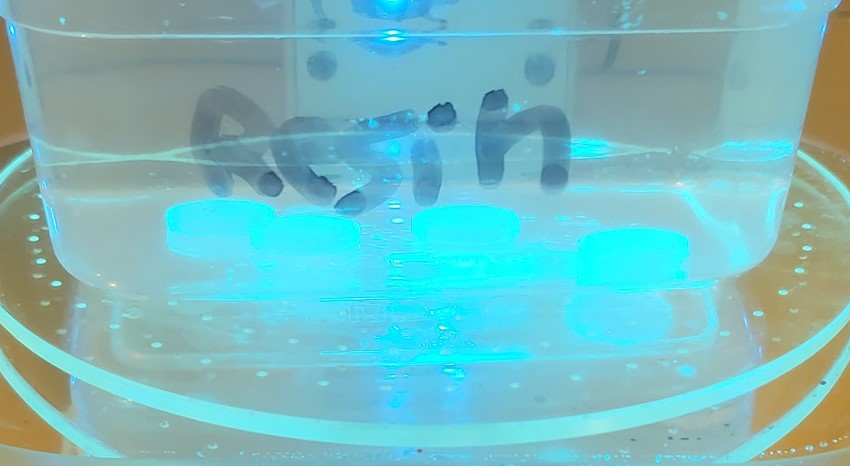

I cure these lenses under water. As I understand it, this helps prevent (most of the) yellowing, and also allows for much shorter curing times. In this case, 1.5m was more than plenty for 4 lenses. You can go longer, but you risk (increased) yellowing.

Coating:

The last step, and the one what brings back most of our transparency. Get some glossy clear coat spray and apply generously! I've also heard good things about pledge/future floor polish, but have not tried it myself yet.

Before varnish on the left, after varnish on the right:

Good luck, and please let me know if this worked for you as well, or if you have suggestions for improvement!

Let's start at the end, just to give you an idea what's possible:

So let's get started. You're free to model your own lenses, or use the ones I designed: Printables

Modeling:

You probably want to keep these lenses fairly thin, as even "clear" 3D printing resin isn't entirely clear.

Thin lenses will also need less time to cure, which will help us later.

Printing:

I used a resin printer (Mars 2) at 0.02mm layer heights, with Anycubic Clear resin. It's the only clear resin I've used so far, though I've heard good things about Sirayatech Blu Clear as well.

As you can see, the lenses are extremely clear right out of the tank, but unfortunately they're not ready for use yet.

Cleaning:

Wash the lenses in IPA, and wash them well. I use a two-stage process to get rid of any excess resin. First 7 minutes inside a wash&cure stirrer, and then some manual shaking in a pickle jar with very clean IPA.

The cleaning process gives the lenses a frosted appearance, this is normal.

Curing:

I cure these lenses under water. As I understand it, this helps prevent (most of the) yellowing, and also allows for much shorter curing times. In this case, 1.5m was more than plenty for 4 lenses. You can go longer, but you risk (increased) yellowing.

Coating:

The last step, and the one what brings back most of our transparency. Get some glossy clear coat spray and apply generously! I've also heard good things about pledge/future floor polish, but have not tried it myself yet.

Before varnish on the left, after varnish on the right:

Good luck, and please let me know if this worked for you as well, or if you have suggestions for improvement!