Spartan137

Well-Known Member

New update for you!

I've been working in co-operation with Michael Vroegop (AKA Vrogy), who has built a rather splendid CNC mill, and I'm in the process of vacuum forming CNC'd armor parts. Vrogy sent me the first of the CNC'd parts a while back, which was the MK VI handplate (based upon Robogenisis' model), formed out of MDF wood (to VERY nice quality, even if it did look like a cookie to me). The piece was to serve as my prototype piece for determining the ease and reliability of Vac-forming.

Results where pleasing!

Pics:

Finished gloves! Painted in my Red Alert 1741 colors!

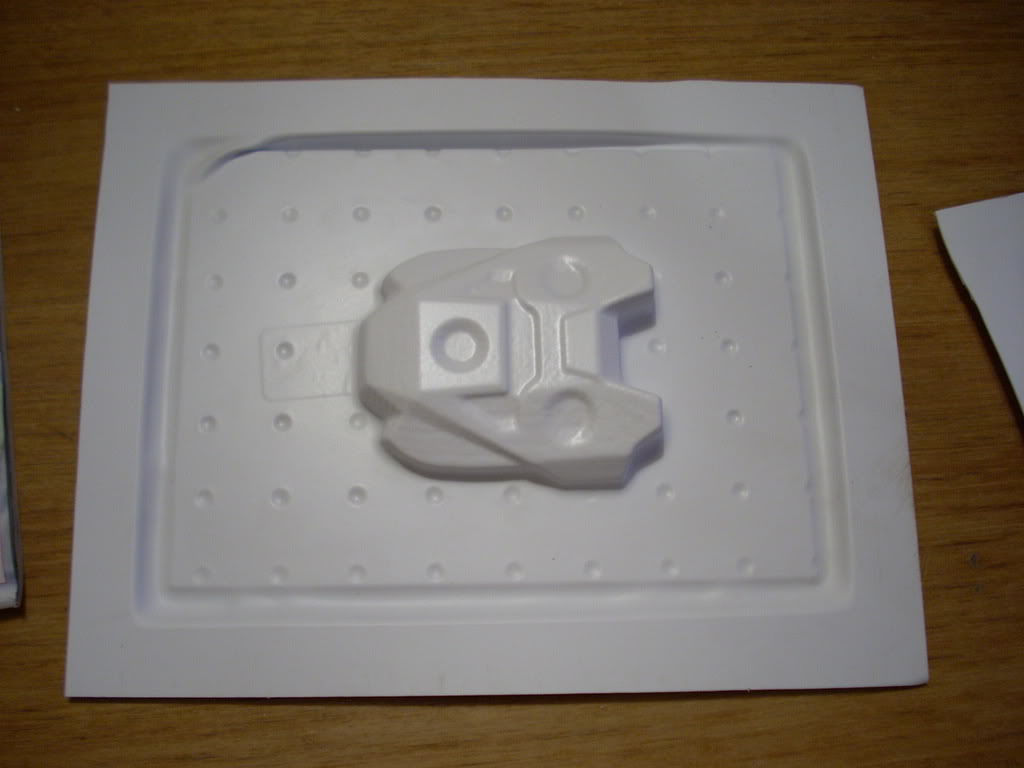

And the first run of Handplates (still need to be trimmed), destined to be shipped to Vrogy:

Thanks goes to my dad for helping me with the table, and to Michael, for helping me create such fantastic pieces.

Constructive criticism only, please.

I've been working in co-operation with Michael Vroegop (AKA Vrogy), who has built a rather splendid CNC mill, and I'm in the process of vacuum forming CNC'd armor parts. Vrogy sent me the first of the CNC'd parts a while back, which was the MK VI handplate (based upon Robogenisis' model), formed out of MDF wood (to VERY nice quality, even if it did look like a cookie to me). The piece was to serve as my prototype piece for determining the ease and reliability of Vac-forming.

Results where pleasing!

Pics:

Finished gloves! Painted in my Red Alert 1741 colors!

And the first run of Handplates (still need to be trimmed), destined to be shipped to Vrogy:

Thanks goes to my dad for helping me with the table, and to Michael, for helping me create such fantastic pieces.

Constructive criticism only, please.

A run of handplates are currently being considered for the 405th community! Please PM me if you are interested so I can get a reference of how many are wanted!

Last edited by a moderator: