You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

War Machine Foam Build- WIP

- Thread starter Kangabox

- Start date

- Status

- Not open for further replies.

Looks good!

you may find the servo control board is pretty big and you might need to fit it into the chest and have a wire running to the helmet or do it wireless, check out http://youtu.be/qQU6xxdqR3Y this will give you the info you need to know

Keep it up man, i'm really impressed with this build so far

Thanks!

Indeed, we've also hit the bump where we realized that the helmet might actually need 2/4 servos in order for it to open and close.

So we'll put it on a generic hinge in the meantime...

Sew the elastic to a piece of nylon strap. Then just hot glue to strap to the foam. The hot glue will infuse the nylon strap and soak into the foam and it will NEVER move.

You would have to disintegrate the foam before the nylon would come off. So, make sure to measure twice and glue once... 'cause you only get one try.

You would have to disintegrate the foam before the nylon would come off. So, make sure to measure twice and glue once... 'cause you only get one try.

captaincaliflour

Active Member

Does it fly? Also I had an idea for how to make his arm guns shoot nerf darts if you'd like to try it.

captaincaliflour

Active Member

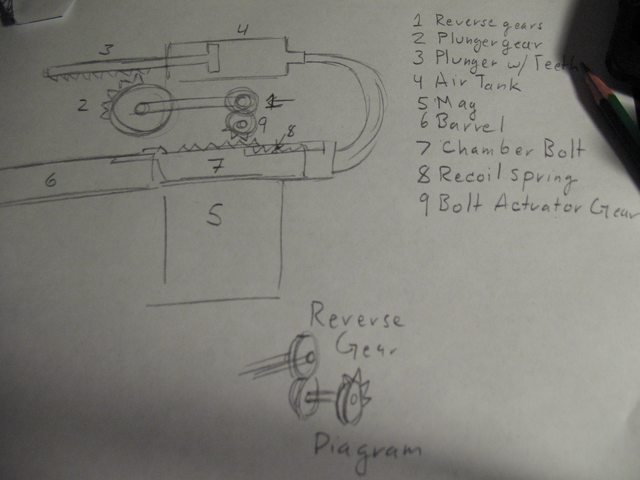

Well my design works like this:

A motor imparts power to a small gear in section 1. This gear turns the two primary motive gears [2] and [9] which both have teeth only on a portion of them. This lets them activate for a short period then release. Gear [2] pulls back the spring loaded plunger (as it does on a stampede) while gear [9] chambers a round by moving the spring loaded chamber bolt foreward. When Gear [2]'s teeth run out, the spring loaded plunger activates (like it does in all nerf guns) pushing the air in the tank foreward and out through the U bend into the bolt chamber, launching the dart out the barrel. When gear [9]'s teeth run out, the chamber bolt slides back on its spring, allowing the process to begin again.

It's basically the same mechanism that's in a Stampede already, just bent in half.

A motor imparts power to a small gear in section 1. This gear turns the two primary motive gears [2] and [9] which both have teeth only on a portion of them. This lets them activate for a short period then release. Gear [2] pulls back the spring loaded plunger (as it does on a stampede) while gear [9] chambers a round by moving the spring loaded chamber bolt foreward. When Gear [2]'s teeth run out, the spring loaded plunger activates (like it does in all nerf guns) pushing the air in the tank foreward and out through the U bend into the bolt chamber, launching the dart out the barrel. When gear [9]'s teeth run out, the chamber bolt slides back on its spring, allowing the process to begin again.

It's basically the same mechanism that's in a Stampede already, just bent in half.

Its actually starting to sound more like the mechanism in AEGs...

Correct me if I'm wrong, but wouldn't I need some sort of anti reversal latch on Gear 2? or is Gear 9 serving as a rudimentary form of one?

Otherwise on paper, it looks like this should technically work.

Housing for the mechanism, and the weight of the F2000s come to mind tho...

Correct me if I'm wrong, but wouldn't I need some sort of anti reversal latch on Gear 2? or is Gear 9 serving as a rudimentary form of one?

Otherwise on paper, it looks like this should technically work.

Housing for the mechanism, and the weight of the F2000s come to mind tho...

TheSlammerss

New Member

Oh my complicated lol good luck my friend I can't wait to see this suit nail some people in the head with a nerf dark gona be sick

captaincaliflour

Active Member

Its actually starting to sound more like the mechanism in AEGs...

Correct me if I'm wrong, but wouldn't I need some sort of anti reversal latch on Gear 2? or is Gear 9 serving as a rudimentary form of one?

Otherwise on paper, it looks like this should technically work.

Housing for the mechanism, and the weight of the F2000s come to mind tho...

Well in essence the Nerf Stampede is just a plastic AEG. Using PVC Pipe and other plastic tubing for the major parts and some plastic gears for the motor system you should be able to keep the weight down to reasonable, foam supportable levels. And plastic is entirely viable because the Stampede uses all plastic gears for its drive system and uses a very small brushed motor.

Gear 9 should be able to prevent any sort of reversals through a pin system, as you can see in the 'Gear Reversal Diagram' at the bottom.

Also, Proof that an all PVC home-made nerf gun can work and work well:

http://nerfhaven.com/homemade/boltsniper_far/

Annanymous

Well-Known Member

looks EPIC!

Also, Proof that an all PVC home-made nerf gun can work and work well:

http://nerfhaven.com/homemade/boltsniper_far/

You're giving me bad ideas mate

That realization when you remember War Machine needs some sort of shoulder mounted weapon as well...

war machine is a pain to build... im glad that u decided for that build mate !

Indeed it is!

On the plus side tho, sizing doesn't become an issue for the build, since you basically oversize all the parts, and can get away with it... XD

So, here's the million dollar question, what do I do with all the seams? And even when you plasticize foam, and give it layers of varnish and acrylic, it still has a bit of a "foam" tinge, and not so much of a "metallic" look.

TL;DR, I'm going to be experimenting with ways to make foam NOT look like foam.

So, I'm going to start off with experimenting with Wall Spackle (Available at your home depot for dirt cheap), on a ab piece that was accidentally mis-sized to fit that of an Oompa Loompa:

Here's how it should work in theory. In theory, if bits of spackle are applied to the seams, they should ahere to it with no problems.

Here's where it gets complicated:

I'm planning on applying a thick coat of spackle on the inflexible pieces, such as the forearms, F2000s, Handplates, thighs, shoulders, shins, and parts of the chest. These pieces will be rendered inflexible by hot gluing a piece of cardboard on the inside of the pieces, and coated over with FB resin. In this sense, I can resin + paint over the spackle + sand it.

TL;DR, "Bondo" for foam.

As far as the other need to flex pieces, like the biceps, Abs, and Cod Piece go, we'll see what happens...

TL;DR, I'm going to be experimenting with ways to make foam NOT look like foam.

So, I'm going to start off with experimenting with Wall Spackle (Available at your home depot for dirt cheap), on a ab piece that was accidentally mis-sized to fit that of an Oompa Loompa:

Here's how it should work in theory. In theory, if bits of spackle are applied to the seams, they should ahere to it with no problems.

Here's where it gets complicated:

I'm planning on applying a thick coat of spackle on the inflexible pieces, such as the forearms, F2000s, Handplates, thighs, shoulders, shins, and parts of the chest. These pieces will be rendered inflexible by hot gluing a piece of cardboard on the inside of the pieces, and coated over with FB resin. In this sense, I can resin + paint over the spackle + sand it.

TL;DR, "Bondo" for foam.

As far as the other need to flex pieces, like the biceps, Abs, and Cod Piece go, we'll see what happens...

Great idea for experimenting!

Here's two ideas for you to try out as well:

1, make sure your gaps are sealed and there's no excess glue and then use a decent plastic coat primer before spraying with metallic paint.

Or

2, you can use RD65 I think it is to properly plastic coat the foam. This process will set the piece of hard as its causing the foam to soak up plastic and the benefits are more endurable armour that when painted looks just like the real thing.

2 is a long process though. You need to build up about 6 layers of PVA then another couple of the RD65, it's also a bit expensive. But the end result is brilliant.

Go to YouTube and check out Xrobots there's a video of his showing how you do this.

Good luck buddy

Here's two ideas for you to try out as well:

1, make sure your gaps are sealed and there's no excess glue and then use a decent plastic coat primer before spraying with metallic paint.

Or

2, you can use RD65 I think it is to properly plastic coat the foam. This process will set the piece of hard as its causing the foam to soak up plastic and the benefits are more endurable armour that when painted looks just like the real thing.

2 is a long process though. You need to build up about 6 layers of PVA then another couple of the RD65, it's also a bit expensive. But the end result is brilliant.

Go to YouTube and check out Xrobots there's a video of his showing how you do this.

Good luck buddy

- Status

- Not open for further replies.