Thank you very much, but progress is slow, now I am planning to use your harness system to attach the leg armor

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1st build masterchief 3d halo 4 + undersuit

- Thread starter 405caveman

- Start date

-

- Tags

- 1st build

- Status

- Not open for further replies.

thank you very much, I have to say that years ago I made a BOBAFETT suit from hay that I like both the weather and the wearyour progress looks amazing! Everything came together very nicely. Love the paint job and the weathering

Weathering and wear seems to make a whole piece better. Adds more character to armor or propsthank you very much, I have to say that years ago I made a BOBAFETT suit from hay that I like both the weather and the wear

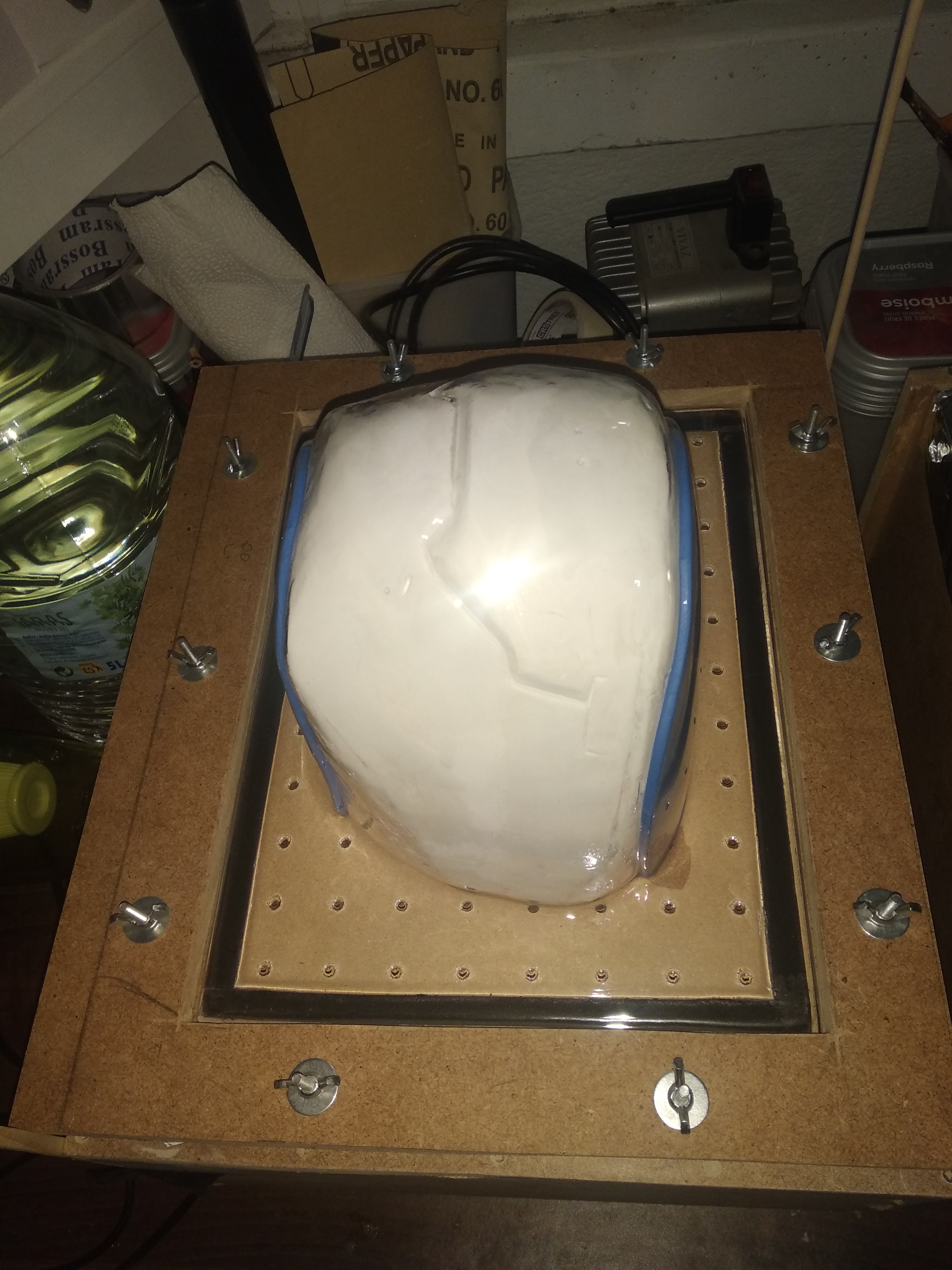

Hello, today I am going to show you how I made the thermoforming machine,

I am not going to go into details of the measurements, since I understand that each one will make the machine according to their needs and I will not go into the type of material in this case wood, only in the errors What did I do and how did I solve them?

I am not going to go into details of the measurements, since I understand that each one will make the machine according to their needs and I will not go into the type of material in this case wood, only in the errors What did I do and how did I solve them?

I bought a pegboard used to hang tools on the wall, so I didn't have to drill the "suction bed",

then raise the bed above the level of the thermoforming machine so that when I put it on top, the frame with the plastic sheet, make more vacuum. I also put a foam frame around the suction bed to make the perfect vacuum, in the first attempts it did not vacuum properly, since then everything was better, in two of the corners of the suction bed, I put a wooden rod as a guide so that when you put the hot plastic it will go straight down to the mold.

then raise the bed above the level of the thermoforming machine so that when I put it on top, the frame with the plastic sheet, make more vacuum. I also put a foam frame around the suction bed to make the perfect vacuum, in the first attempts it did not vacuum properly, since then everything was better, in two of the corners of the suction bed, I put a wooden rod as a guide so that when you put the hot plastic it will go straight down to the mold.

Also say that the aspirator I use is not very powerful and it still worked very well

, I used some tubes to attach the aspirator to the center of the vacuum machine, I did not want the suction socket to be on one side I preferred the suction to be more uniform.

, I used some tubes to attach the aspirator to the center of the vacuum machine, I did not want the suction socket to be on one side I preferred the suction to be more uniform.

To heat the plastic I used a horizontal toaster, at first I had my doubts, and I didn't know if it would be enough to reach the temperature, but then I realized that it is enough even more, I made a wooden structure lined with paper of aluminum to prevent the wood from catching fire, and everything went quite well, nothing caught fire.

I also made a cardboard lid lined with aluminum foil to cover the heating oven and it will take less time for the plastic to reach temperature, it also worked that once the plastic was burned, it reduced the heating time by half (this has been translated by Google)

I bought a pegboard used to hang tools on the wall, so I didn't have to drill the "suction bed",

Also say that the aspirator I use is not very powerful and it still worked very well

To heat the plastic I used a horizontal toaster, at first I had my doubts, and I didn't know if it would be enough to reach the temperature, but then I realized that it is enough even more, I made a wooden structure lined with paper of aluminum to prevent the wood from catching fire, and everything went quite well, nothing caught fire.

I also made a cardboard lid lined with aluminum foil to cover the heating oven and it will take less time for the plastic to reach temperature, it also worked that once the plastic was burned, it reduced the heating time by half (this has been translated by Google)

TylerBH2014

Active Member

How did you make the forming buck?

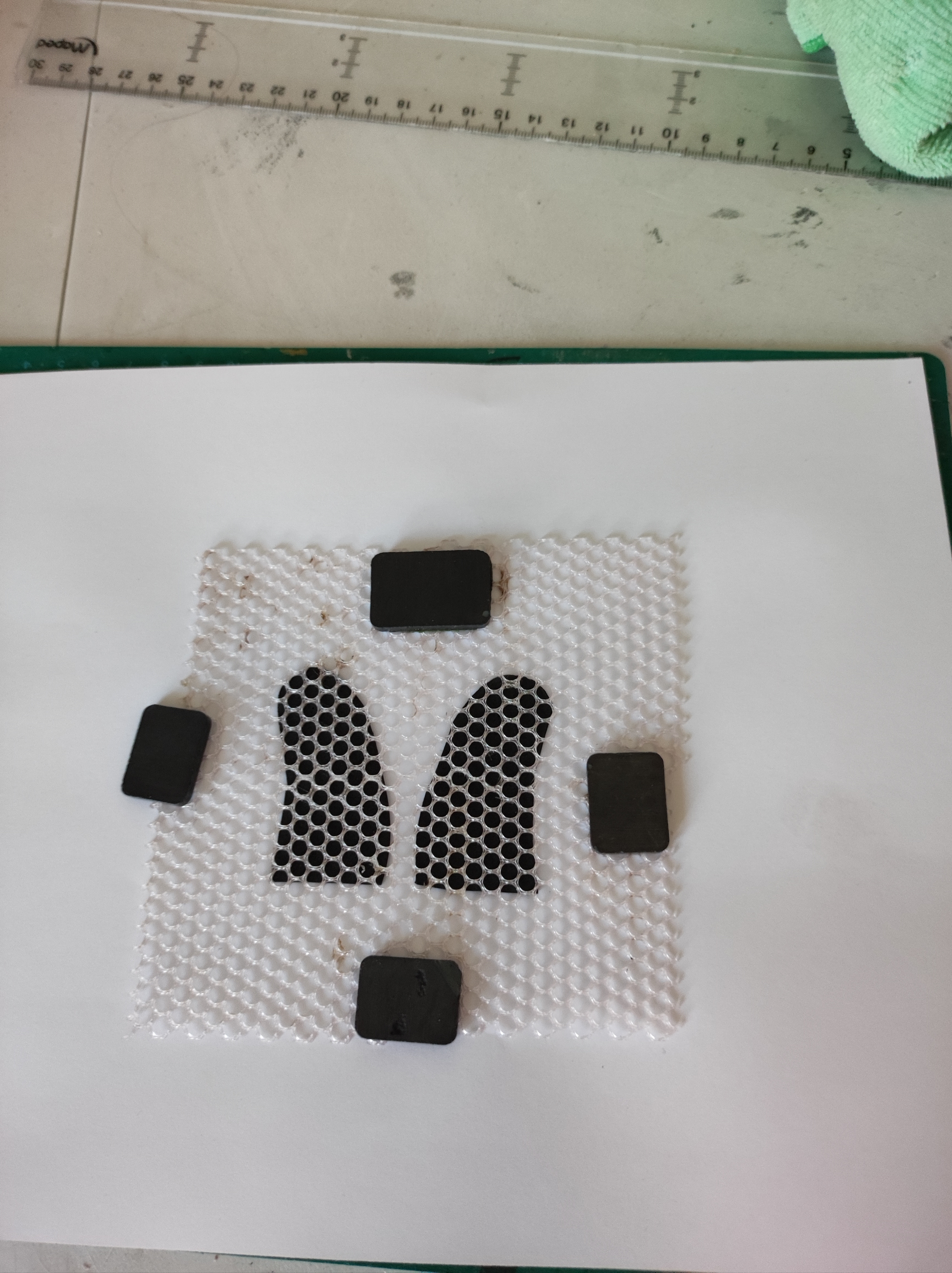

Hello, the mold is made of plaster.

I first made the visor that came with the 3d printed helmet model in PLA.

Then I made a negative cast in plaster and filled it in plaster to get the negative out, I don't have pictures of the process but I had to repeat the positive cast up to 3 times, after a lot of sanding, fill in 10x I finished something half decent

, at this point I must say that even though the mold is resistant, very heavy which comes in handy when empty, I think it is better to make a 3d printed mold and that's it, once you master the technique with one or two attempts you get a good viewer and it doesn't make much sense to have a plaster cast for a single visor, unless you want to make more visors to market

, at this point I must say that even though the mold is resistant, very heavy which comes in handy when empty, I think it is better to make a 3d printed mold and that's it, once you master the technique with one or two attempts you get a good viewer and it doesn't make much sense to have a plaster cast for a single visor, unless you want to make more visors to market

I first made the visor that came with the 3d printed helmet model in PLA.

Then I made a negative cast in plaster and filled it in plaster to get the negative out, I don't have pictures of the process but I had to repeat the positive cast up to 3 times, after a lot of sanding, fill in 10x I finished something half decent

TylerBH2014

Active Member

It's looking good. Thank you.Hello, the mold is made of plaster.

I first made the visor that came with the 3d printed helmet model in PLA.View attachment 321712

Then I made a negative cast in plaster and filled it in plaster to get the negative out, I don't have pictures of the process but I had to repeat the positive cast up to 3 times, after a lot of sanding, fill in 10x I finished something half decentView attachment 321713, at this point I must say that even though the mold is resistant, very heavy which comes in handy when empty, I think it is better to make a 3d printed mold and that's it, once you master the technique with one or two attempts you get a good viewer and it doesn't make much sense to have a plaster cast for a single visor, unless you want to make more visors to market

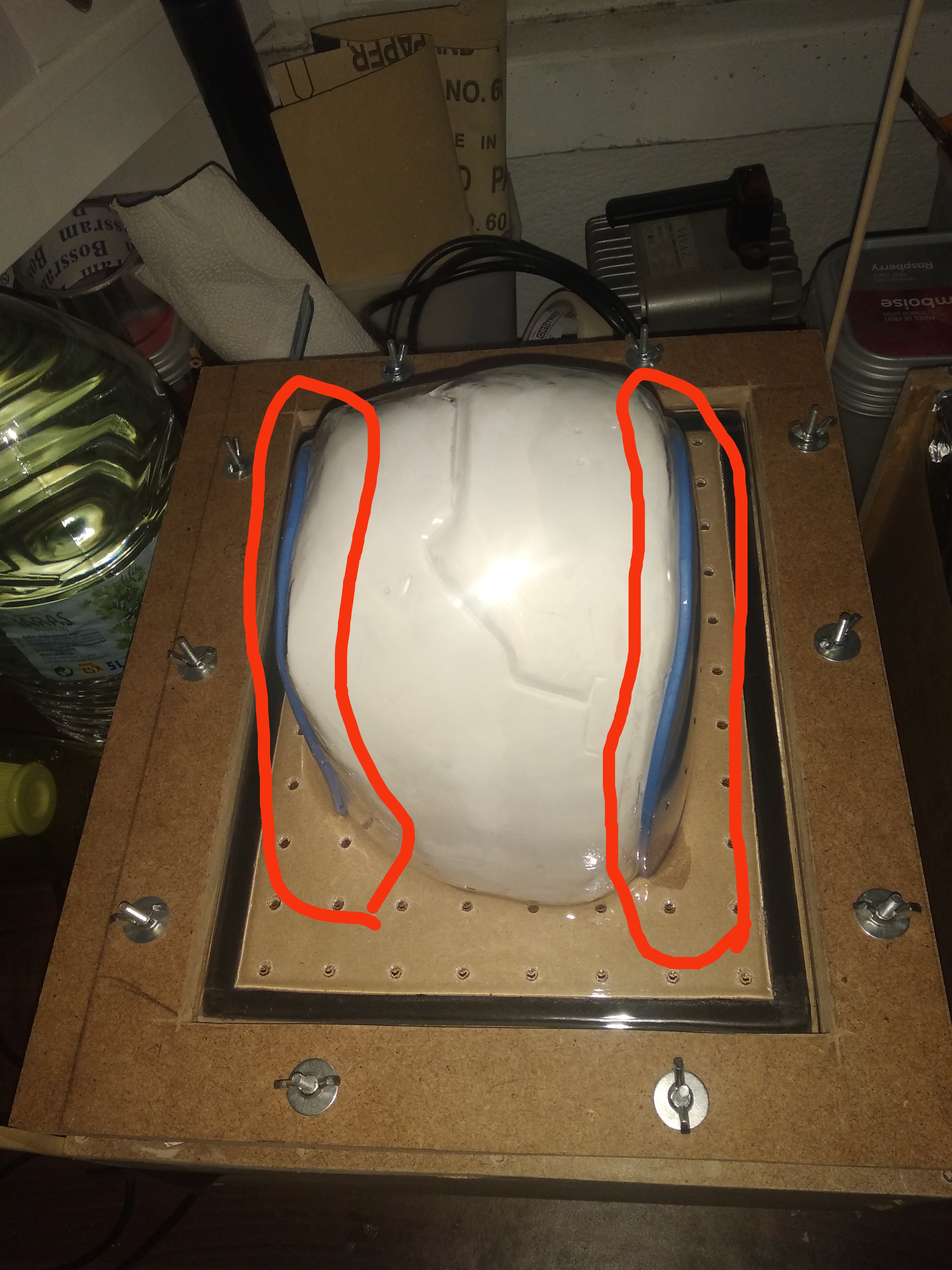

After several attempts at thermoforming, it was very difficult for me to unmold the visor and I thought that a little foam on the sides would help me take it out more easily,

and it didn't, it didn't help me unmold it more easily, but I discovered that the plastic that was fallen on top of the Foam was more transparent and could be seen better through it, than the one that was in direct contact with the plaster, that's why I lined the mold with Foam from above as well and it gave me quite a good result,

and it didn't, it didn't help me unmold it more easily, but I discovered that the plastic that was fallen on top of the Foam was more transparent and could be seen better through it, than the one that was in direct contact with the plaster, that's why I lined the mold with Foam from above as well and it gave me quite a good result,

I hope I have explained myself well (translated by Google)

I hope I have explained myself well (translated by Google)

Hello, to be finished with the thermoforming of the visor.

This is the type of plastic I use.

The temperature at which I heated the plastic was 155°C and a heating time of approximately 2 minutes, the glass has to make a kind of bubble of about 4 or 5 cm and it is only necessary to turn on the vacuum cleaner and put the frame with the hot plastic on top, I have to say that it is necessary to wear a mask (because of the vapors and the bad smell) and gloves so as not to burn (in the video I forgot to put them on because of the recording).

Say that I also used a wooden stick to make the little bumps on the viewfinder that were not marked on the video if they were not clearly visible.

Also to say that this was my ninth attempt to get a decent viewer, thank you very much for following, I leave the video here.

This is the type of plastic I use.

The temperature at which I heated the plastic was 155°C and a heating time of approximately 2 minutes, the glass has to make a kind of bubble of about 4 or 5 cm and it is only necessary to turn on the vacuum cleaner and put the frame with the hot plastic on top, I have to say that it is necessary to wear a mask (because of the vapors and the bad smell) and gloves so as not to burn (in the video I forgot to put them on because of the recording).

Say that I also used a wooden stick to make the little bumps on the viewfinder that were not marked on the video if they were not clearly visible.

Also to say that this was my ninth attempt to get a decent viewer, thank you very much for following, I leave the video here.

- Member DIN

- S713

I love your build for the fact you're making Halo 4 Chief alone and that you're taking time to do all the details on it

Thank you very much, and let me tell you that your Commander Palmer thread has been a benchmark of detail and scale, very good job, looking forward to seeing your new suit, and I also hoped that the commander would come out in the halo series, too bad, good luck with your suit (translated by Google)I love your build for the fact you're making Halo 4 Chief alone and that you're taking time to do all the details on it

- Member DIN

- S713

Thank you so much! I'm very honored to hear that. I hope to deliver even better with this one.Thank you very much, and let me tell you that your Commander Palmer thread has been a benchmark of detail and scale, very good job, looking forward to seeing your new suit, and I also hoped that the commander would come out in the halo series, too bad, good luck with your suit (translated by Google)

MadHeartParagon

Member

What you would you estimate the price of making a thermoforming machine at?

- Member DIN

- S151

Also curious on the cost at making one of these.What you would you estimate the price of making a thermoforming machine at?

Hello, as for the price is not much:What you would you estimate the price of making a thermoforming machine at?

-vacuum cleaner €60

-horizontal toaster €19

-perforated board €9

The rest would be some screws, silicone, wood and some PVC pipe, I can't calculate the cost of the wood because I made it with some thin boards that were left over from a reform, I don't think it was more than €40 for all these things like that that between €100-150 of total cost I would say. (translated by Google)

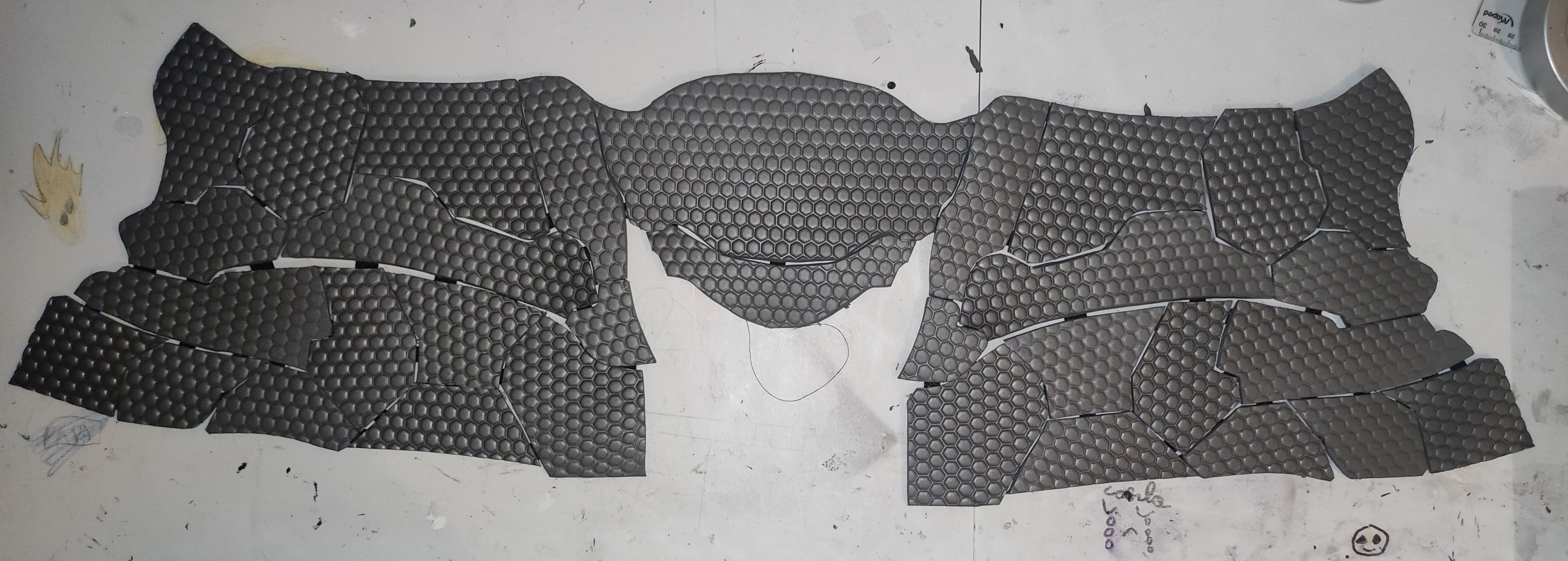

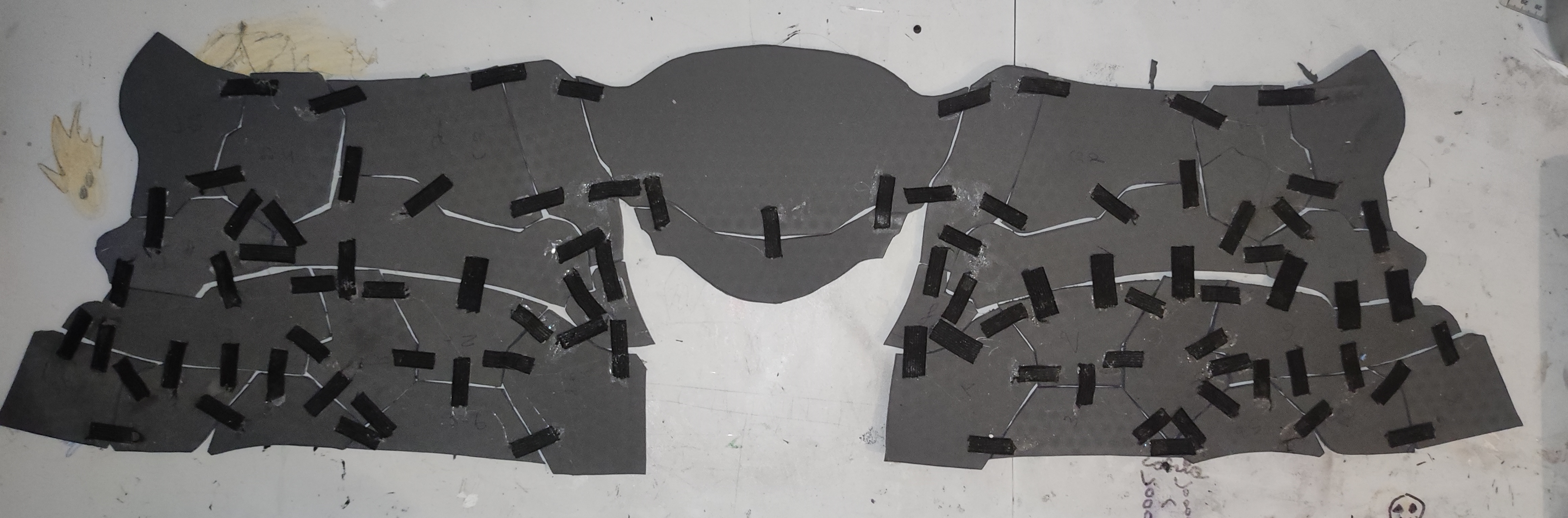

Hello, while I am still solving the mobility of the leg area, I have made the gloves again, because the first ones were tight, the pieces of the armor of the hands are made in 3d and the details of the glove's inner suit are made in 2mm black foam and painted with silver airbrush paint, with a template I made printed in 3d,

just like the dolls painted in silver with airbrush with a hexagonal template printed in 3d, thanks

just like the dolls painted in silver with airbrush with a hexagonal template printed in 3d, thanks

Hi, I'm still working on the suit, especially improving mobility and the inner suit, but I have a Cosplay event in November and I don't have time to post things here, as soon as it's over I'll be back, I'll show the progress, I'll leave some photos of the suit's torso inside, thank you

- Member DIN

- S121

Wow the undersuit detail is awesome!!! That extra mile you went will make a huge difference with the overall "feel" of the whole set.

Hello, I have finished the event I had, so soon I will collect the information on the improvements made to the suit and those that have worked and those that have not, I leave you a link to a fun video so you can see the mobility, thanks

Masterchief mobility twerking test

Masterchief mobility twerking test

- Status

- Not open for further replies.

Similar threads

- Replies

- 15

- Views

- 1,974