Drewhinkle09

New Member

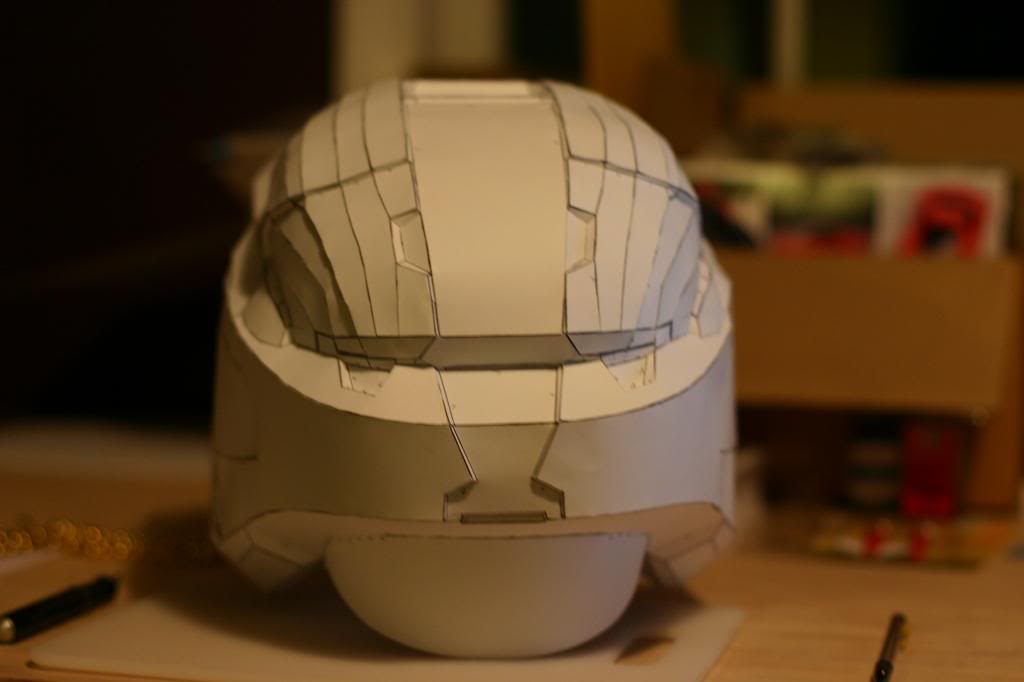

Current Status Shot:

Hey guys,

Well, I finally got started on my first build. I'm working on an HD mk VI helmet, using flyingsquirl's file scaled to 290mm.

I don't have much to show yet but by the end of the week I should be able to at least get this beast resined and ready for strengthening. This is my first build, and I'm new to the forum, so I'd really appreciate any input and pointers I can take!

Anyway, here are a few pics of where I'm at so far. The helmet is pepped, with the exception of some of the support struts. Theres a couple trouble areas but I'll try to sort those out before I put some resin on it.

Like I said, there's a few spots that need some love, but overall it's pretty straight and crisp, so it shouldn't be anything I can't work out in the next stages.

Thanks a bunch and lemme know what you think! I'm hoping to have updates at least a few times a week, so stick around!

-Drew

Hey guys,

Well, I finally got started on my first build. I'm working on an HD mk VI helmet, using flyingsquirl's file scaled to 290mm.

I don't have much to show yet but by the end of the week I should be able to at least get this beast resined and ready for strengthening. This is my first build, and I'm new to the forum, so I'd really appreciate any input and pointers I can take!

Anyway, here are a few pics of where I'm at so far. The helmet is pepped, with the exception of some of the support struts. Theres a couple trouble areas but I'll try to sort those out before I put some resin on it.

Like I said, there's a few spots that need some love, but overall it's pretty straight and crisp, so it shouldn't be anything I can't work out in the next stages.

Thanks a bunch and lemme know what you think! I'm hoping to have updates at least a few times a week, so stick around!

-Drew