You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hex pattern proving grounds :)

- Thread starter EVAkura

- Start date

- Status

- Not open for further replies.

Well, I am too!!!! I am currently making YET ANOTHER master because the last one, even though it was SOOOO close to perfect, the edges would not seamlessly align like I need them to. This one, I have focused on that requirement. So, Ver. 3.5 hopefully will be the one!

EDIT: Well, near tragedy avoided! I was focused too much on the alignment of everything, that I totally spaced on the pattern! I accidentally added one too many sides, which meant that there was no possible way for it to seamlessly connect to another one. Luckily, my wife told me to "just cut out one row". This made me stop and think for a second. My first option was to wait until next month when my new scroll saw arrives, but then it dawned on me that I could just use a band saw! Well, it is all corrected meow, and all the criteria has been met. Everything lines up, has the correct padding, and proper shape and depth. This, Version 3.5 is the final product. Now to cast multiple copies of it so I can interconnect them together and make one large master mold.

Also, I wanted to get a better idea of what the finished product would look like, so I cast a piece off of Ver. 3.4. I will tell you now, Smooth-On's mold release is amazing. A good, healthy dose of that on my Rondo mold, then a pour of Rondo into it, wait for it to become rubbery, then de-mold the cast. I works perfectly!

So, in this picture, I have the cast of Ver. 3.4 on the left, the new Ver. 3.5 in the middle (I used a penny for reference), and a bonus shot of the "dials" I have created for the H4 MC armor I am making. These dials will be on the butt plate, the forearms, and the thigh armor. I will need 6 total. The dial on the back of the torso armor is slightly larger, so I will need to recreate that one separately.

EDIT: Well, near tragedy avoided! I was focused too much on the alignment of everything, that I totally spaced on the pattern! I accidentally added one too many sides, which meant that there was no possible way for it to seamlessly connect to another one. Luckily, my wife told me to "just cut out one row". This made me stop and think for a second. My first option was to wait until next month when my new scroll saw arrives, but then it dawned on me that I could just use a band saw! Well, it is all corrected meow, and all the criteria has been met. Everything lines up, has the correct padding, and proper shape and depth. This, Version 3.5 is the final product. Now to cast multiple copies of it so I can interconnect them together and make one large master mold.

Also, I wanted to get a better idea of what the finished product would look like, so I cast a piece off of Ver. 3.4. I will tell you now, Smooth-On's mold release is amazing. A good, healthy dose of that on my Rondo mold, then a pour of Rondo into it, wait for it to become rubbery, then de-mold the cast. I works perfectly!

So, in this picture, I have the cast of Ver. 3.4 on the left, the new Ver. 3.5 in the middle (I used a penny for reference), and a bonus shot of the "dials" I have created for the H4 MC armor I am making. These dials will be on the butt plate, the forearms, and the thigh armor. I will need 6 total. The dial on the back of the torso armor is slightly larger, so I will need to recreate that one separately.

Attachments

So, I noticed that the hex pattern on the MC gloves were much smaller than that of the main part of the suit. So, in addition to creating the hex pattern for the suit, I took on the challenge of the smaller one for the gloves

Either I have been doing this for so long that it comes naturally, or I just got really lucky, but I managed to create a high detail and accurate mold in just one day!!!

The photos below are of the mold, which is made of Rondo and painted matte black to show detail better.

EDIT: Just to be clear, none of my work is 3D printed, this is all hand made

Critique away!!!!

Either I have been doing this for so long that it comes naturally, or I just got really lucky, but I managed to create a high detail and accurate mold in just one day!!!

The photos below are of the mold, which is made of Rondo and painted matte black to show detail better.

EDIT: Just to be clear, none of my work is 3D printed, this is all hand made

Critique away!!!!

Attachments

Well, this is for those that have not been following my Facebook posts.

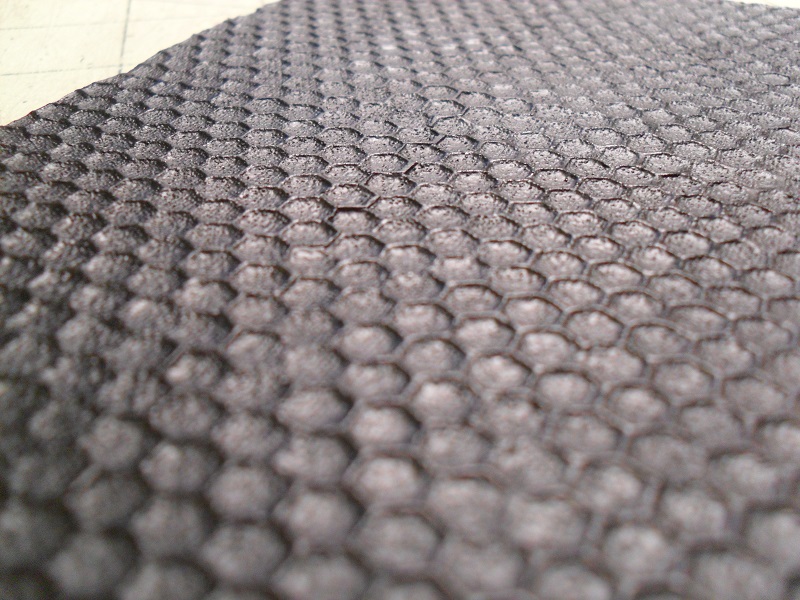

The small hex pattern shown above just did not make the cut for me. So, I created a hard cast of the same pattern, and filed each line of each hex to make it more defined, as well as flattened the tops by wet sanding it smooth. That made it so much more like my reference pictures. At that point, that piece became my buck. I created a hard cast of that, and that became my new mold. Then, I applied some liquid mask latex and Mixol black colorant, and let it cure for just shy of 24hrs.

I did the same thing with a test piece of the larger hex pattern.

A bit of Italian Olive and Silver paint, and this is what I ended up with!

And a couple of close-ups so you can better see the detail

The small hex pattern shown above just did not make the cut for me. So, I created a hard cast of the same pattern, and filed each line of each hex to make it more defined, as well as flattened the tops by wet sanding it smooth. That made it so much more like my reference pictures. At that point, that piece became my buck. I created a hard cast of that, and that became my new mold. Then, I applied some liquid mask latex and Mixol black colorant, and let it cure for just shy of 24hrs.

I did the same thing with a test piece of the larger hex pattern.

A bit of Italian Olive and Silver paint, and this is what I ended up with!

And a couple of close-ups so you can better see the detail

Attachments

Last edited by a moderator:

Looking good so far. But is it going to be breathable at all?

Had an idea while watching the latest clip, but I don't know how viable it is. Would there be a way to cast individual hexes and adhere them to lycra/spandex for both breathability and stretch/flexibility? My first thought would be to sew a few loose stitches along the fabric, measured out to be roughly in the center or along the inner edge of the hexes. Then pour just enough casting material to fill each individual hex nearly to the top (not enough to flow over the edges and need a tiny bit of space for displacement) and lay the fabric flush over the top of the mold. The displacement I just mentioned would come from the loose stitches being gently pressed into the hex molds so that the thread will be encased in the silicone (or whatever other material is used for the casting).

The method to the madness here is that this would essentially "sew" individually cast hexes to the material while leaving a border in between them all that is free to flex, stretch, and pull without tugging at the silicone itself. Also, the bare lycra/spandex borders will also lend more breathability to the suit compared to a solid silicone length. Obviously some breathability can be maintained in areas that will be covered by the hard armor (chest, back, etc) through using sheer/mesh material there, but if you want to go for a "full" undersuit that can be shown off with or without hard armor, mesh sections won't work so well.

Depending on the spacing between the hexes and how much that space expands when the fabric is stretched, something even lighted and more breathable than spandex/lycra could be used to increase breathability while the hexes themselves provide the modesty.

Just a thought that popped into my head, free for anyone to take it or leave it, so long as test results are also shared freely, because if this does work, it could revolutionize undersuit making in the community.

Had an idea while watching the latest clip, but I don't know how viable it is. Would there be a way to cast individual hexes and adhere them to lycra/spandex for both breathability and stretch/flexibility? My first thought would be to sew a few loose stitches along the fabric, measured out to be roughly in the center or along the inner edge of the hexes. Then pour just enough casting material to fill each individual hex nearly to the top (not enough to flow over the edges and need a tiny bit of space for displacement) and lay the fabric flush over the top of the mold. The displacement I just mentioned would come from the loose stitches being gently pressed into the hex molds so that the thread will be encased in the silicone (or whatever other material is used for the casting).

The method to the madness here is that this would essentially "sew" individually cast hexes to the material while leaving a border in between them all that is free to flex, stretch, and pull without tugging at the silicone itself. Also, the bare lycra/spandex borders will also lend more breathability to the suit compared to a solid silicone length. Obviously some breathability can be maintained in areas that will be covered by the hard armor (chest, back, etc) through using sheer/mesh material there, but if you want to go for a "full" undersuit that can be shown off with or without hard armor, mesh sections won't work so well.

Depending on the spacing between the hexes and how much that space expands when the fabric is stretched, something even lighted and more breathable than spandex/lycra could be used to increase breathability while the hexes themselves provide the modesty.

Just a thought that popped into my head, free for anyone to take it or leave it, so long as test results are also shared freely, because if this does work, it could revolutionize undersuit making in the community.

I like the idea Zaff, but for this application, I really need to bulk up my "customer". I am going with an Exo-suit very similar to mine (but with some wicked enhancements), and will essentially be "Skinning" this material to the individual pieces. Breathability in this case, should not be an issue since he will have quite a bit of room between his body and the Exo-suit (especially in the torso) in which I am planning on a ducted air flow system for cooling

killerownz11

Member

Its possible, the idea of casting that many (5000+) hexes makes me shiver though. I sculpted my undersuit in latex and its not really breathable, but it gives enough flexibility to move.

Now maybe what i did could be greatly improved ( better sculpt, more pieces, breathable wetsuit, breathable casting material) but for now, we're stuck. Its so difficult to build a simple undersuit. I think this is a great design, but again im woundering how practical sheets of hexes will be. ( no criticism, id do it if i could) but i feel its so many steps to make an undersuit out of foam and then add the hex's. I really just want to try to build the most practical undersuit down the road, im kinda curious how halo 5 multiplayer spartan undersuits will be and how we as a community will adapt to that challenge. I think we all should brain storm/ research and all put our ideas in. Maybe we could come up with a more comfortable, more realistic, and of course super accurate undersuit.

Sorry for the rant, everything on this sight gets my brain going. Everyones ideas are brilliant, and i wish they could all fuze together to get a more realistic halo style armor.

Anyway Evakura, your work is gorgeous, congrts on all this work, youre the closest to the real deal so far.

check out my halo 4 recon build http://www.405th.com/showthread.php/41283-Halo-4-armor-build-under-suit-(PIC-heavy)-WIP

Now maybe what i did could be greatly improved ( better sculpt, more pieces, breathable wetsuit, breathable casting material) but for now, we're stuck. Its so difficult to build a simple undersuit. I think this is a great design, but again im woundering how practical sheets of hexes will be. ( no criticism, id do it if i could) but i feel its so many steps to make an undersuit out of foam and then add the hex's. I really just want to try to build the most practical undersuit down the road, im kinda curious how halo 5 multiplayer spartan undersuits will be and how we as a community will adapt to that challenge. I think we all should brain storm/ research and all put our ideas in. Maybe we could come up with a more comfortable, more realistic, and of course super accurate undersuit.

Sorry for the rant, everything on this sight gets my brain going. Everyones ideas are brilliant, and i wish they could all fuze together to get a more realistic halo style armor.

Anyway Evakura, your work is gorgeous, congrts on all this work, youre the closest to the real deal so far.

check out my halo 4 recon build http://www.405th.com/showthread.php/41283-Halo-4-armor-build-under-suit-(PIC-heavy)-WIP

This is looking really good; kind of makes me want to toss out my plan to use neoprene and just order sheets of this stuff from you. Any chance that would be possible?

Also, just for curiosity's sake I would really like to see how this stuff holds up in some stress testing, specifically;

If this holds up like I think it will I really think you've pushed the 405th's undersuit tech to a new level, congrats!

Also, just for curiosity's sake I would really like to see how this stuff holds up in some stress testing, specifically;

- How do unfinished edges hold up to stretching or folding?

- Can this fabric be run through a sewing machine without horrible frustration?

- How does the fabric hold up after being sewn (ie. puckers or pulling away from the thread)?

If this holds up like I think it will I really think you've pushed the 405th's undersuit tech to a new level, congrats!

EVAkura said:I like the idea Zaff, but for this application, I really need to bulk up my "customer". I am going with an Exo-suit very similar to mine (but with some wicked enhancements), and will essentially be "Skinning" this material to the individual pieces. Breathability in this case, should not be an issue since he will have quite a bit of room between his body and the Exo-suit (especially in the torso) in which I am planning on a ducted air flow system for cooling

That's a bit of a lucky break then. Most undersuit builders try to cut down the silhouette, but wanting to add bulk makes it easier to work in things like cooling systems and the necessary tubing channels to go with it. I've toyed with the idea of a water pump cooling system before and always ran into the problem of how to conceal it, as well as how to get the tubing to reach as much of the body as possibly without having too much effect on mobility or binding in the joints.

And yea, Killerownz, that would indeed be a very tedious and unenviable task, as not only do the individual hexes all need to be cast, but the "anchors" also need to be sewn in all over the suit. Which begs the question of whether the bodysuit should be put together first and then cast, or if the fabric should be "hexed" and then sewn into a suit. Either method has complications, as casting on a completed suit could be complex, and sewing together a suit and getting all the hexes to align could be equally difficult.

This is looking really good; kind of makes me want to toss out my plan to use neoprene and just order sheets of this stuff from you. Any chance that would be possible?

Also, just for curiosity's sake I would really like to see how this stuff holds up in some stress testing, specifically;

- How do unfinished edges hold up to stretching or folding?

- Can this fabric be run through a sewing machine without horrible frustration?

- How does the fabric hold up after being sewn (ie. puckers or pulling away from the thread)?

If this holds up like I think it will I really think you've pushed the 405th's undersuit tech to a new level, congrats!

You have a PM

First sheet pulled! I really think this is going to work for me

Attachments

Are you going to be selling this stuff? I might be interested in buying a sheet or two... or three.

As of now, and until I complete this suit, I have to say no. I have to focus on getting this thing done in time, and to my standard of quality, so I don't have any time for anything else at the moment. After I complete this build, I will revisit the possibility of doing so. If and when that does become a thing (high possibility), I will be sure to make it very well known and available.

As of now, and until I complete this suit, I have to say no. I have to focus on getting this thing done in time, and to my standard of quality, so I don't have any time for anything else at the moment. After I complete this build, I will revisit the possibility of doing so. If and when that does become a thing (high possibility), I will be sure to make it very well known and available.

And, I would imagine, you want to put it through the paces to see just how much abuse it can take so you'll be able to give any potential buyers the full rundown of what it can and can't do. You do good work, and you want to make sure that anything you do for others reflects that.

Very true Zaff  I am getting a bit overwhelmed with requests for this material (not a bad thing). I feel a bit bad that I can not fulfill requests for it, but I honestly just don't have the time, nor have I really messed with it that much. I don't think it would do much good to anyone that wanted to use it any other way than what I designed it for... to be skinned over EVA for an Exo-suit. It is too flimsy by itself, and will not provide definition unless it is attached to something like EVA that has a bit of rigidity to it.

I am getting a bit overwhelmed with requests for this material (not a bad thing). I feel a bit bad that I can not fulfill requests for it, but I honestly just don't have the time, nor have I really messed with it that much. I don't think it would do much good to anyone that wanted to use it any other way than what I designed it for... to be skinned over EVA for an Exo-suit. It is too flimsy by itself, and will not provide definition unless it is attached to something like EVA that has a bit of rigidity to it.

With that said, here is progress with the material. I will update further when I get the gloves my client is sending me as they get skinned with the smaller hex pattern.

A photo of the first piece skinned. These are part of the chest.

With that said, here is progress with the material. I will update further when I get the gloves my client is sending me as they get skinned with the smaller hex pattern.

A photo of the first piece skinned. These are part of the chest.

Attachments

For those who have not been catching the work I have been doing with this material on Facebook, here is a few photos of a build I am doing where I am skinning EVA to create a custom fit Exo-suit for a 6'11' buddy.

The hard parts are made of sculpted Rondo, and the rest is mask latex skinned EVA.

Breastplate bits:

Back progress:

... and the underside, showing the woven elastic that holds all the parts together, yet allows for stretch, and also the nuts and washers that retain the sculpted spine parts with their inset bolts

Next test I am performing tonight is: Infusing Lycra into the hex pattern's mask latex

The hard parts are made of sculpted Rondo, and the rest is mask latex skinned EVA.

Breastplate bits:

Back progress:

... and the underside, showing the woven elastic that holds all the parts together, yet allows for stretch, and also the nuts and washers that retain the sculpted spine parts with their inset bolts

Next test I am performing tonight is: Infusing Lycra into the hex pattern's mask latex

Attachments

This looks WAY cool! Make sure you pad over the bolt heads on the inside. I used the same bolt approach for attaching flex tubes to my Borg bodysuit and armor, and can tell you it's not at all comfortable if they're not padded over.

I might have to give something like this a try. I have a strong aversion to sewing but I think I could do something like this. If you ever sell casts or sheets of the hex pattern in the future I might have to buy some to use for this. Plus you could wear it with any suit you make, no need to make multiples.

Edit: A technique like this with a tighter pattern could make a really cool Crysis 3 style Nanosuit.

- Gray

Edit: A technique like this with a tighter pattern could make a really cool Crysis 3 style Nanosuit.

- Gray

This looks WAY cool! Make sure you pad over the bolt heads on the inside. I used the same bolt approach for attaching flex tubes to my Borg bodysuit and armor, and can tell you it's not at all comfortable if they're not padded over.

No stone unturned

This just gets better and better. That's a pretty novel approach to the hex pattern and the suit you are making for your client is coming along in spectacular fashion. It's a pleasure watching your work unfold.

Thanks so much! I am really pleased as well, as this is all unchartered territory for me as well... kind of a learn-as-I-go sort of thing

I might have to give something like this a try. I have a strong aversion to sewing but I think I could do something like this. If you ever sell casts or sheets of the hex pattern in the future I might have to buy some to use for this. Plus you could wear it with any suit you make, no need to make multiples.

Edit: A technique like this with a tighter pattern could make a really cool Crysis 3 style Nanosuit.

- Gray

Good news with this so far is, there has been, and should not be, any sewing needed with this suit (I hate sewing as well!) For skinning, I am using contact cement and it appears to be holding awesome, even in high temperatures. Everything else past that point is just high temp hot glue and nuts 'n bolts

As far as selling sheets... no solid plans yet. I do know that HALOSPRTAN will be doing so (almost identical to mine) in the near future, but will have to keep an eye out for that possibility if/when he does so.

Last edited by a moderator:

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 1,549

- Replies

- 4

- Views

- 1,233

- Replies

- 4

- Views

- 4,486

Similar threads

- Replies

- 4

- Views

- 1,233

- Replies

- 4

- Views

- 4,486