Timuche

Active Member

Hello everyone !

I come to present you the making of my new replica : the M6H2 MAGNUM from HALO 5.

Compared to my other replicas I wanted to make it modular in order to have the possibility to create all the existing versions of this weapon : the basic, the Gunfighter, the Whispered Truth and the Tactical.

I used a 3D printer to provide me with a structural basis with global dimensions, but I remade the vast majority of the Magnum.

Here are some pictures of the making.

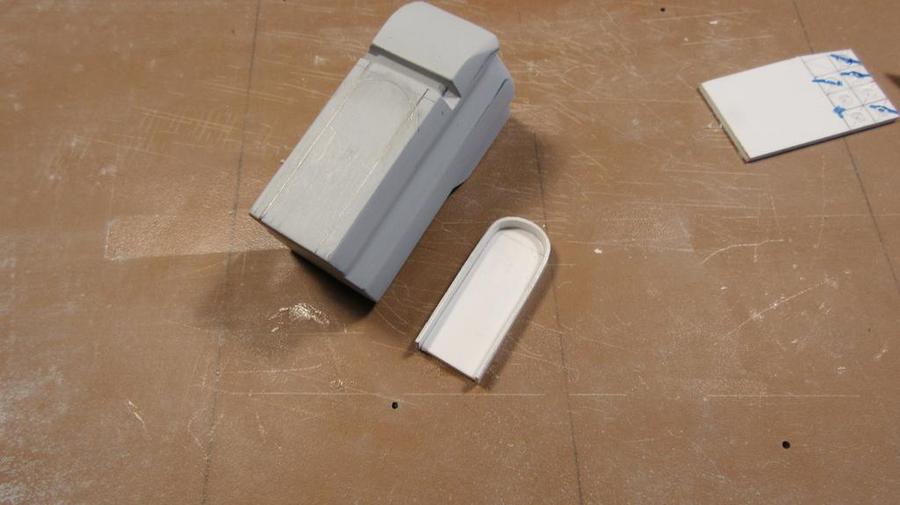

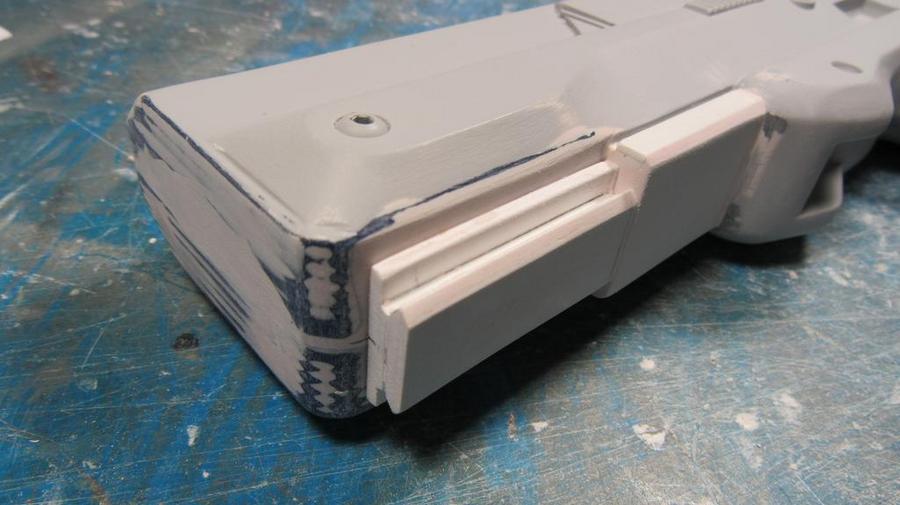

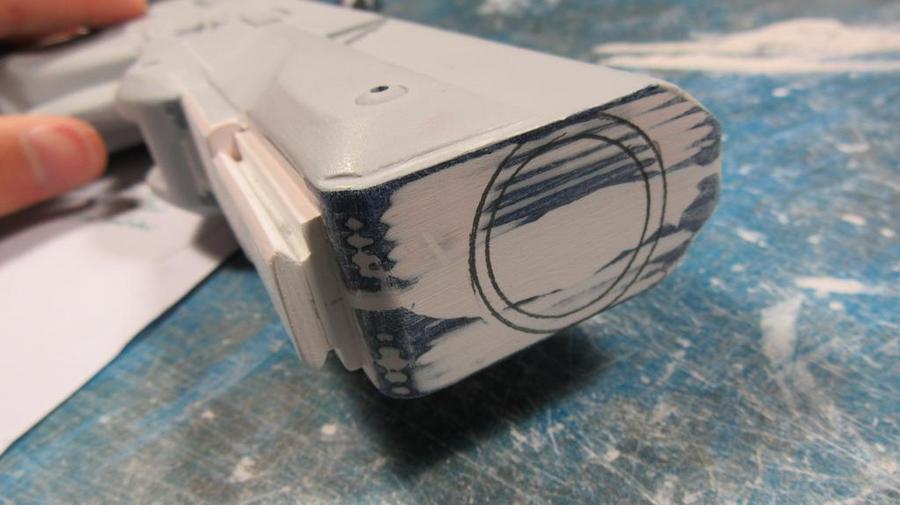

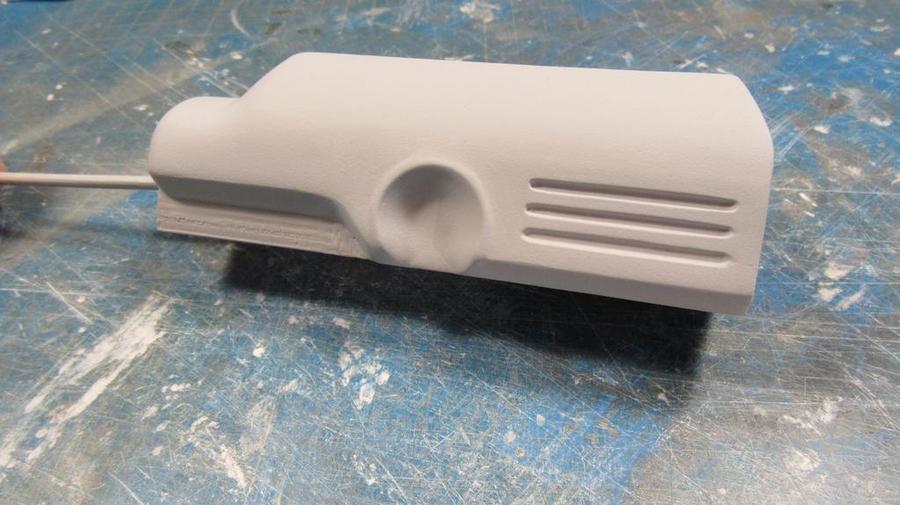

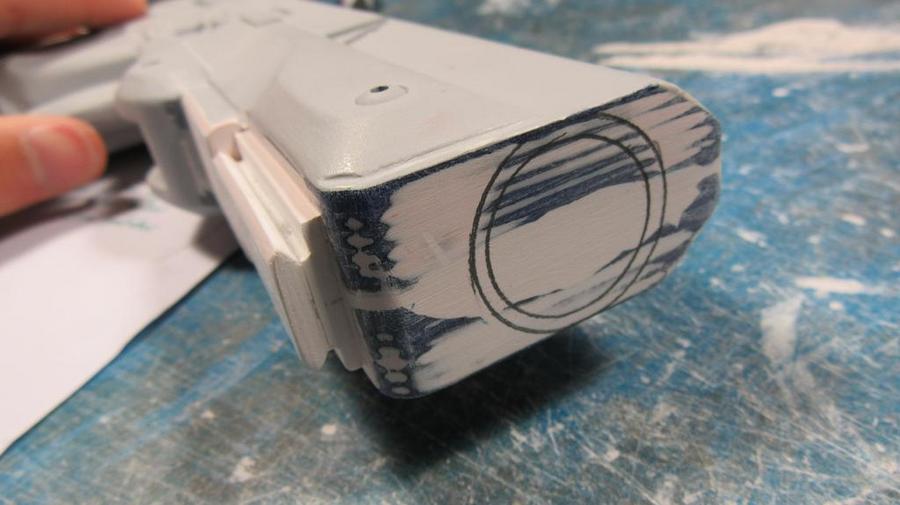

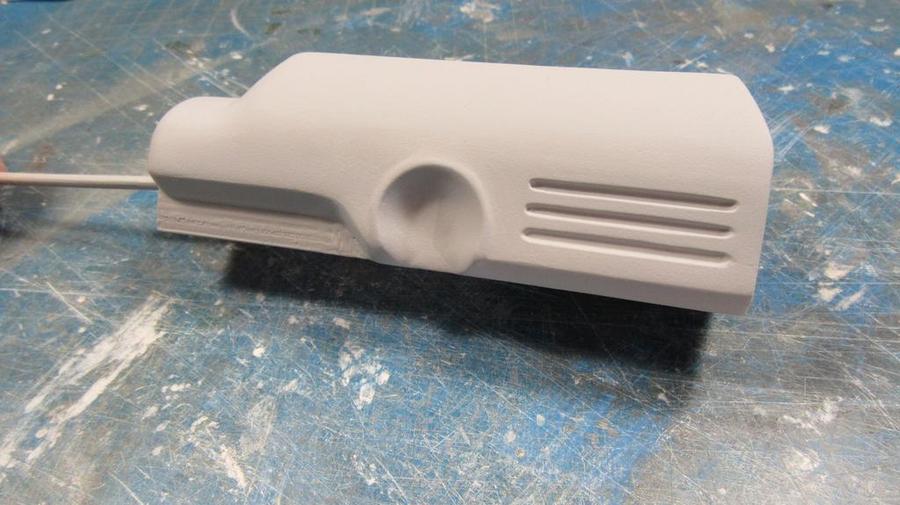

I started with a 3D print to give me a structure with which to work.

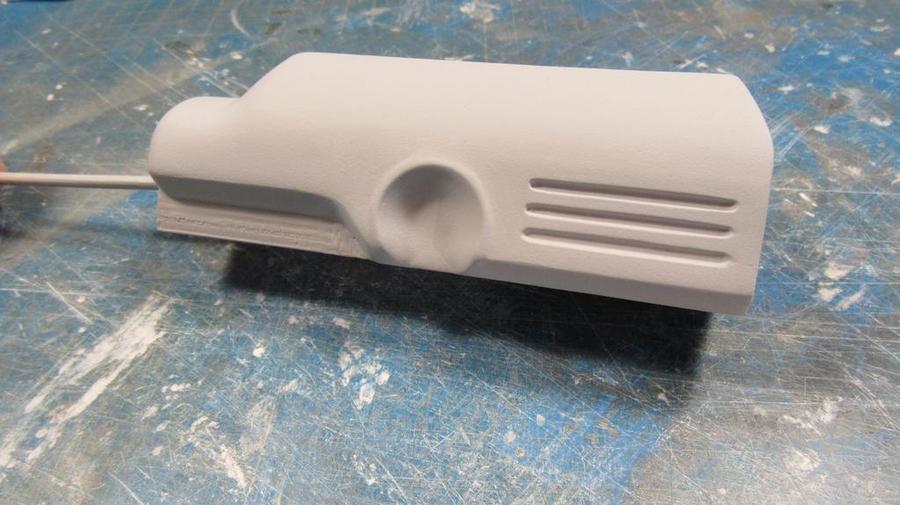

I use a bit of XTC-3D to smooth the surface.

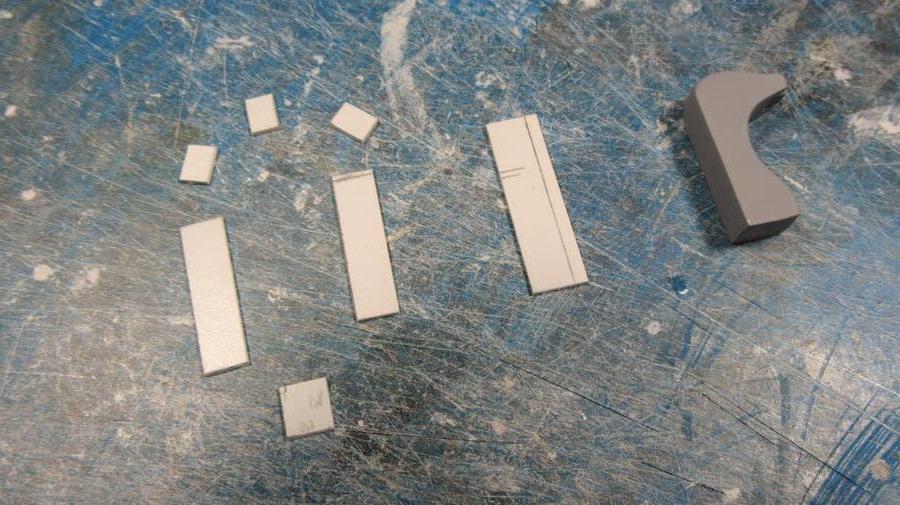

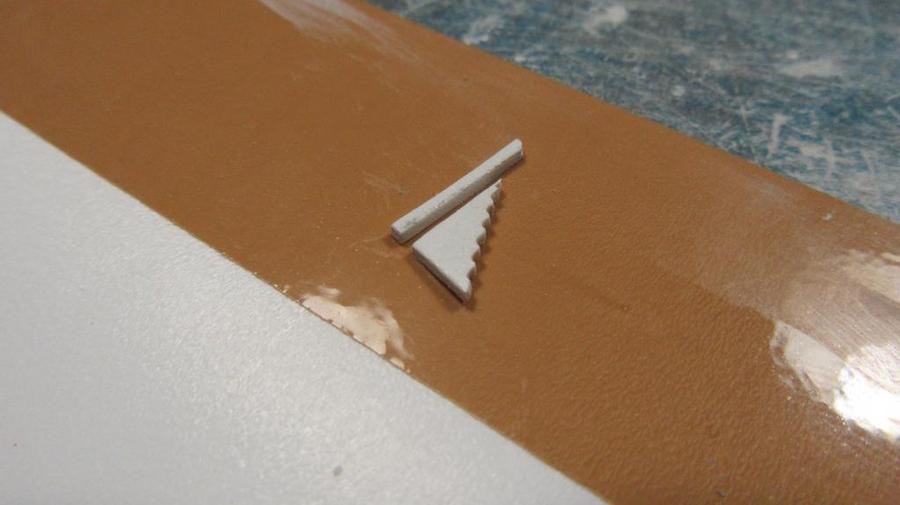

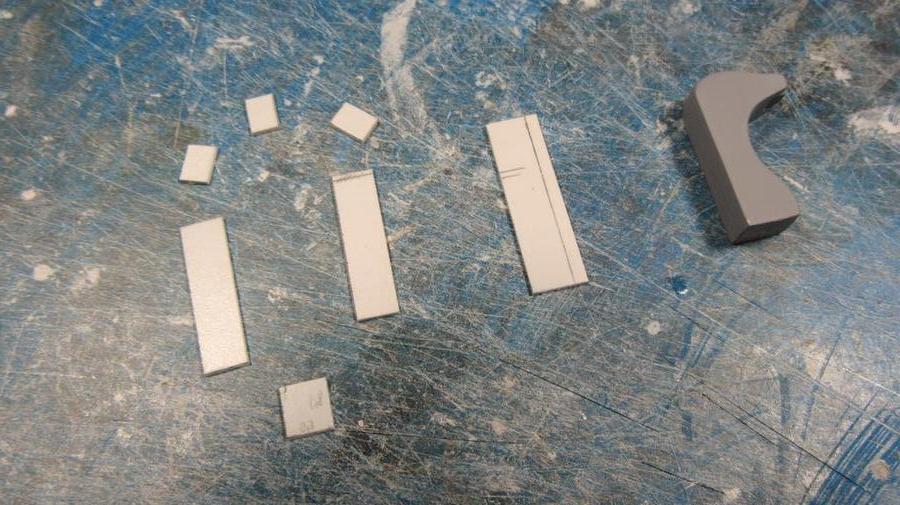

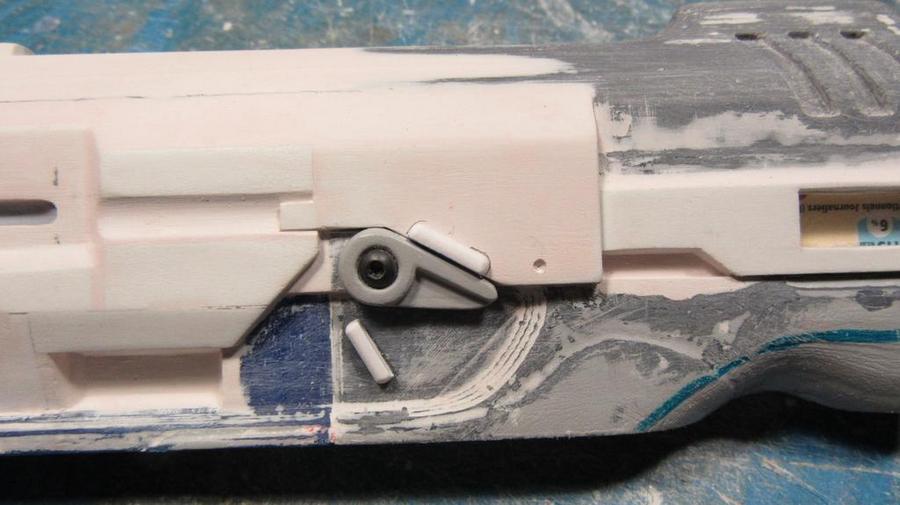

I make the hammer of the magnum with plastic card.

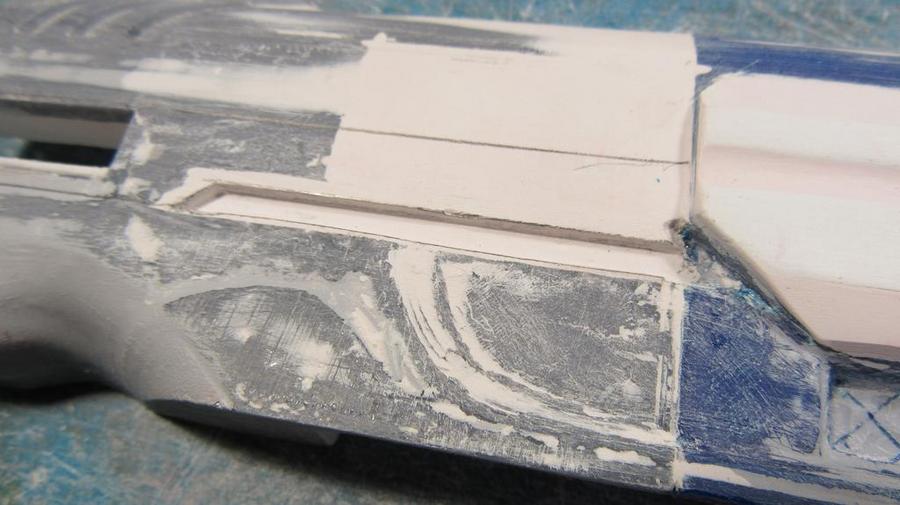

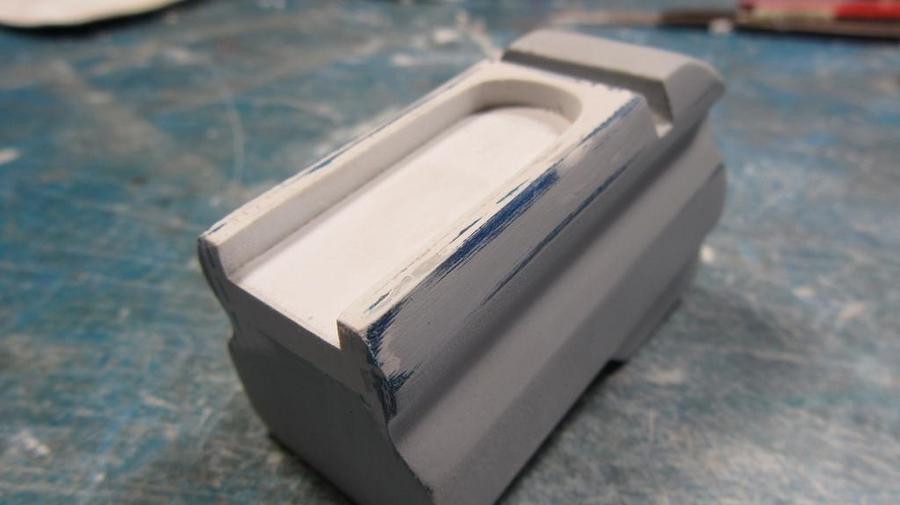

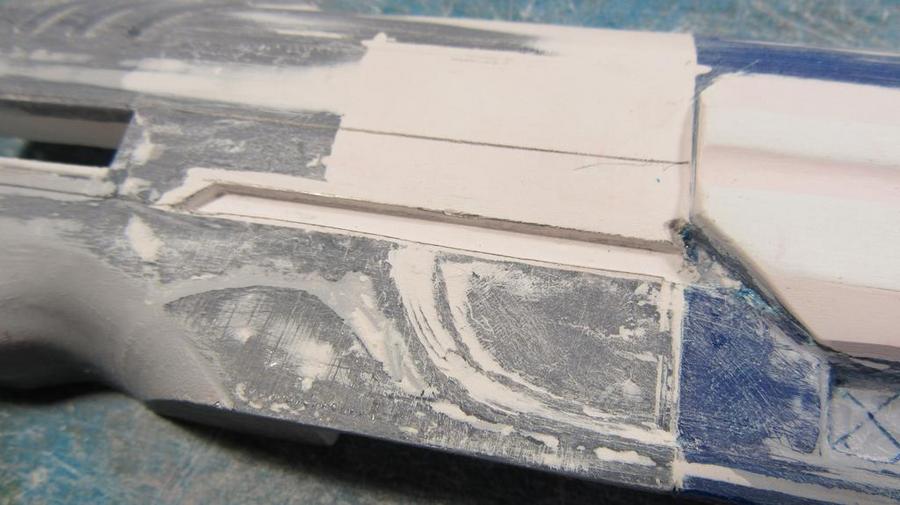

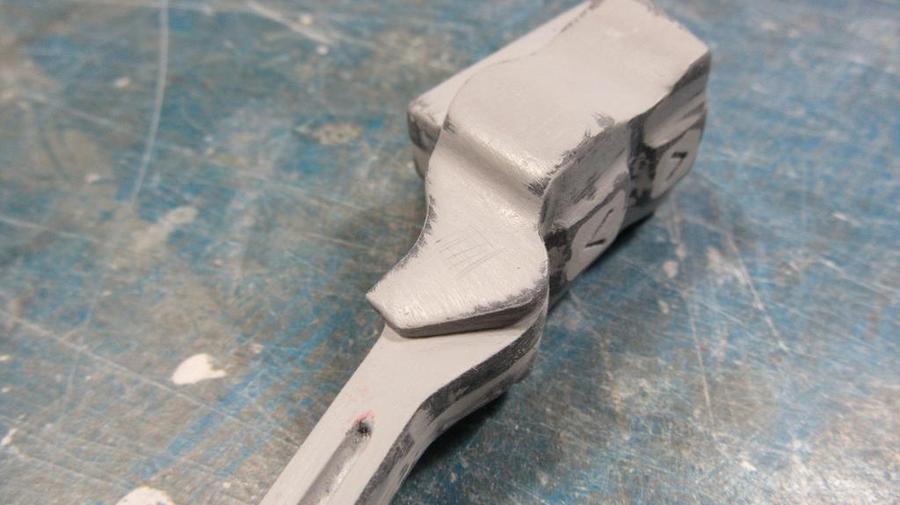

Then I redo all the structure and the details with putty and plastic card.

It is not finished yet but almost.

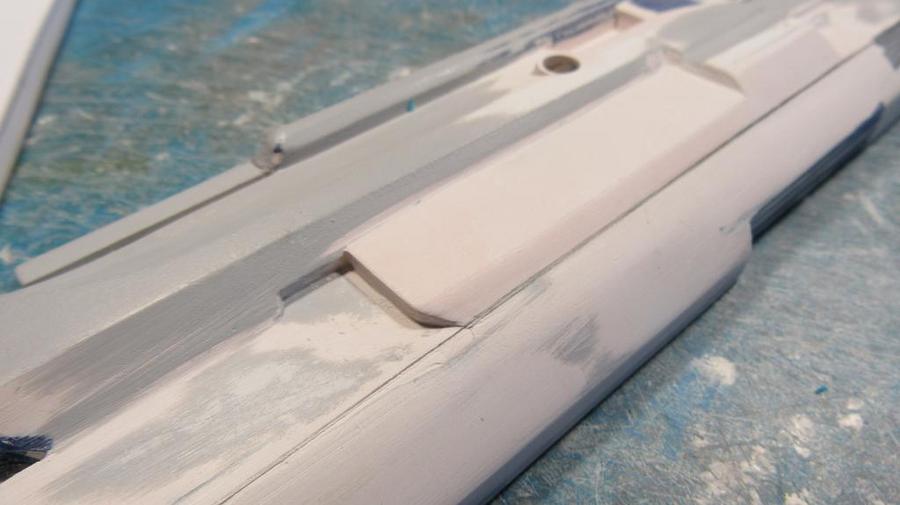

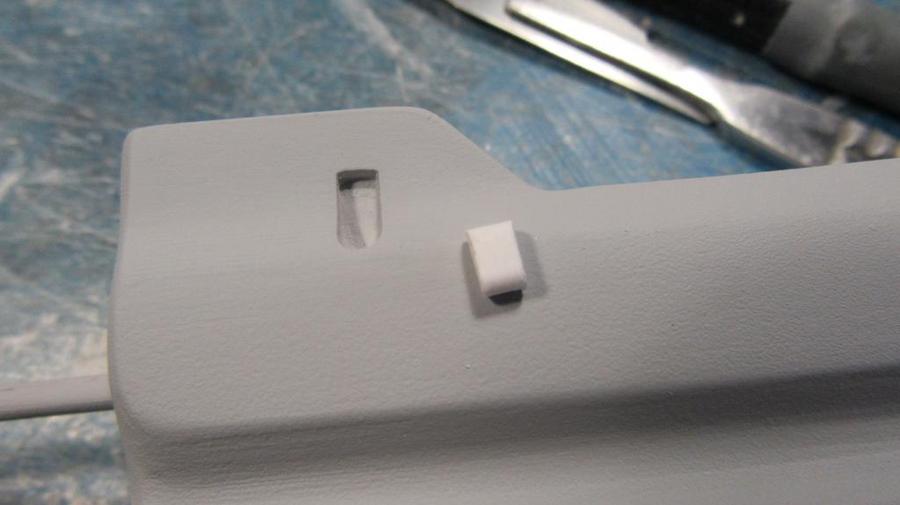

A little detail.

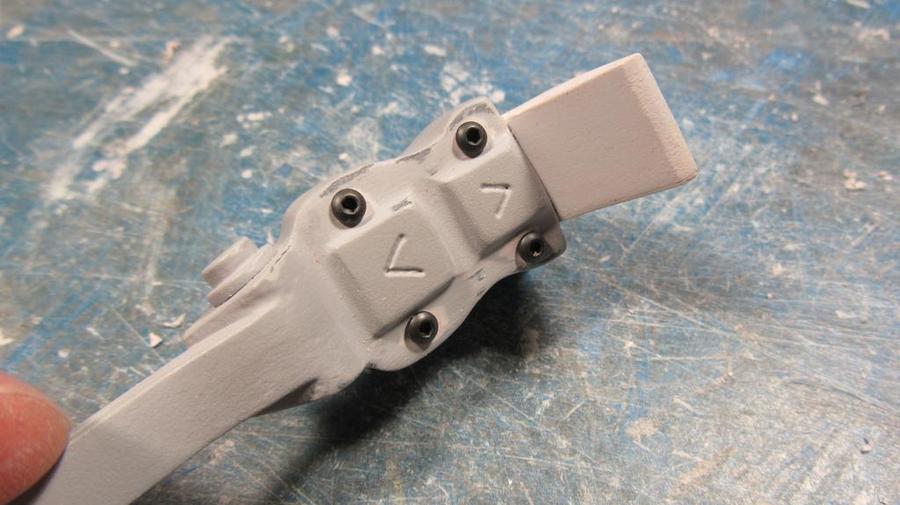

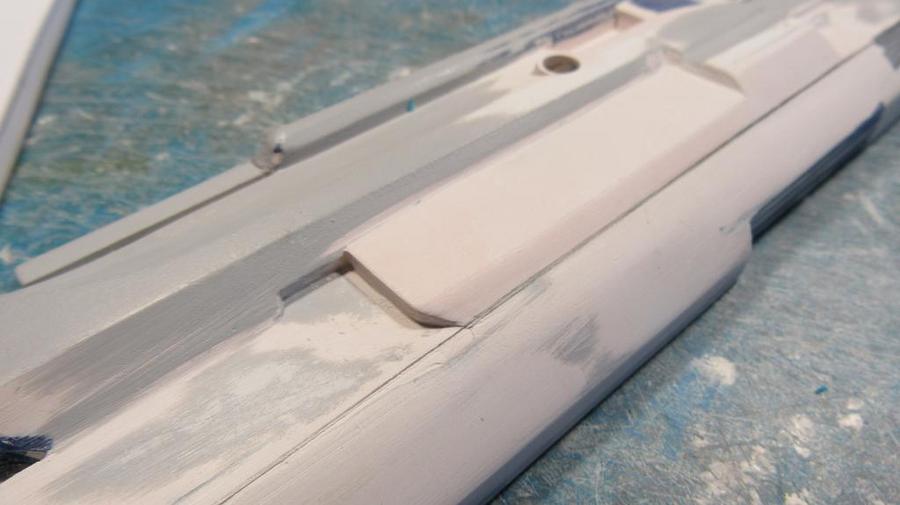

I do the same on the other side that does not have the same forms.

With putty I add a detail on the handle of the magnum.

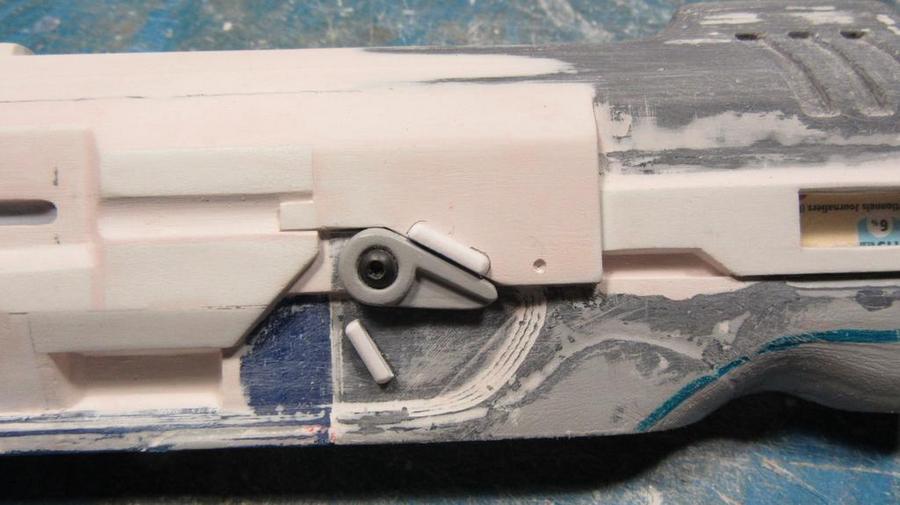

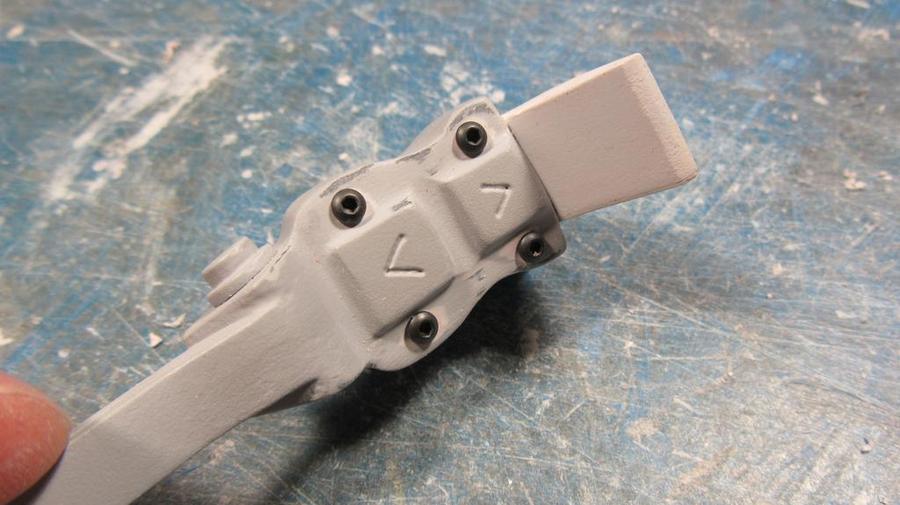

Then I modify and add some things about the guard of the magnum.

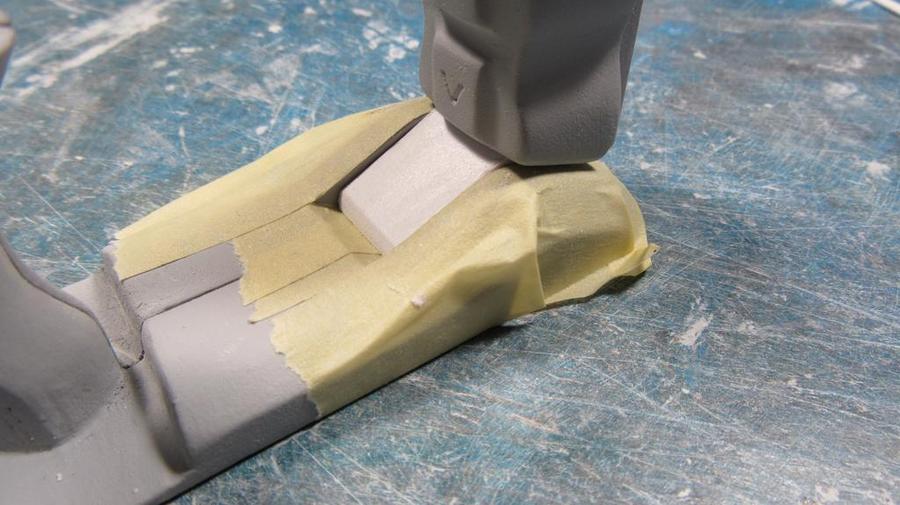

With putty I make sure everything fits perfectly.

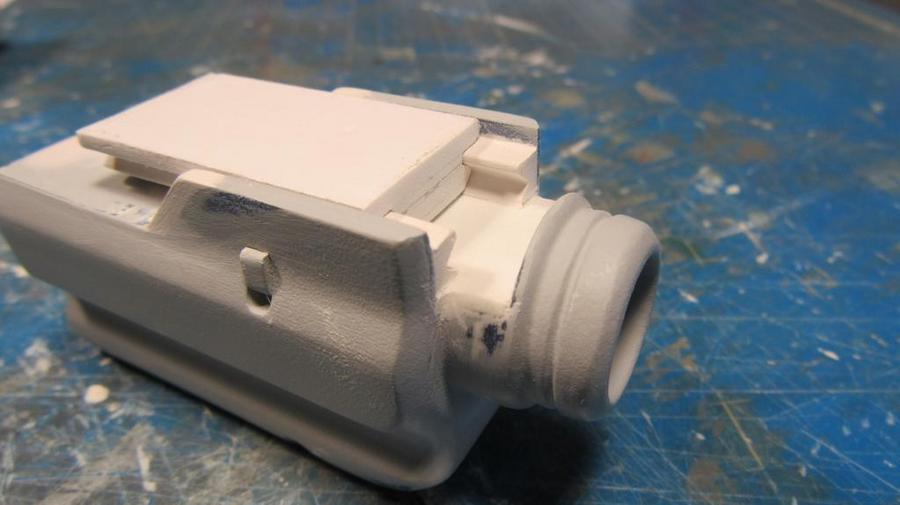

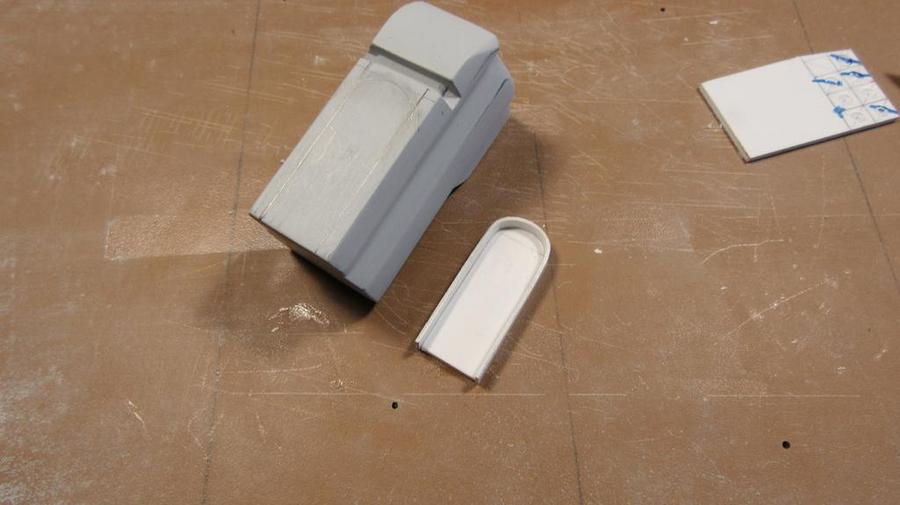

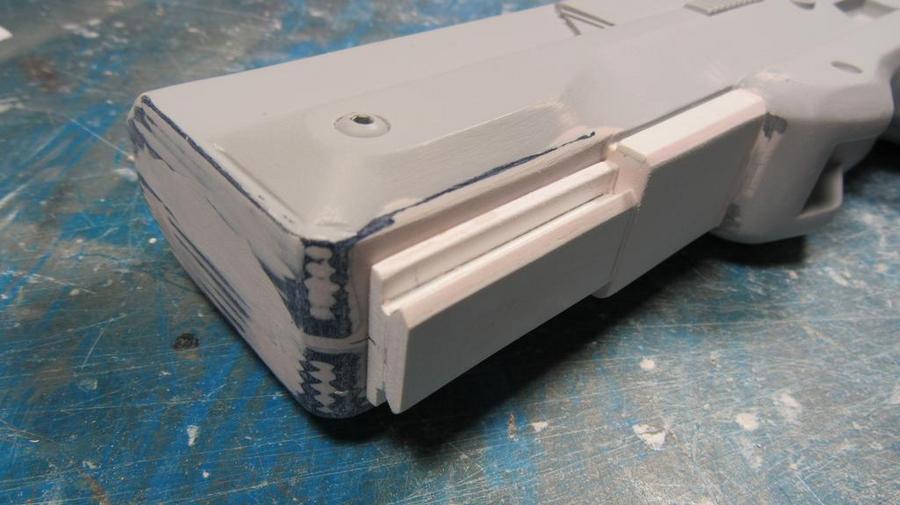

For the module that fits underneath I also add details.

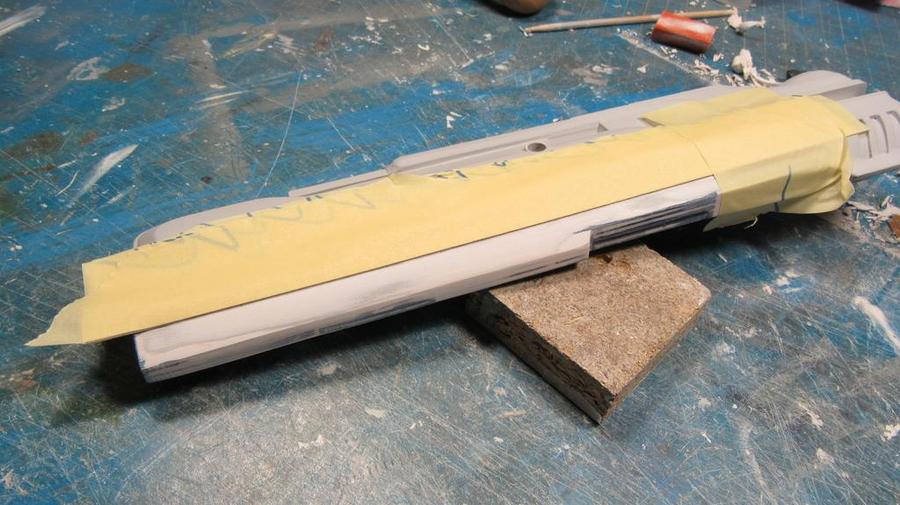

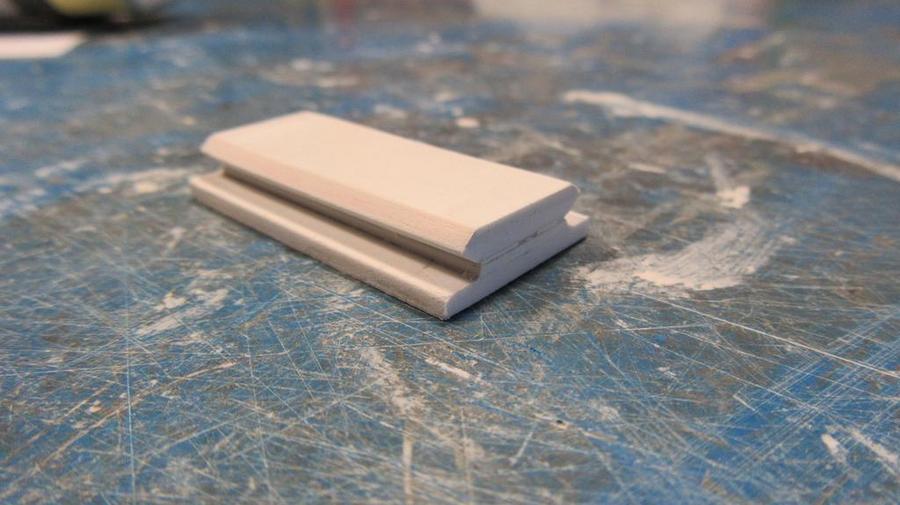

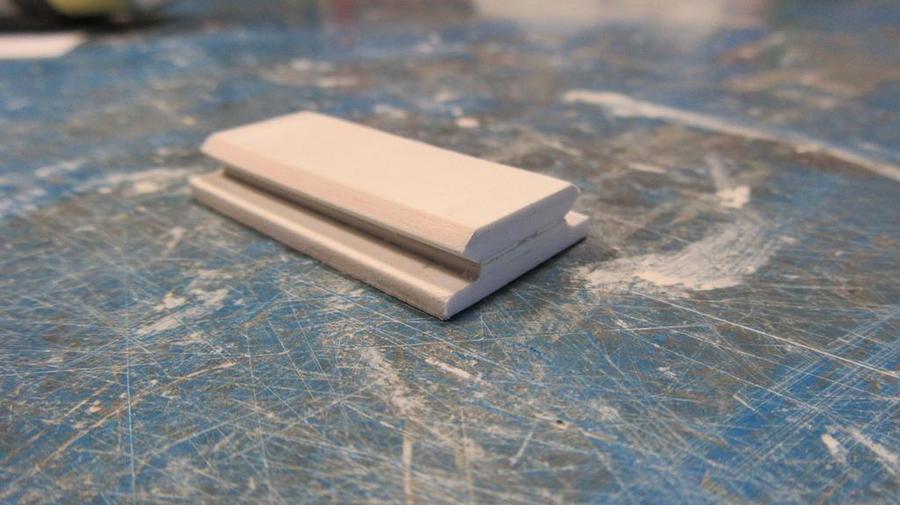

Then the fixing rail must be made.

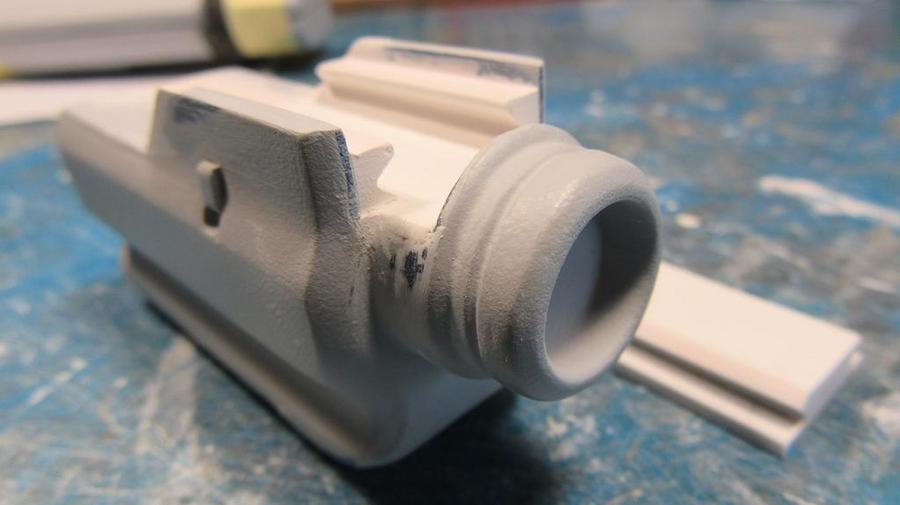

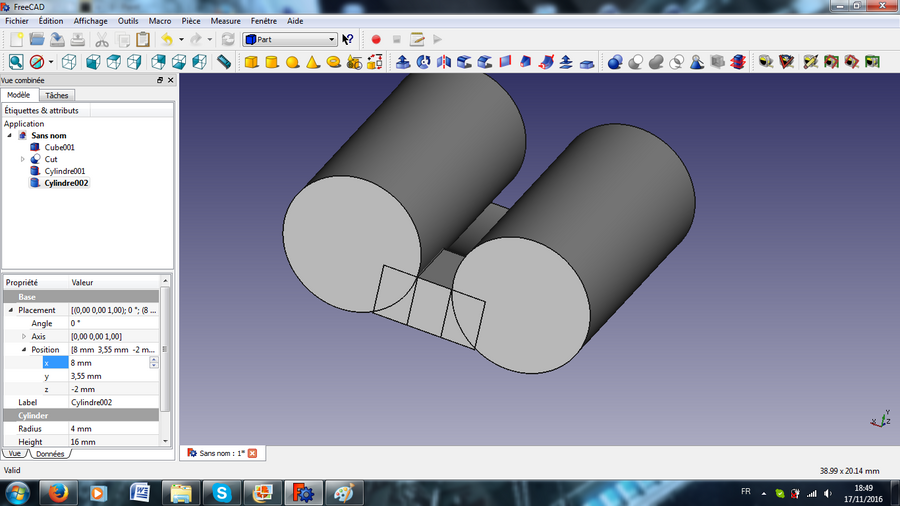

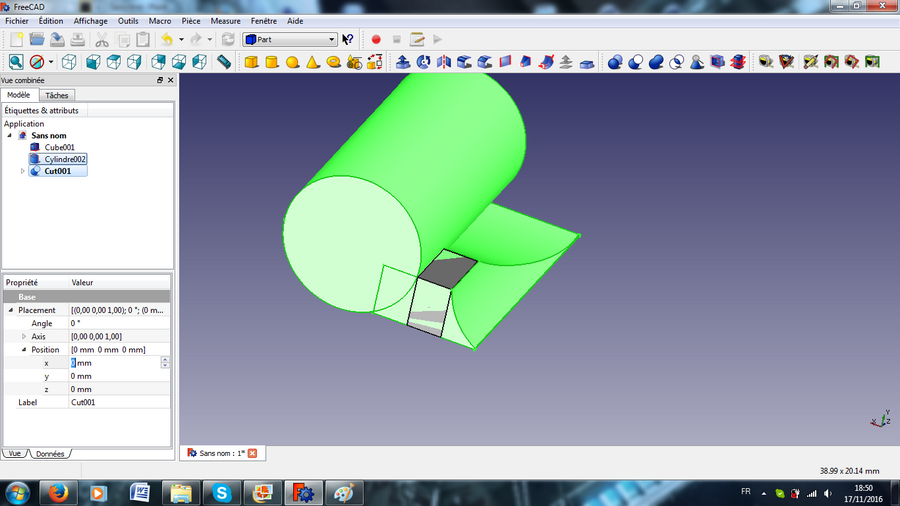

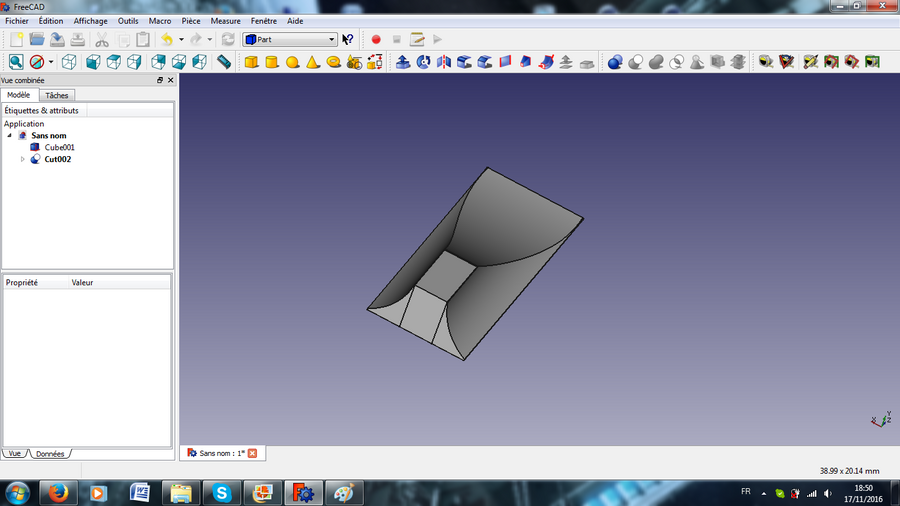

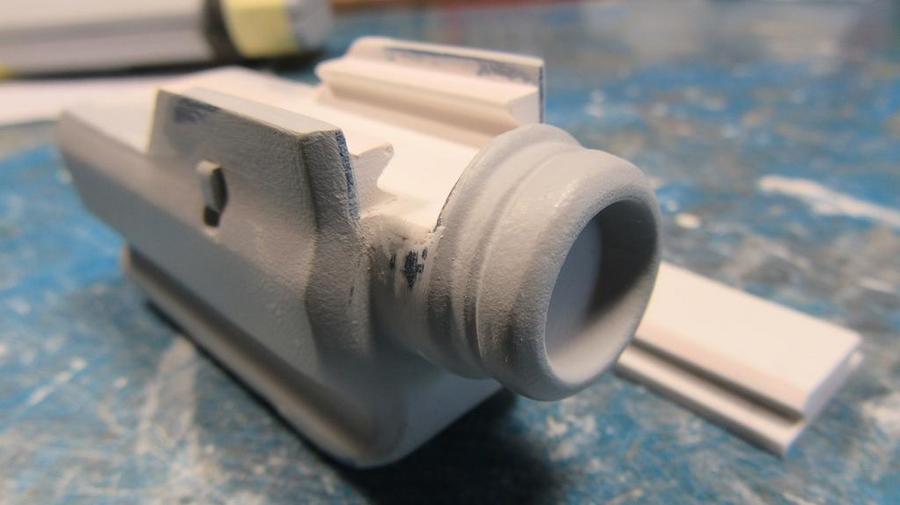

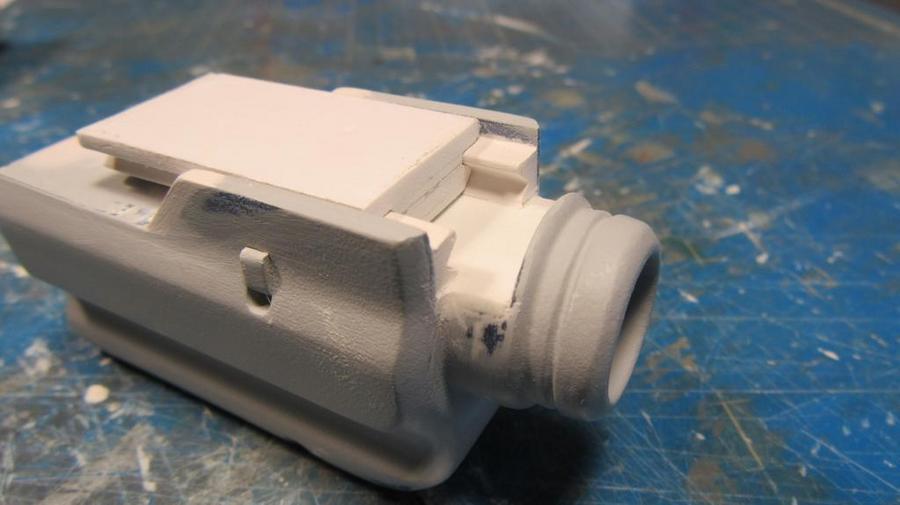

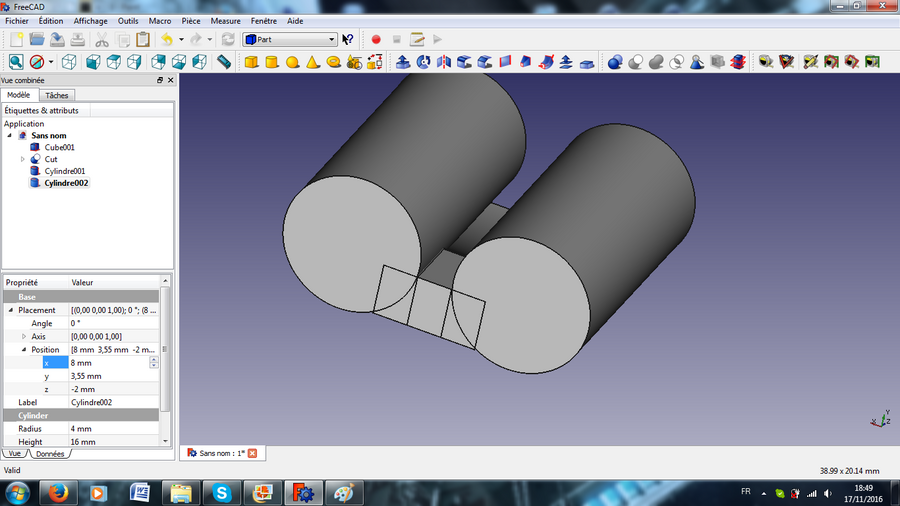

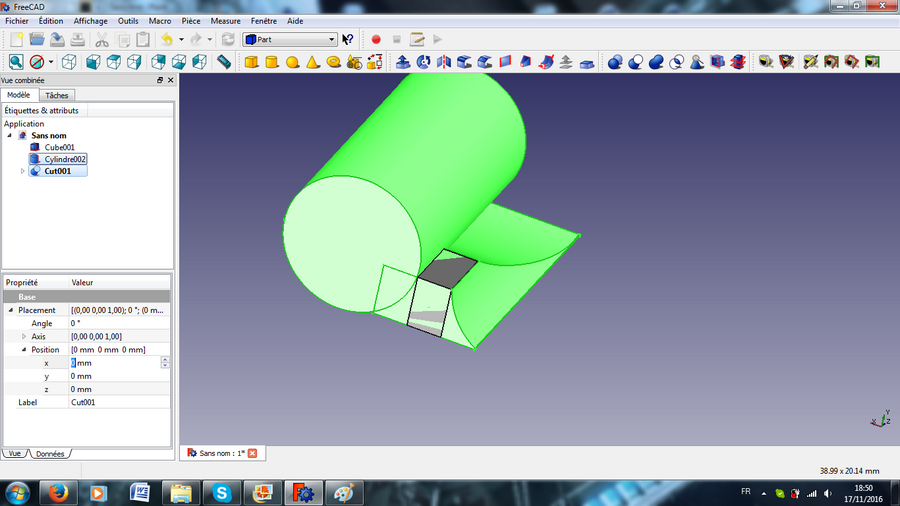

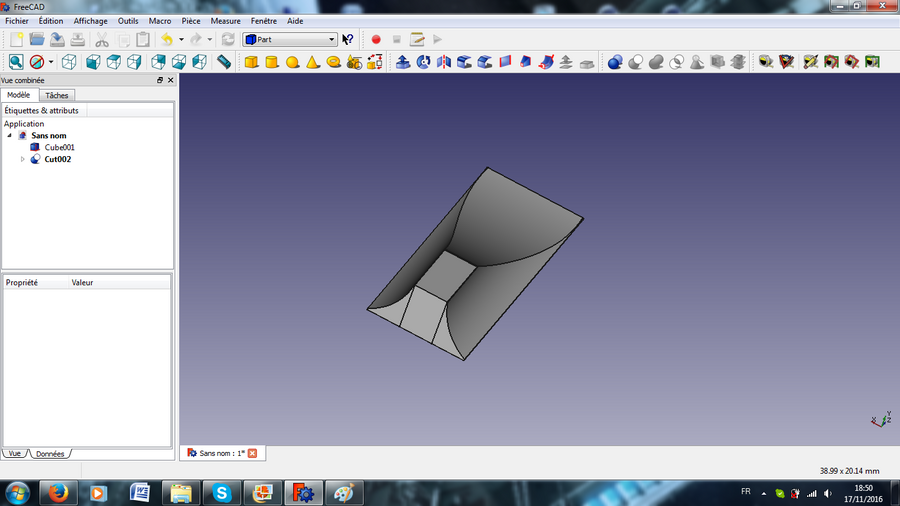

I make the viewfinder in 3D.

I wanted to make the mouth of the magnum removable for easy molding.

A small detail in plastic card.

Another part of the magnum.

It is also necessary to create the Grip texture on the handle.

The molding will soon begin ! And the next accessory will be the silencer for with the Whispered Truth version.

I come to present you the making of my new replica : the M6H2 MAGNUM from HALO 5.

Compared to my other replicas I wanted to make it modular in order to have the possibility to create all the existing versions of this weapon : the basic, the Gunfighter, the Whispered Truth and the Tactical.

I used a 3D printer to provide me with a structural basis with global dimensions, but I remade the vast majority of the Magnum.

Here are some pictures of the making.

I started with a 3D print to give me a structure with which to work.

I use a bit of XTC-3D to smooth the surface.

I make the hammer of the magnum with plastic card.

Then I redo all the structure and the details with putty and plastic card.

It is not finished yet but almost.

A little detail.

I do the same on the other side that does not have the same forms.

With putty I add a detail on the handle of the magnum.

Then I modify and add some things about the guard of the magnum.

With putty I make sure everything fits perfectly.

For the module that fits underneath I also add details.

Then the fixing rail must be made.

I make the viewfinder in 3D.

I wanted to make the mouth of the magnum removable for easy molding.

A small detail in plastic card.

Another part of the magnum.

It is also necessary to create the Grip texture on the handle.

The molding will soon begin ! And the next accessory will be the silencer for with the Whispered Truth version.