You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rabbit's build

- Thread starter TheRabbit

- Start date

- Status

- Not open for further replies.

looking good , hows the helmet coming along

Just about done with it. Have less than a page of pieces left to attach. Hopefully I'll be posting pics of it completed tonight.

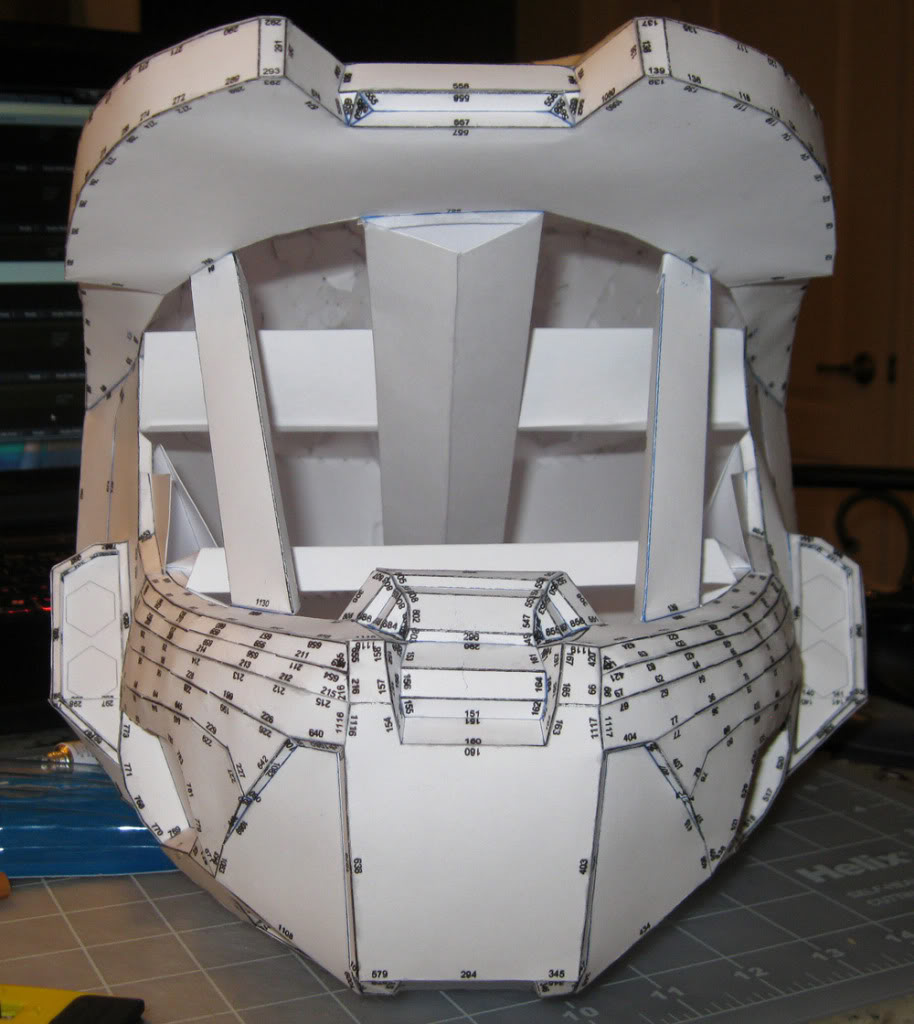

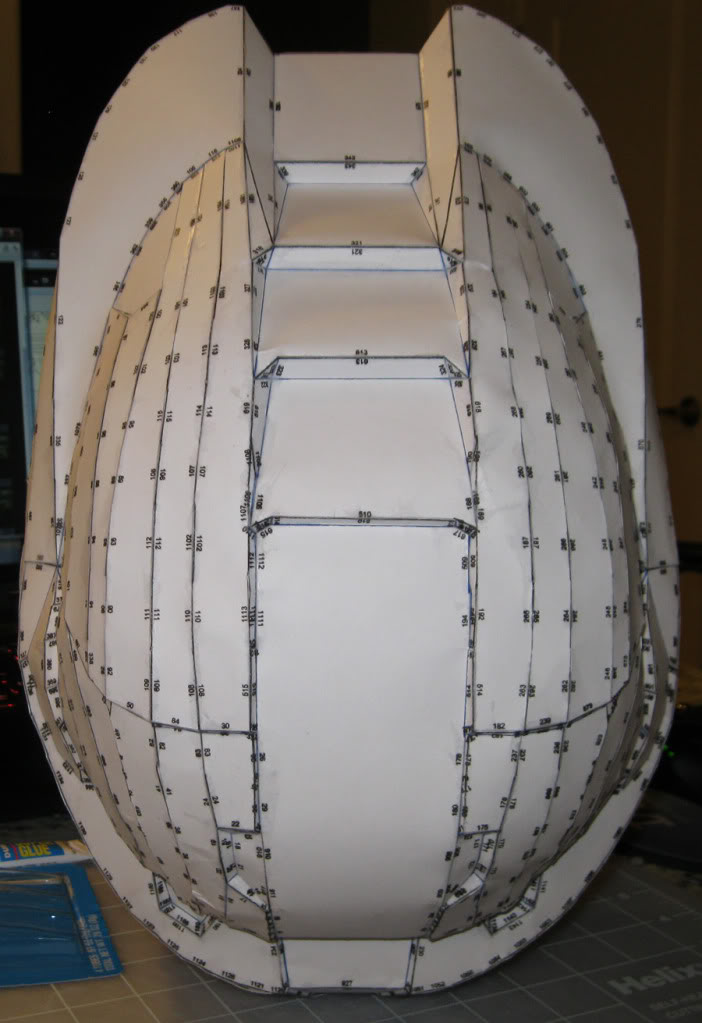

Done!

I think this came out way straighter.

There is a slight warp to the nose piece, and a very slight divot (looks way worse in the picture than it does in RL due to the shadow from the flash) on the back left curve.

I'll probably attempt resining tomorrow! I'll use the 1st helmet as a test bed for the resin. Wish me luck!

I think this came out way straighter.

There is a slight warp to the nose piece, and a very slight divot (looks way worse in the picture than it does in RL due to the shadow from the flash) on the back left curve.

I'll probably attempt resining tomorrow! I'll use the 1st helmet as a test bed for the resin. Wish me luck!

That is hilarious! I've got the same glue and brushes that I'm using for my current project..lol! Only difference is mine are in a 2 pack for the glue and 1/3 pack of the brushes I believe.

Also, great work on pepping the helmet. Turned out really well.

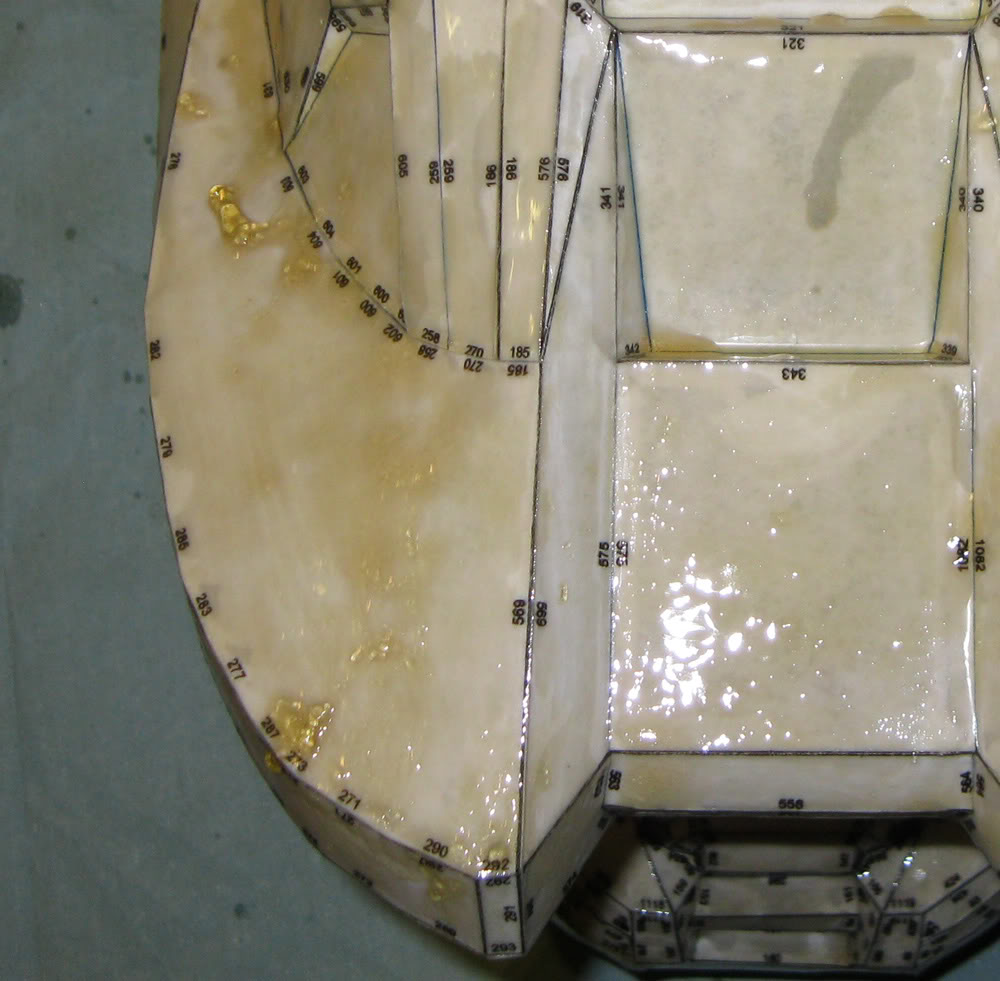

Alright, applied 2 coats of resin to the helmet. Unfortunately I ended up with some little blobs when doing the second coat, I guess I wasn't working fast enough.

And here's a closeup of the blobs:

Will I be able to just cut/sand those off once it has fully cured?

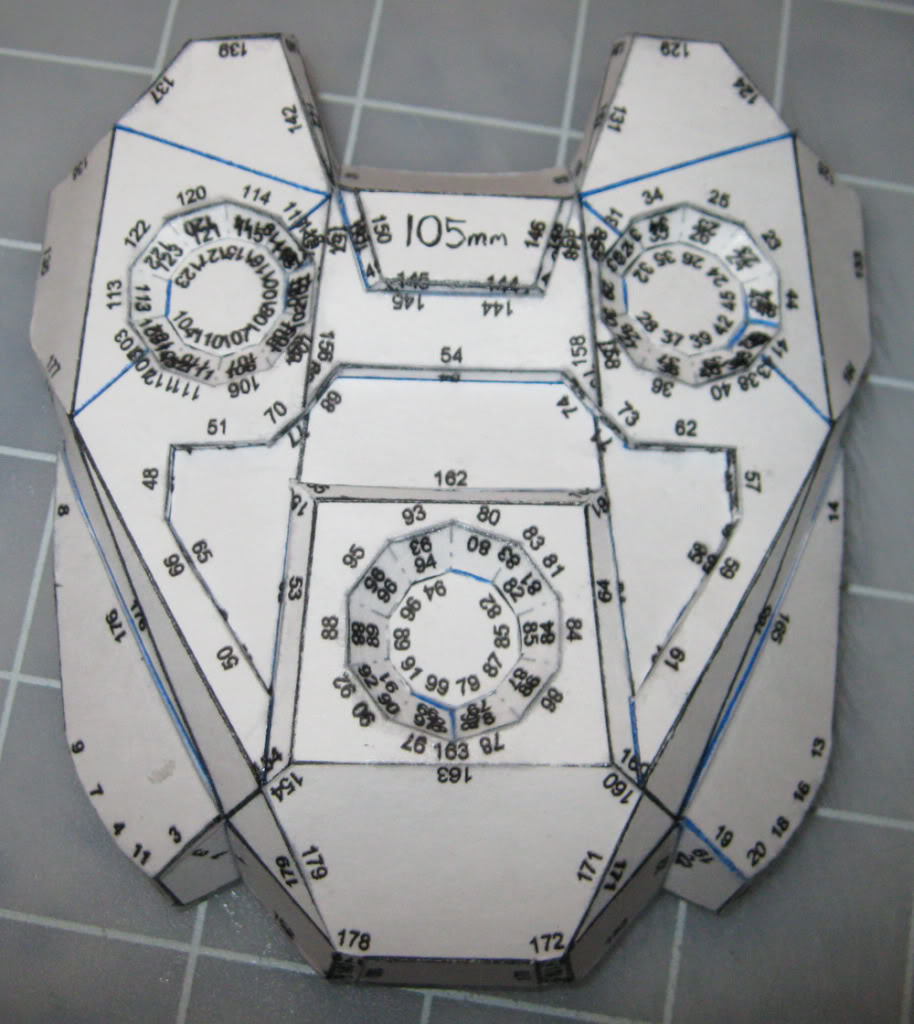

Also, I made another hand plate because I wasn't super happy with the inner edges and I wanted it to be slightly bigger.

The matching handplate is printed and prep'd, just needs to be glued together (that may happen in the next hour depending on if the wife wants to go to bed sooner or later).

And here's a closeup of the blobs:

Will I be able to just cut/sand those off once it has fully cured?

Also, I made another hand plate because I wasn't super happy with the inner edges and I wanted it to be slightly bigger.

The matching handplate is printed and prep'd, just needs to be glued together (that may happen in the next hour depending on if the wife wants to go to bed sooner or later).

The blobs could be not going fast enough, or it could be that you mixed too big of a batch, or you may have added a few drops too much hardener. They will sand off when it all cures, but it is going to take some elbow grease. If you happen to see blobs again then I would suggest scrapping them off with a knife (not one used for food though) to save a bunch of time and effort sanding. Making smaller batches of resin saves material and effort.

Other than the blobs it looks like you resined well, no obvious warping, and only one or two drips. Great job! Also, good job repepping the hand plate, some people don't want to repep parts because it feels like they are good enough and they don't want to feel like they wasted their time on the first piece. You are much better off pepping a second part and being happier with it.

Keep up the good work!

PS, if the helmet is hard enough I would suggest removing the blobs before the next coat of resin on the outside. But don't force them too much, It would suck to see the helmet get warped for that.

Other than the blobs it looks like you resined well, no obvious warping, and only one or two drips. Great job! Also, good job repepping the hand plate, some people don't want to repep parts because it feels like they are good enough and they don't want to feel like they wasted their time on the first piece. You are much better off pepping a second part and being happier with it.

Keep up the good work!

PS, if the helmet is hard enough I would suggest removing the blobs before the next coat of resin on the outside. But don't force them too much, It would suck to see the helmet get warped for that.

RSpartain7

Jr Member

Very nice. Whats the trick to getting the folds nice and clean? Most of my helmets I've made are all really warped.

Lots of time spent prepping the pieces. I run a pen over each fold several times to make sure it creases well, and then I spend a lot of time making sure I cut things out exactly along their lines. Once that's done just make sure the folds line up when gluing pieces together.Very nice. Whats the trick to getting the folds nice and clean? Most of my helmets I've made are all really warped.

RSpartain7

Jr Member

That's a good idea, never thought of going over it with a pen. Thanks for the advise!Lots of time spent prepping the pieces. I run a pen over each fold several times to make sure it creases well, and then I spend a lot of time making sure I cut things out exactly along their lines. Once that's done just make sure the folds line up when gluing pieces together.

Small boring update.

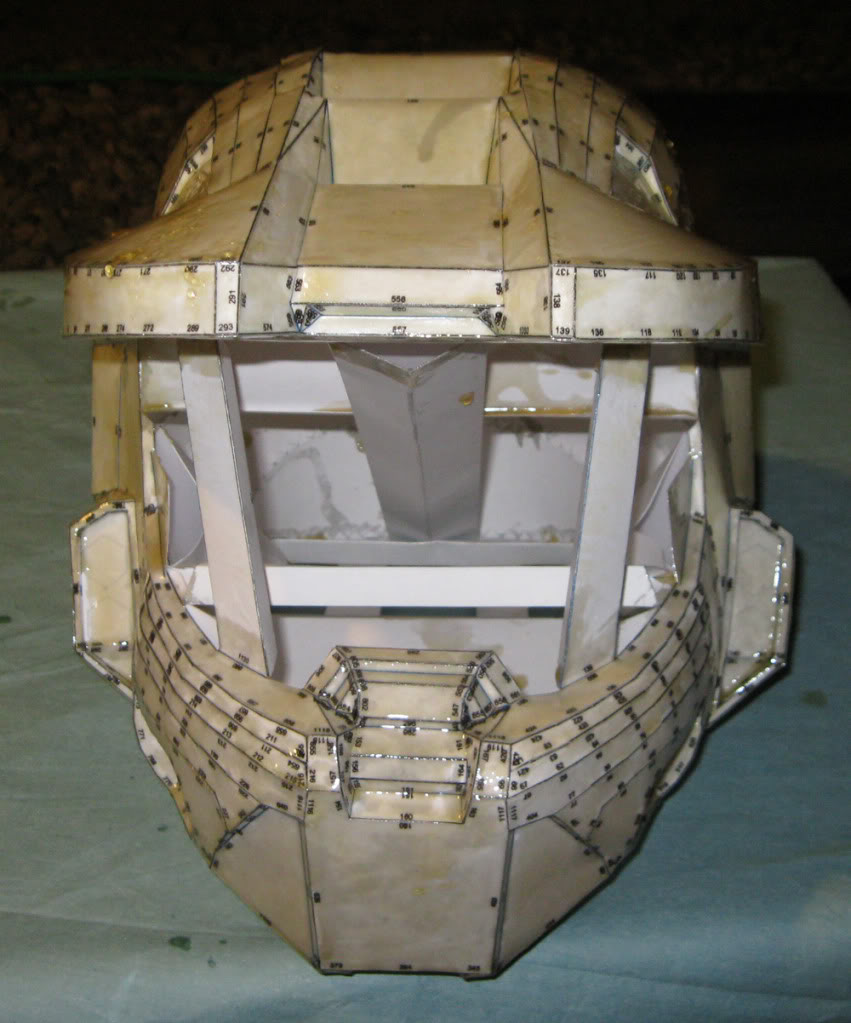

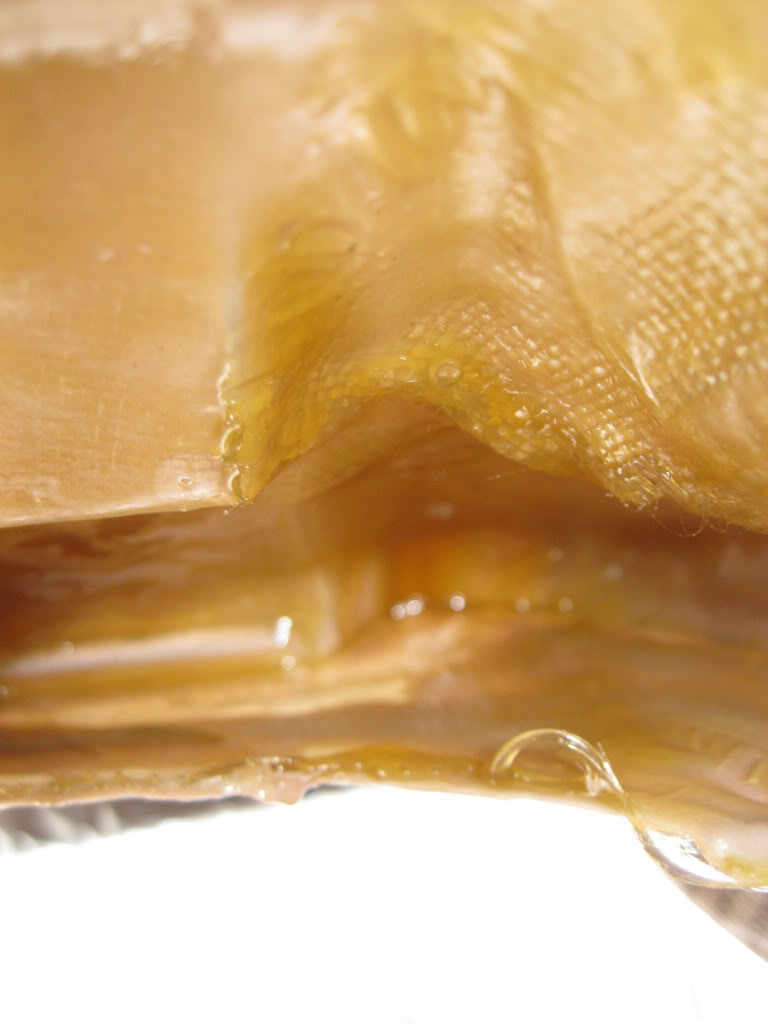

Did a full layer of fiberglass on the inside of the helmet. First of all, WOW, I am having a ton of fun fiberglassing, it's a lot of fun figuring out what size strips of cloth to use, wedge them into place, resin them, etc. Having way more fun doing this than I have pepping. Also, I'm amazed at the strength this has added to the helmet. The thing feels rock solid now, way better than how it felt after just resining the outside and rondoing the inside.

PICTURES!

Here's the muzzle:

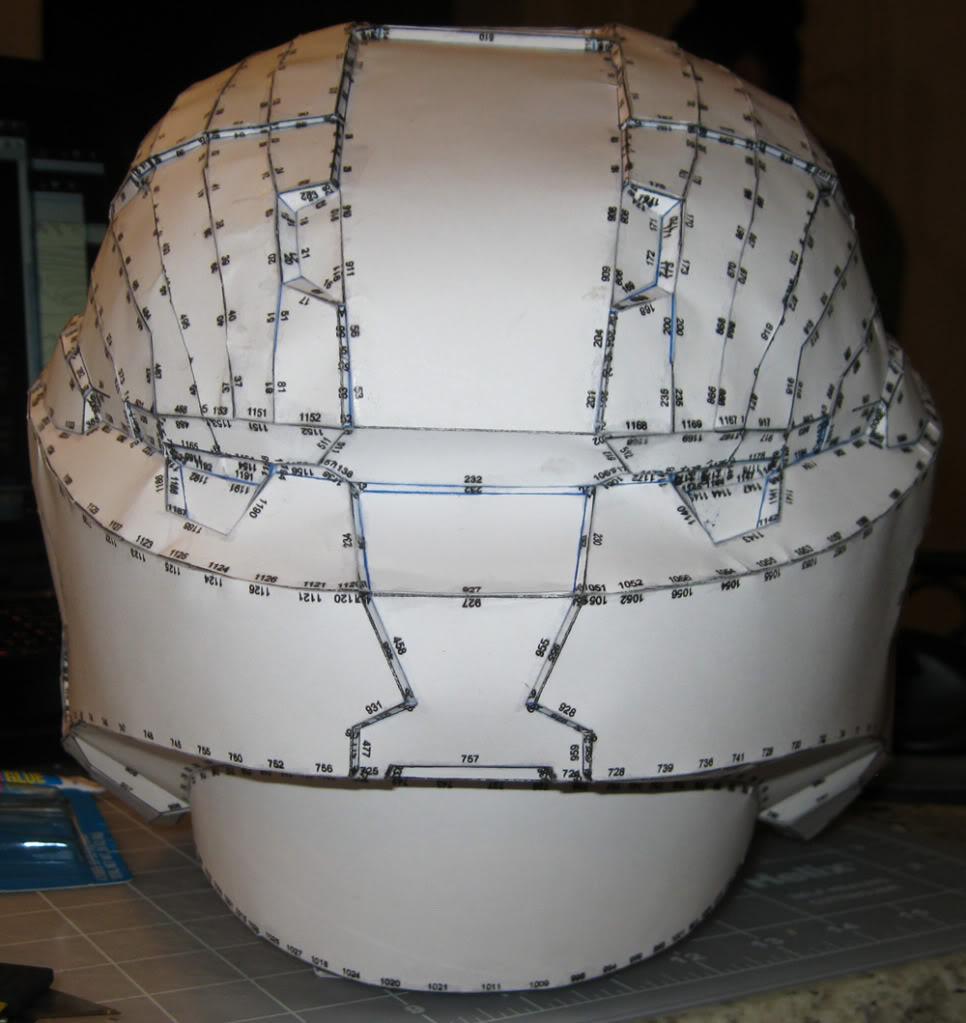

Here's the back:

Here's the dome:

Here's inside the brim:

I have some air bubbles in there, which I'm sure you can see, but I don't think they'll be that big of an issue. I'm going to do another layer of fiberglass for super reinforced strength and then start working on smoothing the outside with bondo.

Did a full layer of fiberglass on the inside of the helmet. First of all, WOW, I am having a ton of fun fiberglassing, it's a lot of fun figuring out what size strips of cloth to use, wedge them into place, resin them, etc. Having way more fun doing this than I have pepping. Also, I'm amazed at the strength this has added to the helmet. The thing feels rock solid now, way better than how it felt after just resining the outside and rondoing the inside.

PICTURES!

Here's the muzzle:

Here's the back:

Here's the dome:

Here's inside the brim:

I have some air bubbles in there, which I'm sure you can see, but I don't think they'll be that big of an issue. I'm going to do another layer of fiberglass for super reinforced strength and then start working on smoothing the outside with bondo.

nice. You are about ready for the bondo stage, then the sanding and detailing, then painting and visor installation.

Yea, that's going to have to wait until I have more budget to be able to purchase sanding and painting materials... I've gotten about 1/3 of the second fiberglass layer completed. Once this layer of fiberglass is complete I'll go through and trim up all the sharp little strands sticking out and then work on how I'm going to actually get my head inside it...nice. You are about ready for the bondo stage, then the sanding and detailing, then painting and visor installation.

Looks like an excellent job of fiberglassing. I only saw a few strands of glass sticking up, but no point in doing anything about them until the second layer is done.

Also, you are the first person I have met on the 405th who seems to really like the fiberglassing work. Most seem to think that it is tedious, annoying, sticky, hard to stop the cloth from sticking to your gloves, etc. Seems to drive people away from fiberglass towards foam armour. Glad you like it though.

You mentioned that you used rondo inside the helm before you did fiberglass. If you want to save some time, you can press fiberglass cloth into the wet rondo for your first layer. You just need to make sure that your rondo is runny enough to soak through the cloth properly. The technique is called mudglassing, and I think there are a few short tutorials around the forums somewhere if you want more info.

Also, you are the first person I have met on the 405th who seems to really like the fiberglassing work. Most seem to think that it is tedious, annoying, sticky, hard to stop the cloth from sticking to your gloves, etc. Seems to drive people away from fiberglass towards foam armour. Glad you like it though.

You mentioned that you used rondo inside the helm before you did fiberglass. If you want to save some time, you can press fiberglass cloth into the wet rondo for your first layer. You just need to make sure that your rondo is runny enough to soak through the cloth properly. The technique is called mudglassing, and I think there are a few short tutorials around the forums somewhere if you want more info.

Very nice work Rabbit, cudos on the cleanness of the fiberglass work, looks like an excellent job. I second Nessy's note about mudglassing tho, I've used it on other projects and it can make the first layer far easier to work with. I too don't see why glassing turns so many away. Provided you're using disposable gloves its a lot of fun.

- Status

- Not open for further replies.