I'm loving that there are so many great new pics popping up! It will make for some great new models! So I figured its time for an update. I cut off most of the keys, leaving the ones on the ear area and the centerline of the helmet. I rearranged them so there are 7 along the centerline and will do the mold in two halves, like Ithica did on his recon. This will eliminate the locked mold problems and will make it easier to make the mold. I have the dividing wall made as well. I had planned on getting the fiberglass done today, it was a beautiful afternoon, but as I went to the store to get some stuff for mixing the resin, and a cold front moved in. So I will have to wait until we get a little more warmth outside. I am itching to get this done!!! Makes me wish I was still in Texas. I will update with pics once I get my hands on a camera.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reach: An Lt Wip

- Thread starter Brandon McClain

- Start date

- Status

- Not open for further replies.

Sorry I couldn't get this up sooner...

Three part shells make for more complicated molds, and usually the more complicated things are the easier something can go wrong during construction.

This shows a three part vs two part mold support shell design. The main problem with the two part design is the keys create many undercuts and the shell will be locked onto the mold itself. With shell utilizing more pieces, you have a greater flexibility in making sure the shell wont lock on.

It seems that you have solved your problem Brandon, but for those that wanted to see what I am referring to, see the attached image.

Edit: This graphic is specific to Brandon's original key layout. There are ways to use a two part mold, and avoid the problems that require three part shells.

Three part shells make for more complicated molds, and usually the more complicated things are the easier something can go wrong during construction.

This shows a three part vs two part mold support shell design. The main problem with the two part design is the keys create many undercuts and the shell will be locked onto the mold itself. With shell utilizing more pieces, you have a greater flexibility in making sure the shell wont lock on.

It seems that you have solved your problem Brandon, but for those that wanted to see what I am referring to, see the attached image.

Edit: This graphic is specific to Brandon's original key layout. There are ways to use a two part mold, and avoid the problems that require three part shells.

Hey Spase, can't thank you enough for that. Looks like you put a lot of time and effort into that sketch. That means a lot! I moved the keys to have a centerline registration so its a two part mold. If only the weather would smarten up here.

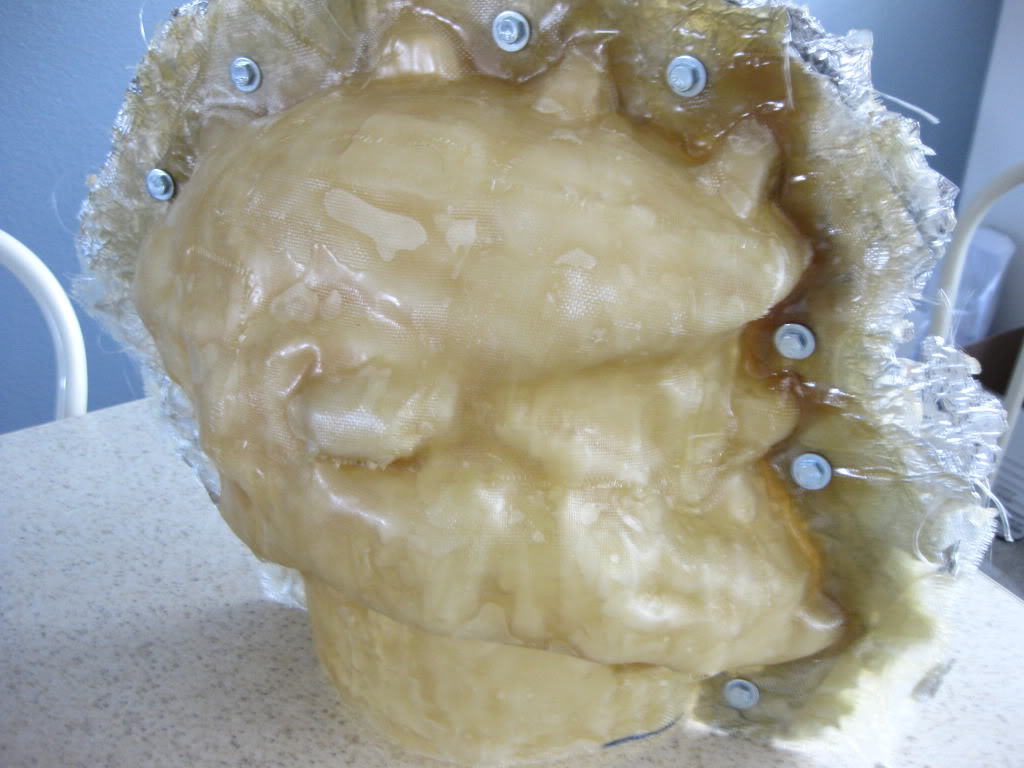

Alright!!! Update!! So I built a heat box because I couldn't stand to wait for this stupid weather to warm up. I not only finished the mother mold, but did my first pull today. I had a few bubbles in the print layer, and a few other small flaws, but nothing serious, most of the flaws popped of easily. Took some pics so yall could see. So here you go!

Before the first pull

All the parts of the mold, the original, and the first pull. So excited!

Original and the first pull

Flaw number 1

Flaw number 2

Flaw number 3

Flaw number 4

So I will do a couple pulls from this mold, and then redo the mold using a slower curing silicon for the print layer to eliminate the bubbles. I will probably do a run in the classified section.

Before the first pull

All the parts of the mold, the original, and the first pull. So excited!

Original and the first pull

Flaw number 1

Flaw number 2

Flaw number 3

Flaw number 4

So I will do a couple pulls from this mold, and then redo the mold using a slower curing silicon for the print layer to eliminate the bubbles. I will probably do a run in the classified section.

Shaymin Sky

Well-Known Member

Oh mah goodness gracious! That is so AWESOME!

A Guardian

Well-Known Member

If you plan on selling, I want to know a price.

those look awsome!!!

those look awsome!!!

Very nice my friend. The flaws are minor and would probably be a quick fix so I think over all even the first pull could be called a success.

bboyfresco

Active Member

My eyes opened up really wide when I saw the pic of the first pull. Awesome work

FrozenSniper

Jr Member

Awesome helm man!  love the paint and all the details. i will definately have to get me some foamies when i do mine.

love the paint and all the details. i will definately have to get me some foamies when i do mine.

nice mold btw!

nice mold btw!

SchizophrenicMC

Well-Known Member

Make a note, here: Huge Success.

If I had a money, I would make a purchase.

If I had a money, I would make a purchase.

the master

Jr Member

i think this is the fastes build and molding wip that iv ever seen,

Good job on the molding though

PS: it still looks great even with the flaws,

makes it look like is seen battle

-cheers

Good job on the molding though

PS: it still looks great even with the flaws,

makes it look like is seen battle

-cheers

Hey Y'all, thanks for all the positive feedback! I am really happy with how it turned out. It still has some work left to go, just paint and weathering details. I have over 120 hours into it already. I bondoed myself silly on this thing. I have a least 55 hours in just bondo and sanding. Crazy I know. It might just be that I am slow, but I really wanted to get all the details in. For those who said it is elite worthy, well, that means a lot. I would say wait until you see it done, I have a lot of little ideas for paint and finish. I test fit a large scorpion helmet replacement liner yesterday, and it fits perfect. Looking forward to getting it 100% finished. All the positive feedback keeps me going.

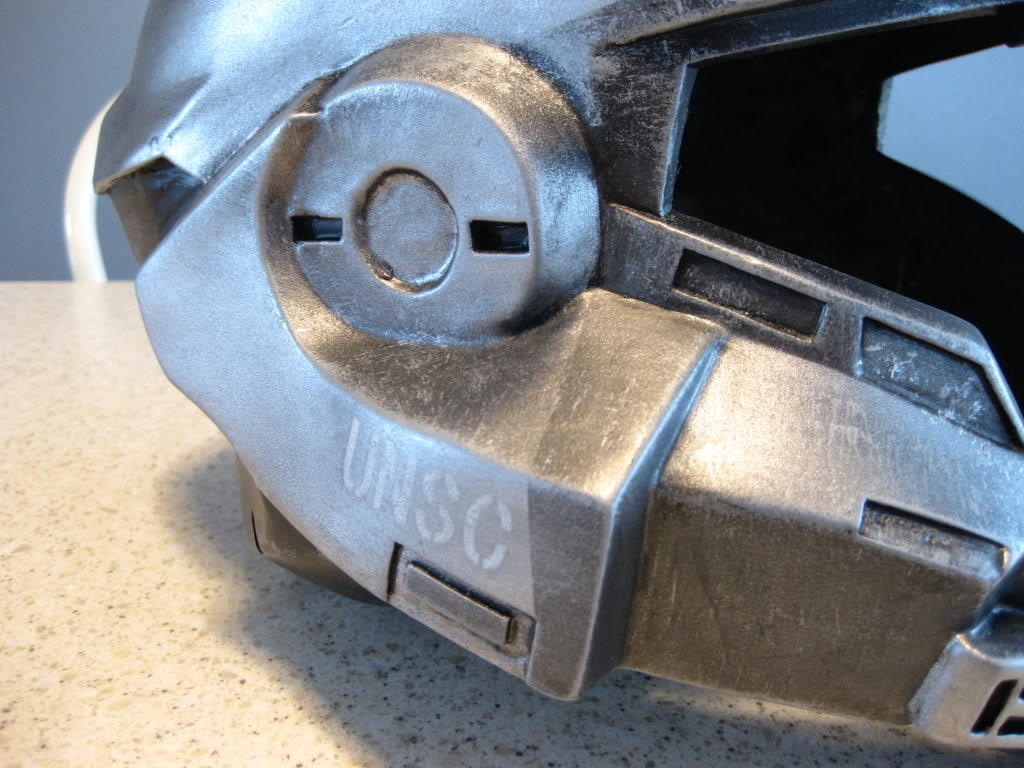

Small update, did the white wash, black wash, UNSC tag and dry brushing on the helm today. Many thanks to Adam for his awesome weathering tutorial. I cut the UNSC stencil from 110 lb cardstock, got it a little wet the layed out where I wanted it. Gave it a light spray, then went over it with the dry brush. The helm really looks a lot better in person than the pictures do justice, I am glad I went with the weathered look. Much better! Heres a couple pics!

SchizophrenicMC

Well-Known Member

All it needs now is a badass visor. You did good.

the master

Jr Member

that is the best helmet i have seen yet

are you going to vacume forme the visor

or going to make a clear mold and cast thing

-cheers

are you going to vacume forme the visor

or going to make a clear mold and cast thing

-cheers

As far as the visor goes, I am going to use a motorcycle visor. I have it, but just have to finish the small red and yellow triangles and then I will do the visor. It looks sick.

S1l3nt V1p3r

Sr Member

Beautiful! <3

- Status

- Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 671

- Replies

- 2

- Views

- 255