nrettenmaier

Member

All you electronics geniuses, I need your help!!

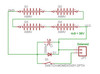

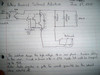

I'm working on building the AR from Reach and I want the bolt to actually move when I pull the trigger, as if a round was actually being fired. I've been looking online and from what I've seen it seems like people usually do this one of two ways, either with a solenoid or with a small electric motor. However, from what I've been able to find out, they both have their downsides (the solenoid takes up a lot of energy and the motor makes noise)

I was wondering if any of you guys have ever done this and had any ideas for me. Or if anyone else knows of any other ways to do this or can just give more information about one of the methods mentioned above (what solenoid/motor to use, etc.). Also, does anyone knw of any sites I can look at that would help me out? Let me know!

I should mention that I don't necessarily want to be able to feel recoil on it (so it doesn't need to be that powerful). I just want the bolt to move.

Thanks in advance

I'm working on building the AR from Reach and I want the bolt to actually move when I pull the trigger, as if a round was actually being fired. I've been looking online and from what I've seen it seems like people usually do this one of two ways, either with a solenoid or with a small electric motor. However, from what I've been able to find out, they both have their downsides (the solenoid takes up a lot of energy and the motor makes noise)

I was wondering if any of you guys have ever done this and had any ideas for me. Or if anyone else knows of any other ways to do this or can just give more information about one of the methods mentioned above (what solenoid/motor to use, etc.). Also, does anyone knw of any sites I can look at that would help me out? Let me know!

I should mention that I don't necessarily want to be able to feel recoil on it (so it doesn't need to be that powerful). I just want the bolt to move.

Thanks in advance