Not only that but I have seen suits where the width and depth aren't quite right and the thighs haven't matched the suit scale properly.

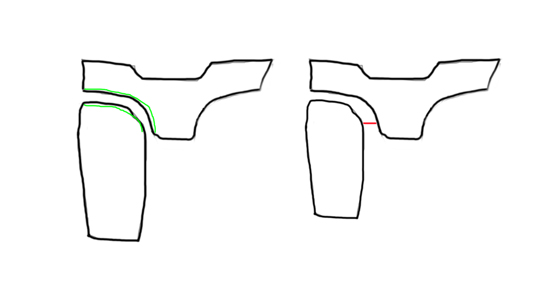

In my crappy diagram the green lines show the holes I am talking about (couldn't do a perspective sketch as am not very good at drawing with a mouse). The left diagram is scaled correctly. On the right the red line is the gap that will be created if it's slightly off. Now you might get away with it but I have noticed in some builds people haven't because they scaled the thigh to make sure the hight is right which brings in the depth and width too much. I never got to finishing my thighs for this exact reason. I am hoping my next attempt at it with a bit of modification should be scaled right, I hope!! I've done 3 of the stupid things already but the last attempt came close.

Ah I see. So far I've used the same scale factor for the whole suit and the only part I've had any problems with is the waist. Even then, it's an easy solve by cutting off the rigid sides and replacing them with foam.

I just laid the cod on the floor with the thigh under it. Looks ok so far.