And so here it is, another thrilling installment of the progress on my helmet...

I know some of the techsperts here are going to flip a... well, something really bad anyway at the distinct lack of electrical expertise that I will now convey, but I will admit I know relatively nothing about resistors and what not, and that I am relying solely on what I was taught in year six science... That was eighteen years ago, and besides, my crumby wiring actually does work, despite my huge blobs of solder (I clearly have a fear that I won't make the proper joins without copious amounts of the stuff. Go figure...)

Regardless, as a novice I can however offer some great safety advice.

1) I don't have a proper workspace for doing my electrical stuff, so I use the kitchen sink drain. There are two very good reasons I do work here. It's very well lit via a window and light above it. Proper illumination is essential when working on stuff like this. And, the sink itself is non-flamable... Little drips of solder won't (hopefully) set the house on fire if they drop onto the sink, plus they don't stick too well to stainless steel, and as a result, it just wipes off!

...

2) Wear the proper safety equipment. Eye goggles/glasses are an essential when doing soldering. The flux that is embedded in the solder tends to want to have a spit or two. You don't want that stuff in your eyes for very obvious reasons...

For further safety advice, I suggest you check the forums... For electrical advice, check this

link. It'll give better advice than I can ever possibly imagine. But I digress...

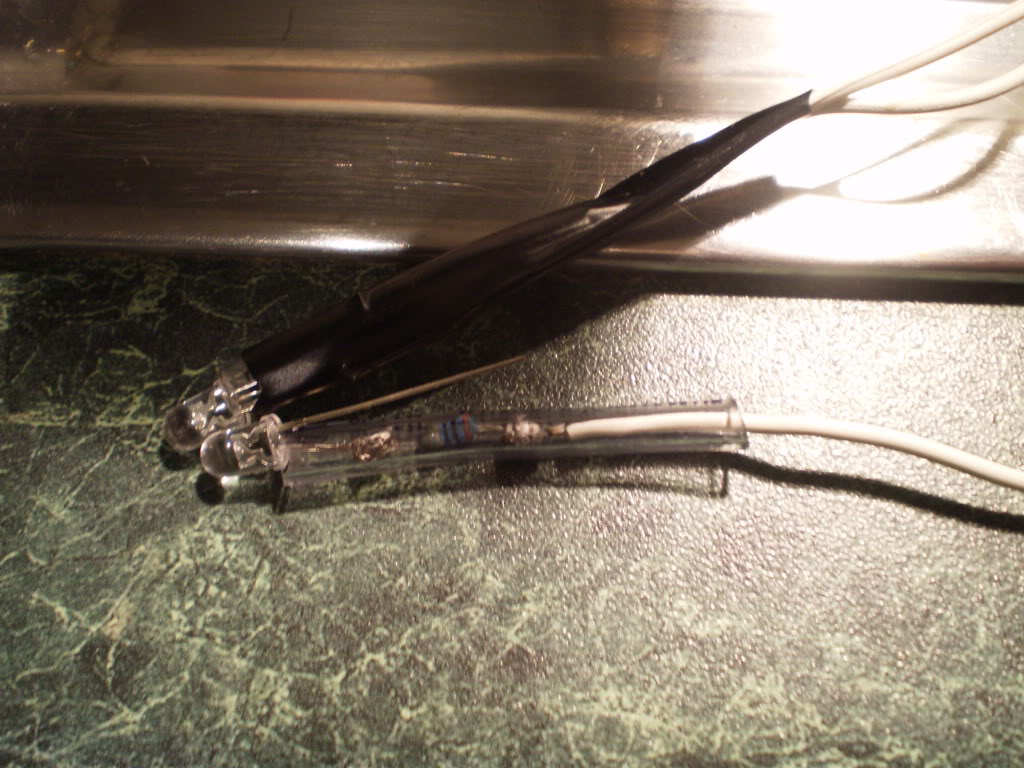

Following a good rule; "one LED=one resistor", I made up the lights as a kit so to speak. The two lots of lights are pretty much the same (in fact, I made them identical), so I wired up a resistor to the positive side each on four LED's. With all of them the same, I was minimizing the risk of making mistakes. Like so...

Once I had them all made up, I stripped the ends off some "bell" wire (the wire generally used to wire up doorbells) and twisted it in place on the resistors before soldering them as well. Seeing as my town demands that there be a shortage of shrink wrap plastic, I had to think outside of the cuboid prism and come up with plan B. Plan B consists of electrical tape and a small cut of 4mm clear vinyl tube. I used the tubing as "spaghetti" (not my terminology, but what it's actually called) to isolate the positive from the negative so they wouldn't come in contact with each other and short out... I also wrapped a bit of electrical tape over the negative cathode coming from the LED after I had soldered it up for the same reasons. Here's one I prepared earlier...

Anyway, the switches I bought are just simple toggle switches. However, they're tiny little buggers, so I had to solder the two incoming wires together into a common single positive wire due to a lack of space on the bottom of my switches... I hope that makes sense... Again, I twisted the wires together before soldering, allowing to cool, then wrapping in electrical tape...

Ok, so there wasn't any premade bulb reflectors in the electric/hobby shop I was in, so I went back to what I used for my EVA helmet. They're actually nothing to do with electronics. These little babies are called MACDRIVE nails. They're used in the building industry in the place of DYNABOLT's, where using a nail would be easier than using a bolt to hold non-structural framework to a cement slab or masonry wall... As the nail is driven home in a pre-drilled hole, the tip splits open and flairs, holding the frame in place... I must be the only person to have bought these from my work in the last 3 years... Again, I'm going off topic a bit here. I removed the nail and cut the head off the lead sleeve (remember to use safety glasses and a respirator when cutting lead) with my Dremel, then filed the backs off smooth before drilling into the backs to allow the LED's to sit further forward behind them. My cordless drill was going flat at this point in time, so the lower RPM actually made for a much easier job as the lead heads are quite soft... What I ended up with was 4 mock up reflectors, like so...

I test fitted just to make sure they were going to work. I had to file the side off one just a little to get a better fit on the right hand side, but made sure to follow the curve of it to make sure it wouldn't stand out... Thankfully, any marks I made on them while in this stage would dull off naturally over time, so I wasn't fretting too much about being careful with them...

Because they all fit pretty good, I went ahead and glued them in place, again using the Fullaprene I've spoken of before...

Waiting for them to dry was going to take a while, so I started on the mesh inside the rebreather vents. I plan on using a polyester cloth over the inside of these again, minimizing the chance of any light coming in through the vents and thus showing my face... I probably won't get to that though until I line the inside of the helmet...

And finally, here's a photo of my very basic wiring rigs, just to show how simple the set ups can be... I need to get another battery, but I did test both circuits, and both work just fine... Those in the know will identify them as parallel circuits. You get a more even distribution of electricity over series circuits with this kind of set up, so, other novices, pay close attention, you'll get a more professional finish if you go with this type of circuit...

And that's all I've got time for today. This was the last day of my 2 and a half week holiday, and while I didn't get to finish all the helmet off, I did get a fair bit done and I'm very happy with that. If I get some more time this up coming weekend, I should be able to get the circuits in the helmet and start to line the inside... If not, maybe later... Anyway, I'm off to iron some work shirts now, then I'm going to bed, so tootle ohms and bai bai...