dung0beetle

Well-Known Member

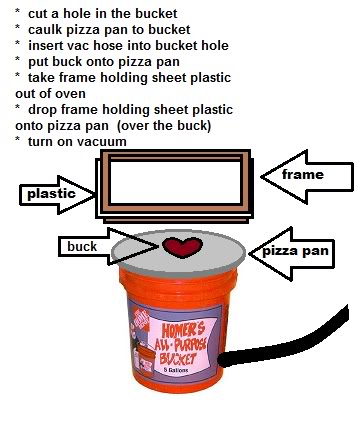

I was wondering about what design to make my vac forming rig, and this idea came to mind. It is quick, cheap and easy.

You need a small pizza pan with the holes in it, a home depot bucket (or similar), caulk (or other adhesive), and a hole saw.

I haven't installed photoshop on my new computer yet, so paint is it.

I'm thinking of adding some sort of guide to it, to keep the sheet plastic from tearing or wrinkling, but that will be designed after the clearance around the pan/bucket is determined.

What do you think?

You need a small pizza pan with the holes in it, a home depot bucket (or similar), caulk (or other adhesive), and a hole saw.

I haven't installed photoshop on my new computer yet, so paint is it.

I'm thinking of adding some sort of guide to it, to keep the sheet plastic from tearing or wrinkling, but that will be designed after the clearance around the pan/bucket is determined.

What do you think?