More Pictures on page 4.

Current Progress:

View media item 2549

I'm back!

Alright, I wanted to save this until I officially go the green light for this project.

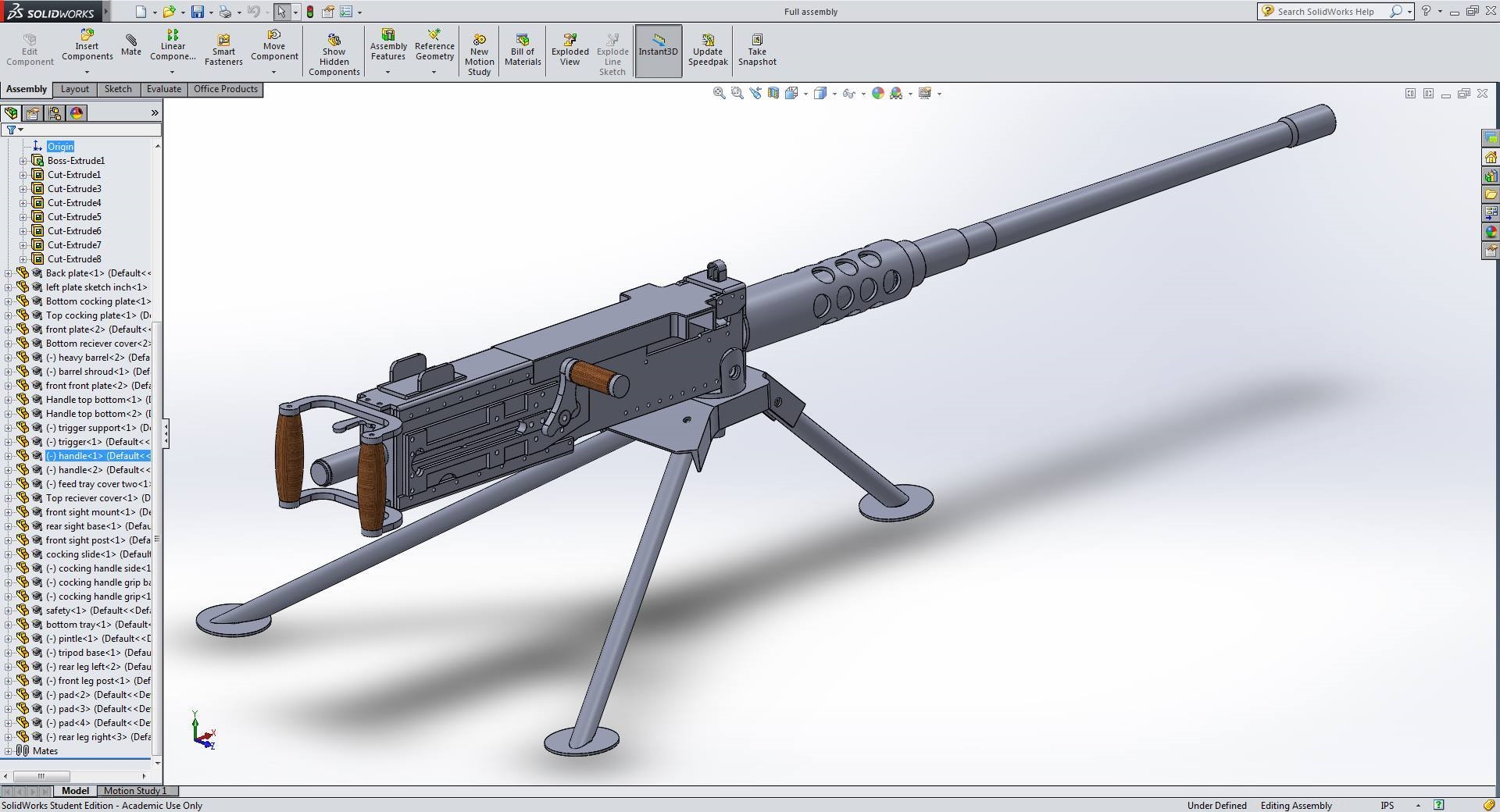

Roughly six months ago, I started working on building an assembly in Solidworks of an M2 .50 Cal machinegun as a couple of friends and I wanted to turn out some airsoft .50's and that'd be freakin' sweet. Right?!

Well, I finished that in a matter of days. Here's the final design:

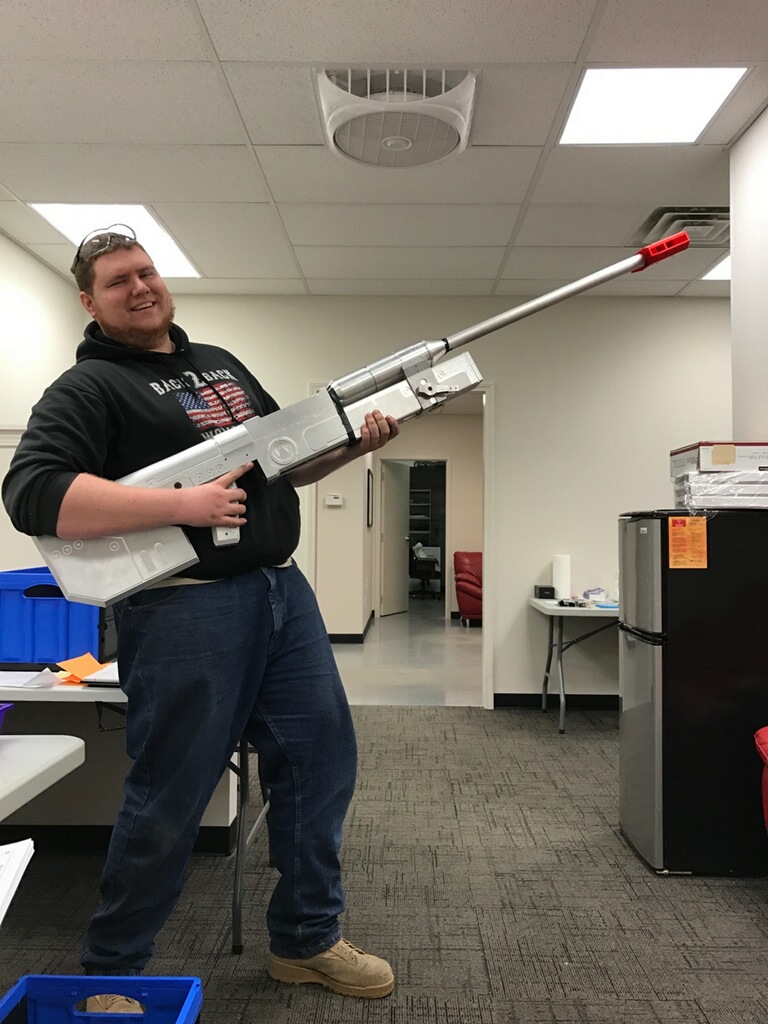

And we've started to machine parts out out of plate aluminum. Here's one of the receiver bodies (we're making 3 of these in total):

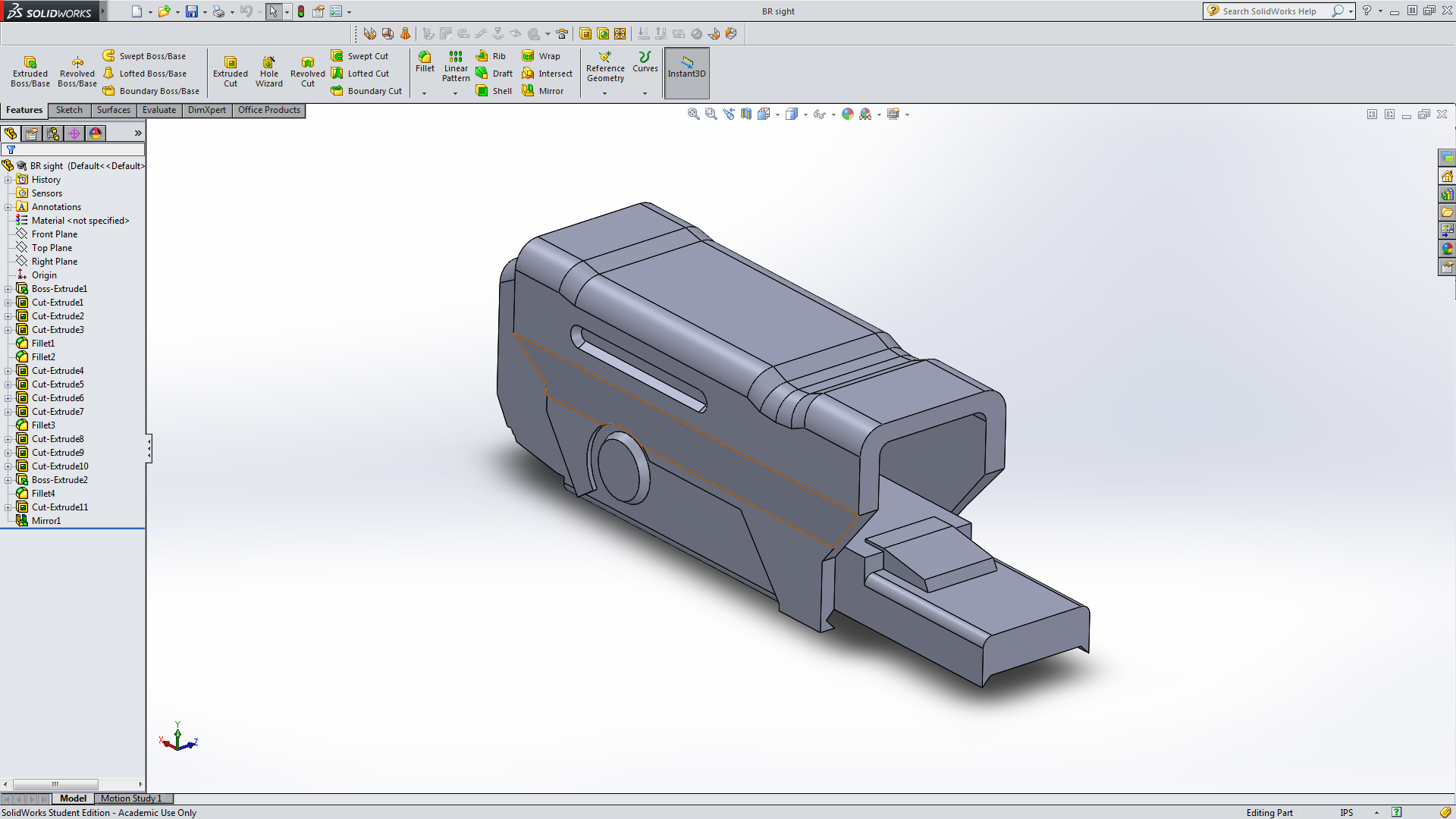

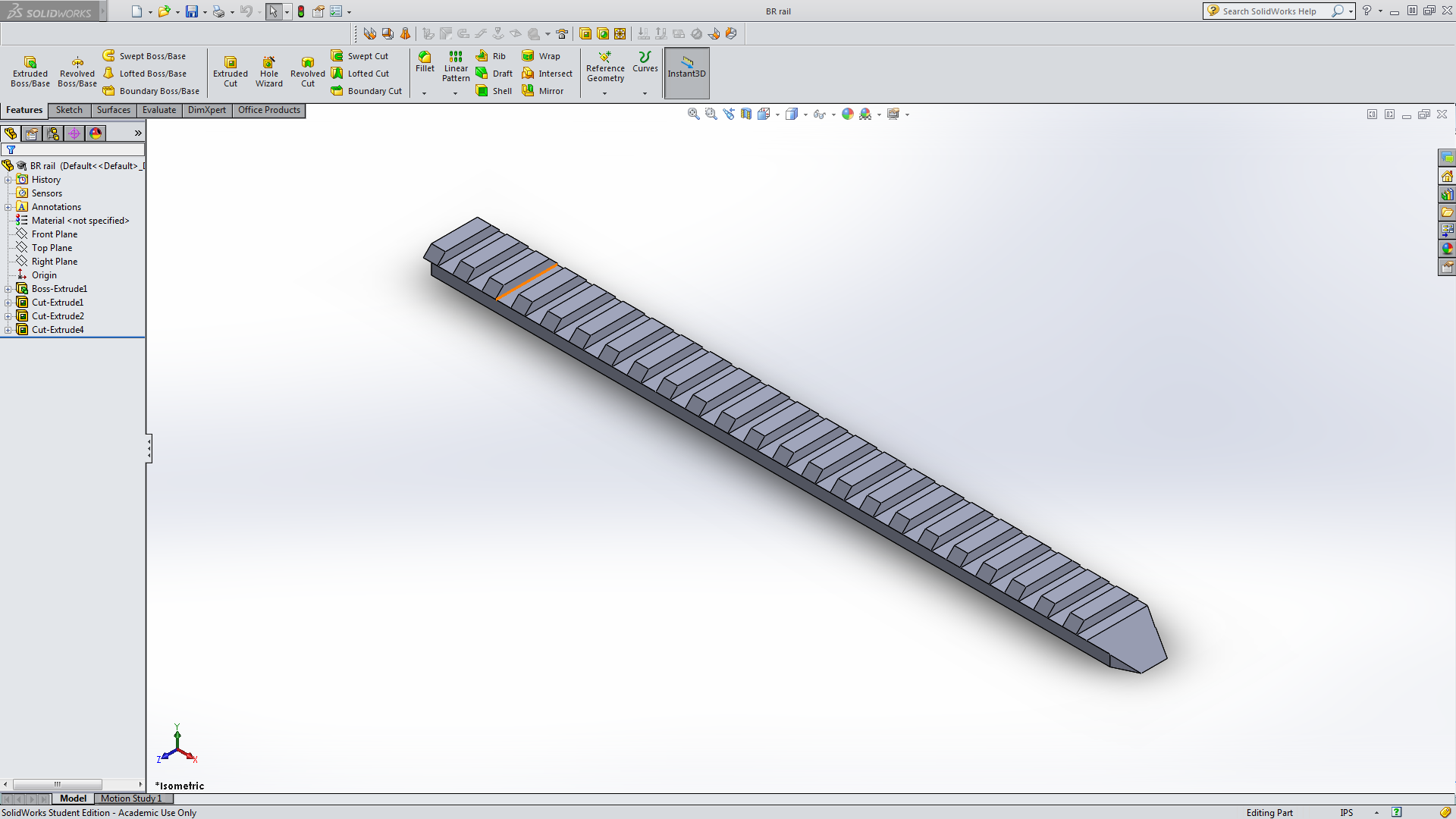

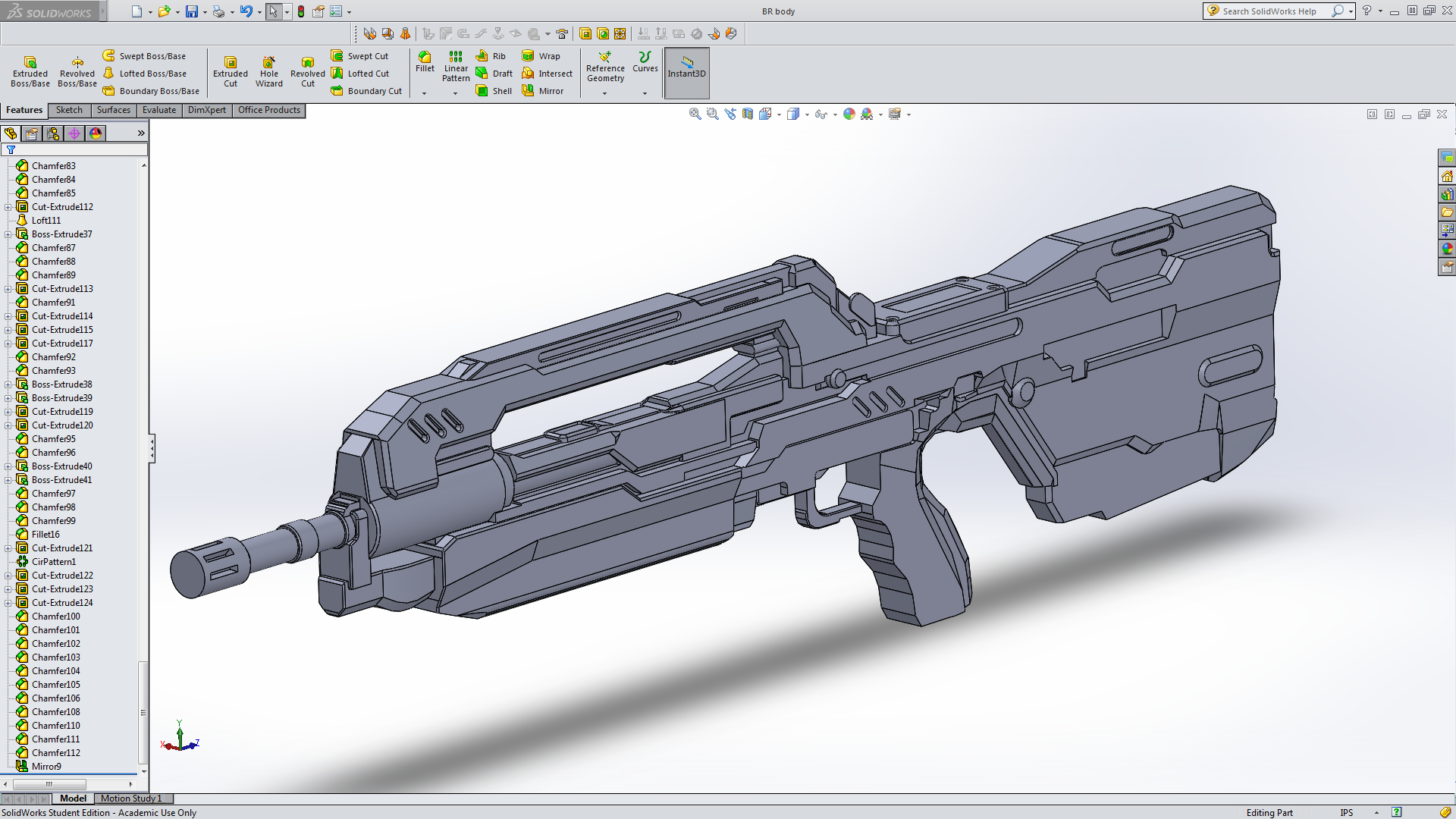

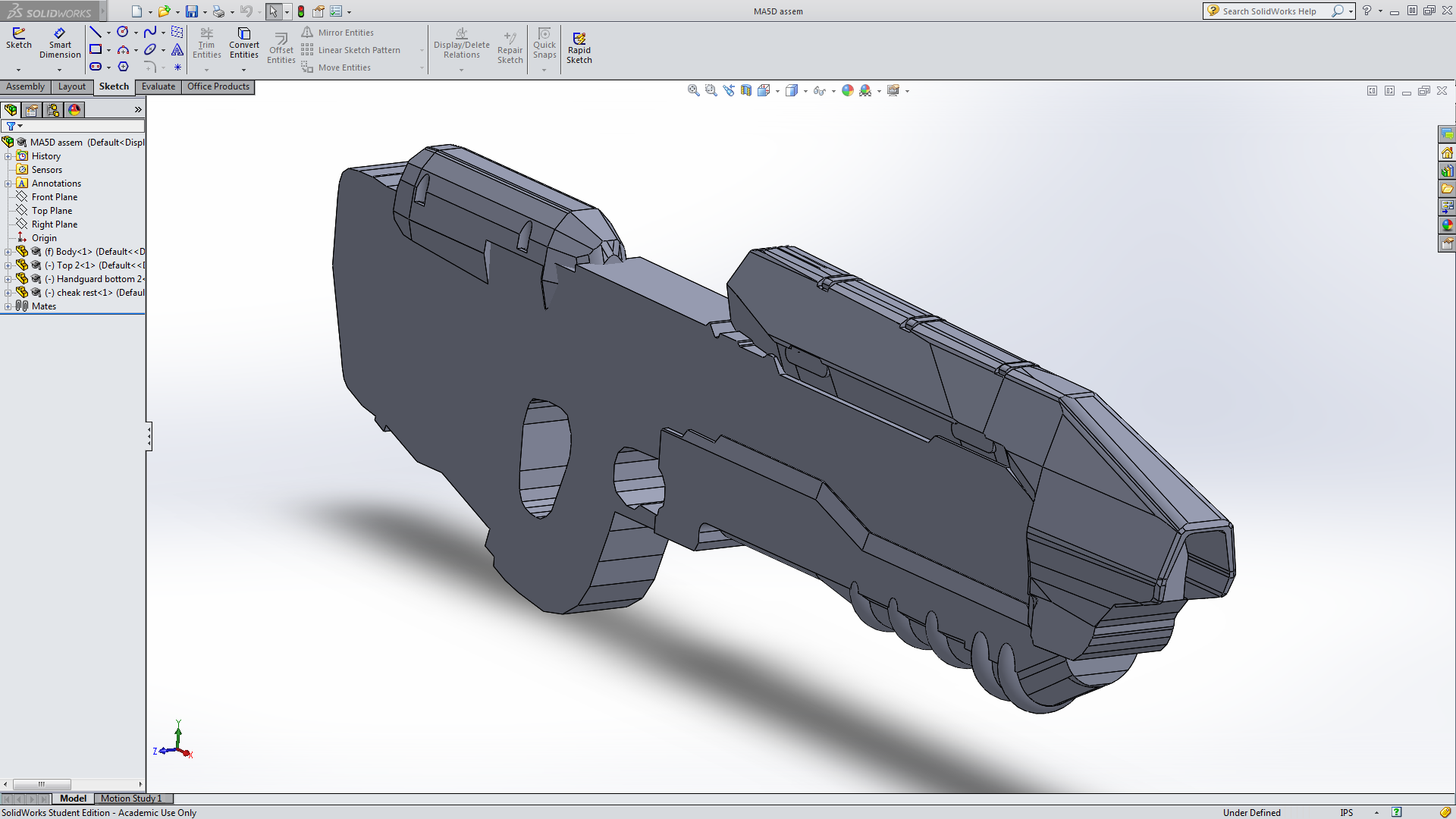

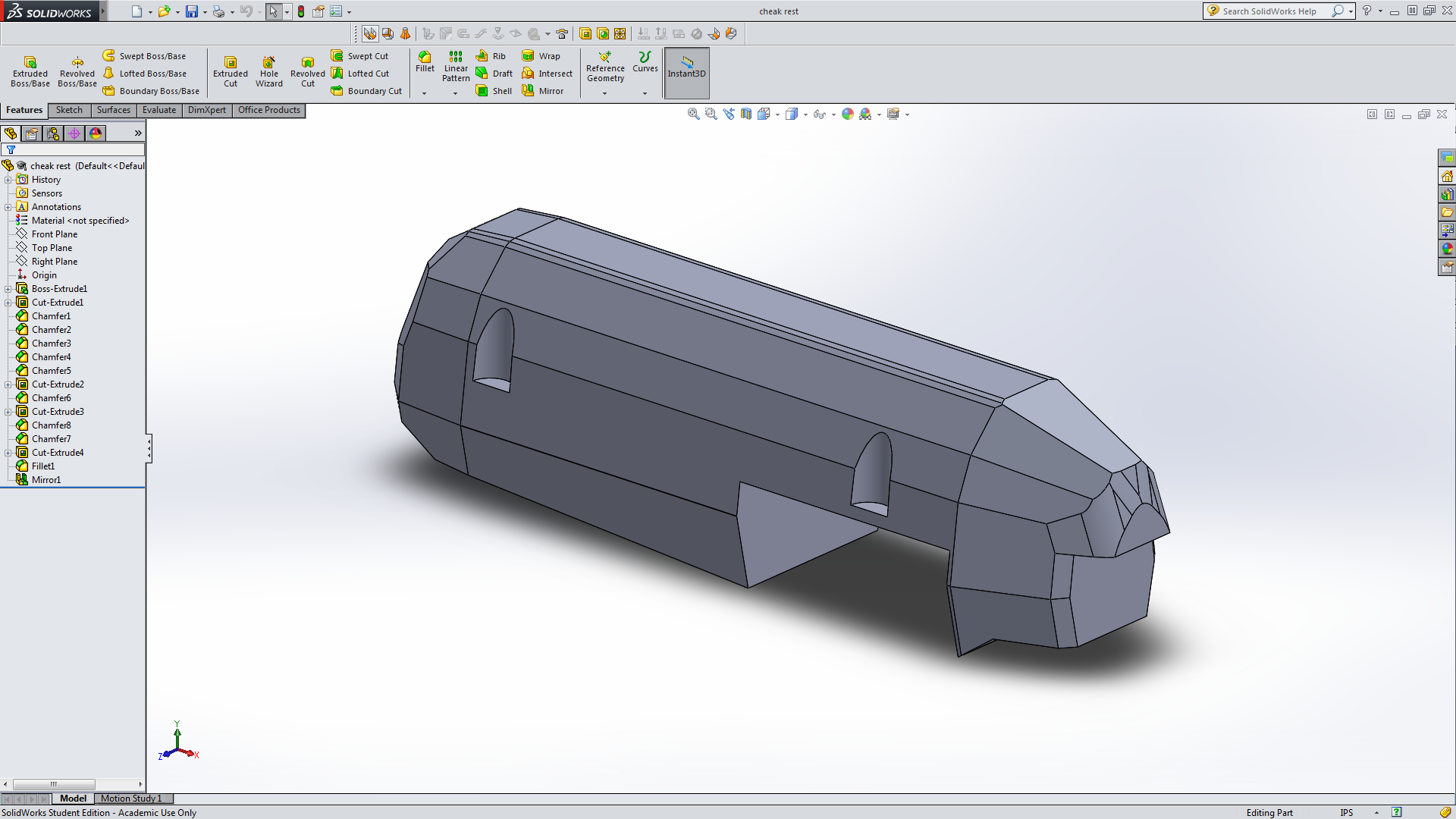

Over the past couple of months, I have been working on building CAD assemblies of several UNSC weapons in Solidworks. I've started on the Halo 4 Battle Rifle and Halo 4 Assault Rifle which I'll attach pics of in a sec.

Basically, the intent is to design the external shape of the guns, and then start creating cavities on the insides for electric airsoft components such as the gearbox, motor, etc. as well as to make the magazines function as they should in their bullpup form. They will also have functioning charging handles and whatnot. The parts will then be machined from aluminum and assembled into functioning airsoft guns. The first and only ones of their kind in the world.

So while the .50 was being machined, I started working on the BR and AR designs.

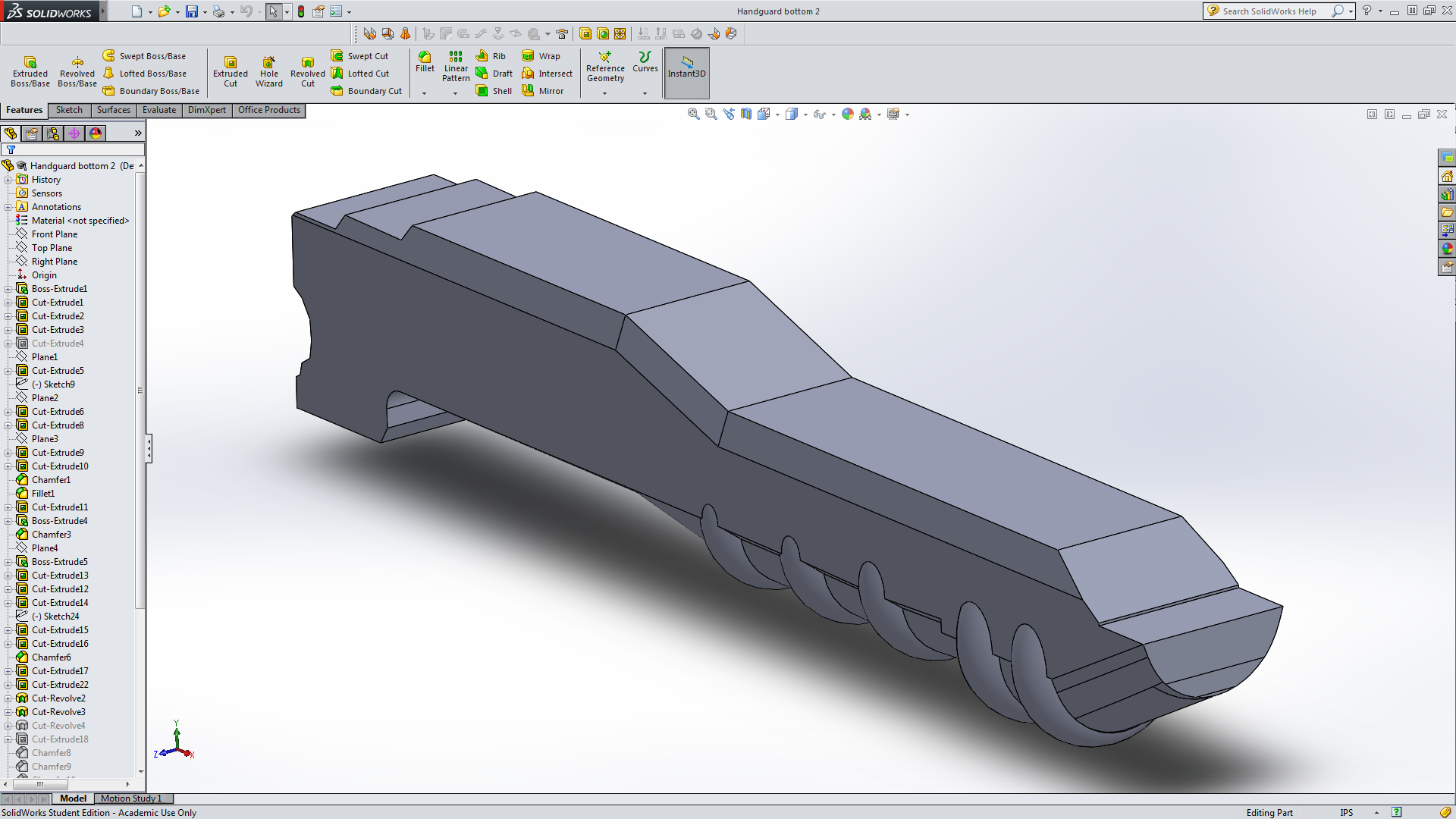

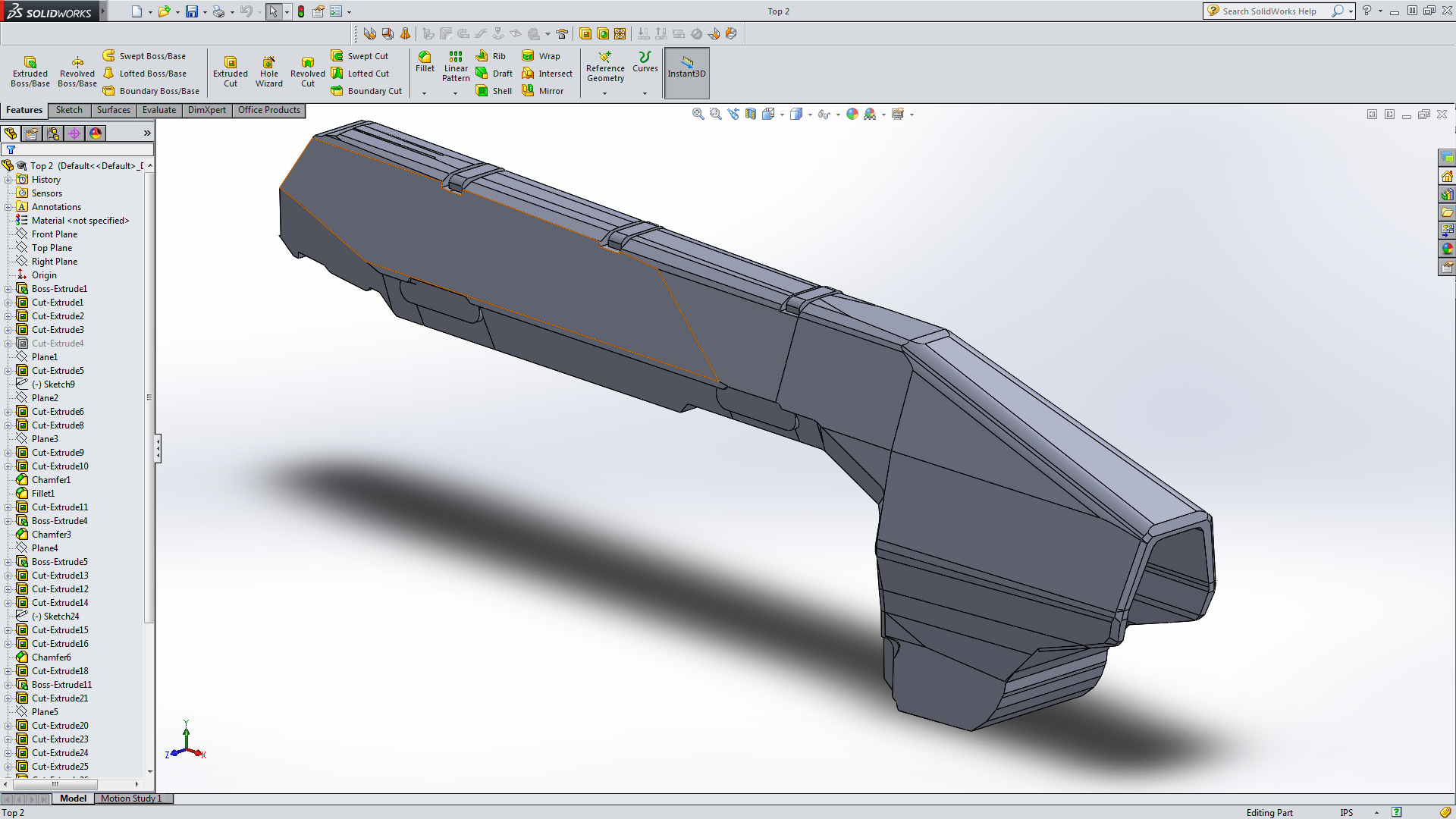

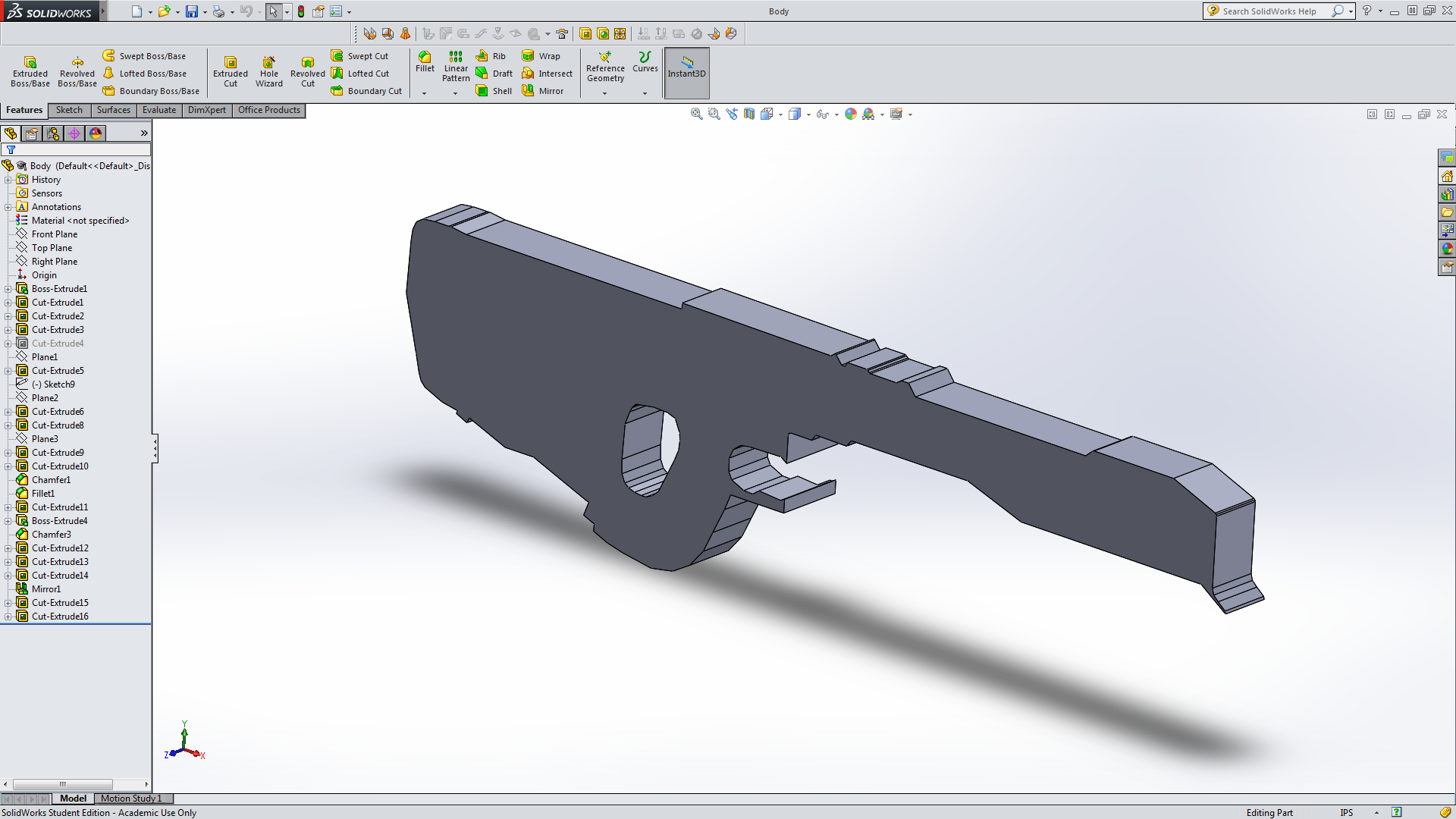

The BR is made up of a bunch of different parts at the moment, and more will be added as i start adding the airsoft guts.

Not fully done with that guy yet. And the grip is kind of a bastard so I took a break from that for a while and started on the AR. This one isn't as flushed out as much as the BR yet.

But I'm definitely looking forward to getting these made.

Now, here's the best part of it all.

My buddy and I were also talking about making the sniper rifle from Halo 3. However, we were going to throw a twist on it and make it a gas blowback rifle. If you don't know what gas blowback means, it's basically where the airsoft gun functions exactly like a real steel rifle, but only fires airsoft bbs from a magazine. (still confused? this oughtta help:

).

He didn't have time to work on the SR, so I offered to take it over this spring. At my college, there is a course that I can take which is an independent design course for seniors. I pitched the project to one of my professors, and I received permission to design and machine this piece of awesomeness!

And the best part is that I'll be receiving credit for this project. Woo hoo! Can't get any better than that.

I'll keep this up to date and hopefully have weekly postings once the new semester starts. I'll be starting on this over the winter break as well so I'll post updates from that.

Below is the project description if you want to get a better idea on how the gas system works on a gbb rifle as well as some design intentions. (Oh yeah, and I'm going to try to make a working scope display as well. Wouldn't be a sniper without a scope right? haha)

The project that our group would work on is to build a green gas powered airsoft replica from the Halo 3 video game. The intent is to use an object file taken from the videogame and use it as a reference to build a scale model of the SRS99D-S2 AM from Halo 3 from assemblies constructed using a CAD package.

Internal gas-powered internal components will also be measured and modeled in the CAD package. Cavities and mounting points will be cut and finite element methods applied to the mounts to ensure structural integrity under shear and impact loading. The parts will then be machined from aluminum and the components installed and tested to determine functionality. Alignment is critical for components as mis-alignment will keep the replica from firing or cause the gas to not be directed into the inlet in the piston which will prevent proper cycling of the bolt.

WE Tech M4 gas piston assembly. Location 1 shows the inlet gas port. Point 2 shows the feed pin which strips bb’s from the magazine and feeds them into the hop-up unit.

The complete bolt carrier group with the piston installed.

Hop-up assembly showing the feed ramp, inlet area, and alignment ports.

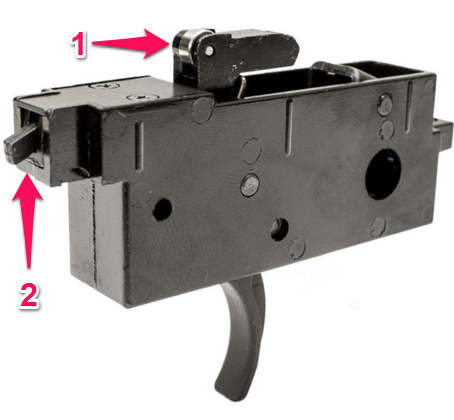

When the trigger is pulled, the hammer (Point 1) in the following figure, strikes a carriage assembly (Point 2) which presses a pin connected to the gas release valve on the magazine releasing a short burst of green gas or propane.

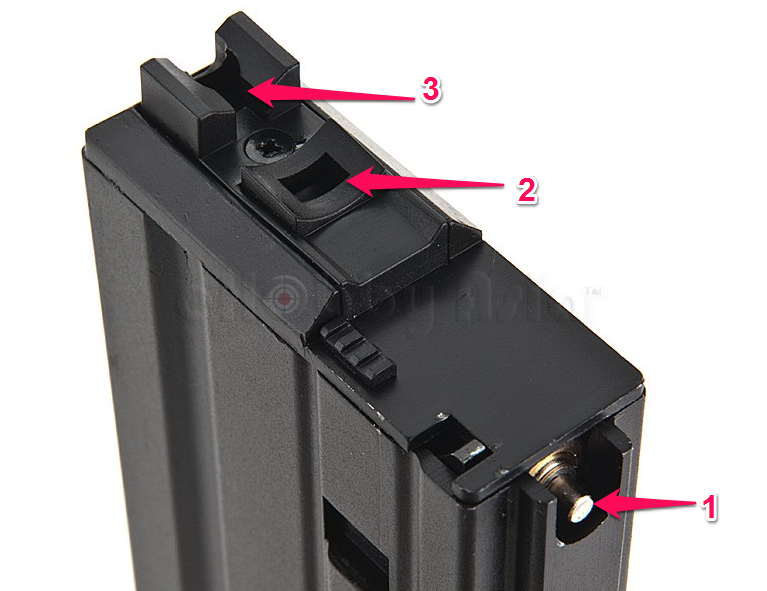

Standard M4 gas magazine. Point 1 is the pin connected to the gas release valve. Point 2 shows where the gas escapes into the piston. Point 3 is the keeper for the bb’s which will be fed into the hop-up unit.

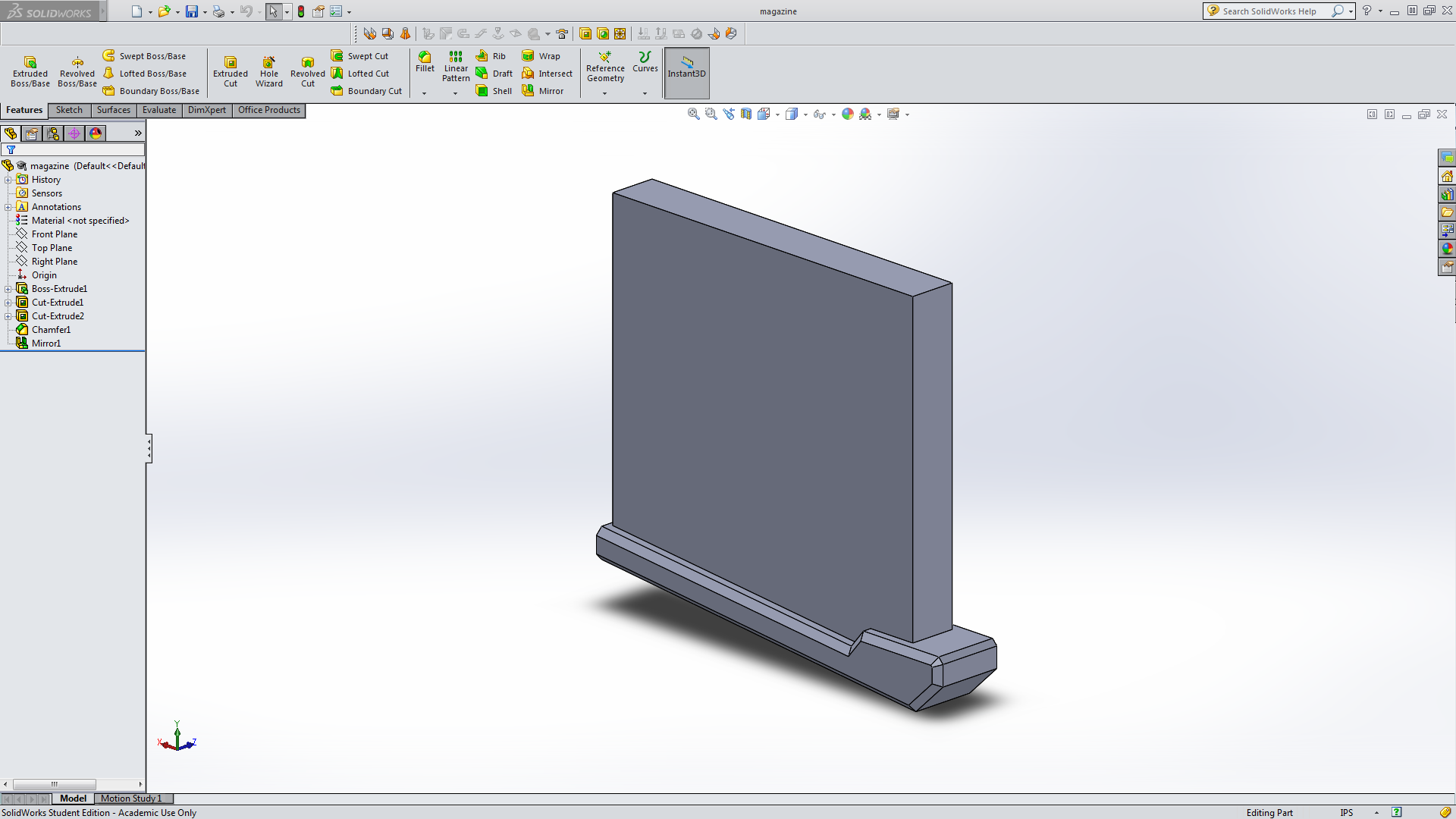

Aside from designing the replica to hold the manufactured/purchased parts in proper alignment, custom designing will be necessary to make all parts cooperate in the new body. An extended pin will need to be designed and placed in-between the trigger box and airsoft magazine so that the gas is released with every trigger pull. The replica magazine will need to be designed to lock into the body when inserted. This will be done with a spring-loaded retention pin connected to the body. When the magazine is inserted, the pin will then sit in a well in the magazine. A bolt-return system will need to be designed to take the impact force of the bolt carrier group and return it into battery without damaging the replica or the internal components. In addition, the bipod legs will be functional, and the charging handle will operate the bolt and reciprocate with the bolt carrier group after each trigger pull.

The projected market for the airsoft SRS99D-S2 AM would be decently large. As an industry on its own, Airsoft has grown rapidly as a sport around the world. With new developments in safety and industry standards, as well as licensing with firearms manufacturers such as Colt, Barrett, Heckler and Koch, etc. replica airsoft arms have made the sport safer and more popular. Evike, an airsoft distributor in California manufactured a short set of replica airsoft rifles based on the Halo 1 MA5B in 2014. The replica was in high demand and retains its resale value very well. Similarly, costume play (cosplay) has grown over the past years into a dedicated hobby enjoyed by many such as the 405th Infantry Division, a group of custom costume and prop makers who share a passion of building full scale Halo replicas. These two groups, in addition to the numerous physical persons who I have shared my current project of designing other Halo airsoft replicas (see below) would create a high demand for this product (in addition to the commission requests received in years past for my work in this field). To see early prototype stages of work I’ve done in this field, see: 405th - Halo Costuming . The post has received thousands of views and much support over the past years.

The above BR85 Heavy Barrel Service Rifle and the MA5D Individual Combat Weapon System are works in progress and will be designed to use electrical components so that the SRS99D-S2 AM will remain a unique project for the MMAE 494 course.

NOTE:

Of important note (since I do not know the final product requirements for the course), if this project needs to be brought in, internal components will be removed so that it is non-functional in compliance with IIT policy and will only be a physical video game prop which is allowed on campus.

Current Progress:

View media item 2549

I'm back!

Alright, I wanted to save this until I officially go the green light for this project.

Roughly six months ago, I started working on building an assembly in Solidworks of an M2 .50 Cal machinegun as a couple of friends and I wanted to turn out some airsoft .50's and that'd be freakin' sweet. Right?!

Well, I finished that in a matter of days. Here's the final design:

And we've started to machine parts out out of plate aluminum. Here's one of the receiver bodies (we're making 3 of these in total):

Over the past couple of months, I have been working on building CAD assemblies of several UNSC weapons in Solidworks. I've started on the Halo 4 Battle Rifle and Halo 4 Assault Rifle which I'll attach pics of in a sec.

Basically, the intent is to design the external shape of the guns, and then start creating cavities on the insides for electric airsoft components such as the gearbox, motor, etc. as well as to make the magazines function as they should in their bullpup form. They will also have functioning charging handles and whatnot. The parts will then be machined from aluminum and assembled into functioning airsoft guns. The first and only ones of their kind in the world.

So while the .50 was being machined, I started working on the BR and AR designs.

The BR is made up of a bunch of different parts at the moment, and more will be added as i start adding the airsoft guts.

Not fully done with that guy yet. And the grip is kind of a bastard so I took a break from that for a while and started on the AR. This one isn't as flushed out as much as the BR yet.

But I'm definitely looking forward to getting these made.

Now, here's the best part of it all.

My buddy and I were also talking about making the sniper rifle from Halo 3. However, we were going to throw a twist on it and make it a gas blowback rifle. If you don't know what gas blowback means, it's basically where the airsoft gun functions exactly like a real steel rifle, but only fires airsoft bbs from a magazine. (still confused? this oughtta help:

He didn't have time to work on the SR, so I offered to take it over this spring. At my college, there is a course that I can take which is an independent design course for seniors. I pitched the project to one of my professors, and I received permission to design and machine this piece of awesomeness!

And the best part is that I'll be receiving credit for this project. Woo hoo! Can't get any better than that.

I'll keep this up to date and hopefully have weekly postings once the new semester starts. I'll be starting on this over the winter break as well so I'll post updates from that.

Below is the project description if you want to get a better idea on how the gas system works on a gbb rifle as well as some design intentions. (Oh yeah, and I'm going to try to make a working scope display as well. Wouldn't be a sniper without a scope right? haha)

The project that our group would work on is to build a green gas powered airsoft replica from the Halo 3 video game. The intent is to use an object file taken from the videogame and use it as a reference to build a scale model of the SRS99D-S2 AM from Halo 3 from assemblies constructed using a CAD package.

Internal gas-powered internal components will also be measured and modeled in the CAD package. Cavities and mounting points will be cut and finite element methods applied to the mounts to ensure structural integrity under shear and impact loading. The parts will then be machined from aluminum and the components installed and tested to determine functionality. Alignment is critical for components as mis-alignment will keep the replica from firing or cause the gas to not be directed into the inlet in the piston which will prevent proper cycling of the bolt.

WE Tech M4 gas piston assembly. Location 1 shows the inlet gas port. Point 2 shows the feed pin which strips bb’s from the magazine and feeds them into the hop-up unit.

The complete bolt carrier group with the piston installed.

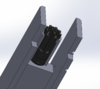

Hop-up assembly showing the feed ramp, inlet area, and alignment ports.

When the trigger is pulled, the hammer (Point 1) in the following figure, strikes a carriage assembly (Point 2) which presses a pin connected to the gas release valve on the magazine releasing a short burst of green gas or propane.

Standard M4 gas magazine. Point 1 is the pin connected to the gas release valve. Point 2 shows where the gas escapes into the piston. Point 3 is the keeper for the bb’s which will be fed into the hop-up unit.

Aside from designing the replica to hold the manufactured/purchased parts in proper alignment, custom designing will be necessary to make all parts cooperate in the new body. An extended pin will need to be designed and placed in-between the trigger box and airsoft magazine so that the gas is released with every trigger pull. The replica magazine will need to be designed to lock into the body when inserted. This will be done with a spring-loaded retention pin connected to the body. When the magazine is inserted, the pin will then sit in a well in the magazine. A bolt-return system will need to be designed to take the impact force of the bolt carrier group and return it into battery without damaging the replica or the internal components. In addition, the bipod legs will be functional, and the charging handle will operate the bolt and reciprocate with the bolt carrier group after each trigger pull.

The projected market for the airsoft SRS99D-S2 AM would be decently large. As an industry on its own, Airsoft has grown rapidly as a sport around the world. With new developments in safety and industry standards, as well as licensing with firearms manufacturers such as Colt, Barrett, Heckler and Koch, etc. replica airsoft arms have made the sport safer and more popular. Evike, an airsoft distributor in California manufactured a short set of replica airsoft rifles based on the Halo 1 MA5B in 2014. The replica was in high demand and retains its resale value very well. Similarly, costume play (cosplay) has grown over the past years into a dedicated hobby enjoyed by many such as the 405th Infantry Division, a group of custom costume and prop makers who share a passion of building full scale Halo replicas. These two groups, in addition to the numerous physical persons who I have shared my current project of designing other Halo airsoft replicas (see below) would create a high demand for this product (in addition to the commission requests received in years past for my work in this field). To see early prototype stages of work I’ve done in this field, see: 405th - Halo Costuming . The post has received thousands of views and much support over the past years.

The above BR85 Heavy Barrel Service Rifle and the MA5D Individual Combat Weapon System are works in progress and will be designed to use electrical components so that the SRS99D-S2 AM will remain a unique project for the MMAE 494 course.

NOTE:

Of important note (since I do not know the final product requirements for the course), if this project needs to be brought in, internal components will be removed so that it is non-functional in compliance with IIT policy and will only be a physical video game prop which is allowed on campus.

Last edited by a moderator: