- Member DIN

- S505

I initially had no plans to document this build due to how rushed it will be and the overall nature of the build, but some stuff came up that I felt was interesting enough to document and could be helpful to others. I will also be trying a new post processing technique for 3d printing on thus build.

Some more background. A bit over a year ago, I created a life sized kanohi kraahkan from Bionicle as a commission for Essenger, an electronic music artist. Flash forward to a few days ago. Essenger was returning from the first half of his current tour when his tour van caught on fire. He and his friend were able to get out of the van, then the van exploded. Everything was lost from music equipment to personal items, including the mask. This 2nd mask is a gift, rather than a commission, to help Essenger recover what he can. My goal is to try to get this mask done and shipped out to him before he leaves for the 2nd half of his tour. Worst case, he still gets the mask back at some point.

Now for what I wanted to document. About 53.5 hours into 3d printing this mask, I noticed one of the supports kept getting hit and knocked around. When taking a closer look, I could see the nozzle was randomly extruding mid air where there were no supports. The extra extruded material was sticking to the nozzle, then hitting and whipping off on the supports, causing lumps and potentially support failure.

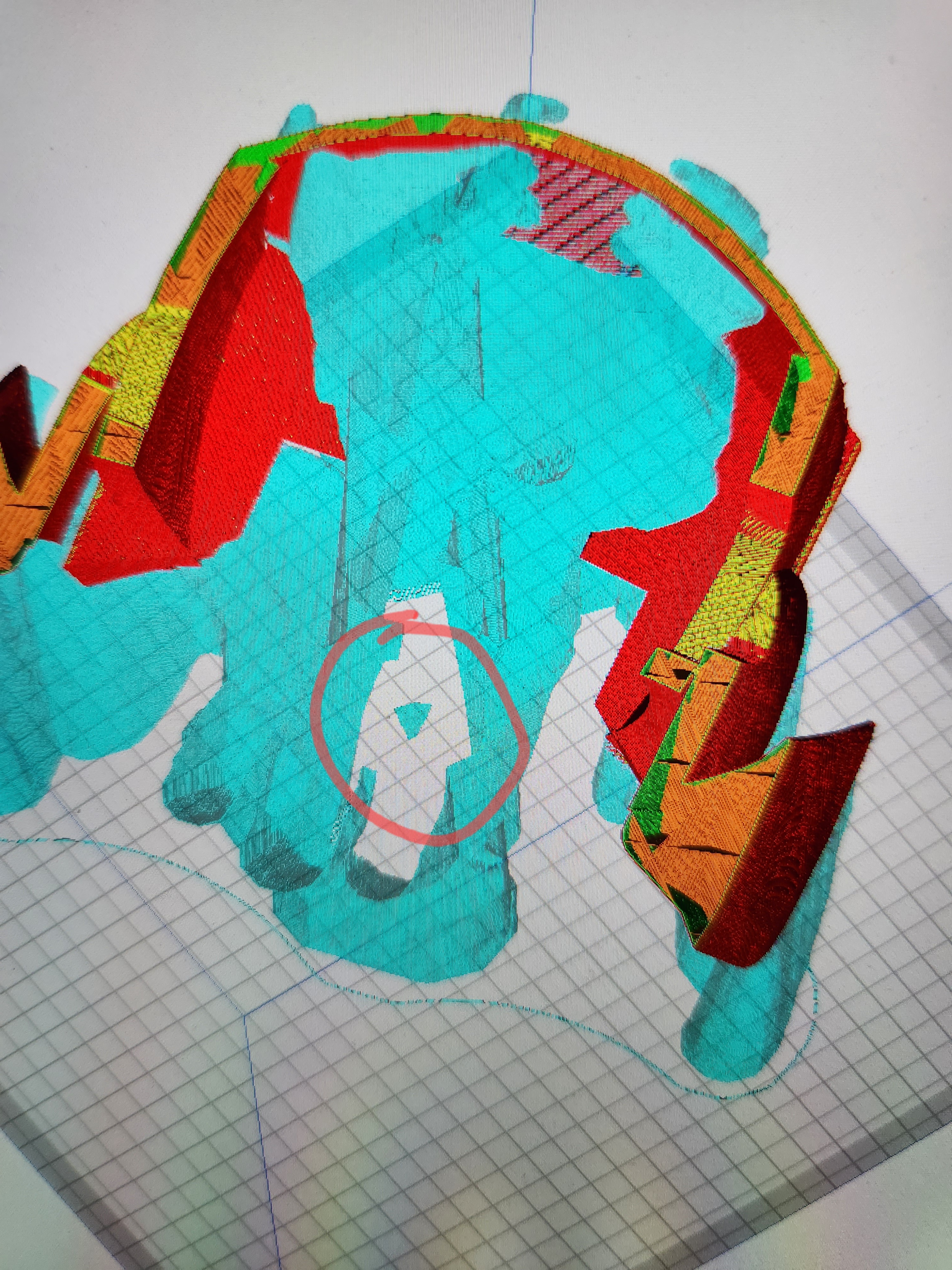

I pulled up the gcode and found there is a support structure that starts mid air on this print.

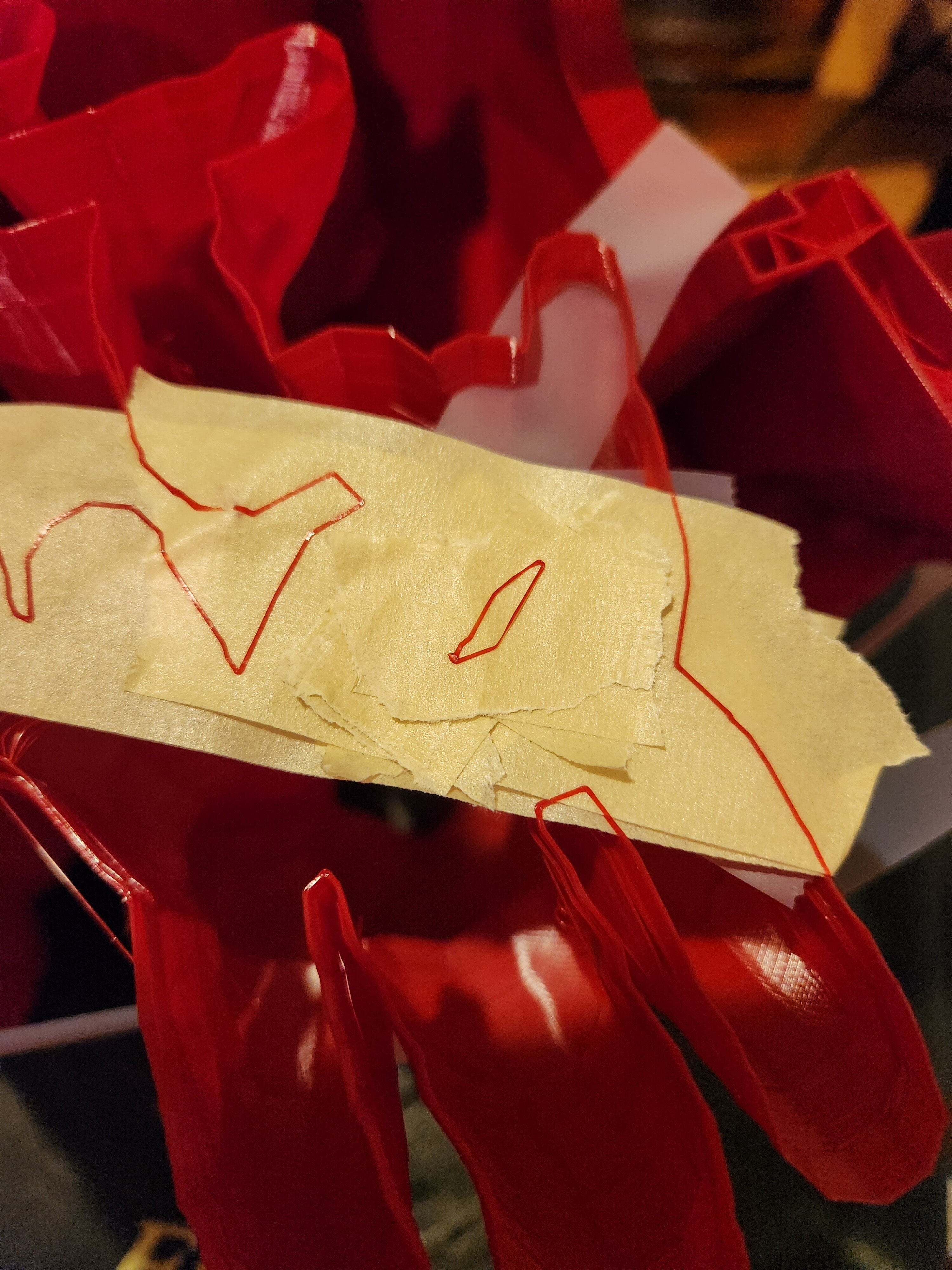

This print takes about 760g and due to the time crunch of this project, restarting with new code is not an option. With no way to change the code mid print and prevent material from extruding, I had to find a way for the extra material to not get in the way. I decided to try making a surface for the extra support to start building itself on. If the support actually builds up, then the extra material would not be knocked into the other supports. I used masking tape to build a bridge across the other supports, which would be removed when the print is done, so there is no damage to the actual part. I chose masking tape specifically because it is commonly used for adhesions on 3d pri ting beds. I had to stack some layers of tape to get it level with the current layer.

About an hour later and the support continued to build itself and its been smooth printing from here.

Some more background. A bit over a year ago, I created a life sized kanohi kraahkan from Bionicle as a commission for Essenger, an electronic music artist. Flash forward to a few days ago. Essenger was returning from the first half of his current tour when his tour van caught on fire. He and his friend were able to get out of the van, then the van exploded. Everything was lost from music equipment to personal items, including the mask. This 2nd mask is a gift, rather than a commission, to help Essenger recover what he can. My goal is to try to get this mask done and shipped out to him before he leaves for the 2nd half of his tour. Worst case, he still gets the mask back at some point.

Now for what I wanted to document. About 53.5 hours into 3d printing this mask, I noticed one of the supports kept getting hit and knocked around. When taking a closer look, I could see the nozzle was randomly extruding mid air where there were no supports. The extra extruded material was sticking to the nozzle, then hitting and whipping off on the supports, causing lumps and potentially support failure.

I pulled up the gcode and found there is a support structure that starts mid air on this print.

This print takes about 760g and due to the time crunch of this project, restarting with new code is not an option. With no way to change the code mid print and prevent material from extruding, I had to find a way for the extra material to not get in the way. I decided to try making a surface for the extra support to start building itself on. If the support actually builds up, then the extra material would not be knocked into the other supports. I used masking tape to build a bridge across the other supports, which would be removed when the print is done, so there is no damage to the actual part. I chose masking tape specifically because it is commonly used for adhesions on 3d pri ting beds. I had to stack some layers of tape to get it level with the current layer.

About an hour later and the support continued to build itself and its been smooth printing from here.