- Member DIN

- S2424

Greetings my fellow 4045th-ers.....Seeing as I have competition.....Kusak3 is currently building the same weapon......I chose to use my all time favorite building material......FOAM-BOARD!!!! You guys must be sick of me w/ this stuff already..........But we press onward.....

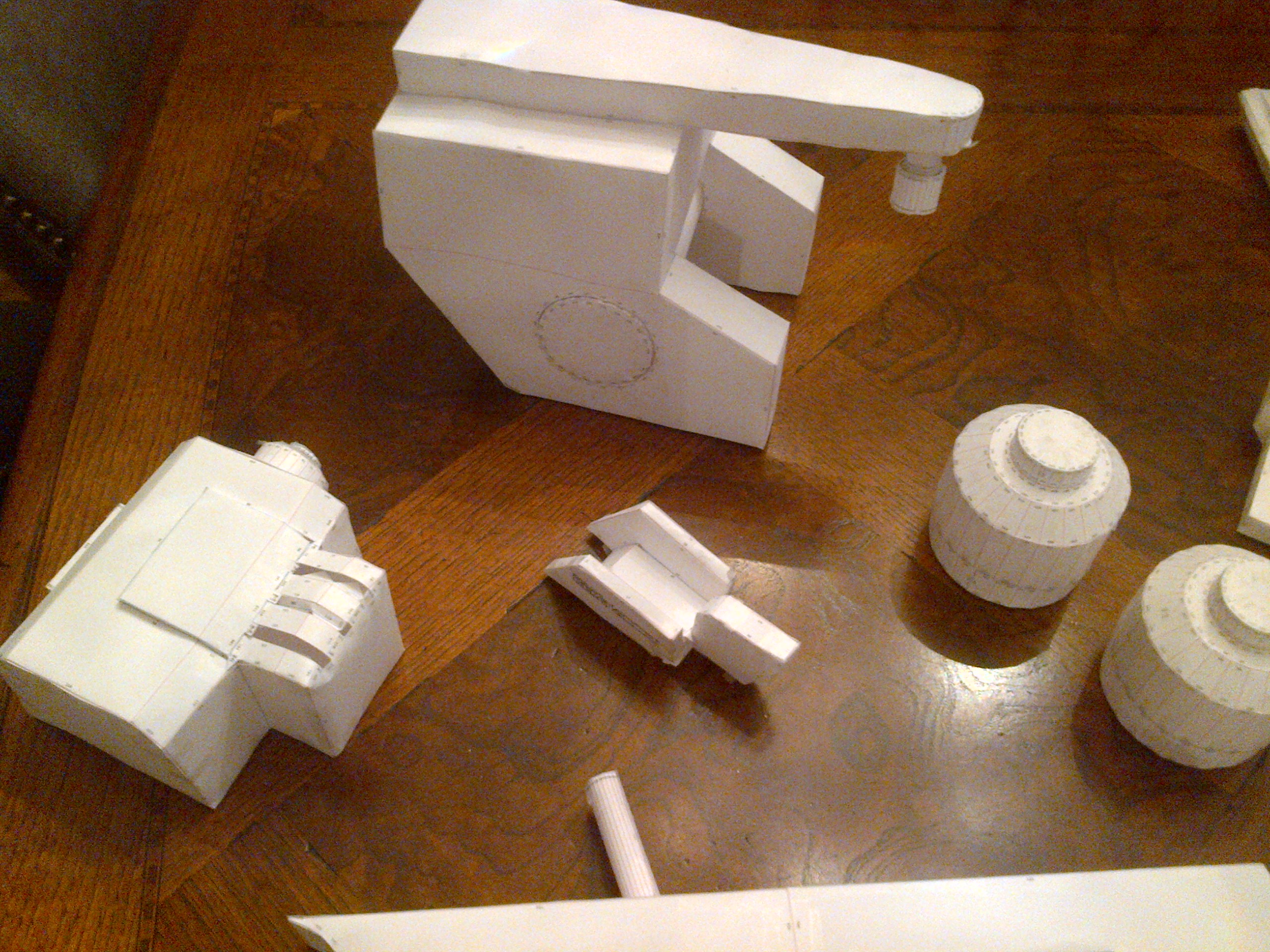

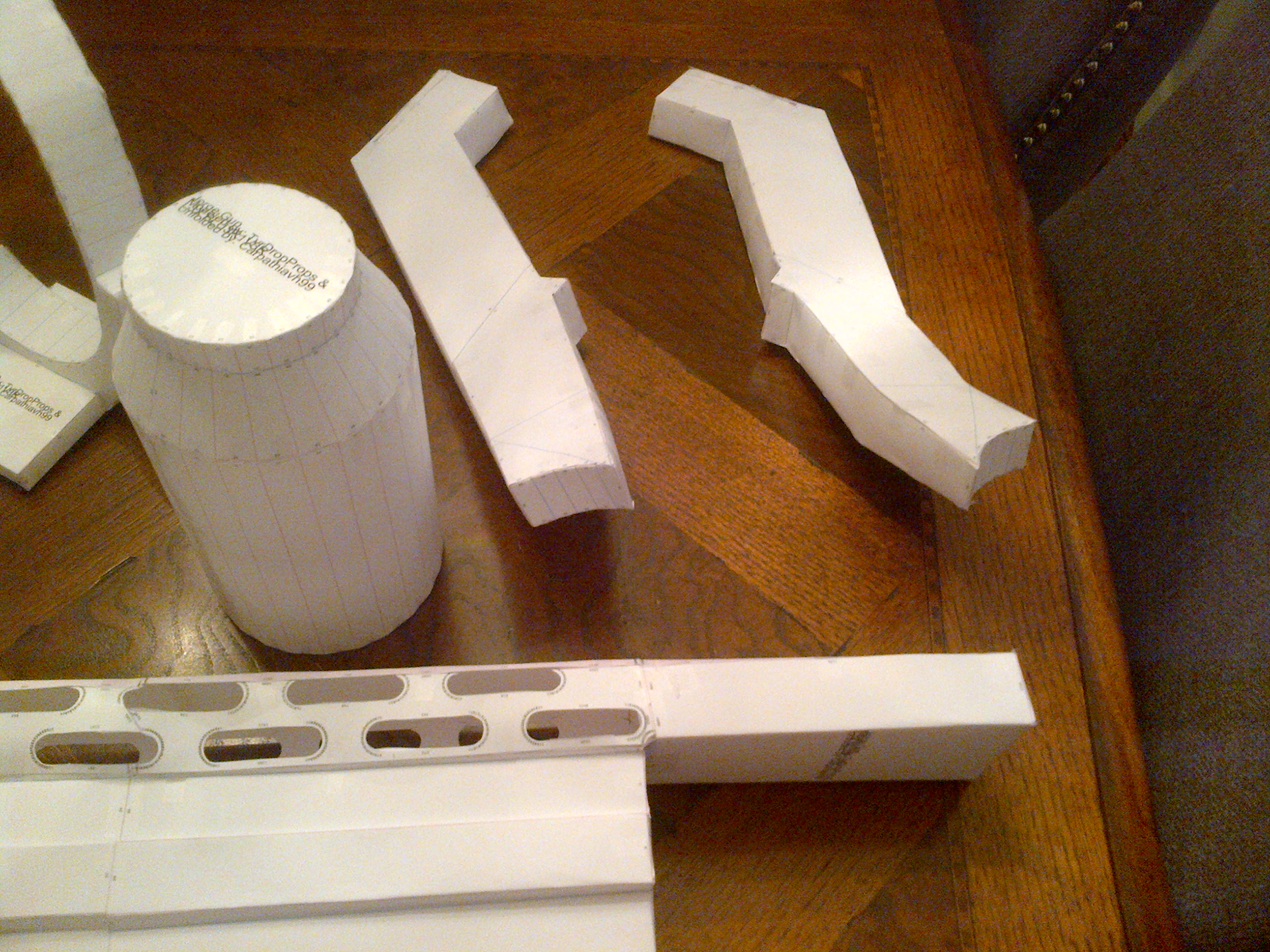

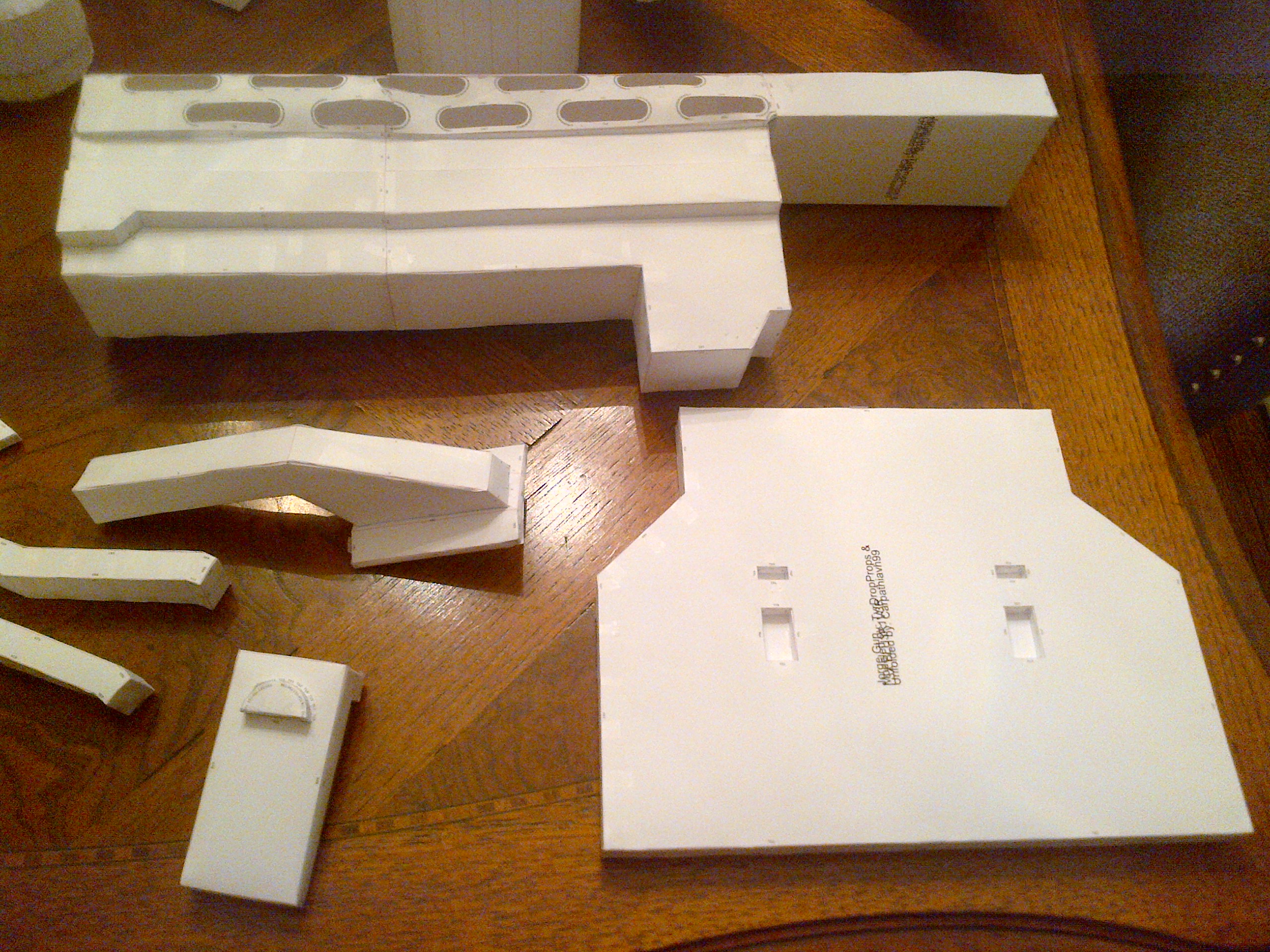

I have all the files printed out and have begun assembly of my test pieces first..........Why you ask? Well for one thing.......I don't know how large this thing is going to be. Second, using FB will require recalculations on each piece to ensure an accurate fit when all the individual pieces are assembled together. And lastly, I need to know if FB is a good material on certain pieces. It would be very hard to create a cylinder shape out of FB w/o messing up the circumference needed. So that being said.....let's look as some test pieces:

There as still plenty of pieces left to build but so far so good. I'm using 90lb paper (The thickest my personal printer can handle, work one can take the 110lb) and just scotch taping everything. Don't want to waste my good 110lb on this and regular printer paper is way too thin so I found something in between. Since I haven't decided which pieces can and cannot be FB....I'm just assembling "Loosely" to start. The pieces that I feel can't be FBed I will most probably reprint w/ the 110lb and fiberglass it.

Already I see which pieces can and cannot, so once I finish assembling each individual test piece, I'll start FBing it up.

I was also thinking that because it will be so light in weight that I would fill it w/ expanding foam in the dead spaces to "Beef" it up a bit.

That's all for now folks, I'll post next when I finish all my pieces and start in w/ the FB.

I have all the files printed out and have begun assembly of my test pieces first..........Why you ask? Well for one thing.......I don't know how large this thing is going to be. Second, using FB will require recalculations on each piece to ensure an accurate fit when all the individual pieces are assembled together. And lastly, I need to know if FB is a good material on certain pieces. It would be very hard to create a cylinder shape out of FB w/o messing up the circumference needed. So that being said.....let's look as some test pieces:

There as still plenty of pieces left to build but so far so good. I'm using 90lb paper (The thickest my personal printer can handle, work one can take the 110lb) and just scotch taping everything. Don't want to waste my good 110lb on this and regular printer paper is way too thin so I found something in between. Since I haven't decided which pieces can and cannot be FB....I'm just assembling "Loosely" to start. The pieces that I feel can't be FBed I will most probably reprint w/ the 110lb and fiberglass it.

Already I see which pieces can and cannot, so once I finish assembling each individual test piece, I'll start FBing it up.

I was also thinking that because it will be so light in weight that I would fill it w/ expanding foam in the dead spaces to "Beef" it up a bit.

That's all for now folks, I'll post next when I finish all my pieces and start in w/ the FB.

Last edited by a moderator: