- Member DIN

- S530

I have been on here a long time, but i haven't completed a halo costume since 2012, which is disappointing. So i thought I would try my hand at foam. I want to document the whole build from start to finish, and hopefully we'll get some questions answered along the way.

I will be using the foam templates from the armory unfolded by L3X BLU3R1V3R and the back pieces by RUZE 789.

So here goes...

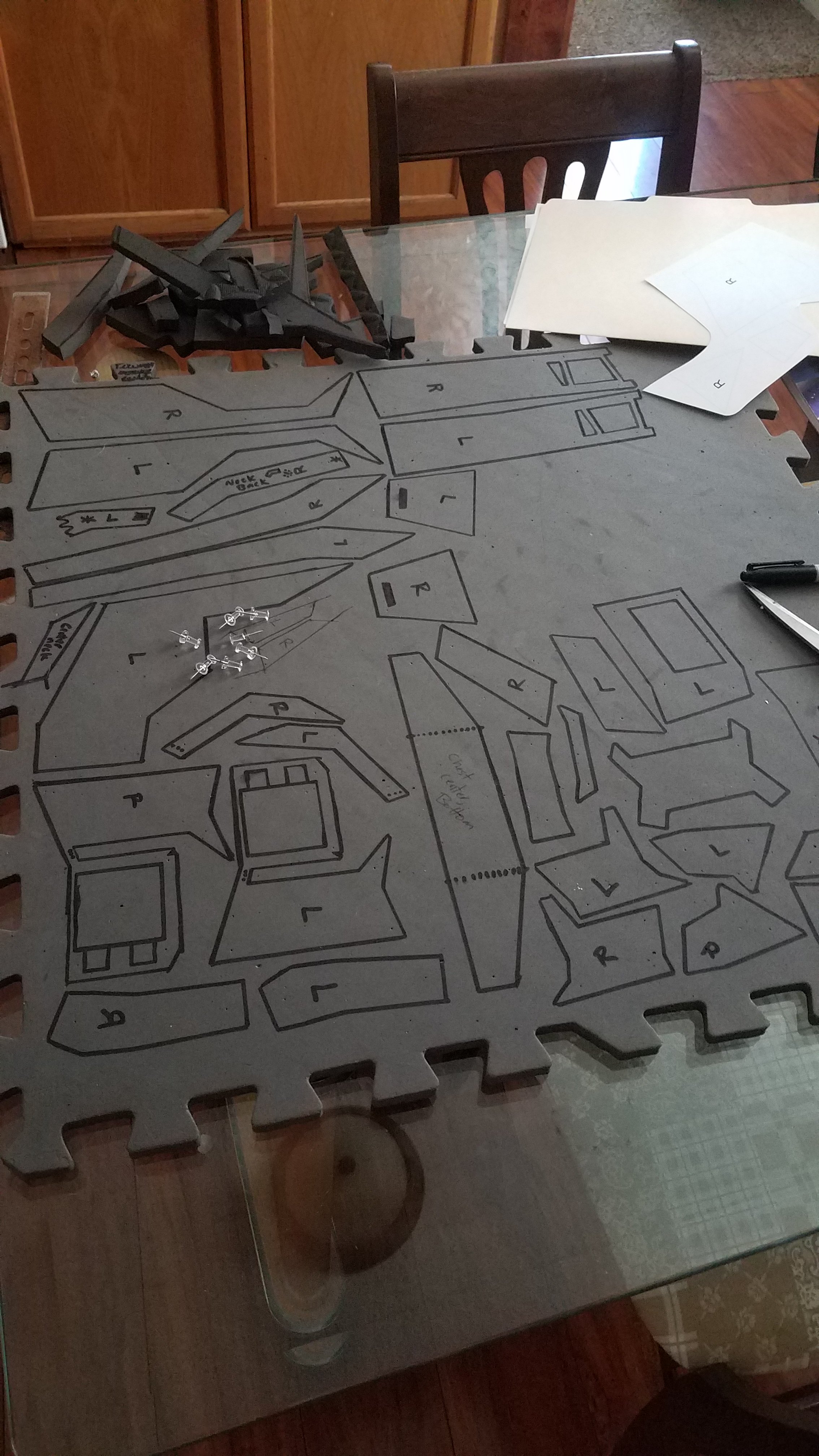

Getting the templates cut out:

I will be using the foam templates from the armory unfolded by L3X BLU3R1V3R and the back pieces by RUZE 789.

So here goes...

Getting the templates cut out: