Hey guys! I'd like to show off one of my more recent projects here. It's been a long time in the making, as I haven't actually worked on it since December, but I'm hoping to finish it before August.

A little while back I got the crazy idea to make a custom airsoft rifle, a replica of the VSS Vintorez sniper rifle. It turned out fairly well, and I became drunk with power. As an avid airsofter and a huge fan of science fiction, the world had opened up to me and there was no limit to what I could do, save for my own creativity and motivation. Both of those have proben to be troublesome, but we'll ignore that part for now.

I decided I wanted to build a field-worthy, modular, fully functional and fully upgradeable BR55-HB battle rifle for use in airsoft, and I'll explain to you how I went about doing it.

First I had to decide on a base gun. I had a lot of factors going into the decision. How much will it cost? Can I get upgradeable and replacement parts for the innards? What's it made of, and can I work with the material?

My first idea was to use a plastic-bodied FAMAS rifle, but the reason I avoided this was twofold. For one, the FAMAS has a very complicated shape and would be difficult to fuse plastic plate to, Second, the design is so old that nobody makes replacement parts or magazines for it anymore, which means that I wouldn't be able to service my creation after building it.

I settled on an inexpensive Steyr AUG Civilian model rifle that featured select-fire capability, a modular gearbox, and plentiful aftermarket magazines to play with.

Stock photo for reference:

The BR55 for comparison:

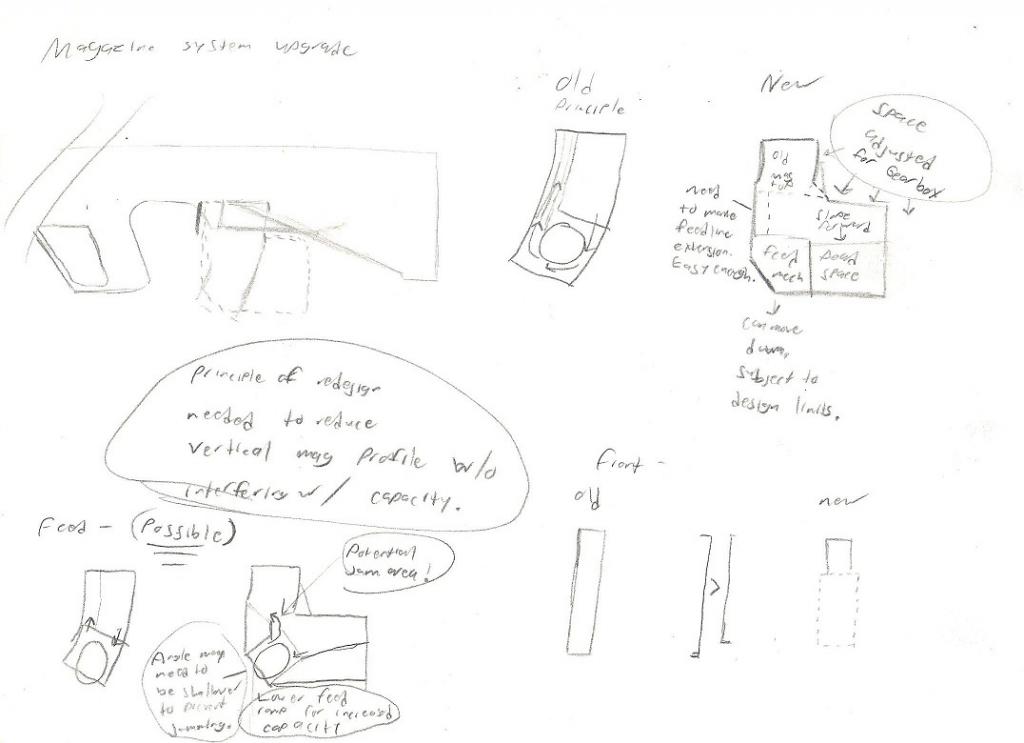

The first step was to draw out some concept work. Most of this didn't end up getting used, as it would have badly interfered with the way the magazine release works with the magazine. I'm leery to make a mechanical part like this, just yet, due to issues with the precision of my tools.

It helps to have an idea before you start, even if that idea changes.

The next step was to take and hacksaw off any part that I didn't need or want, in order to streamline the build process.

After this was done, I started framing the rear of the receiver and added an extension to the existing magazine release.

When that was done, it was time to start building the cheek rest. SInce this gun is getting knocked around a bit, on the field, I added a bulkhead reinforcement everywhere the build stopped, started, or changed direction.

Then came framing out the sides with flat plate stock, machining out holes with my Dremel to ensure that I'd be able to disassemble the gun again for maintenance or upgrades once I finished.

THen some cosmetic detailing, the siderails in particular, along with some reinforcement to the side of the stock. THis was especially necessary given how much of the original gun I'd just cut away.

Skip ahead a week and I'd begun to build the front half of the gun from scratch, given that there was no base to work from. This proved a bit tricky, but it looks and feels solid at this point.

And as of the end of the last wave of construction, I'd framed out the sides of the front end, cleaned up the interface, and devised a way to attach and remove a foregrip to allow for convenient battery placement inside the gun. At this point the gun is functional, but unfinished cosmetically.

As of this moment in time, I need to make a buttstock, clean up the rear of the carry rail, detail the muzzle and find a barrel extension suitable for my preferred look.

If anyone would like to pursue this option, I'm more than happy to help.

A little while back I got the crazy idea to make a custom airsoft rifle, a replica of the VSS Vintorez sniper rifle. It turned out fairly well, and I became drunk with power. As an avid airsofter and a huge fan of science fiction, the world had opened up to me and there was no limit to what I could do, save for my own creativity and motivation. Both of those have proben to be troublesome, but we'll ignore that part for now.

I decided I wanted to build a field-worthy, modular, fully functional and fully upgradeable BR55-HB battle rifle for use in airsoft, and I'll explain to you how I went about doing it.

First I had to decide on a base gun. I had a lot of factors going into the decision. How much will it cost? Can I get upgradeable and replacement parts for the innards? What's it made of, and can I work with the material?

My first idea was to use a plastic-bodied FAMAS rifle, but the reason I avoided this was twofold. For one, the FAMAS has a very complicated shape and would be difficult to fuse plastic plate to, Second, the design is so old that nobody makes replacement parts or magazines for it anymore, which means that I wouldn't be able to service my creation after building it.

I settled on an inexpensive Steyr AUG Civilian model rifle that featured select-fire capability, a modular gearbox, and plentiful aftermarket magazines to play with.

Stock photo for reference:

The BR55 for comparison:

The first step was to draw out some concept work. Most of this didn't end up getting used, as it would have badly interfered with the way the magazine release works with the magazine. I'm leery to make a mechanical part like this, just yet, due to issues with the precision of my tools.

It helps to have an idea before you start, even if that idea changes.

The next step was to take and hacksaw off any part that I didn't need or want, in order to streamline the build process.

After this was done, I started framing the rear of the receiver and added an extension to the existing magazine release.

When that was done, it was time to start building the cheek rest. SInce this gun is getting knocked around a bit, on the field, I added a bulkhead reinforcement everywhere the build stopped, started, or changed direction.

Then came framing out the sides with flat plate stock, machining out holes with my Dremel to ensure that I'd be able to disassemble the gun again for maintenance or upgrades once I finished.

THen some cosmetic detailing, the siderails in particular, along with some reinforcement to the side of the stock. THis was especially necessary given how much of the original gun I'd just cut away.

Skip ahead a week and I'd begun to build the front half of the gun from scratch, given that there was no base to work from. This proved a bit tricky, but it looks and feels solid at this point.

And as of the end of the last wave of construction, I'd framed out the sides of the front end, cleaned up the interface, and devised a way to attach and remove a foregrip to allow for convenient battery placement inside the gun. At this point the gun is functional, but unfinished cosmetically.

As of this moment in time, I need to make a buttstock, clean up the rear of the carry rail, detail the muzzle and find a barrel extension suitable for my preferred look.

If anyone would like to pursue this option, I'm more than happy to help.