Tigersgrace

Member

Yet another Pep update (i know i work slow)

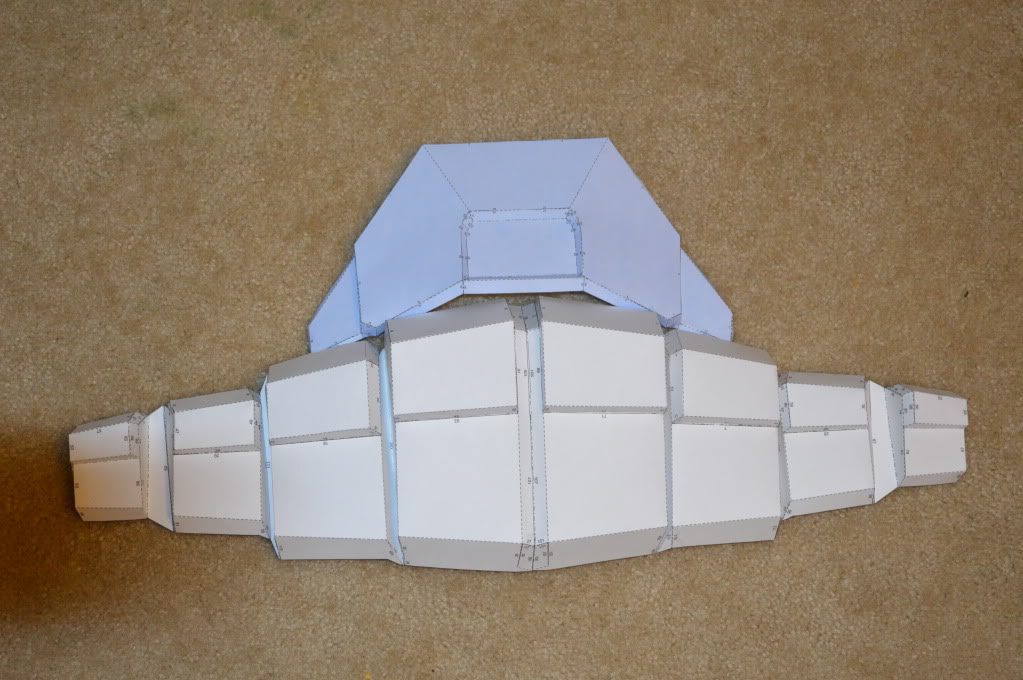

So i've been building the HD Rhinoc MKV ammo belt and ab plate and had some trouble putting the ab plate somewhere. In the reference pics that i have the plate and the belt are not one piece. However, to wear that piece as an individual part would be almost impossibe in my mind. so here's what i came up with.

And the way that i attached them

The idea is to have this brace in 4 places on the back side of the pieces and then after resining and fiberglassing they should be one piece. Then some minor bondo work and they will meld together seamlessly.

So i've been building the HD Rhinoc MKV ammo belt and ab plate and had some trouble putting the ab plate somewhere. In the reference pics that i have the plate and the belt are not one piece. However, to wear that piece as an individual part would be almost impossibe in my mind. so here's what i came up with.

And the way that i attached them

The idea is to have this brace in 4 places on the back side of the pieces and then after resining and fiberglassing they should be one piece. Then some minor bondo work and they will meld together seamlessly.