Xtreme TACTICS 101

Sr Member

Hey everybody!

Well, as I anounced in my MJOLNIR Mk.VI thread, I have put that project on hold. Why? Because Me and my friend who made the bet (Just a refresher-Me and him made a bet that he would pay me $100.00 and buy me Halo 3:ODST if I made a full "Blank" costume by the reliece of Halo 3:ODST) Now, he said a Master Chief costume, BUT, 3 days later he said a ODST costume. I totally forgot about that, and when I had my Torso, Shin, and Thigh all peped, he reminded me. So, here I am today with my new project well under way. The Weta ODST.

For the helmet, I used NZ-TK's original Halo 3 ODST Helmet. Was it suicidal or very hard to build? Not even close. Why? Because I re-unfolded it in a smoother way.

Here it is peped and ready for resin:

Now, right now, I have two coats of resin on it, and I may add a third:

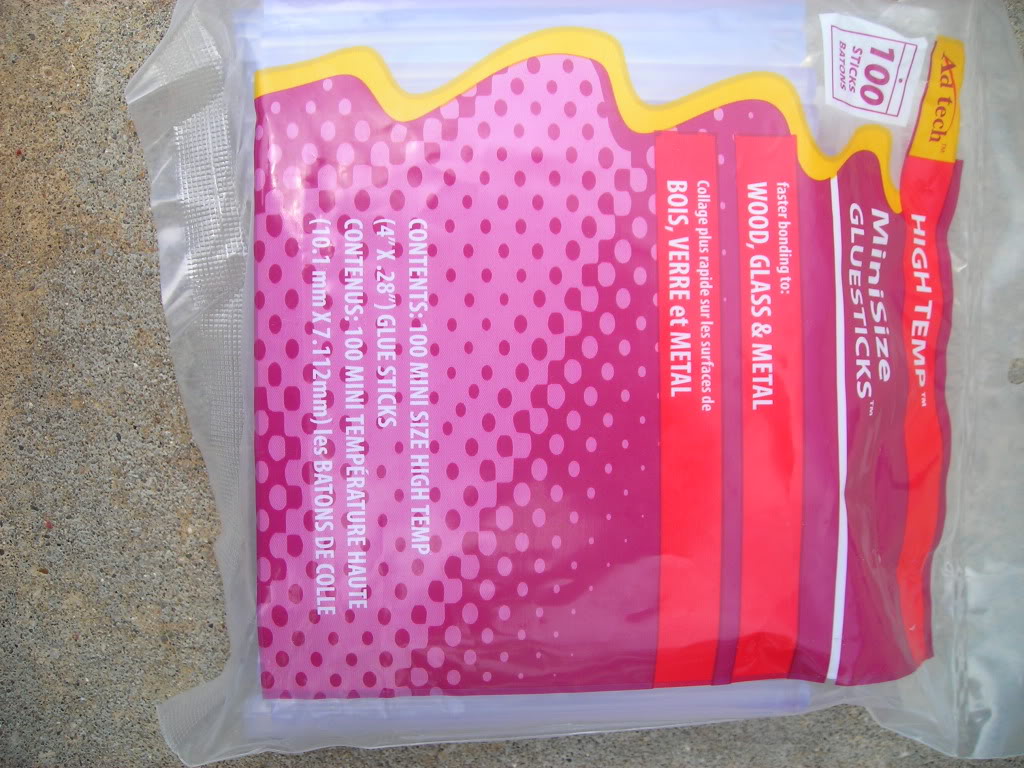

Now, instead of the way everybody does their armour with Fiberglass and Resin, Im taking a differant approach. The Hot Glue Method.

I got about 1000 high temp. Hot Glue sticks for only $50.00!

I also have the Weta Battle Rifle in progress. If you want to check it out, heres the link: "WETA Battle Rifle WIP" Thread.

Well, tell me what you think. I will update soon with more armour peped, the main chest plate resined and the helmet hot glued soon.

Constructive criticism please!

CHEERS!

Well, as I anounced in my MJOLNIR Mk.VI thread, I have put that project on hold. Why? Because Me and my friend who made the bet (Just a refresher-Me and him made a bet that he would pay me $100.00 and buy me Halo 3:ODST if I made a full "Blank" costume by the reliece of Halo 3:ODST) Now, he said a Master Chief costume, BUT, 3 days later he said a ODST costume. I totally forgot about that, and when I had my Torso, Shin, and Thigh all peped, he reminded me. So, here I am today with my new project well under way. The Weta ODST.

For the helmet, I used NZ-TK's original Halo 3 ODST Helmet. Was it suicidal or very hard to build? Not even close. Why? Because I re-unfolded it in a smoother way.

Here it is peped and ready for resin:

Now, right now, I have two coats of resin on it, and I may add a third:

Now, instead of the way everybody does their armour with Fiberglass and Resin, Im taking a differant approach. The Hot Glue Method.

I got about 1000 high temp. Hot Glue sticks for only $50.00!

I also have the Weta Battle Rifle in progress. If you want to check it out, heres the link: "WETA Battle Rifle WIP" Thread.

Well, tell me what you think. I will update soon with more armour peped, the main chest plate resined and the helmet hot glued soon.

Constructive criticism please!

CHEERS!