You used 405mm, correct? I believe mine now are actually 375mm. Just so you know! I don't know how tall you are.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rainbow dash's Mark VI Armor Build

- Thread starter rainbow dash

- Start date

- Status

- Not open for further replies.

rainbow dash

Well-Known Member

Yes, I used 405mm with the warped thighs. I'm 179cm / 5.8 feet / 70.5 inch tall.

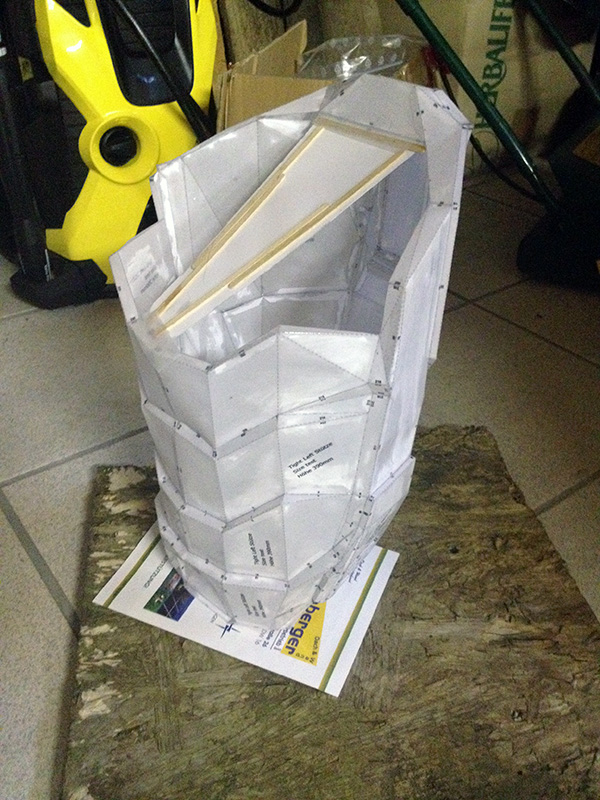

I built a Tester Thigh based on Robogenesis LD model (I know you can't compare that 1:1 to the HD files) with a height of 380. I put it on, and the end at the bottom was really tight. So maybe I'll go with a size beetween 380 and 390mm.

(the new thighs have 390mm)

And because the lower end of the thighs is somewhere loose, could warp easily, but has to perfectly fit my real thigh (the part above the knee) I thought of either

- fixing it really really good with these little wooden support struts etc.

- or resining it while wearing the thighs. I'll resining the upper part first, let it dry, then put on the thigh and do the rest, so it will automatically get the shape I'll need for wearing them.

What do you think?

I built a Tester Thigh based on Robogenesis LD model (I know you can't compare that 1:1 to the HD files) with a height of 380. I put it on, and the end at the bottom was really tight. So maybe I'll go with a size beetween 380 and 390mm.

(the new thighs have 390mm)

And because the lower end of the thighs is somewhere loose, could warp easily, but has to perfectly fit my real thigh (the part above the knee) I thought of either

- fixing it really really good with these little wooden support struts etc.

- or resining it while wearing the thighs. I'll resining the upper part first, let it dry, then put on the thigh and do the rest, so it will automatically get the shape I'll need for wearing them.

What do you think?

rainbow dash

Well-Known Member

I guess it's not the best solution to resin the thighs while wearing them.. for safety reasons.

The dummy idea is a good one.

But now, with the the new support structure from carpathiavh99 this problem is successfully solved.

So, I've been long enough in the pepping stage, I want some results now, so you'll get something finished to see here, and I'll get new motivation.

I decided to finish the helmet. I'm now in the bondo/detailing stage. My question: Do I need a respirator for working with bondo? Do i need one while sanding down the helmet?

The dummy idea is a good one.

But now, with the the new support structure from carpathiavh99 this problem is successfully solved.

So, I've been long enough in the pepping stage, I want some results now, so you'll get something finished to see here, and I'll get new motivation.

I decided to finish the helmet. I'm now in the bondo/detailing stage. My question: Do I need a respirator for working with bondo? Do i need one while sanding down the helmet?

ViZiONEER

New Member

Wearing a respirator is always a good choice. Resin and bodyfiller are both toxic fabrics, I really recommend to use one! And on the sanding stage? Definitely!!! The micro fine dust really shouldn't get into your lungs, also be sure to wear some protective glasses if your respirator is not a full face variant. Maybe you refer to the safety guide for prop making that is posted somewhere here in the forums, really essential safety tips in there.

I am sorry for your thighs, they look like they molt in the sun.

Good luck on your (re)build!

I am sorry for your thighs, they look like they molt in the sun.

Good luck on your (re)build!

rainbow dash

Well-Known Member

Thanks for the safety informations, so in short terms: from the resin stage to the painting stage wearing a respirator is obligatory.

I build another helmet, because my head didn't fit through. The new one has a height of 300mm (old one 274mm). My head barely fit's through the new helmet. But I don't know if it's too big, it might look unproportional to the rest of the armor. I can't tell, because I haven't pepped the torso yet. It's the width of the helmet I have a problem with, am I supposed to cut something off?

The new one has a height of 300mm (old one 274mm). My head barely fit's through the new helmet. But I don't know if it's too big, it might look unproportional to the rest of the armor. I can't tell, because I haven't pepped the torso yet. It's the width of the helmet I have a problem with, am I supposed to cut something off?

Another question I have is this one: I have finished resining the cod piece, what's the best/easier way to continue now?

1)to fiberglass the whole codpiece in his entirety at once and split it into 4 parts later

or

2) cut it into 4 parts now and fiberglas every single part on it's own?

I build another helmet, because my head didn't fit through.

Another question I have is this one: I have finished resining the cod piece, what's the best/easier way to continue now?

1)to fiberglass the whole codpiece in his entirety at once and split it into 4 parts later

or

2) cut it into 4 parts now and fiberglas every single part on it's own?

rainbow dash

Well-Known Member

Update time:

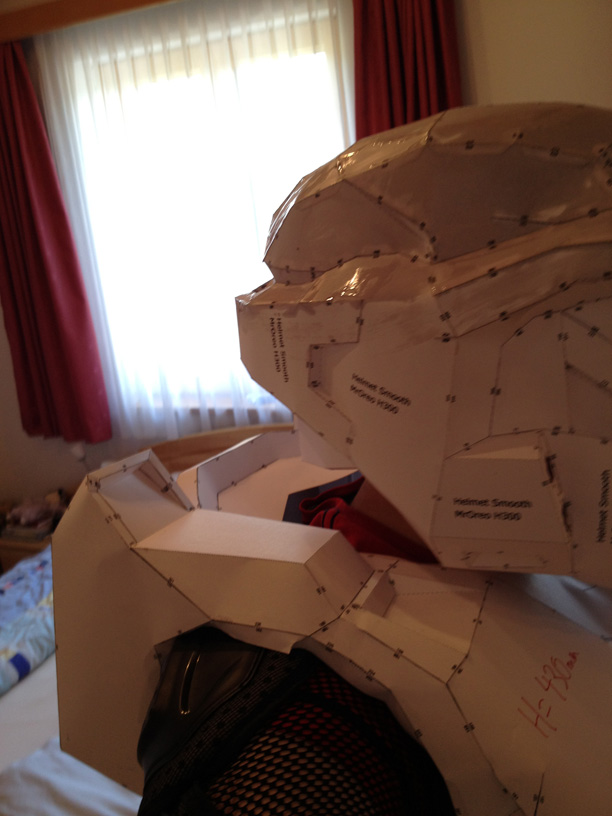

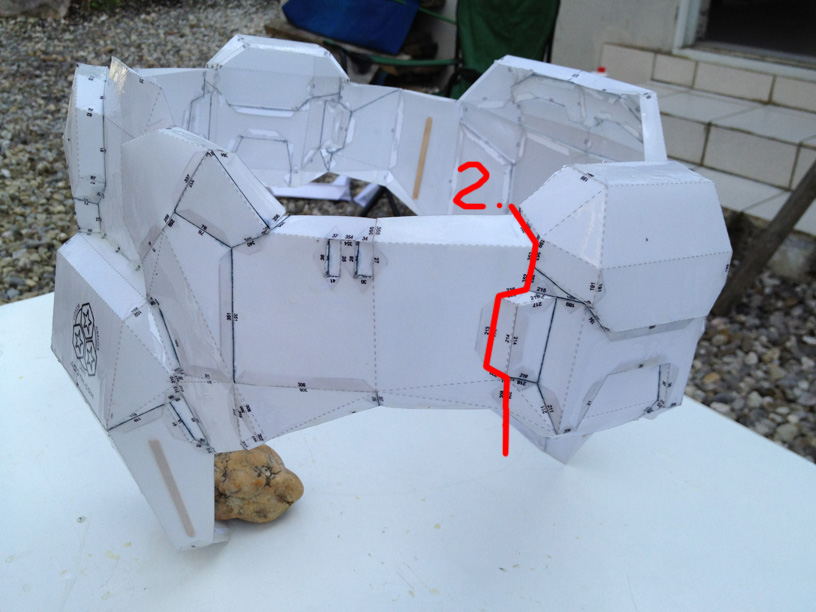

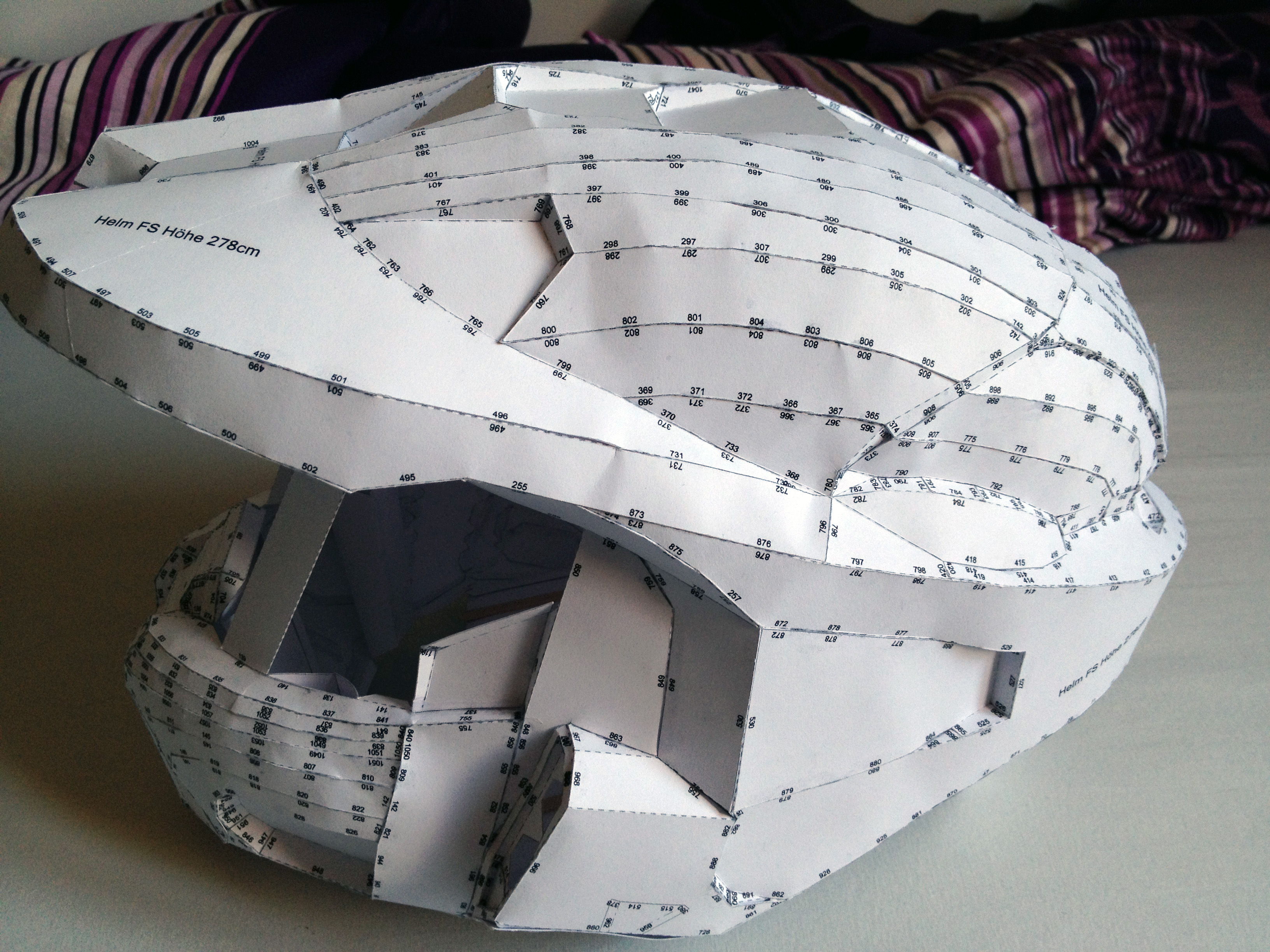

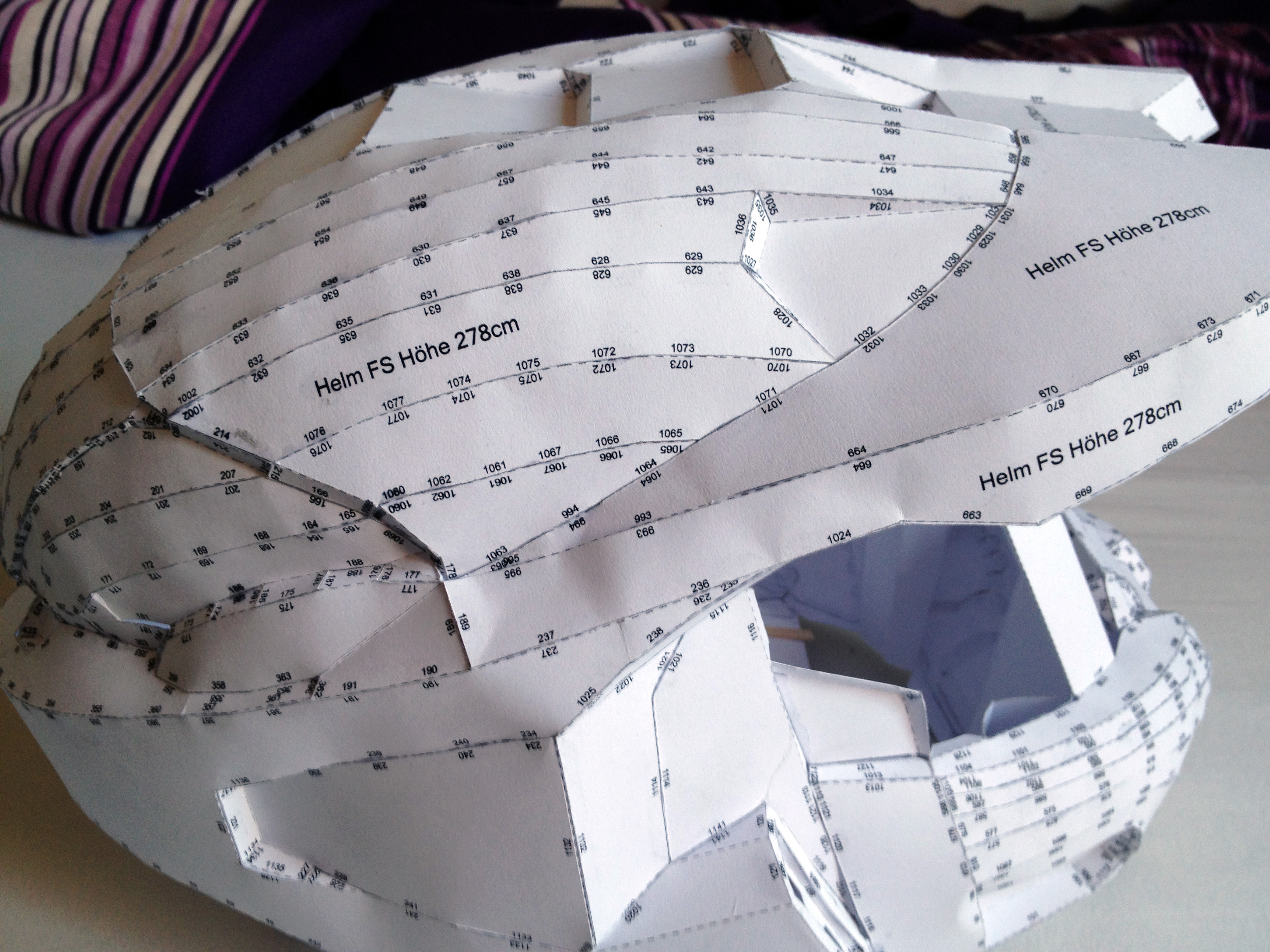

A pic of the new helmet with a torso-tester. It's definitely too big, sorry i have no comparison pic between old and new one, because I have to cut something of first to be able to wear it. I will hand that in later.

I did the thighs again, this time they turned out much better with absolutely no warping, thanks again to carpathiavh99 for providing the new supports.

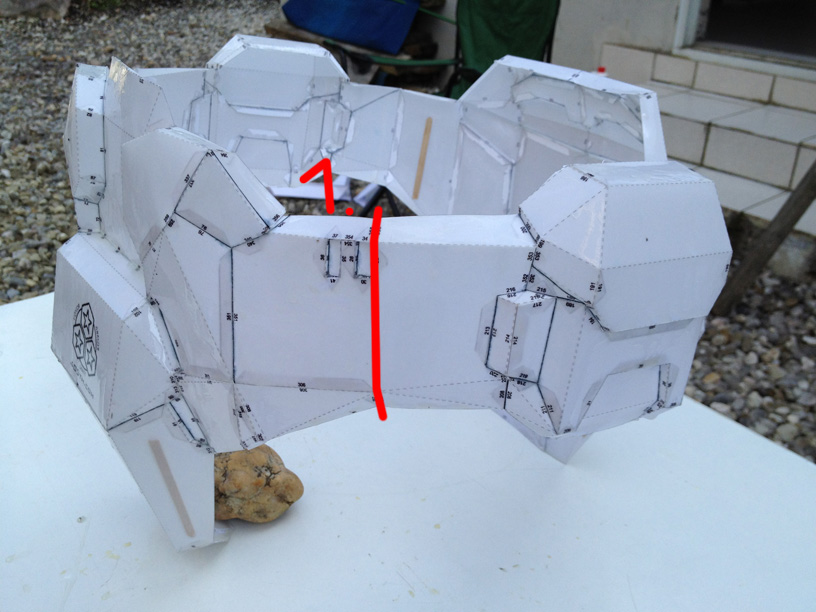

I didn't fiberglass the cod-piece yet. I removed the support struts, still wondering where to cut it off.

Any suggestions?

A pic of the new helmet with a torso-tester. It's definitely too big, sorry i have no comparison pic between old and new one, because I have to cut something of first to be able to wear it. I will hand that in later.

I did the thighs again, this time they turned out much better with absolutely no warping, thanks again to carpathiavh99 for providing the new supports.

I didn't fiberglass the cod-piece yet. I removed the support struts, still wondering where to cut it off.

Any suggestions?

rainbow dash

Well-Known Member

Maybe, I really don't know what's better to do first. It's easier to fiberglass the single parts, I don't really think it will warp (that much) as it's already resined.

rainbow dash

Well-Known Member

Maybe I will just fiberglass the area where I'll split it later, so the connecting area is safe from warping. Then split it with a dremel and fiberglass the rest. Does that sound like a good idea? ^^

Most of the armors I've seen have option 2, but there are some nice suits with option 1 out there. Other than my initiall intend I think I will go with option 2.

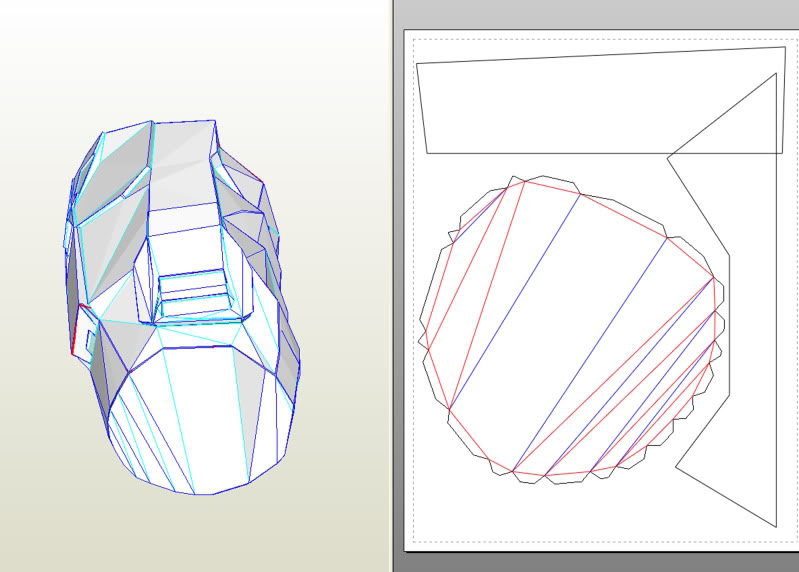

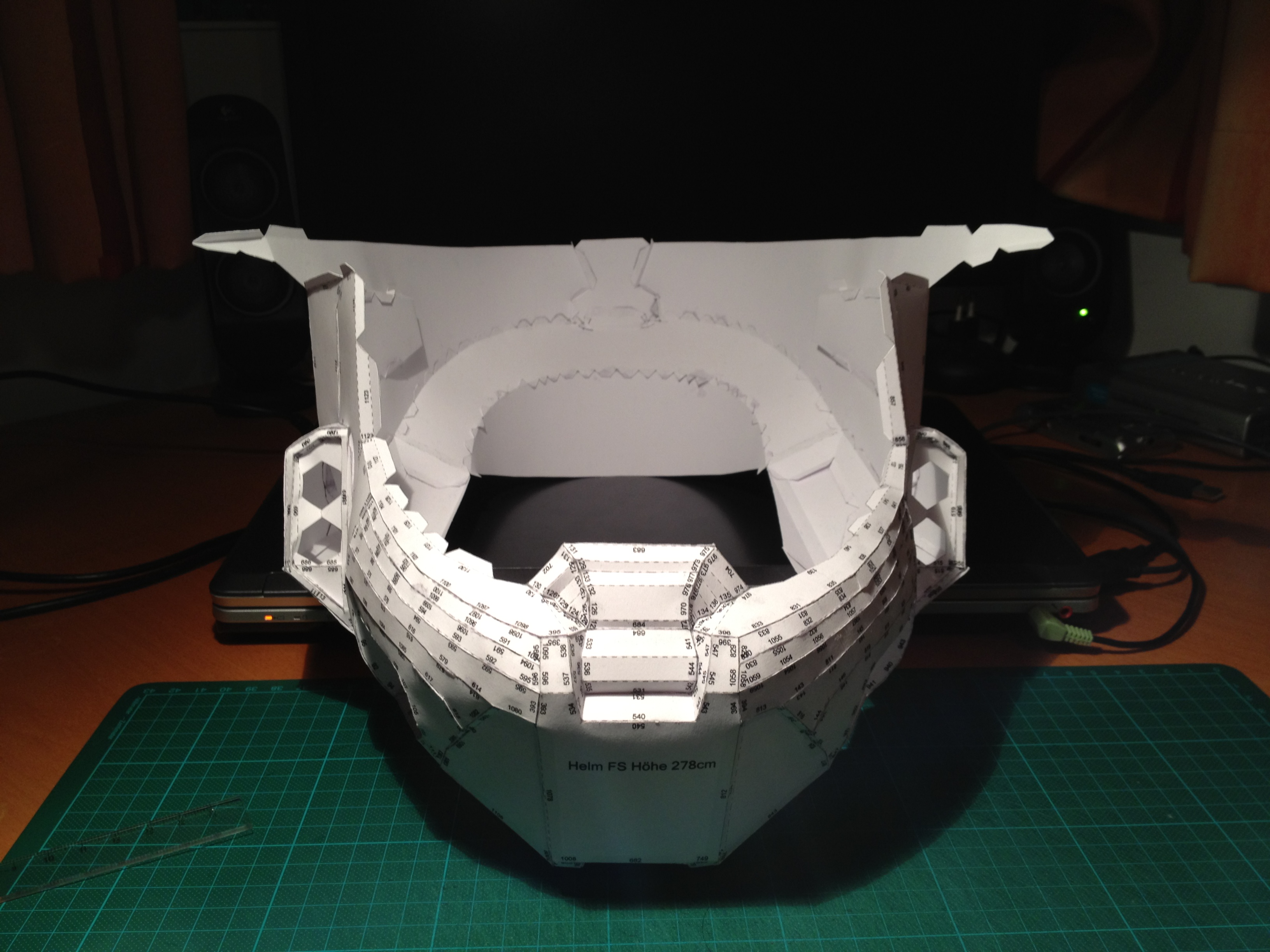

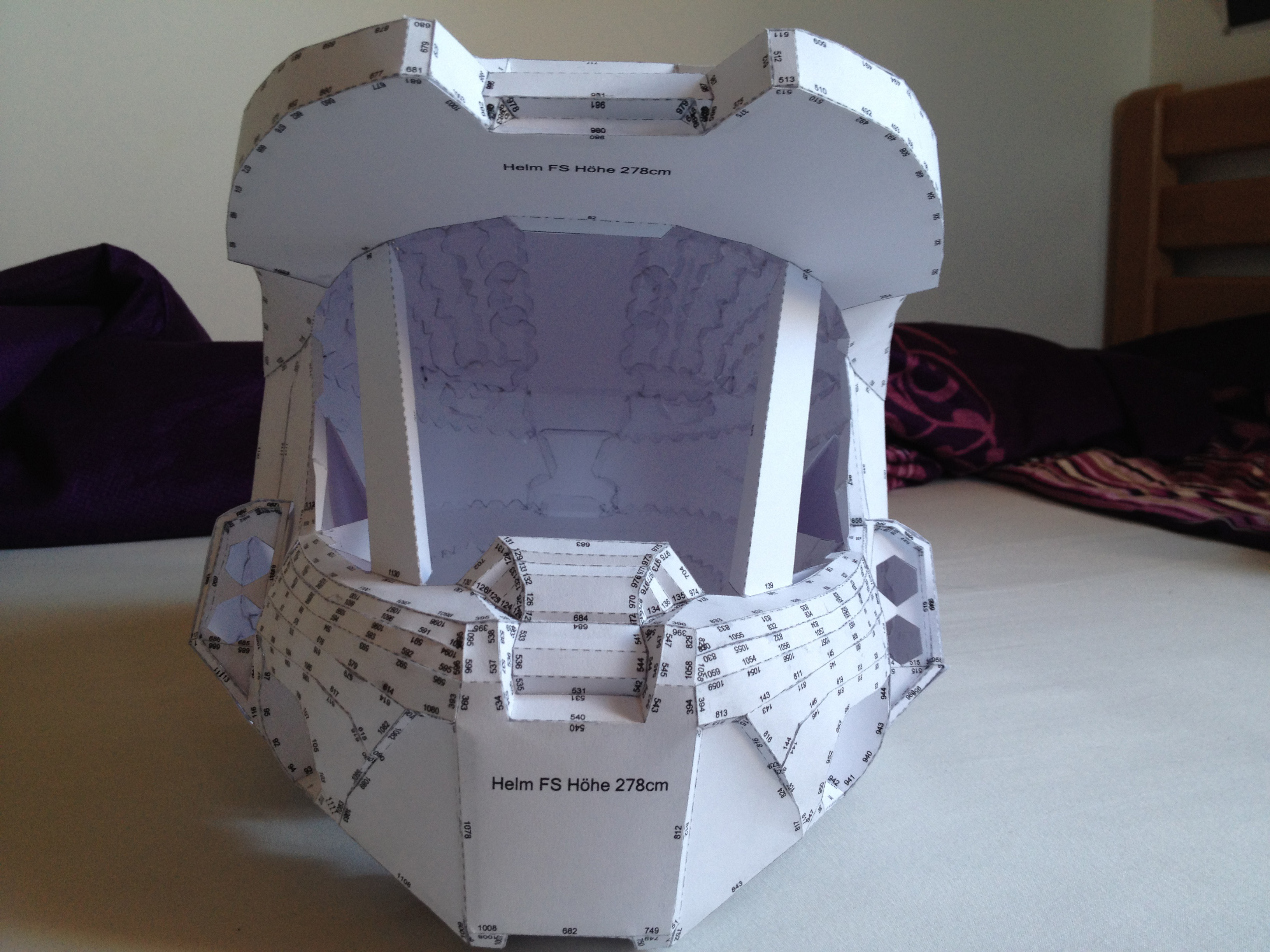

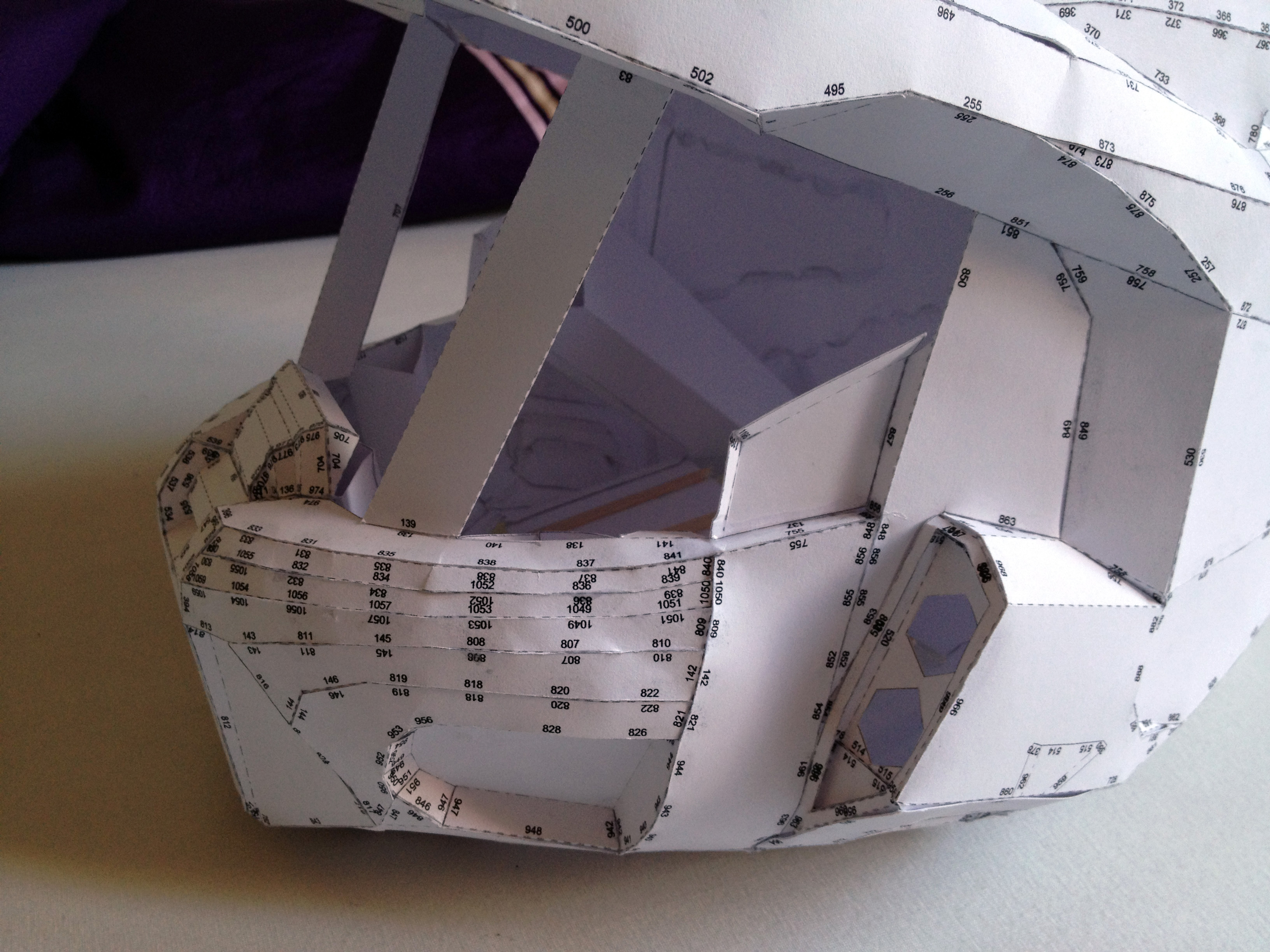

Btw: This is the HD helmet by flyingsquirl. It's coming along really nice, but I'm afraid it's gonna be too small for my head That's the reason I stopped pepping right in the middle and built that other one with 300mm.

That's the reason I stopped pepping right in the middle and built that other one with 300mm.

Most of the armors I've seen have option 2, but there are some nice suits with option 1 out there. Other than my initiall intend I think I will go with option 2.

Btw: This is the HD helmet by flyingsquirl. It's coming along really nice, but I'm afraid it's gonna be too small for my head

RSpartain7

Jr Member

looks really good!

rainbow dash

Well-Known Member

UPDATE TIME:

Although some of you find that it would be better to fiberglass the cod first and then split it, i split it before. As far as I can say nothing warped and fiberglassing was much easer with 4 even parts.

As far as I can say nothing warped and fiberglassing was much easer with 4 even parts.

Sorry, I have no pics of fiberglassed stuff as I'm not home right now.

I already got my strapping material.

I ordered this suspenders

and this quick release pistol belt

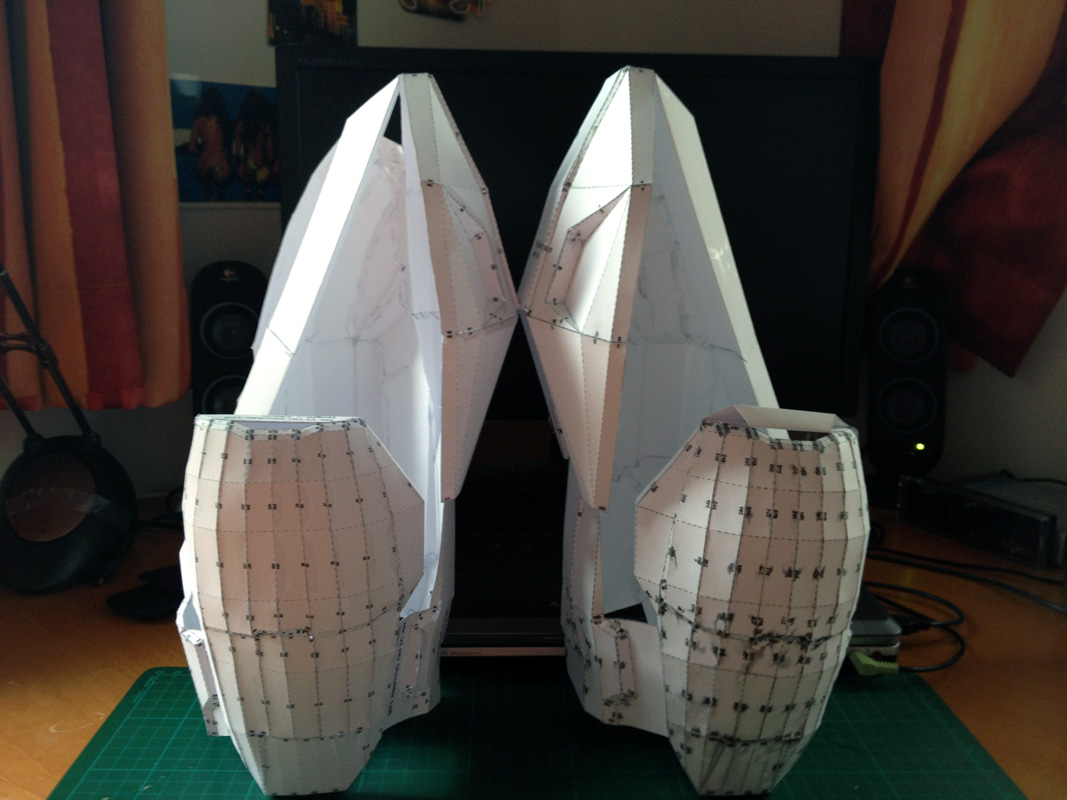

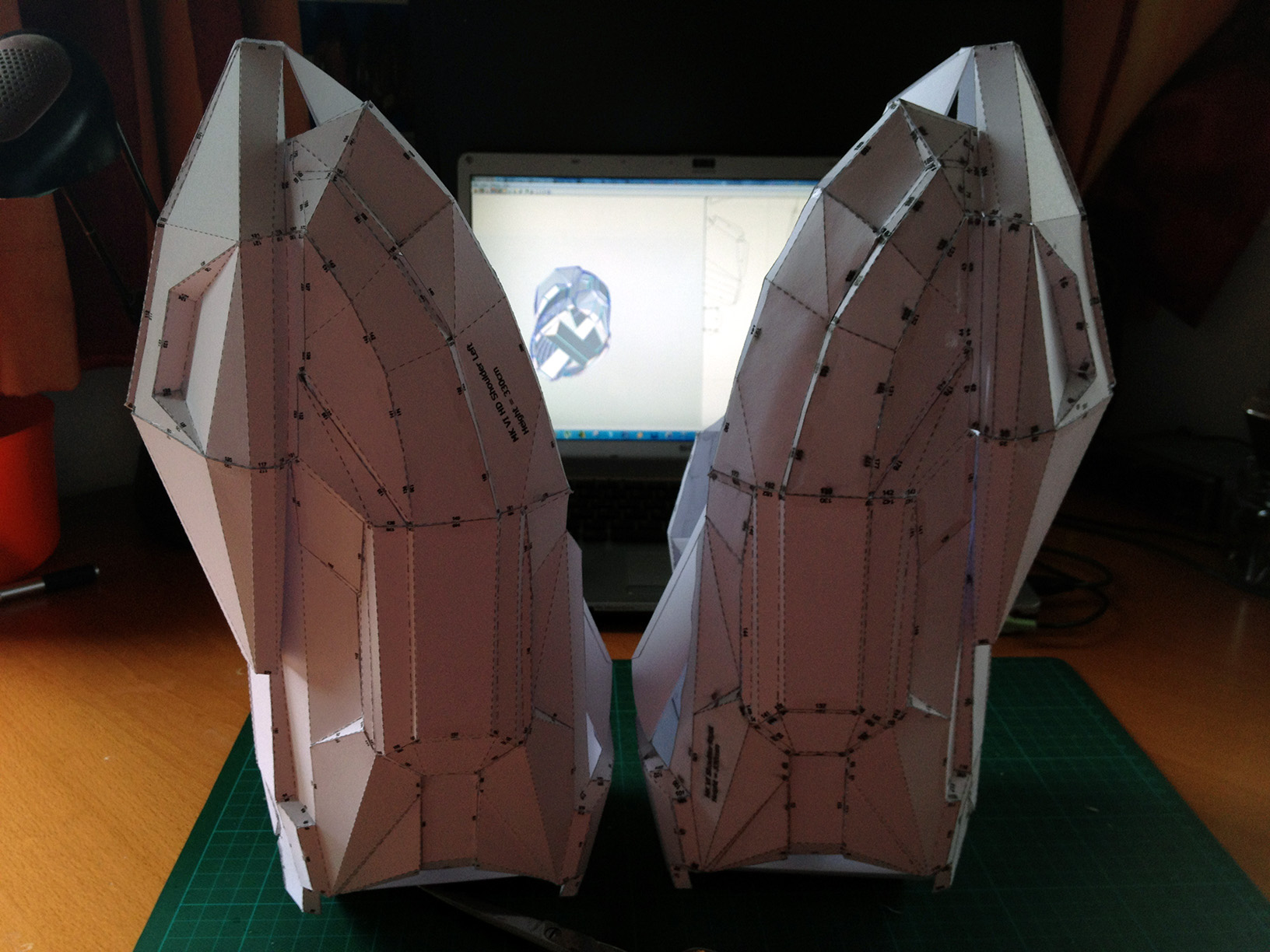

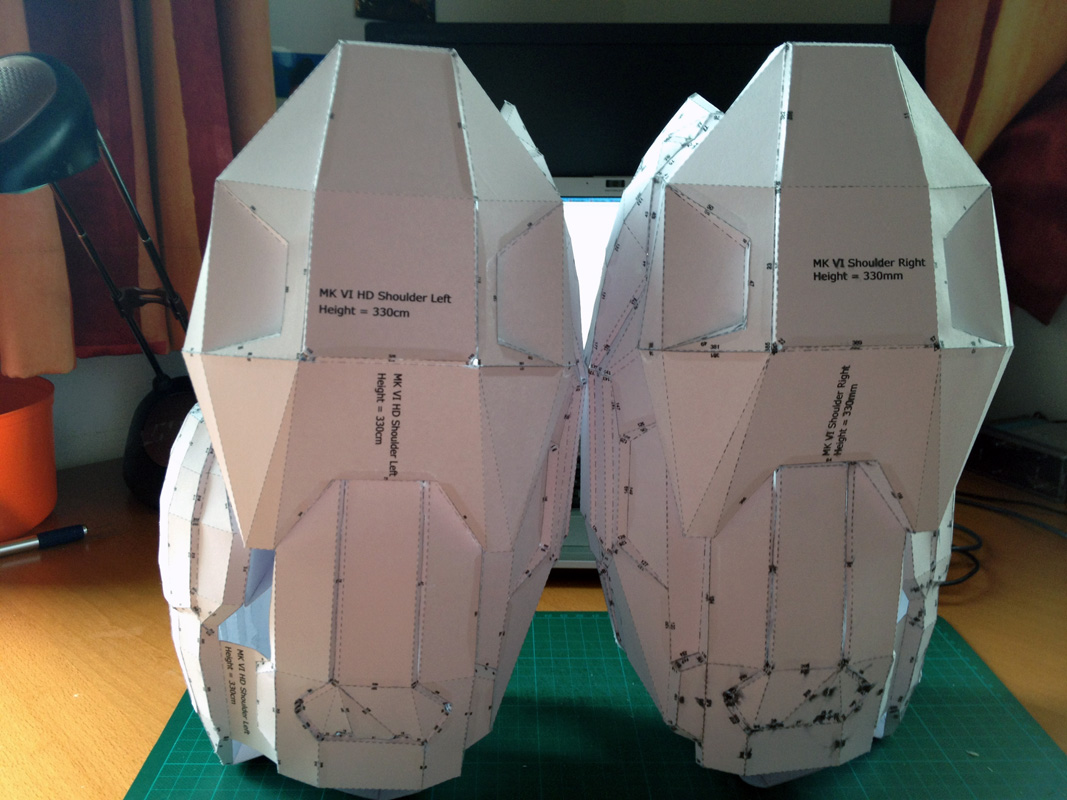

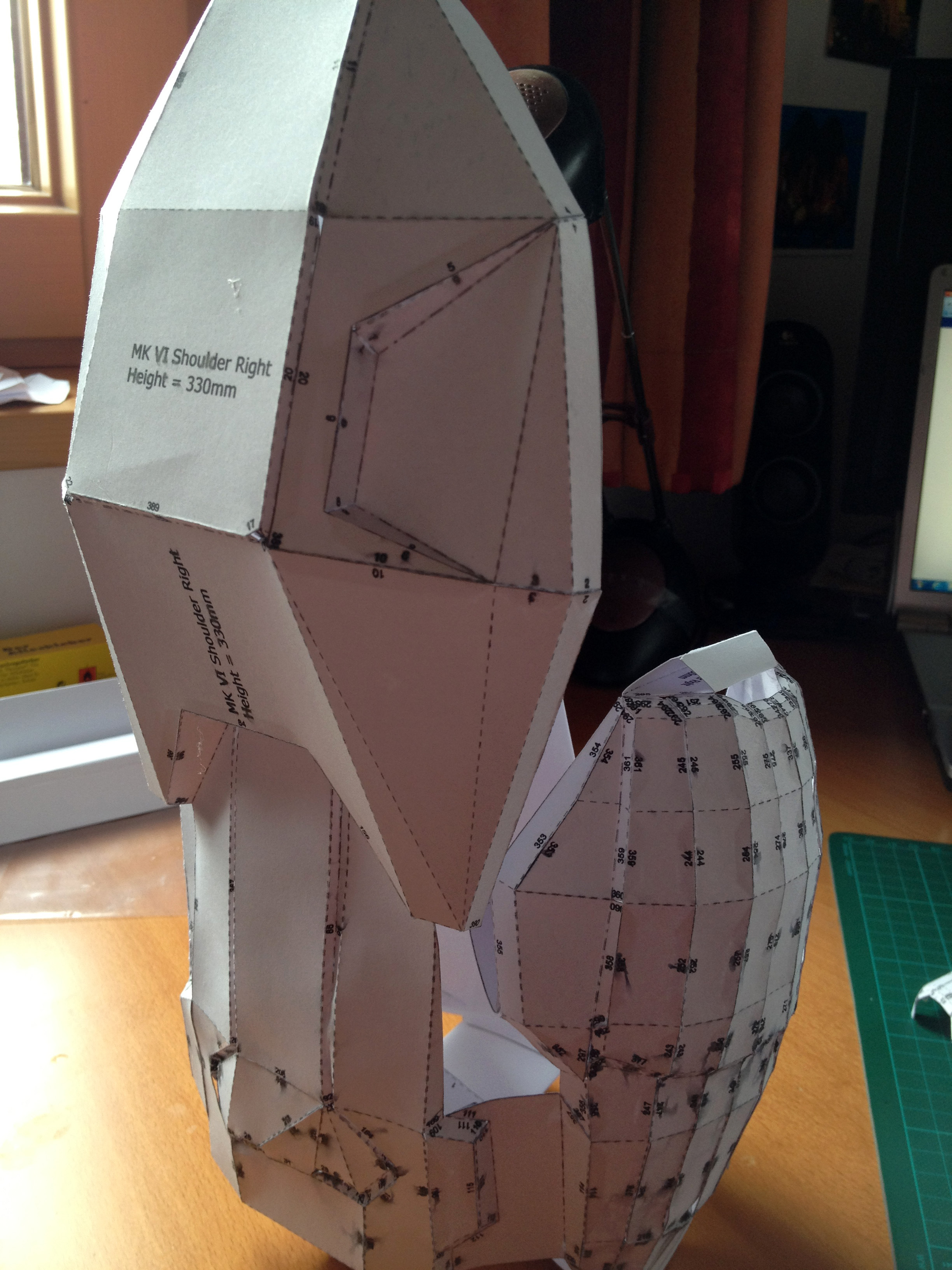

I finally finished pepping the shoulders.

this one got a little wet, not my fault, the roof at my parent's house is leaky, and if we have heavy rain outside it could be that some water drops right on my desk, lol. But it should be repaired already.

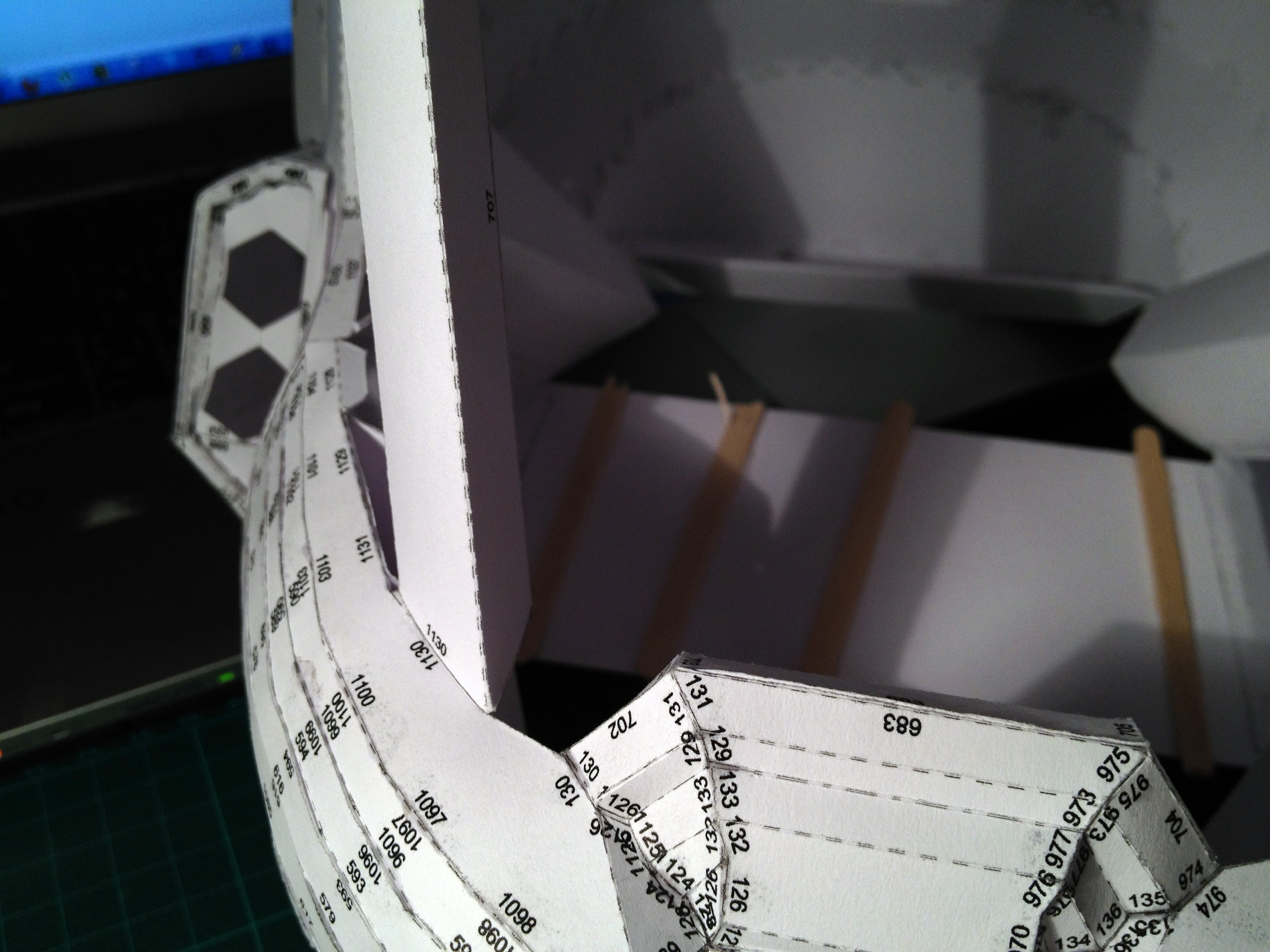

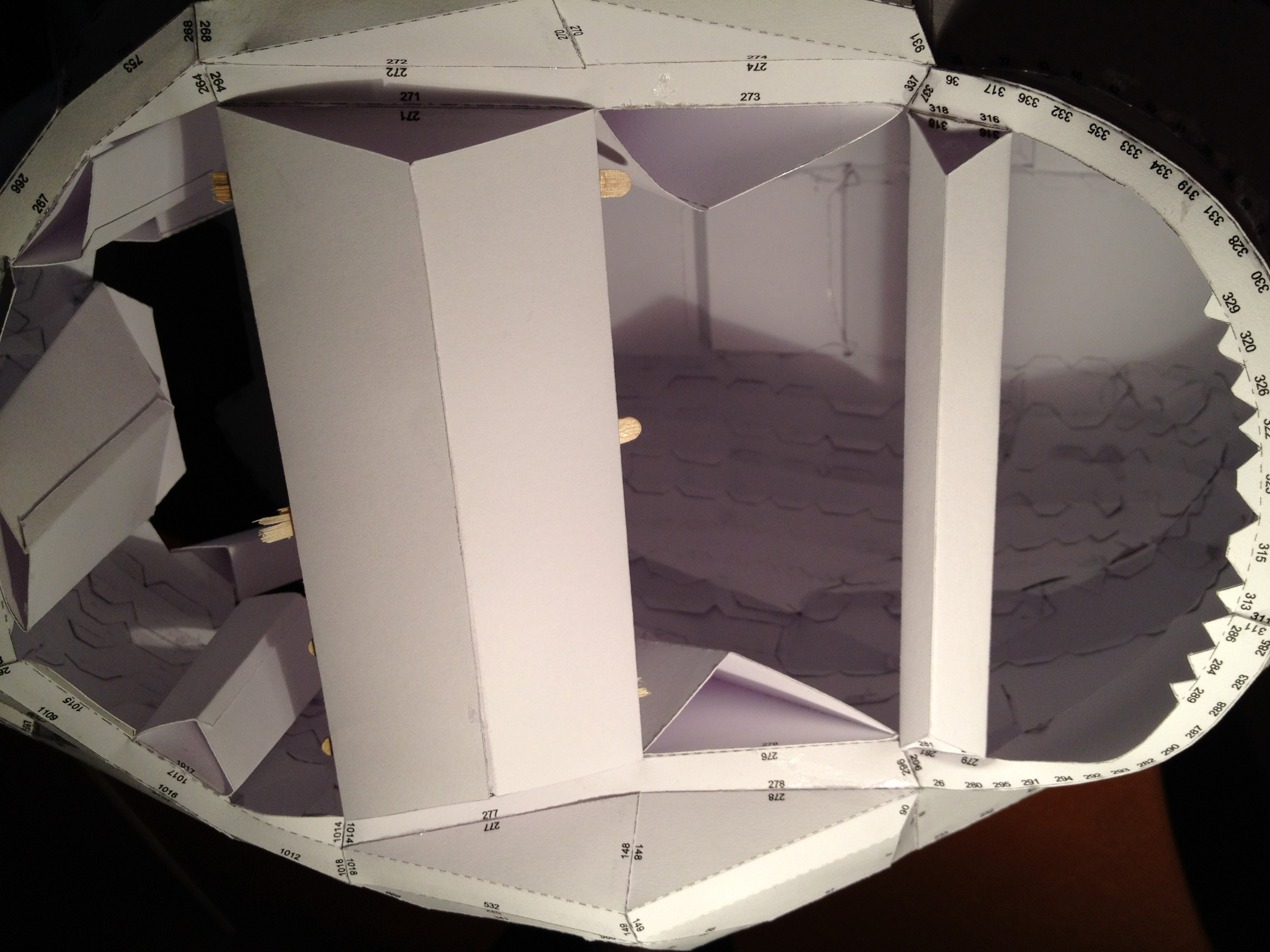

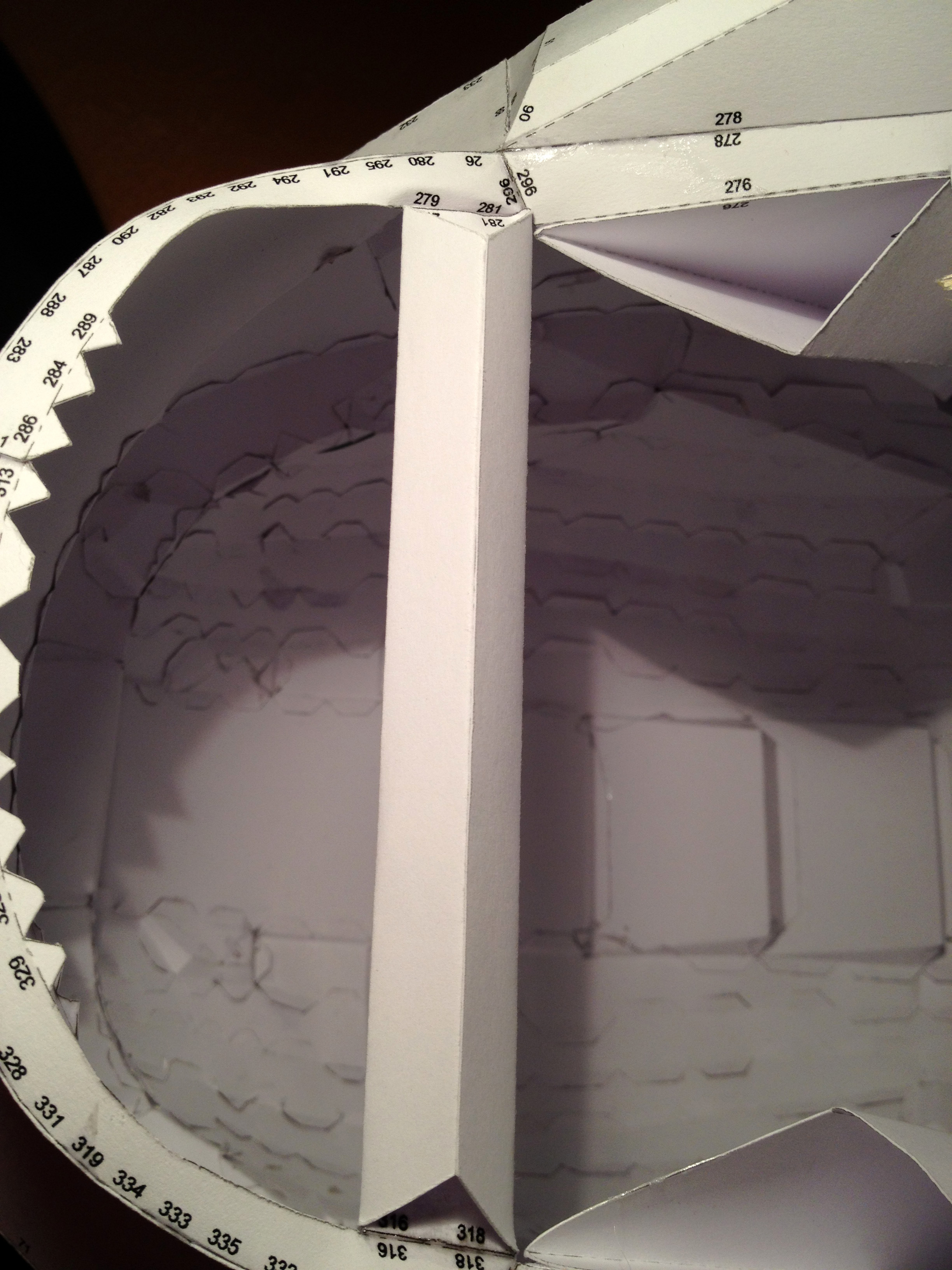

The helmet is also fully pepped. I really like the support struts of the HD version. They ensure that everything stays where it should, you should use them when building this helmet.

I really hope it's not too small and it will fit when cutting of the back part. Then I have to find out how to reattach it, any suggestions?

Due to incorrect scaling or unease I already have a small collection of Mark VI helmets

Sorry for the partially bad quality, I had to take the images with my mobile phone as I misplaced my camera.

I'm currently working on the chest, hopefully I can pep it together till saturday.

Btw. I'm going to give Macattacks64 Recon helmet a try His one turned out real good!

His one turned out real good!

Although some of you find that it would be better to fiberglass the cod first and then split it, i split it before.

Sorry, I have no pics of fiberglassed stuff as I'm not home right now.

I already got my strapping material.

I ordered this suspenders

and this quick release pistol belt

I finally finished pepping the shoulders.

this one got a little wet, not my fault, the roof at my parent's house is leaky, and if we have heavy rain outside it could be that some water drops right on my desk, lol. But it should be repaired already.

The helmet is also fully pepped. I really like the support struts of the HD version. They ensure that everything stays where it should, you should use them when building this helmet.

I really hope it's not too small and it will fit when cutting of the back part. Then I have to find out how to reattach it, any suggestions?

Due to incorrect scaling or unease I already have a small collection of Mark VI helmets

Sorry for the partially bad quality, I had to take the images with my mobile phone as I misplaced my camera.

I'm currently working on the chest, hopefully I can pep it together till saturday.

Btw. I'm going to give Macattacks64 Recon helmet a try

rainbow dash

Well-Known Member

I just found out there's a limit of 15 images per post

More of the helmet ^^

More of the helmet ^^

RSpartain7

Jr Member

All I can say is WOW! this is so awesome. good job!

This has to be the hardest part of the helmet to get straight. I've never seen someone able to have this area line up perfectly.

How come you didn't use the other 3 support struts?

rainbow dash

Well-Known Member

Thank youAll I can say is WOW! this is so awesome. good job!

Thanks. Yes this support strut was very hard to get in, as you can see, it buckled a little. But it's absolutely necessary to get the needed width so you can put your head through.This has to be the hardest part of the helmet to get straight. I've never seen someone able to have this area line up perfectly.

How come you didn't use the other 3 support struts?

I didn't feel the need to add the other 3 support struts as the helmet was stable enough and in the shape I want it to be.

I went with option 2 on my cod. Everything you've been doing look really great!

gute pep arbeit .

Good pepping so far. Glad that u failed on lower detail things. trust me its much sweeter to fail on low detail than on HD things. i had to suffer that feeling D: kinda dieing a part of yourself.

I lost 2 biceps , codpiece and my 2 mk6 HD helmets cos of bad scaling so

But at least i learned it now !

Keep up the good work spartan ! i want to see progress!

Good pepping so far. Glad that u failed on lower detail things. trust me its much sweeter to fail on low detail than on HD things. i had to suffer that feeling D: kinda dieing a part of yourself.

I lost 2 biceps , codpiece and my 2 mk6 HD helmets cos of bad scaling so

But at least i learned it now !

Keep up the good work spartan ! i want to see progress!

rainbow dash

Well-Known Member

I lost 2 biceps , codpiece and my 2 mk6 HD helmets cos of bad scaling so

Thank you!

I don't know if it's already too late for you, but for the Mk VI armor there are some pretty awesome LD-testers out there, they're basically simplified LD files with about 50% less folds. Perfect for scaling reasons. You can easily pep a whole armor within a few days. Link is here Credits go to Mr.Oreo

- Status

- Not open for further replies.

Similar threads

- Replies

- 63

- Views

- 2,272