Been kinda busy with school and work so I haven't really had time to get much done. The handle for the SR came in and looks pretty sweet. I'm gunna see if I can find someone to machine the mag next week.

I also started squaring up the pieces for making the bipod legs. I should be able to finish off the bipod next week.

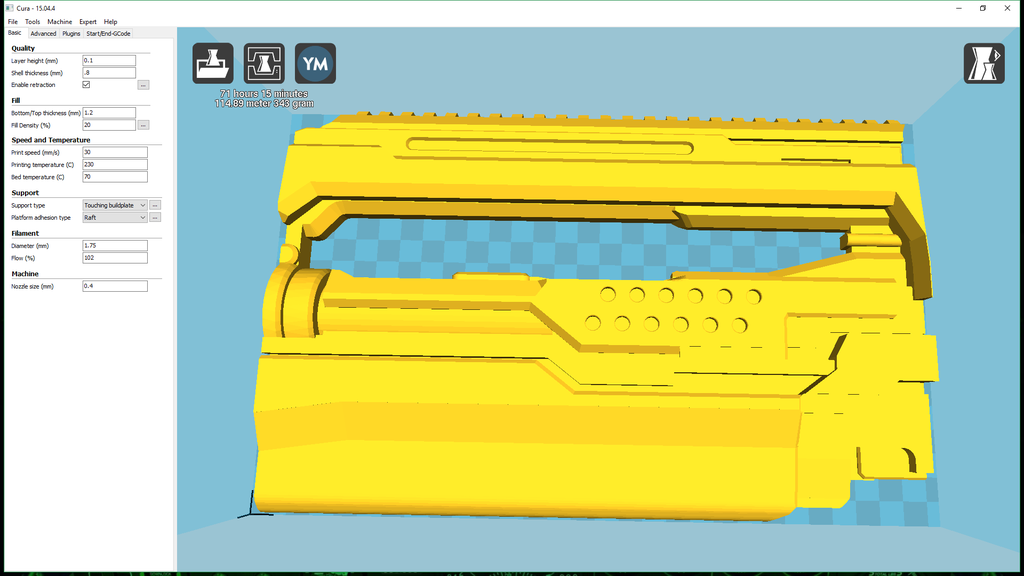

I also started the longest print in my 3D printing history. I'm now printing the left front section of the BR and it's taking up just about the entirety of my print bed (11x7in) and clocks in at just under 72hrs of print time. Wowza!

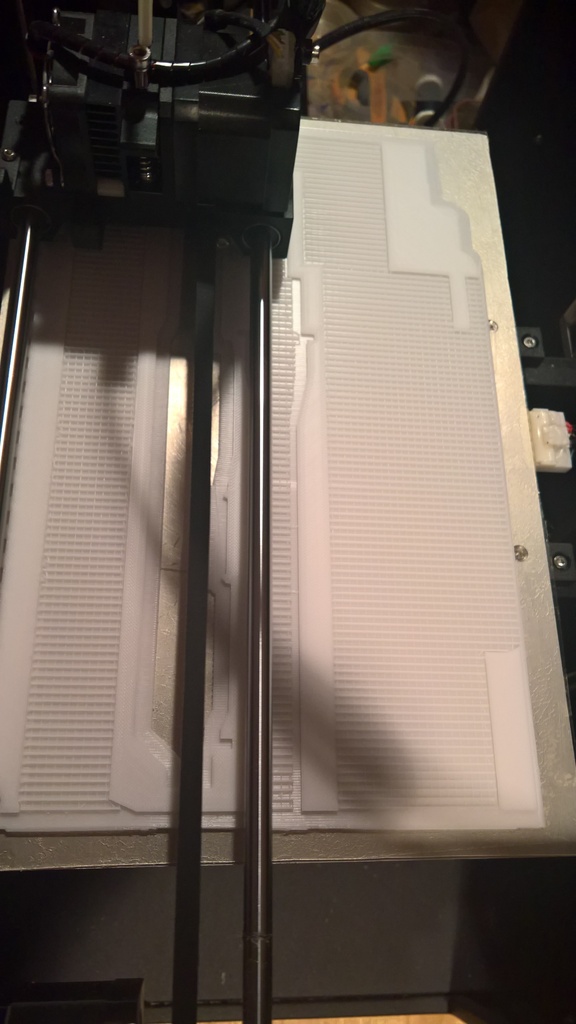

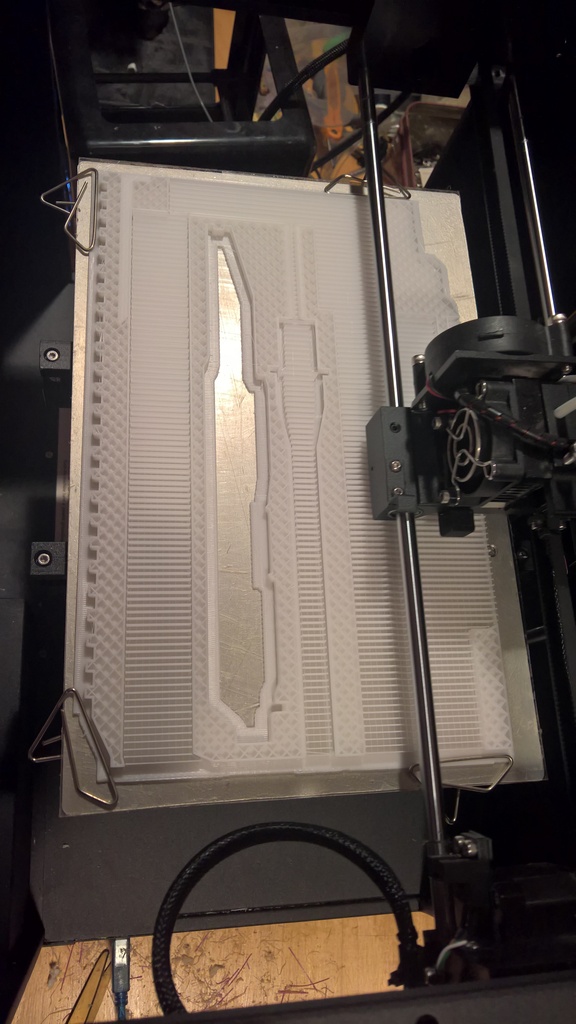

The print still has about 48hrs as of the timestamp on this post. So looking forward to seeing how this turns out!

And for more of a personal update, I will be going to my first Con next weekend. Going with some friends to C2E2 with my hodge-podge of armor that I've made over the years so that should be sweet. This year (once I finish school) I will be working on a more legit ODST suit. So looking forward to that! Also, I've started a Facebook page: Stonewall Replica Armory (@SRAprops) for the guns that will be available later this year and to get the most recent updates. Swing by and check it out!

Stonewall Replica Armory

Welp, back to work!

I also started squaring up the pieces for making the bipod legs. I should be able to finish off the bipod next week.

I also started the longest print in my 3D printing history. I'm now printing the left front section of the BR and it's taking up just about the entirety of my print bed (11x7in) and clocks in at just under 72hrs of print time. Wowza!

The print still has about 48hrs as of the timestamp on this post. So looking forward to seeing how this turns out!

And for more of a personal update, I will be going to my first Con next weekend. Going with some friends to C2E2 with my hodge-podge of armor that I've made over the years so that should be sweet. This year (once I finish school) I will be working on a more legit ODST suit. So looking forward to that! Also, I've started a Facebook page: Stonewall Replica Armory (@SRAprops) for the guns that will be available later this year and to get the most recent updates. Swing by and check it out!

Stonewall Replica Armory

Welp, back to work!