Yeah. I've seen it and it looks like a mechanical nightmare haha. And I wanna say that they were fairly expensive. It's a very cool concept though. Once I get the Battle Rifle working in the AEG configuration, I plan to experiment with making a universal drop in gbbr kit for the BR and the MA5D AR that I am also working on. Just need to get a hold of an RA Tech burst trigger kit for the BR. But that's in the future. My main goal is to get the gbbr SR and the aeg BR working for the 2 day event.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CNC Machined Halo weapons. Pure UNSC Bada$$ery. Airsoft builds :D

- Thread starter DeadzManWalking

- Start date

- Status

- Not open for further replies.

Oh man these are going to be absolutely insane once they're done!

Yeah, I expected it to be expensive when there's a limited quantity and its' the first of it's kind. The price will go down when the begin to mass produce it. Those are some sweet plans you have. So what is your end goal with your fancy halo airsoft guns? Are these just pleasrue projects and being able to show off at the field? lolYeah. I've seen it and it looks like a mechanical nightmare haha. And I wanna say that they were fairly expensive. It's a very cool concept though. Once I get the Battle Rifle working in the AEG configuration, I plan to experiment with making a universal drop in gbbr kit for the BR and the MA5D AR that I am also working on. Just need to get a hold of an RA Tech burst trigger kit for the BR. But that's in the future. My main goal is to get the gbbr SR and the aeg BR working for the 2 day event.

Damn, these are looking great. Need access to this equipment

The SR I will probably keep close to myself and attention whore it out for pics and stuff haha. The BR and AR I will be making molds of so I can cast copies. Those I will probably sell kits of or a completed version depending on my time. But either way I will be keeping the first of both. Due to the cost of the SR, it would take like five figures to get me to look at making additional ones since I'm not machining the bulk of it and that has to get done overseas (and that's not exactly cheap lol).Yeah, I expected it to be expensive when there's a limited quantity and its' the first of it's kind. The price will go down when the begin to mass produce it. Those are some sweet plans you have. So what is your end goal with your fancy halo airsoft guns? Are these just pleasrue projects and being able to show off at the field? lol

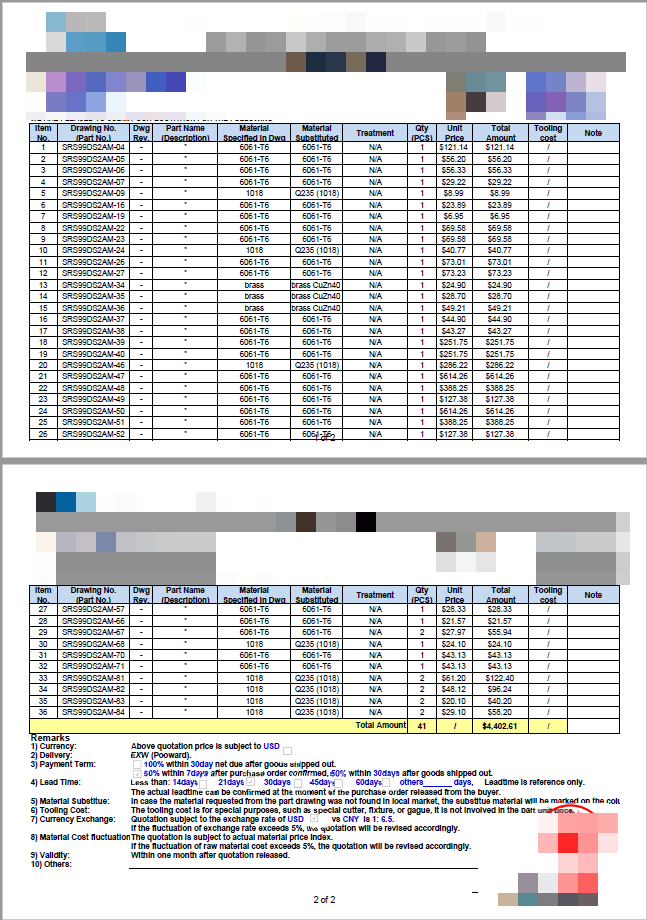

Ok. I am currently wrapping up the last few touches. And by that, I mean I'm saving my parts as .STL files, and the drawings as .PDF's so that the company can quote my components. Just a few more to go and they will be turned over on Saturday. So by Monday evening/Tuesday I should have a quote. Once I receive that, I'll share with you guys the cost per part. I'm hoping for sub $2K total package (fingers crossed  ).

).

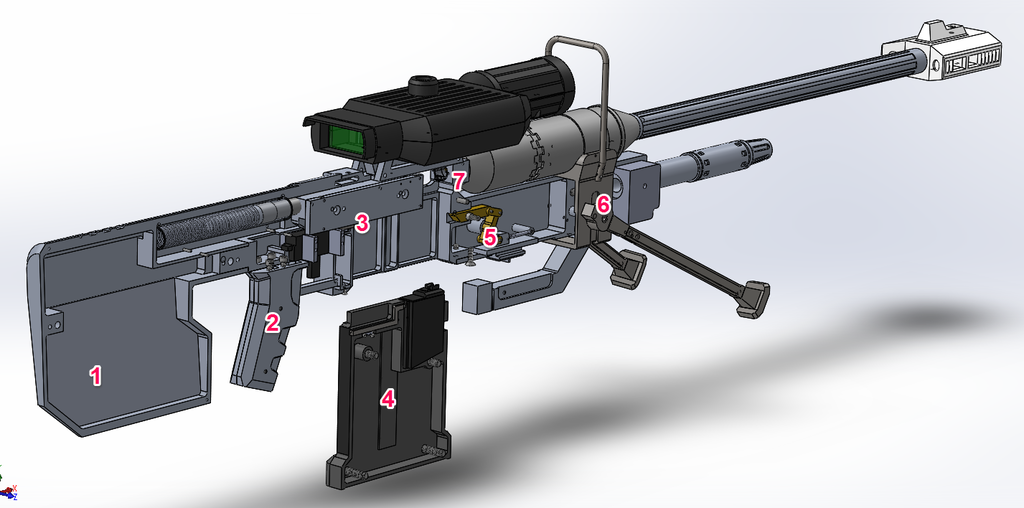

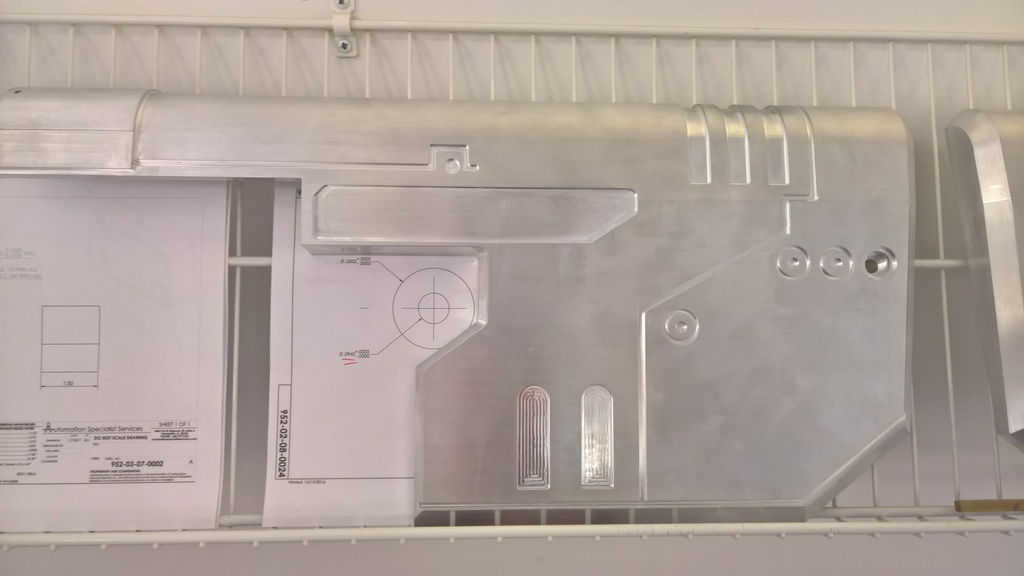

For this post, I'll update you on the revisions and I'll attach some of the reports that I've done for completeness.

Ok, first update:

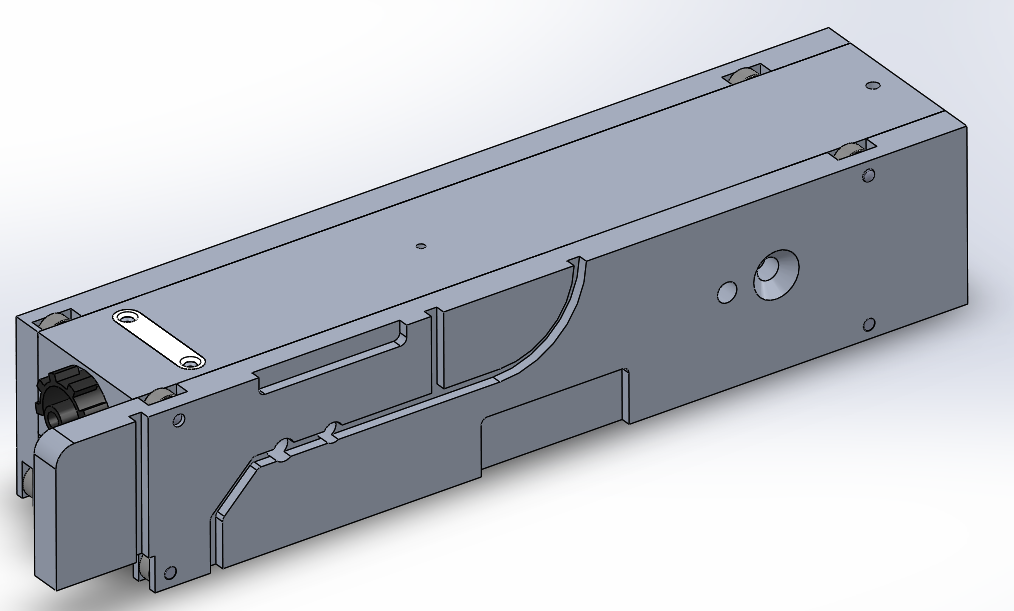

1: Moved the mounting holes, added locating dowels, and added a .1875" radius everywhere possible. Basic concept is to allow a 3/8th inch endmill. On the exterior I added fillets where the part would be machined by a ball mill. Nothin fancy.

2: Split the grip into two pieces for lightweighting and ease of machining.

3: Modified the BCG and receiver. Added more fillets on the receiver for machining and tweaked some small spots. For the BCG, I split it into three components; two wings and a central component. I then added bearings on the top and bottom to make the cycling action more smoothly and I extended the back end by an inch so that the tail would sit in the buttstock rather than trying to roll over a gap where the two body pieces meet. Hopefully this will prevent jamming on the return cycle.

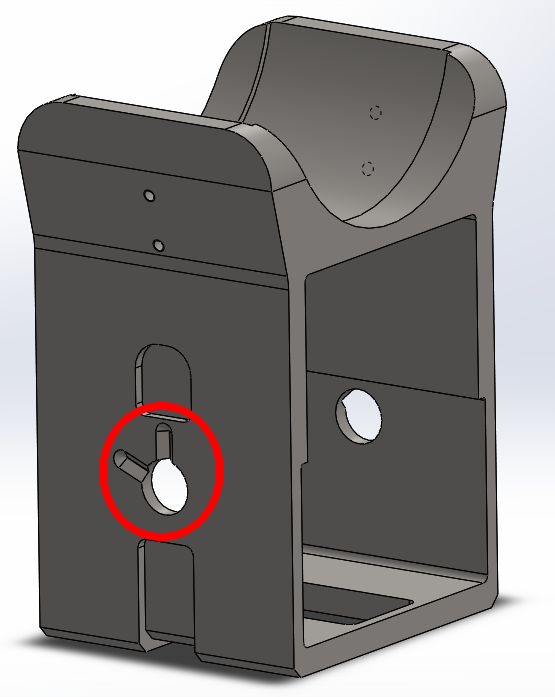

4: I made more lightweighting cuts in the magazine halves, fillited the corners and touched up the edges to make the part easier to machine.

5: The magazine catch was changed to brass (from aluminum) so that it will be easier to manipulate since the brass is self-lubricating.

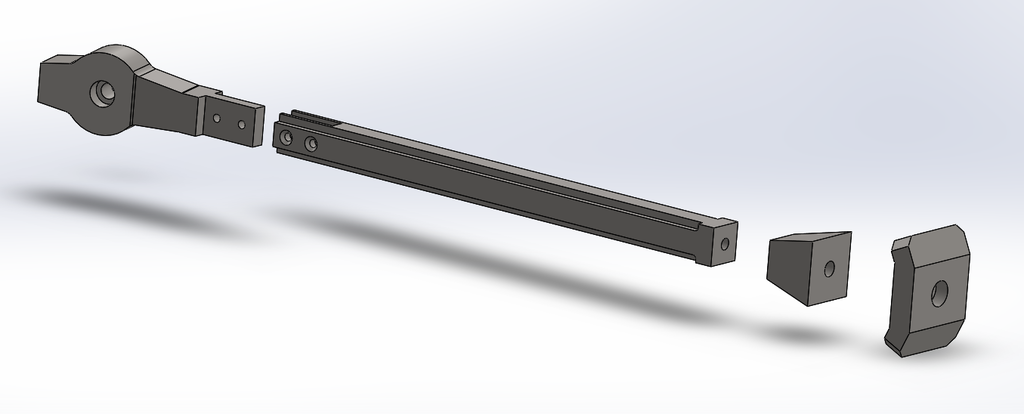

6: The bipod legs were broken up into 4 pieces for easier machining and a feature was added so that I could insert a spring-loaded bearing to act as a detent. Slots were also cut into the receiver block so the bearing can locate and index the bipod leg. The bipod has two positions, the "up" position that we always see in the game, and a "down" position so the legs are full vertical and actually usable.

These components will be made out of steel (for wear resistance and so that the receiver block can have the pocket burned out to hold the tight radii's.

7: Redesigned the hop mount.

Mostly it's been converting all of the screws and dowels to metric and making sure that the faces are machinable and attempting some lightweighting wherever possible (although the CAD model says that it's still approx. 45lbs. :'( ).

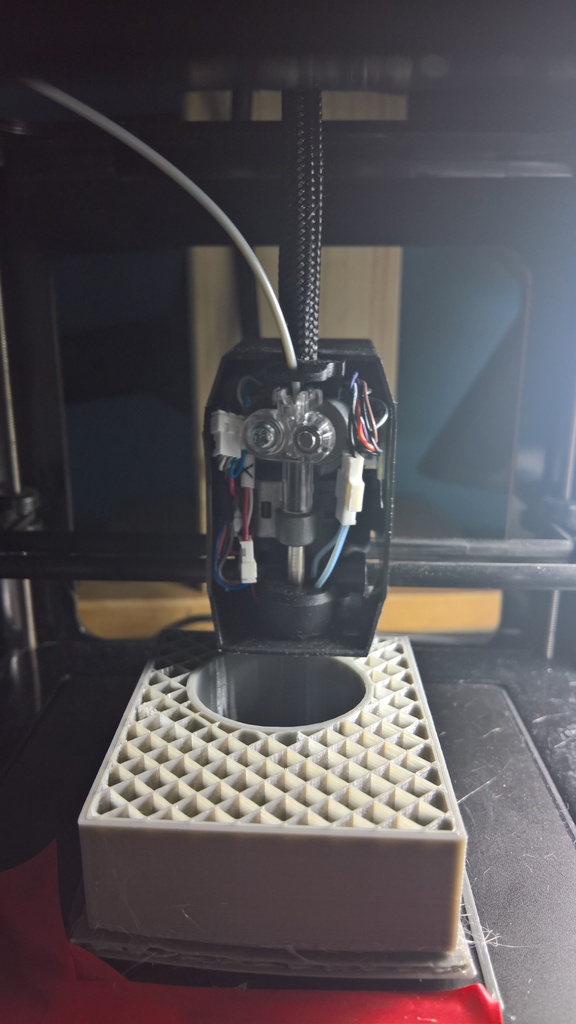

I also printed the gas tube block. I just need to clean it up and it will be a part that I will use in the actual airsoft replica and not a cast part.

So this is where I'm currently at. Lots of long nights after work trying to get this done in time. I will let you guys know as soon as I get the quote/place the order!

For this post, I'll update you on the revisions and I'll attach some of the reports that I've done for completeness.

Ok, first update:

1: Moved the mounting holes, added locating dowels, and added a .1875" radius everywhere possible. Basic concept is to allow a 3/8th inch endmill. On the exterior I added fillets where the part would be machined by a ball mill. Nothin fancy.

2: Split the grip into two pieces for lightweighting and ease of machining.

3: Modified the BCG and receiver. Added more fillets on the receiver for machining and tweaked some small spots. For the BCG, I split it into three components; two wings and a central component. I then added bearings on the top and bottom to make the cycling action more smoothly and I extended the back end by an inch so that the tail would sit in the buttstock rather than trying to roll over a gap where the two body pieces meet. Hopefully this will prevent jamming on the return cycle.

4: I made more lightweighting cuts in the magazine halves, fillited the corners and touched up the edges to make the part easier to machine.

5: The magazine catch was changed to brass (from aluminum) so that it will be easier to manipulate since the brass is self-lubricating.

6: The bipod legs were broken up into 4 pieces for easier machining and a feature was added so that I could insert a spring-loaded bearing to act as a detent. Slots were also cut into the receiver block so the bearing can locate and index the bipod leg. The bipod has two positions, the "up" position that we always see in the game, and a "down" position so the legs are full vertical and actually usable.

These components will be made out of steel (for wear resistance and so that the receiver block can have the pocket burned out to hold the tight radii's.

7: Redesigned the hop mount.

Mostly it's been converting all of the screws and dowels to metric and making sure that the faces are machinable and attempting some lightweighting wherever possible (although the CAD model says that it's still approx. 45lbs. :'( ).

I also printed the gas tube block. I just need to clean it up and it will be a part that I will use in the actual airsoft replica and not a cast part.

So this is where I'm currently at. Lots of long nights after work trying to get this done in time. I will let you guys know as soon as I get the quote/place the order!

Attachments

Awww mate! This is looking great.

I have received a quote back for the parts that I had submitted to the manufacturing company. It was a little higher than I was hoping, but it is without question the cheapest that I am going to get anywhere. I sent in everything minus the barrel components and scope assembly. A lot of the internal components I intend to machine myself, but I sent in anyways just to see how much it would cost (as you can see by the sub $10 components haha).

I was hoping for between $2000-$3000. Not included in this quote is the shipping cost (probably approx. $100) or the cost to get parts anodized (since I will most likely have to hand-fit some of these and file edges to clean up seams which would mean that I would be filing away the coatings). After seeing that number, as anyone could expect, there was a little bit of an "Oh S#!t" moment. So for the time-being, I decided to place a partial order to get the big pieces machined and in hand. The rest I will either machine myself or have to look at ordering down the road when I get some more money. My boss is helping me float some of the cost so the machining can start now rather than two/three weeks from now.

Next step is to order the hardware (ie. dowel pins, socket head cap screws, roller bearings). In addition, I will be obtaining the rest of the airsoft components. While these parts are being machined, I will be working on finishing the 3D printed parts and machining the ribs in the outer barrel. I am printing the last pieces of the chamber right now and they will be done tomorrow.

I will post more pics as parts get finished and as materials show up. The machined components should be in hand by the first week of March so that will be very exciting!

I was hoping for between $2000-$3000. Not included in this quote is the shipping cost (probably approx. $100) or the cost to get parts anodized (since I will most likely have to hand-fit some of these and file edges to clean up seams which would mean that I would be filing away the coatings). After seeing that number, as anyone could expect, there was a little bit of an "Oh S#!t" moment. So for the time-being, I decided to place a partial order to get the big pieces machined and in hand. The rest I will either machine myself or have to look at ordering down the road when I get some more money. My boss is helping me float some of the cost so the machining can start now rather than two/three weeks from now.

Next step is to order the hardware (ie. dowel pins, socket head cap screws, roller bearings). In addition, I will be obtaining the rest of the airsoft components. While these parts are being machined, I will be working on finishing the 3D printed parts and machining the ribs in the outer barrel. I am printing the last pieces of the chamber right now and they will be done tomorrow.

I will post more pics as parts get finished and as materials show up. The machined components should be in hand by the first week of March so that will be very exciting!

Hey guys. Just gunna throw in a little update. I've finished printing the chamber and then glued them together. Um, kinda as expected, but unfortunately it didn't turn out quite as I had hoped... The gas tube is fine. That I just need to clean up the exterior to make it ready for a mold. The chamber is a different story. It turned out OK, but I just think that it would be better to make it out of aluminum tubing pieces turned on a lathe. I'd be able to hold actual tolerances with it so that I will have less issues during assembly.

This is with the removable section taken off to see the supports.

So it's not super great. I wish it would've been cleaner but it's what you get with a tiny 3D printer. Otherwise, I have received my bearings for the bolt carrier. The scope battery, switches, and connectors will be in this Friday. The components for the battle rifle will show up tomorrow so I will be able to start planning the internal cut-outs for that so I can print it as soon as I get access to a larger printer. I will be sending out an order to McMaster soon for the hardware, and another to Shapeways to get the other internal components printed/sintered. I'm thinking that I will have Shapeways 3D print a half muzzle break so that I can make a cleaner mold, and then cast two halves out of resin. That will probably turn out better than my current version. This weekend I am gunna hopefully have the camera up and running, so I will show you guys that setup soon. I'm planning on making it so I can have two different cameras that I can switch between with a slide switch. One behind the optic (7x) and another with no zoom. I'm also looking into getting IR cameras to plug in for night fun (not practical but just for funzies). I'm gunna have to complete the prep work on the scope body and get a mold done for that soon so I can install everything. So between machining the internal components and doing the cleaning, I should have more pictures to show you guys. I'll check in over the weekend with more updates and possibly a video for the scope.

This is with the removable section taken off to see the supports.

So it's not super great. I wish it would've been cleaner but it's what you get with a tiny 3D printer. Otherwise, I have received my bearings for the bolt carrier. The scope battery, switches, and connectors will be in this Friday. The components for the battle rifle will show up tomorrow so I will be able to start planning the internal cut-outs for that so I can print it as soon as I get access to a larger printer. I will be sending out an order to McMaster soon for the hardware, and another to Shapeways to get the other internal components printed/sintered. I'm thinking that I will have Shapeways 3D print a half muzzle break so that I can make a cleaner mold, and then cast two halves out of resin. That will probably turn out better than my current version. This weekend I am gunna hopefully have the camera up and running, so I will show you guys that setup soon. I'm planning on making it so I can have two different cameras that I can switch between with a slide switch. One behind the optic (7x) and another with no zoom. I'm also looking into getting IR cameras to plug in for night fun (not practical but just for funzies). I'm gunna have to complete the prep work on the scope body and get a mold done for that soon so I can install everything. So between machining the internal components and doing the cleaning, I should have more pictures to show you guys. I'll check in over the weekend with more updates and possibly a video for the scope.

Whats the size of your printer's print bed?

About 3.5" cubed. It's the M3D Micro. I'm eventually getting their Pro series, but I'd like bigger for when I do the battle rifle print, but I will just have to make due with that (7" cube print size). I'm going to make molds of the BR (and the AR when I get that done) and offer those for sale as kits or finished airsoft guns (or just props for the non-airsofter haha). Then waaay down the road I intend on looking at making a gas BR and AR with a burst trigger kit for the BR.Whats the size of your printer's print bed?

Today's update has been brought to you in video form! Yay technology.

- Member DIN

- S068

About 3.5" cubed. It's the M3D Micro. I'm eventually getting their Pro series, but I'd like bigger for when I do the battle rifle print, but I will just have to make due with that (7" cube print size).

How has your experience with the M3D Micro been? I've had mine for about eight months and am currently looking at replacing it due to lack of wow factor. Even fine tuning with better quality filament than M3Ds still leads to a less than stellar print completion record.

Yeah. My main problem is that one or multiple parts of it peel away from the raft 99% of the time. I've had OK success, but I'm going to give their Pro series a try. I've had it since September. However I'm severely tempted to buy a bigger printer soon actually. I mainly want something that can handle printing my battle rifle and assault rifle (and eventually the pistol and SMG) so I can make mold casts. I'm not really using them to make finished products. I just want something to make these airsoft builds so I can create casts for a stronger build. Plus I intend to make a gas blow back battle rifle (and maybe assault rifle) later this year.How has your experience with the M3D Micro been? I've had mine for about eight months and am currently looking at replacing it due to lack of wow factor. Even fine tuning with better quality filament than M3Ds still leads to a less than stellar print completion record.

- Member DIN

- S068

Yeah. My main problem is that one or multiple parts of it peel away from the raft 99% of the time. I've had OK success, but I'm going to give their Pro series a try. I've had it since September. However I'm severely tempted to buy a bigger printer soon

The peeling or driving the nozzle into the bed was a fun tweak to get perfect... I'm currently looking at a Wanhao machine, slightly more expensive but a much larger print bed and a more reliable track record with regards to construction and finishing abilities from what research I've done.

Which model? You have a link? I'm somewhat looking for other possibilities mainly a larger print bed size since I need/want to print the BR and AR.The peeling or driving the nozzle into the bed was a fun tweak to get perfect... I'm currently looking at a Wanhao machine, slightly more expensive but a much larger print bed and a more reliable track record with regards to construction and finishing abilities from what research I've done.

And for everybody: Stay tuned in the beginning of the week. I have a very exciting (pic heavy) post coming for your viewing pleasure!!!

- Member DIN

- S068

Which model? You have a link?

The Wanhao Duplicator I3 V2.1 which is around the price I paid with filament for the M3D Micro a few months back. 8"x8"x7" build space which isn't gigantic but it's a leaps and bounds above the Micro.

It's based on the Prusa design and is a steel frame as opposed to most acrylic bodied Chinese ripoff reprap printers.

Looks pretty sweet. I'll keep looking at their stuff. I'm mainly looking for a wide base and don't need much height. The M3D is 7" cubed so it'll be a start. Even if it's like $1000, it'll still be leaps and bounds cheaper than machining stuff.The Wanhao Duplicator I3 V2.1 which is around the price I paid with filament for the M3D Micro a few months back. 8"x8"x7" build space which isn't gigantic but it's a leaps and bounds above the Micro.

It's based on the Prusa design and is a steel frame as opposed to most acrylic bodied Chinese ripoff reprap printers.

So I got a package today in the mail... Here's a little teaser. I will post all of the pictures tonight when I get some more time.

comics1996

Active Member

Intensive amount of info you wrote. Seems like you got it planned good with all the info you wrote

- Status

- Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 1,085