Hello All,

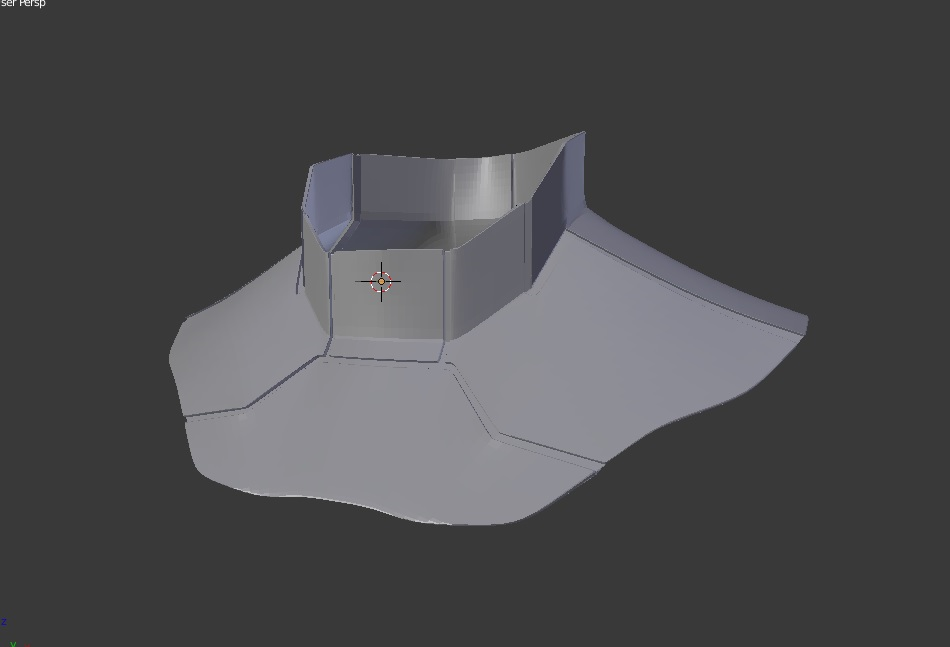

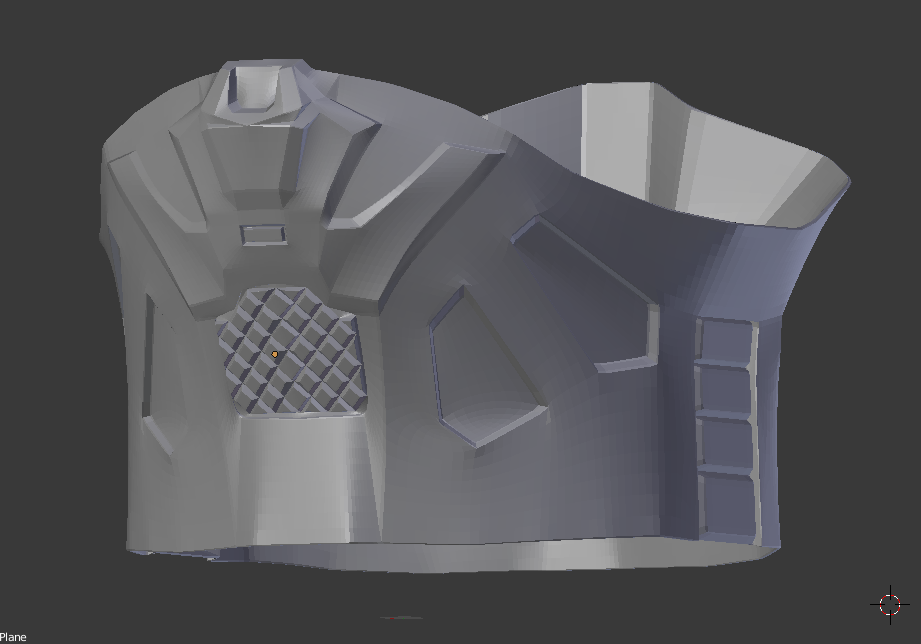

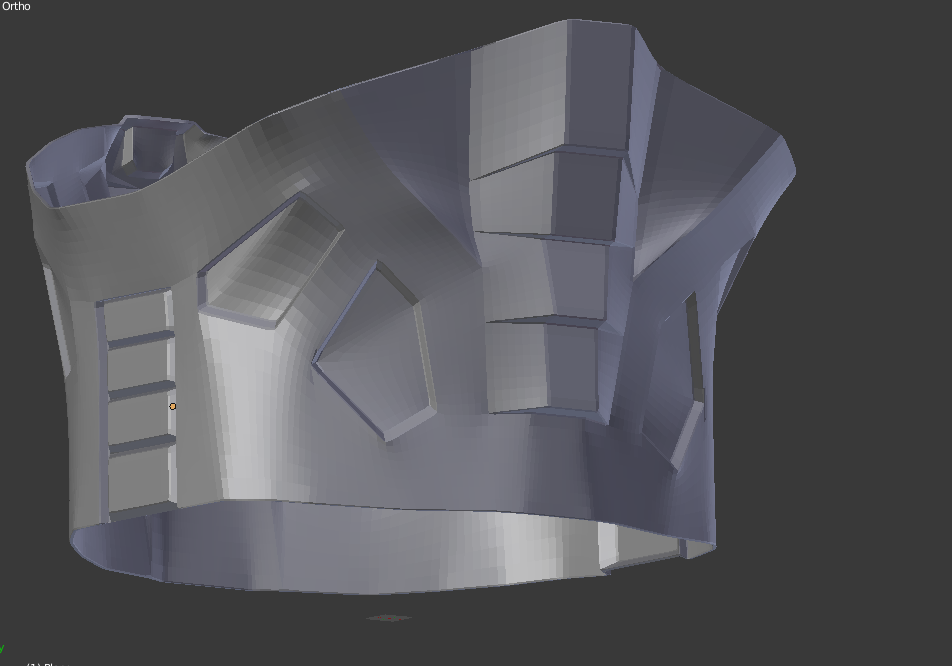

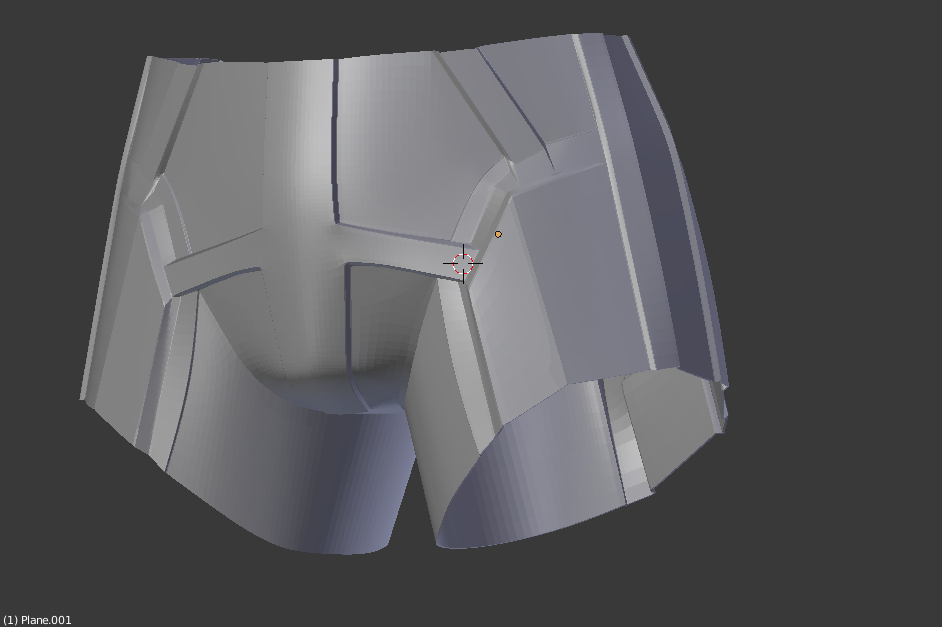

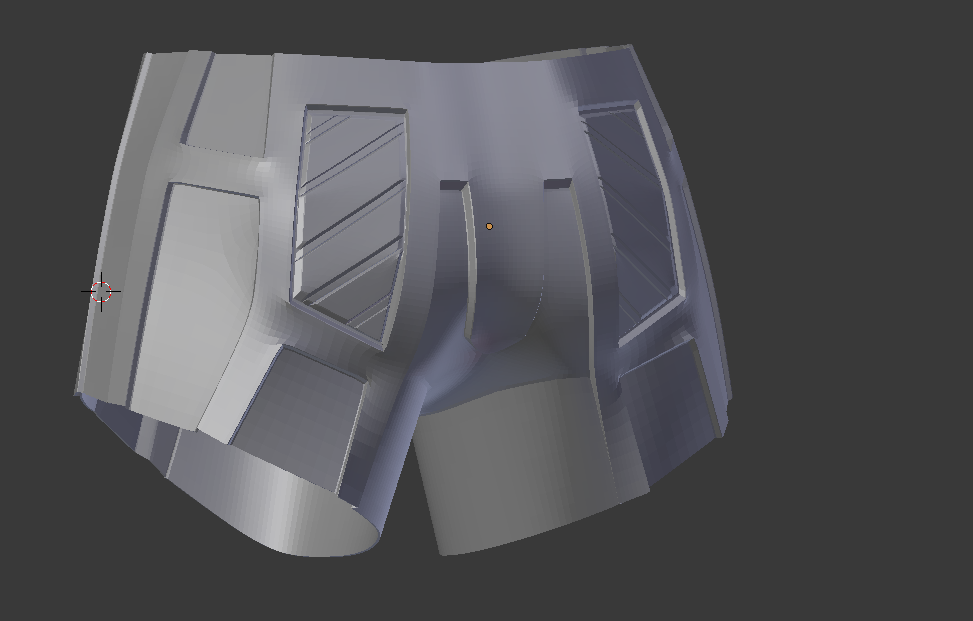

I'm entering the final stages of designing Halo Infinite under armor (Generic). Before I release them, what are your thoughts on the way they Look/Function.

Do you have a suggestion to improve them? Grab an image and draw what you are looking for in functionality (a cut here, opening there to allow for nylon strapping, etc.)

I currently have them with a wall thickness of about 2mm to allow for more flexibility, but this may cause more issues while printing.

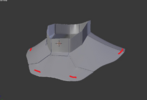

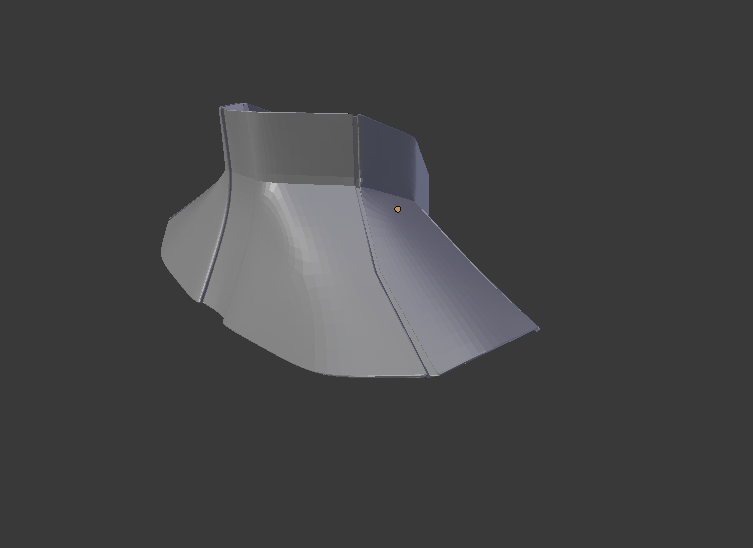

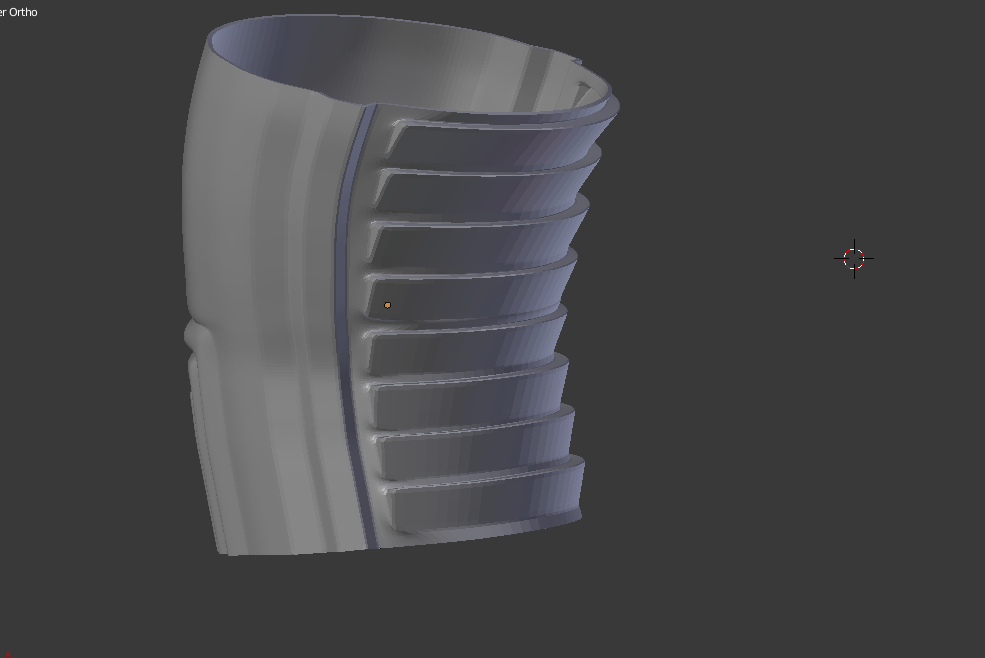

Neck

Should I print with a slice open in the back? Should the neck be higher?

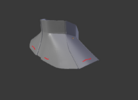

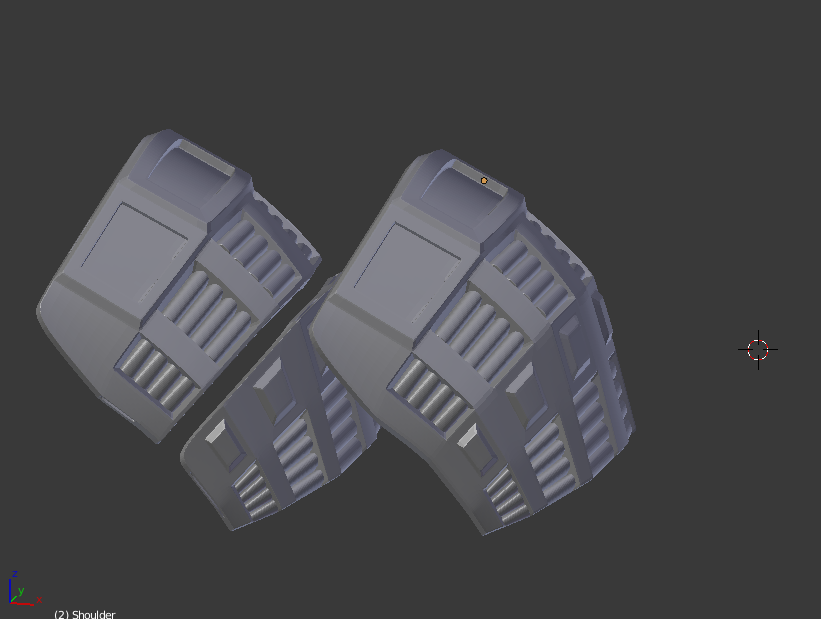

Shoulder: 2 options.

1) Keep it as one piece or 2?

Right now, the broken one has slots for nylon strapping.

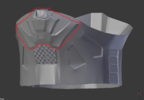

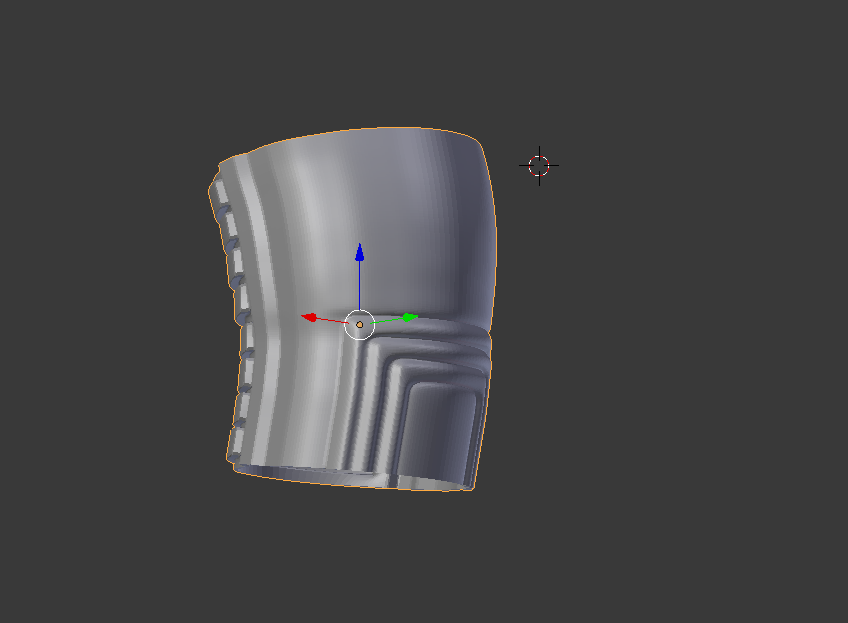

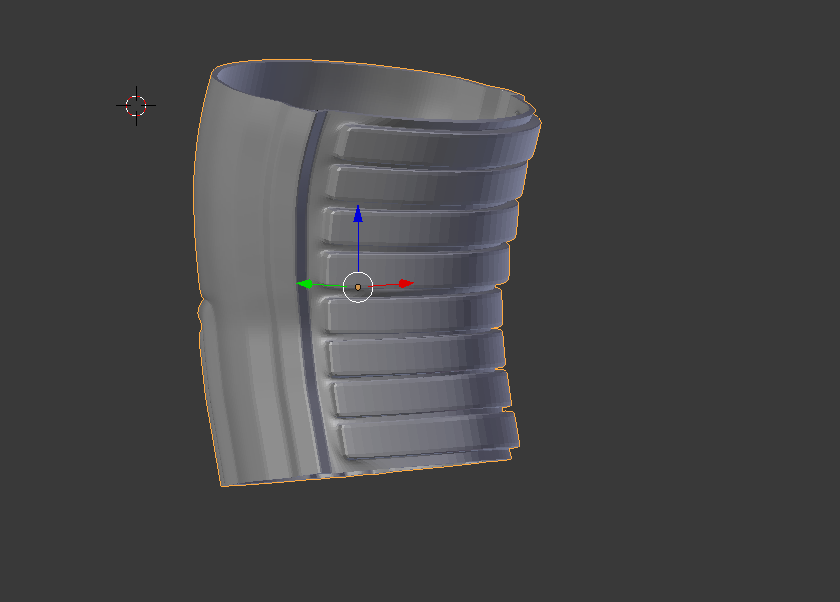

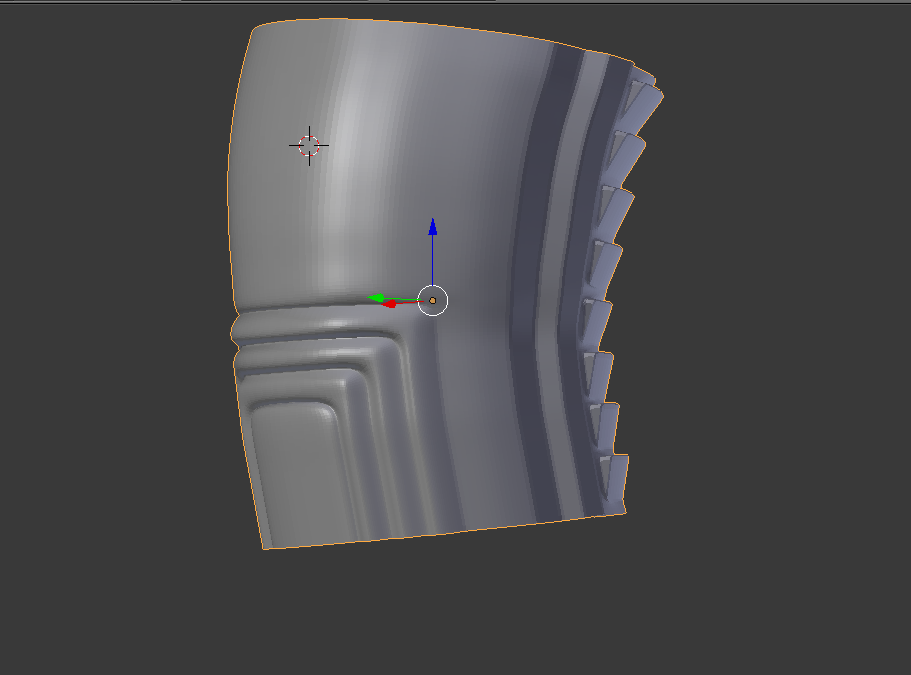

Elbow:

Torso:

Pants:

Knee:

Not much different from the elbow:

I'm entering the final stages of designing Halo Infinite under armor (Generic). Before I release them, what are your thoughts on the way they Look/Function.

Do you have a suggestion to improve them? Grab an image and draw what you are looking for in functionality (a cut here, opening there to allow for nylon strapping, etc.)

I currently have them with a wall thickness of about 2mm to allow for more flexibility, but this may cause more issues while printing.

Neck

Should I print with a slice open in the back? Should the neck be higher?

Shoulder: 2 options.

1) Keep it as one piece or 2?

Right now, the broken one has slots for nylon strapping.

Elbow:

Torso:

Pants:

Knee:

Not much different from the elbow: