You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

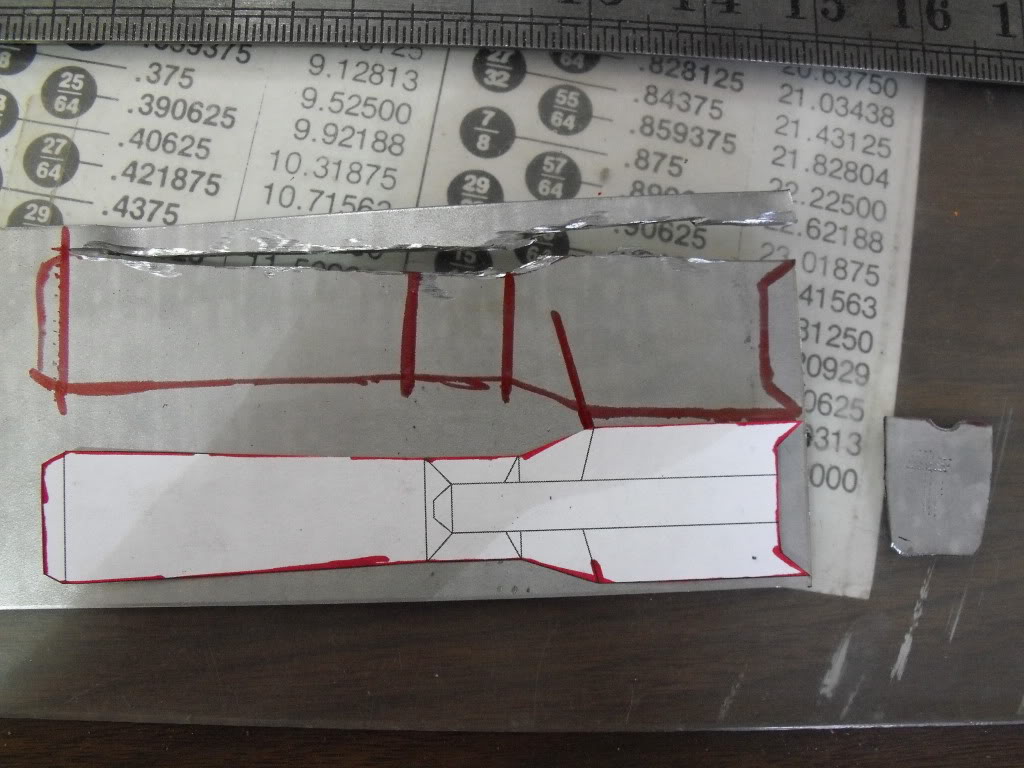

Props Jf140's Metal M6g Wip

- Thread starter JangoFett140

- Start date

- Status

- Not open for further replies.

S1l3nt V1p3r

Sr Member

Geijin said:Very nice. You do realize, though, your going to play hell trying to get that thing detailed and bent into the correct angles. I can't wait to see it, but I'm glad I'm not the one doing it.

Thank god for angle grinders! ;D

Last edited by a moderator:

Geijin said:Very nice. You do realize, though, your going to play hell trying to get that thing detailed and bent into the correct angles. I can't wait to see it, but I'm glad I'm not the one doing it.

yea i know i wont get the best detailing ever, especially since im not the best metal worker aka noob lol. but i figured whats the worst i can do?? fail at something no one else has tried so ill be happy with what ever i get

I realized the other day the my mag is to big for the ammo stated to be used in the M6g on halopedia so im thinking of adding an insert to make it the right size. thoughts??

tomorrow i will have the two slide bases done and maybe the next piece!

Last edited by a moderator:

My question is, is it to wide or to long? If its to wide and still fits the grip, the spacers shouldn't be a problem. Could even deguise them a little bit so you'd never know, or stagger the rounds in the magazine to take up some of the space. If its that its to long, I guess it would depend on how exact you want it to be. If the magazine fits the grip and doesn't have any play in it, I'd say thats pretty good. If your that set on detail, I'd suggest trimming down the magazine a little, and adding a spacer in the back of the grip to shrink down the magazine well, similar to the grip of the Glock 22.

tenfingersofdoom

New Member

Don't point that at any cops.

Geijin, im not sure entirely what you mean, its the spacer would be in the mag, and also im using 16 gauge steal whick a real gun would not be made from. ok on the mag some more I need help from you guys here. I no nothing of bullet types and what not so when Halopedia states that it fires 12.7mm x 40mm M225 Semi-Armor-Piercing High-Explosive/.50 Magnum Caliber Rounds does the 12.7mm refer to the diameter of the bullet or the circumference??

as for progress i have the slide bases cut and the bottom front piece i think i know how im doing the flash suppressor its just hard to explain. Im still not sure on the slide its self either but i have a few ideas, ill whip up a pic tomorrow to show what im thinking.

as for progress i have the slide bases cut and the bottom front piece i think i know how im doing the flash suppressor its just hard to explain. Im still not sure on the slide its self either but i have a few ideas, ill whip up a pic tomorrow to show what im thinking.

protonguy-im using an air saw. im using 16 gauge steel so its to thick for tin snips (over at least the crappy ones we have)

Ok, firstly, 12.7mm should be the diameter. I've never thought to ask before, but based on simple math, that would be my thought, as if it were the circumference you would have a diameter of just a hair over 4mm or about 1/4 of an inch. There is no way you could have enough powder or heavy enough lead for it to be classed as a .50 cal round. For reference, the .22 calibur long rifle round is about 6mm diameter or a little over 1/4 of an inch.

As to my question, you said the magazine was to big. What do you mean to big? Is the magazine loose in the well and how so? Is is sliding around front to back or side to side? If its front to back, then yes you can use a spacer, just like the Glock does. If its side to side, you can use spacers, but you'll probably want to disguise them some how. Or are you worried about the rounds not sitting right in the magazine? If thats the case, then you might be better off to recut the magazine. If you try to use spacers, and plan to have a springloaded magazine to feed the rounds up, then you could run into problems with jamming the spring from faults in the spacer, welds or anything else.

As to my question, you said the magazine was to big. What do you mean to big? Is the magazine loose in the well and how so? Is is sliding around front to back or side to side? If its front to back, then yes you can use a spacer, just like the Glock does. If its side to side, you can use spacers, but you'll probably want to disguise them some how. Or are you worried about the rounds not sitting right in the magazine? If thats the case, then you might be better off to recut the magazine. If you try to use spacers, and plan to have a springloaded magazine to feed the rounds up, then you could run into problems with jamming the spring from faults in the spacer, welds or anything else.

Geijin said:As to my question, you said the magazine was to big. What do you mean to big? Is the magazine loose in the well and how so? Is is sliding around front to back or side to side? If its front to back, then yes you can use a spacer, just like the Glock does. If its side to side, you can use spacers, but you'll probably want to disguise them some how. Or are you worried about the rounds not sitting right in the magazine? If thats the case, then you might be better off to recut the magazine. If you try to use spacers, and plan to have a springloaded magazine to feed the rounds up, then you could run into problems with jamming the spring from faults in the spacer, welds or anything else.

ok

Last edited by a moderator:

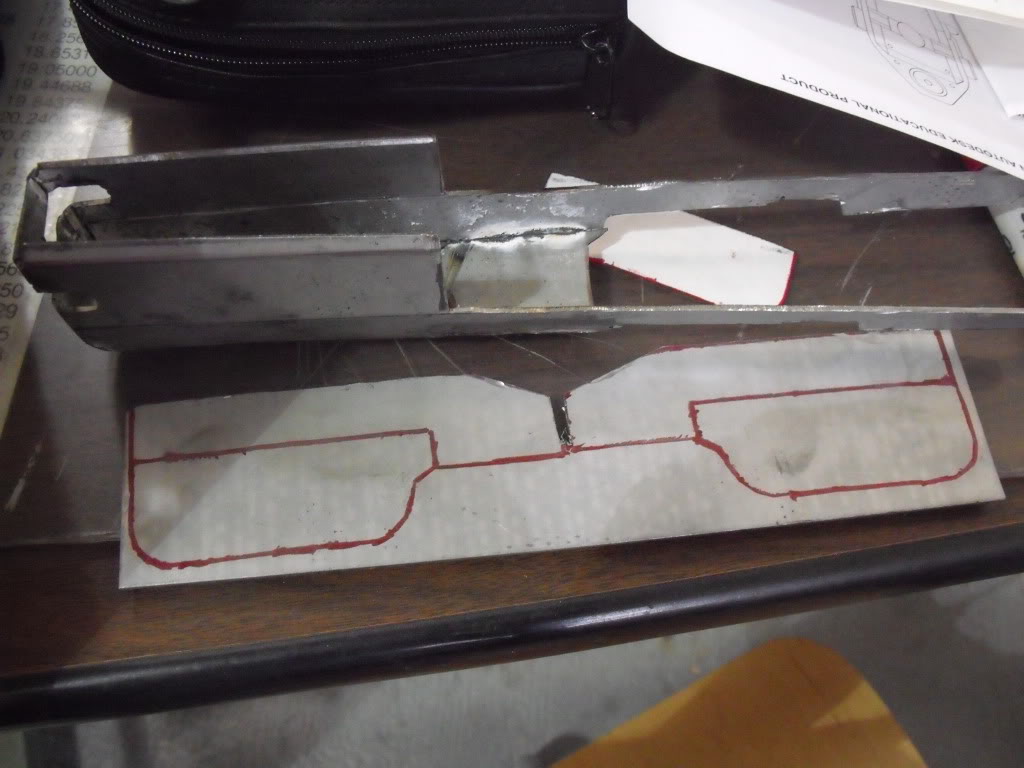

I forgot the measurements ill get them tomorrow. I got some work done today. I started assembling the base of the slide to day. Tomorrow I want to finish the laser housing and start on the slide assembly.

S1l3nt V1p3r

Sr Member

It seems you forgot to bend the metal into shape before you welded it together. A mistake, or do you plan on using an angle grinder to fix it?

S1l3nt V1p3r said:It seems you forgot to bend the metal into shape before you welded it together. A mistake, or do you plan on using an angle grinder to fix it?

Bend Where???

So i forgot the measurements again

So heres what the tops looking like.

Last edited by a moderator:

LeeKegan said:Great progress!

Thanks Lee

Last edited by a moderator:

centerside

Well-Known Member

Hmm, looking good, the handle is looking great, keep everyone updated  Like how it's comming along, very nice work

Like how it's comming along, very nice work

CPU64

Well-Known Member

I strongly recommend shears over (ack!)cutting wheels. Or at least get a nibbler man

Also not saying to start over, but if you used a thinner gauge sheet, it would be so much easier to work with.

And one final tip, think about how pep is built, and use the same approach to this build. You can spot weld, then fill with solder, like old school cars.

You'll get awesome results fast!

Also not saying to start over, but if you used a thinner gauge sheet, it would be so much easier to work with.

And one final tip, think about how pep is built, and use the same approach to this build. You can spot weld, then fill with solder, like old school cars.

You'll get awesome results fast!

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 520