Hello 405th! To christen the brand-spankin-new site, i thought I'd share my freshly made, 3D printable halo weapons!

Long story short, i found an old flash drive FILLED with old pepakura files. after a little trip down nostalgia lane, i realized that i could import these old models into maya, slice and dice em, and make them 3D printable!

So that's what i did!

(i've also included labeled Build guides in case things get confusing)

COVENANT CARBINE

[Download]

Build Guide

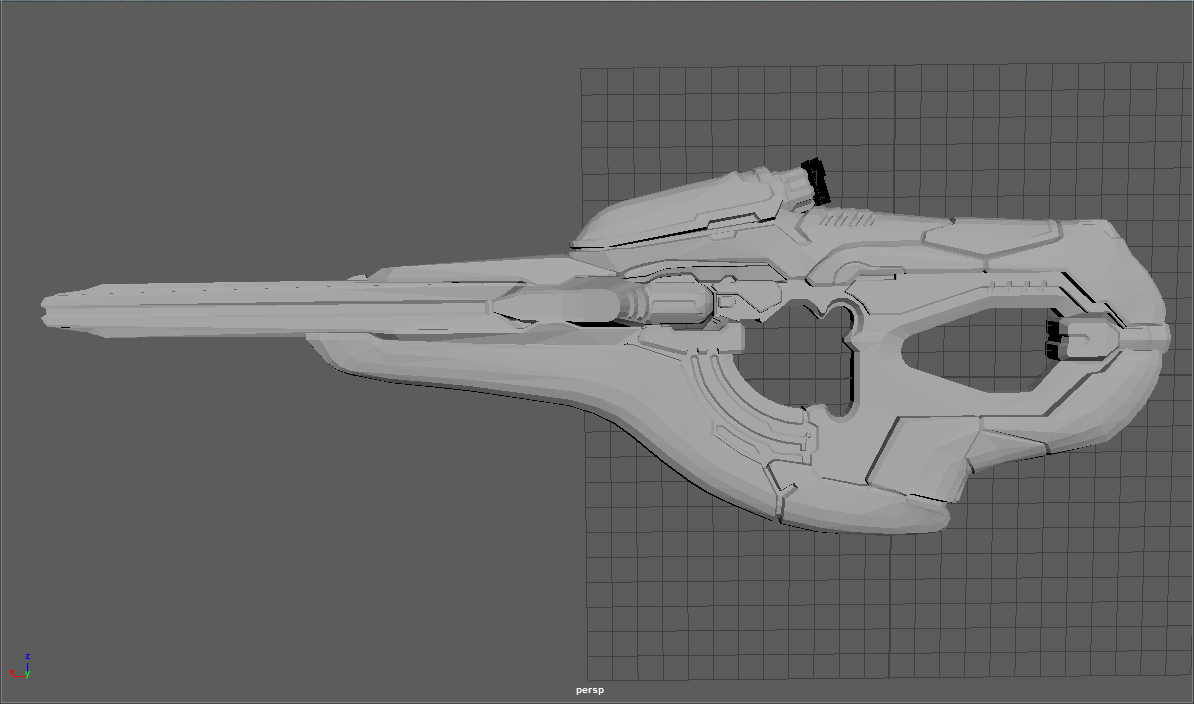

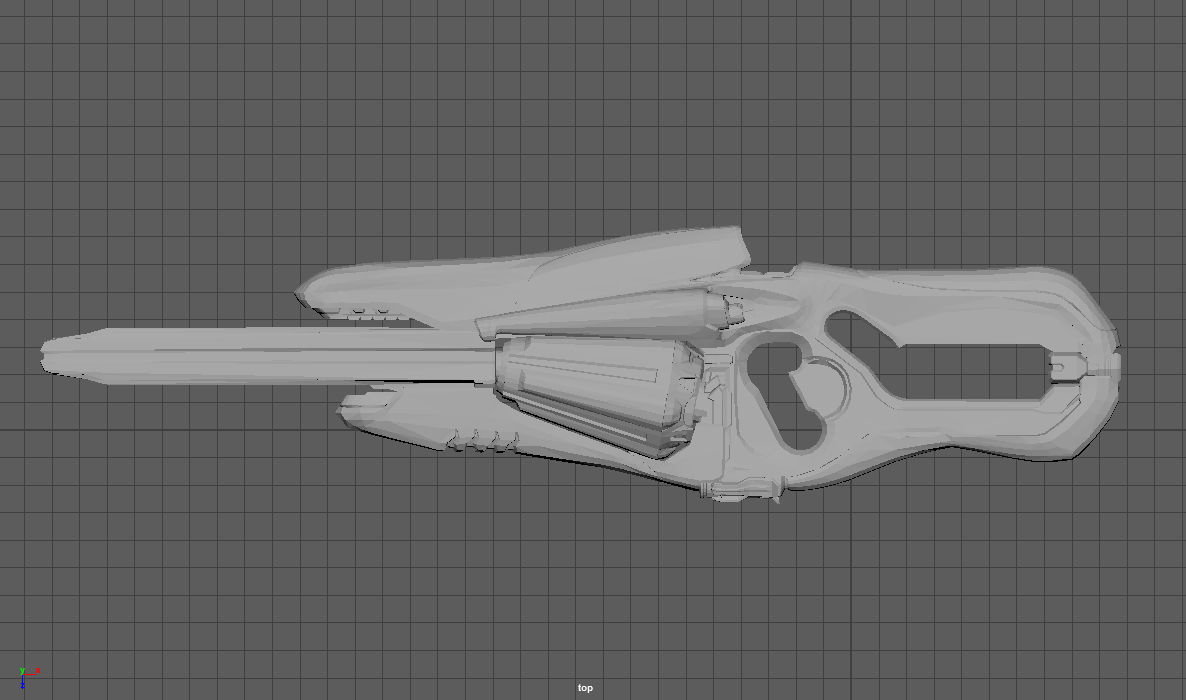

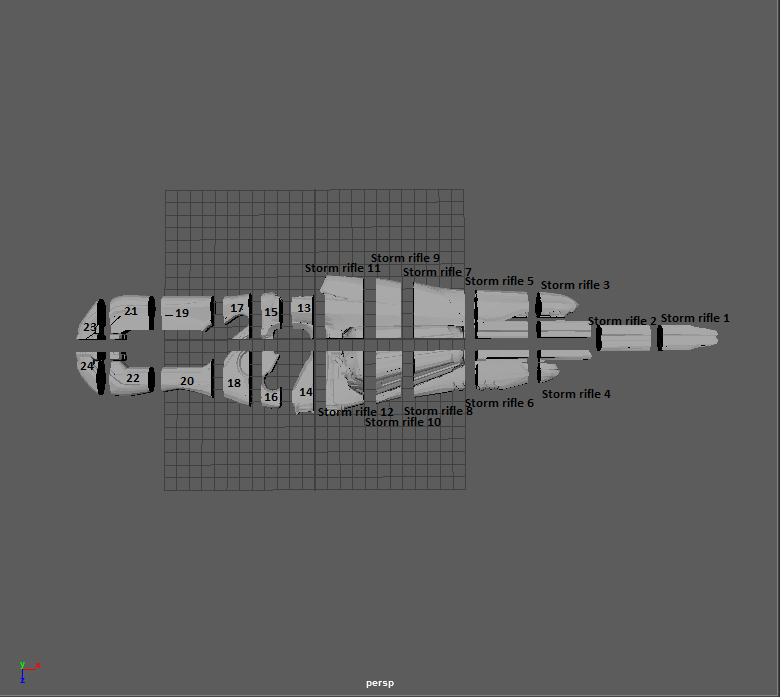

STORM RIFLE

[Download]

Build guide

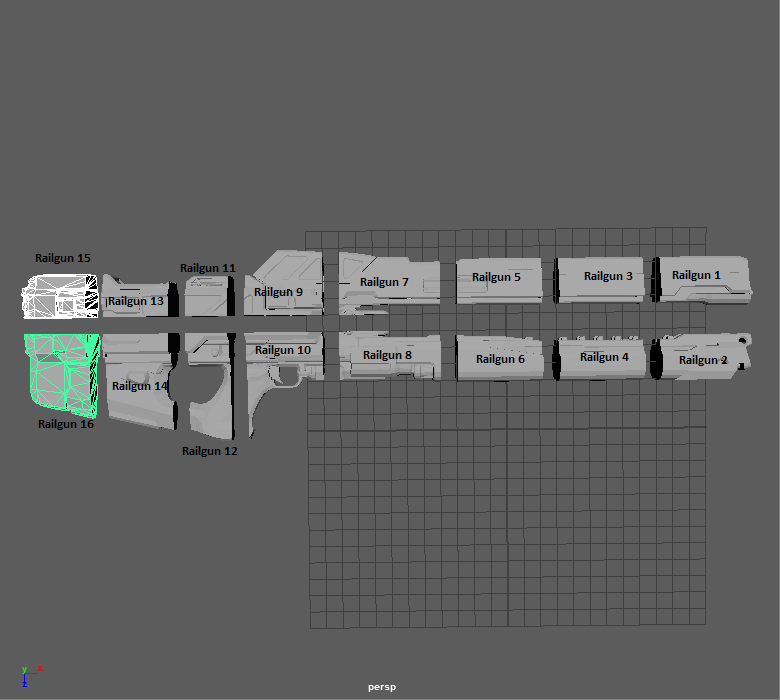

RAILGUN

[Download]

Build guide

SUPPRESSOR

[Download]

Build guide

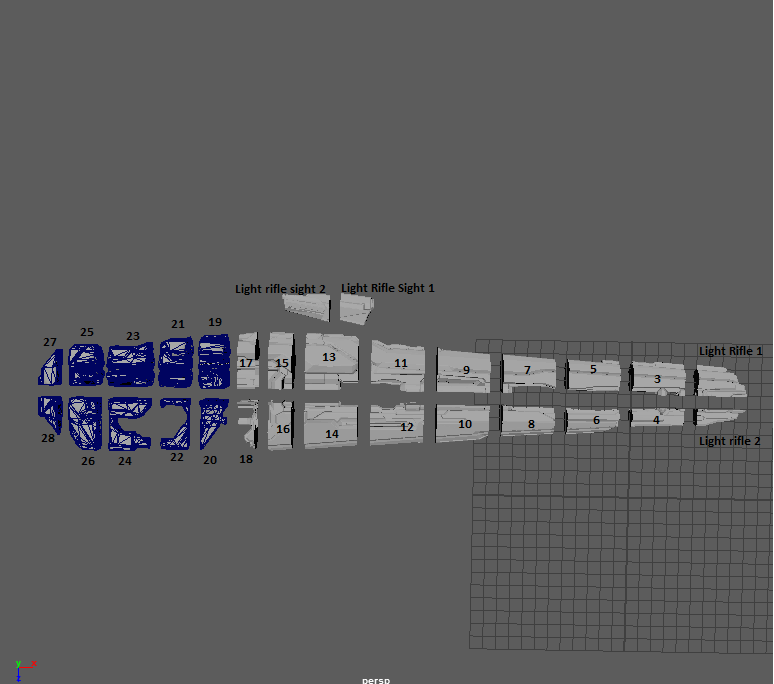

LIGHT RIFLE [needs fixing]

[Download]

Build guide

MA5B

[Download]

Build guide

And that's everything i got so far!

I went through EVERYTHING with a fine-tooth comb to make sure every single piece added up properly to make all the weapons canon size (dimensions taken from Halo: a visual guide) and arranged all the pieces to minimize awkward support material, just to make it super easy. it's just download and print. however, my Robo3D has a pretty big build plate, which i kinda relied on when cutting the pieces. it shouldn't be too much of an issue for most pieces, but some of the wider ones may not fit on the smaller build plates. i can fiddle and fix certain pieces if you let me know.

However, like the title says, i do need a little help. i was relying heavily on the windows azure 3D model repair toolkit to make the sliced models "airtight", but its an automatic service, so it's not 100%. the Light Rifle is the only one affected, and i've marked the STLs that need fixing. so if someone with more modeling skills than me could get in there and try to fix it, i'll be sure to put a big fat thank you at the top once its done!

Lastly: if you have any high-res prop files, send them my way! i only had a few to work with (and am still working on more that i'll add once they're done) and i wanna do more! Otherwise, enjoy!

Long story short, i found an old flash drive FILLED with old pepakura files. after a little trip down nostalgia lane, i realized that i could import these old models into maya, slice and dice em, and make them 3D printable!

So that's what i did!

(i've also included labeled Build guides in case things get confusing)

COVENANT CARBINE

[Download]

Build Guide

STORM RIFLE

[Download]

Build guide

RAILGUN

[Download]

Build guide

SUPPRESSOR

[Download]

Build guide

LIGHT RIFLE [needs fixing]

[Download]

Build guide

MA5B

[Download]

Build guide

And that's everything i got so far!

I went through EVERYTHING with a fine-tooth comb to make sure every single piece added up properly to make all the weapons canon size (dimensions taken from Halo: a visual guide) and arranged all the pieces to minimize awkward support material, just to make it super easy. it's just download and print. however, my Robo3D has a pretty big build plate, which i kinda relied on when cutting the pieces. it shouldn't be too much of an issue for most pieces, but some of the wider ones may not fit on the smaller build plates. i can fiddle and fix certain pieces if you let me know.

However, like the title says, i do need a little help. i was relying heavily on the windows azure 3D model repair toolkit to make the sliced models "airtight", but its an automatic service, so it's not 100%. the Light Rifle is the only one affected, and i've marked the STLs that need fixing. so if someone with more modeling skills than me could get in there and try to fix it, i'll be sure to put a big fat thank you at the top once its done!

Lastly: if you have any high-res prop files, send them my way! i only had a few to work with (and am still working on more that i'll add once they're done) and i wanna do more! Otherwise, enjoy!

Last edited by a moderator: