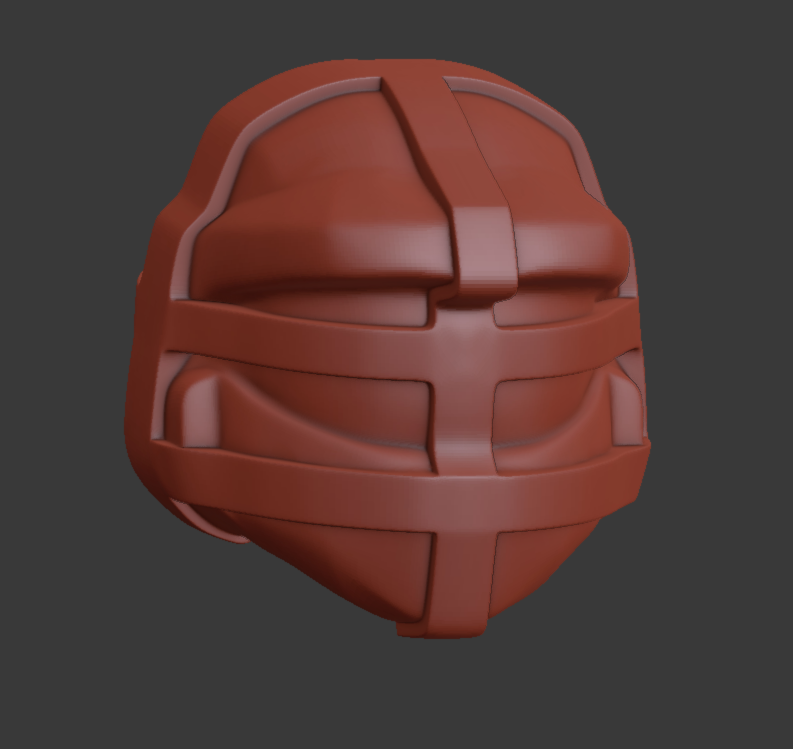

So as I've decided that I wasn't happy with the scale; i've elected to rescale the helmet back to spartan size. Whilst the helmet would otherwise before perfectly scaled; once you add the hard armor; i believe it may actually be too small.

In the meantime that I was awaiting for more filament to arrive and my nozzle upgrade; I've done a few adjustments to the model (Again).

I've seperated areas which be tricky to both mold and cast; to prevent any cases of airbubbles. This is ofcourse the light areas and the vents. This and the fact that on the test print it was a pain in the A$$ to carefully sand.

Because I'm keeping the "Grid pattern" on the lights because of the accuracy as per the photo below; I will try to send the Light domes off to get printed on a SLA printer.

I made sure no one can install them in the wrong orientation by adding slots. To make sure the grid pattern has the correct amount of lines; I counted the lines on the cutscenes.

I do intend to cast these in clear resin. If needed they have a hole to fit a LED.

The face it glues into has a punched hole to allow for easy drilling incase you want to install wires.

As usual; i was a little bit unhappy with the model after seeing 1-1 statues of the halo 2a chief from Outpost; and resorted to one technique to get correct depths of cuts based off textures. Pythagoras theorem. Oh god.

Since the original model is a decimated version of blur; the textures retain some accuracy of the faces just pulled over the decimated areas. To get a correct depth of a certain area which is textured; you have to use pythagoras theorem to get the the missing average and add it as depth to your selected "shallow part" of the texture.

You're basically rotating C back to a 180 degree angle. Blender might have a measurement tool in place to save me all the hassle; but I'm still a novice at blender to bother finding it.

I promise this is the last of the 3d tinkering. I'm satisfied now.