3DVagabond

Active Member

Update Time!

...

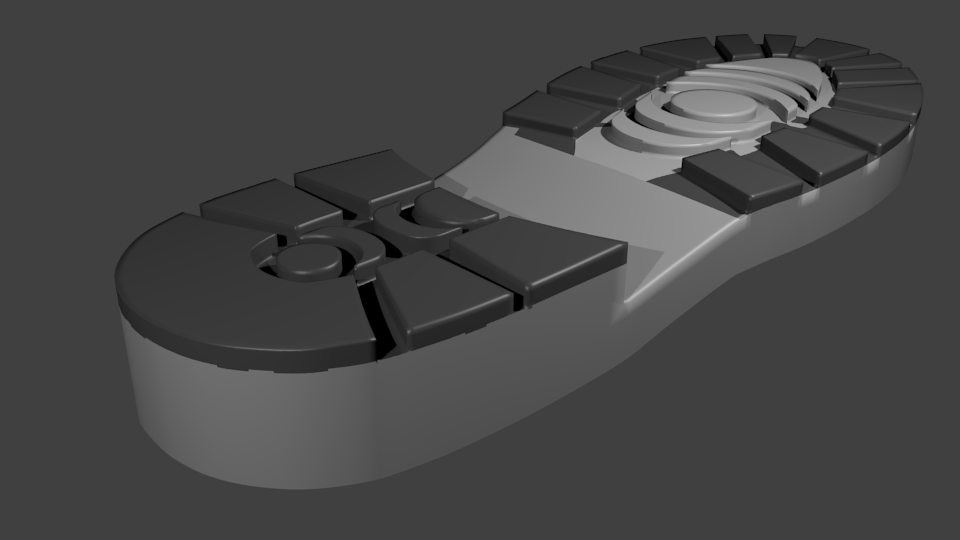

Making an outsole for a boot is hard work!

As much time I looked at how it's crafted, there's not enough information out there when it comes to making it with the research I've done. Either there's not enough information on it or the reason why is because not enough people have actually tried to making it from home. It's actually harder to refine the process than the actual suit and helmet combined!

When it comes to making the outsole of the boot, I have to come across 2 actual factors.

Factor 1 is that I have to come across a design that is slip resistant. I had to take a look at what it looks like on the recent pair of boots I made and tried to understand the design. Some how I got it to work with the mock up.

Of course, I will need to make more groves for the liquid to channel through.

Factor 2 is the part where I will have to create the "crate" or "ribs" section of the boot. This will reduce the weight of the boot and prevent it from making it one gigantic solid piece of rubber. I have not made that yet and more research is needed in order to make that part. I'll have to dive into the internet again to hopefully find the answer to it.

Anyway, that's all for now. The process of the boot continues onward and maybe, I'll have something more to show on the next update.

See you later for now!

...

Making an outsole for a boot is hard work!

As much time I looked at how it's crafted, there's not enough information out there when it comes to making it with the research I've done. Either there's not enough information on it or the reason why is because not enough people have actually tried to making it from home. It's actually harder to refine the process than the actual suit and helmet combined!

When it comes to making the outsole of the boot, I have to come across 2 actual factors.

Factor 1 is that I have to come across a design that is slip resistant. I had to take a look at what it looks like on the recent pair of boots I made and tried to understand the design. Some how I got it to work with the mock up.

Of course, I will need to make more groves for the liquid to channel through.

Factor 2 is the part where I will have to create the "crate" or "ribs" section of the boot. This will reduce the weight of the boot and prevent it from making it one gigantic solid piece of rubber. I have not made that yet and more research is needed in order to make that part. I'll have to dive into the internet again to hopefully find the answer to it.

Anyway, that's all for now. The process of the boot continues onward and maybe, I'll have something more to show on the next update.

See you later for now!

![20231013_134858[1].jpg 20231013_134858[1].jpg](https://405th-f28a.kxcdn.com/forums/data/attachments/337/337003-08ce898bc3e6caee3ea95328437bee65.jpg)

![20231013_135014[1].jpg 20231013_135014[1].jpg](https://405th-f28a.kxcdn.com/forums/data/attachments/337/337005-ce91e7eadba732de792ce9d2b8ae276d.jpg)

![20230901_112056[2].jpg 20230901_112056[2].jpg](https://405th-f28a.kxcdn.com/forums/data/attachments/337/337004-38251442f93285f47bbbe31d745552d9.jpg)

![20231024_132542[1].jpg 20231024_132542[1].jpg](https://405th-f28a.kxcdn.com/forums/data/attachments/337/337579-5881a7ac8b7e0ee68e959b53caef5174.jpg)