Viridiana Sovari

Active Member

Its Go Time!!!!!

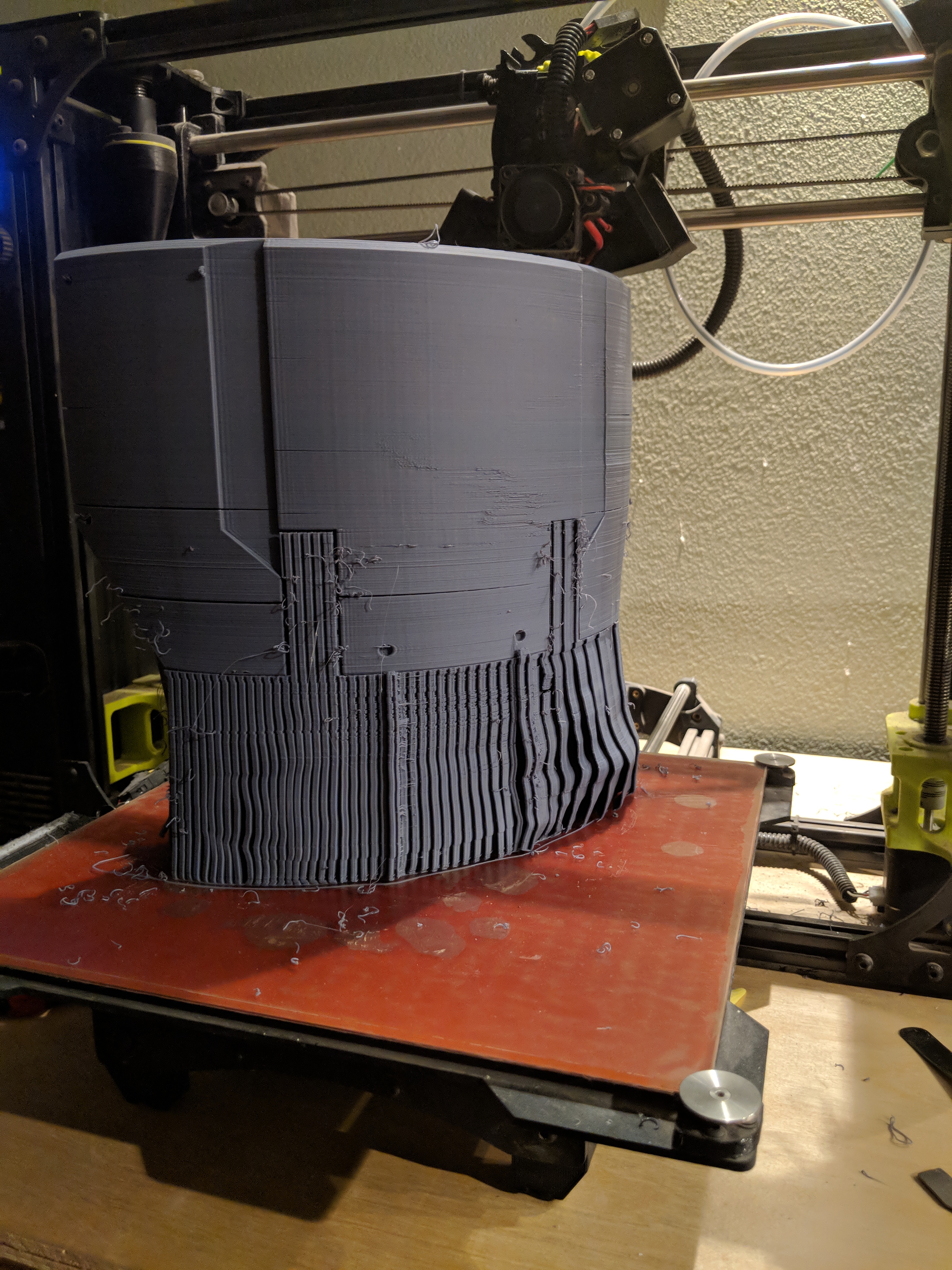

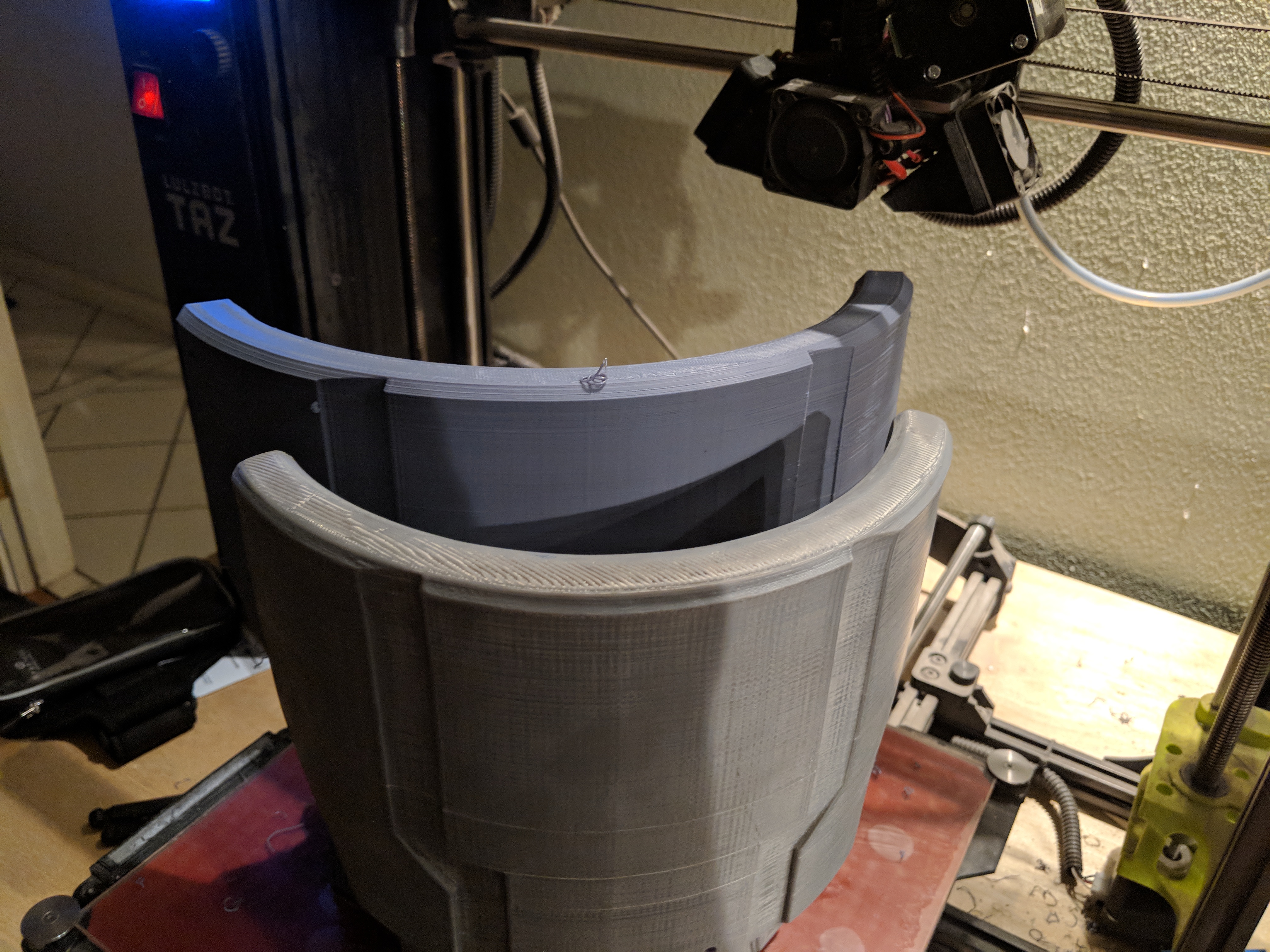

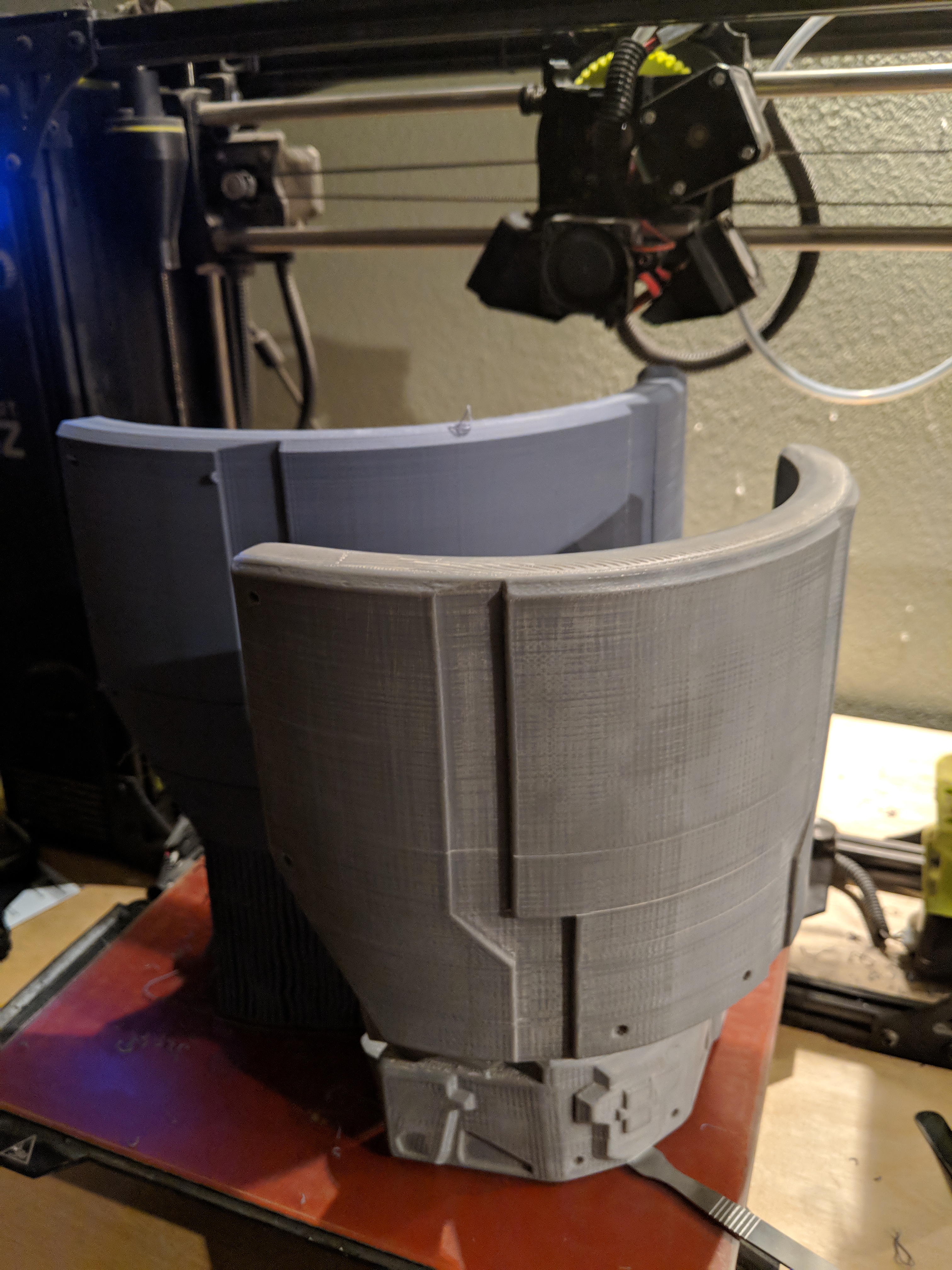

So, more pictures. I wrote about needing to re-print the Commando shoulder and I decided to do just that. Let me just preface that this thing is HUGE and I love it

This time I scaled it to max and then increased the width to I think 200mm. For reference its box dimensions are 200mm x 200mm x 250mm.

Time for pictures fresh off the bed.

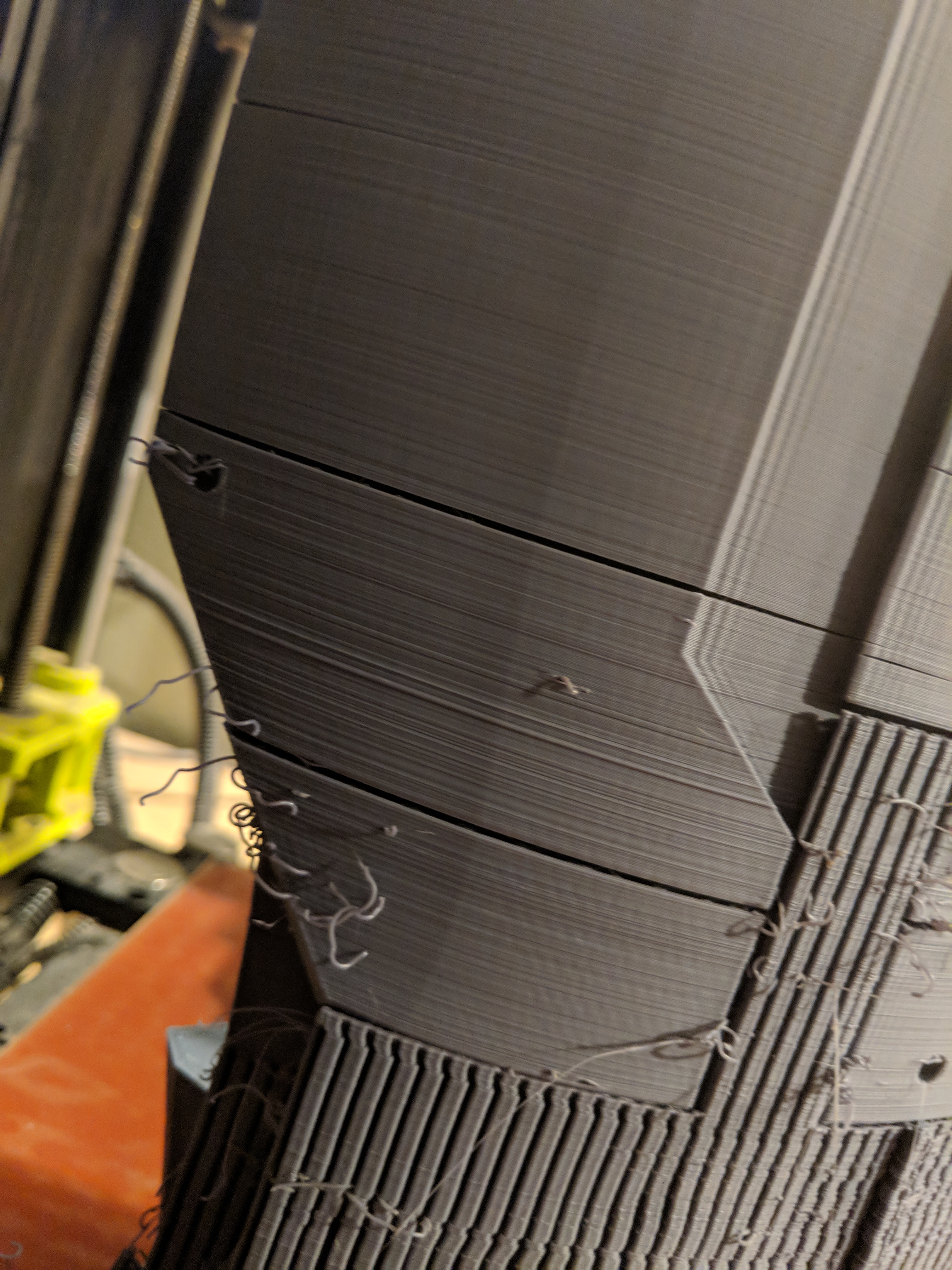

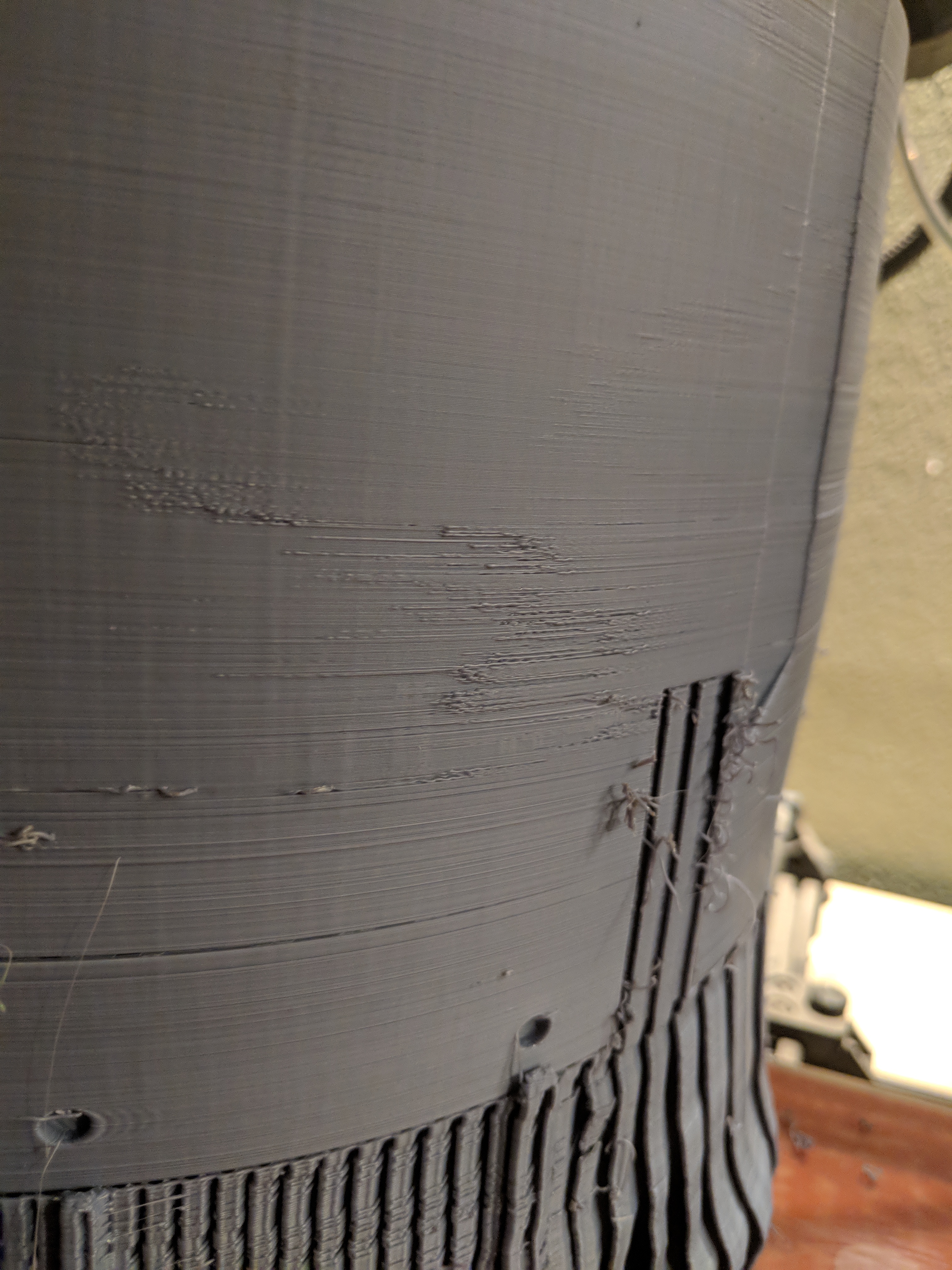

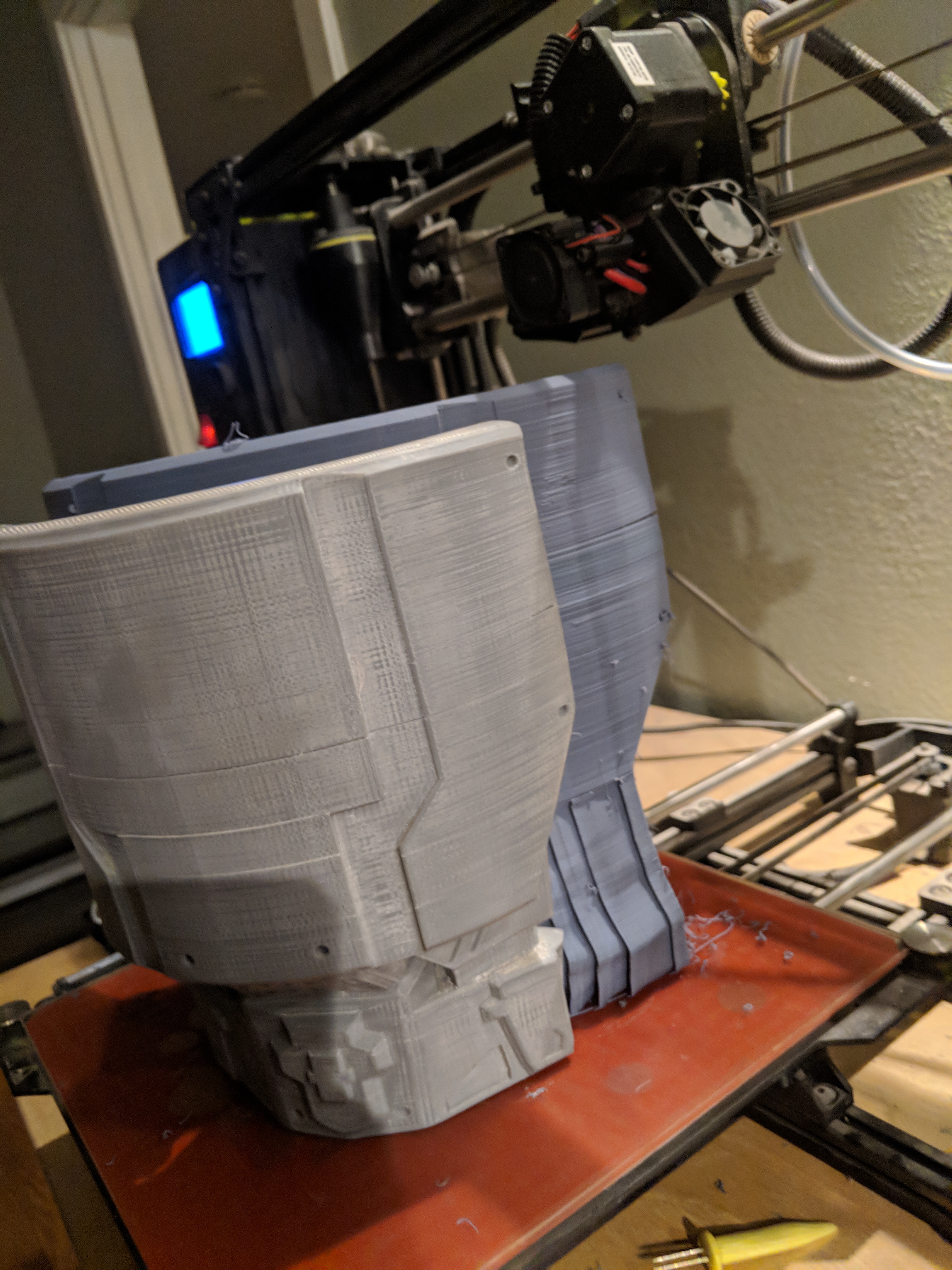

Some printing defects like I had mentioned before:

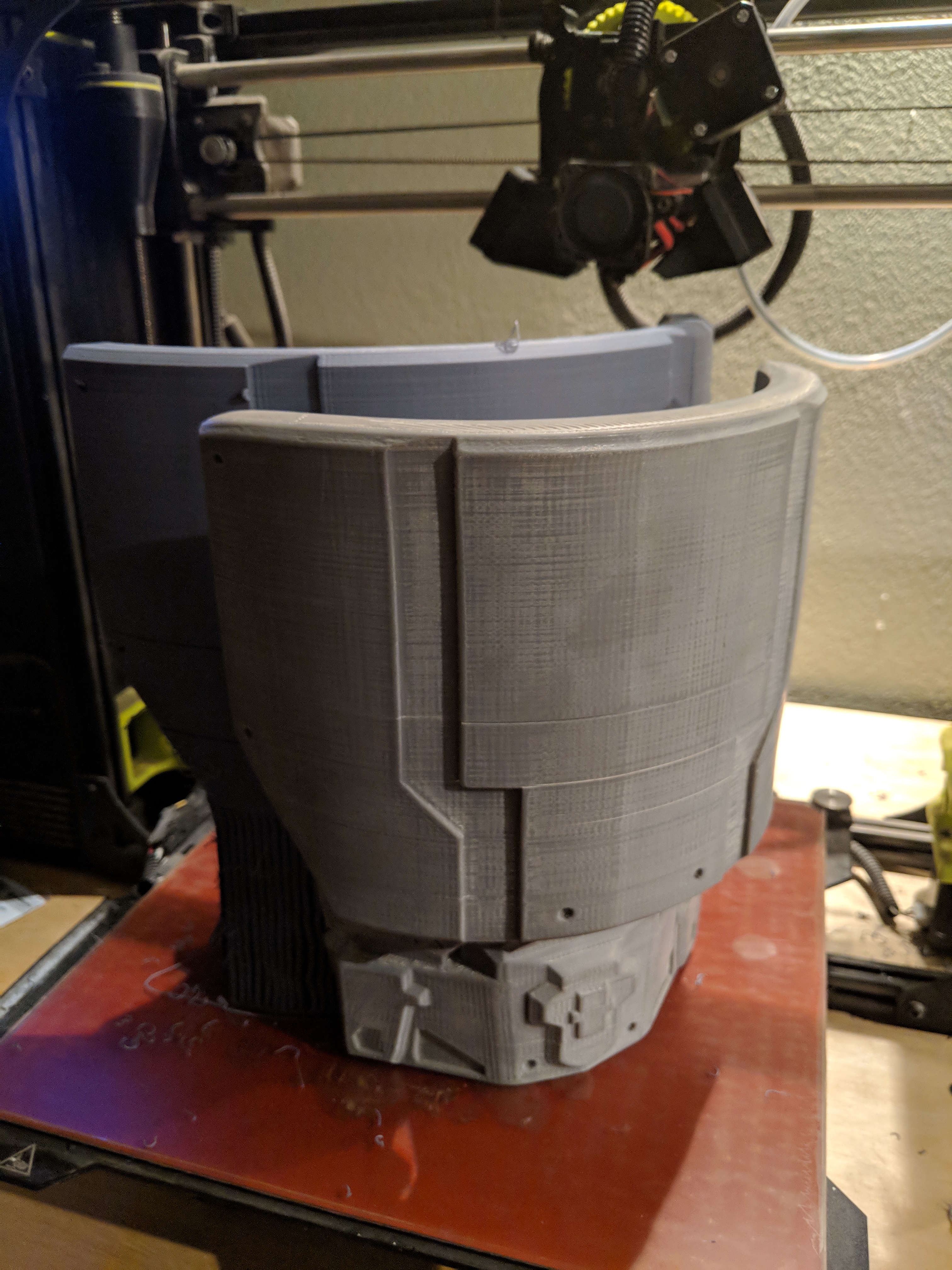

Now size comparison:

as you can see this thing is much better, I'm just hoping it actually fits on my bicep piece!

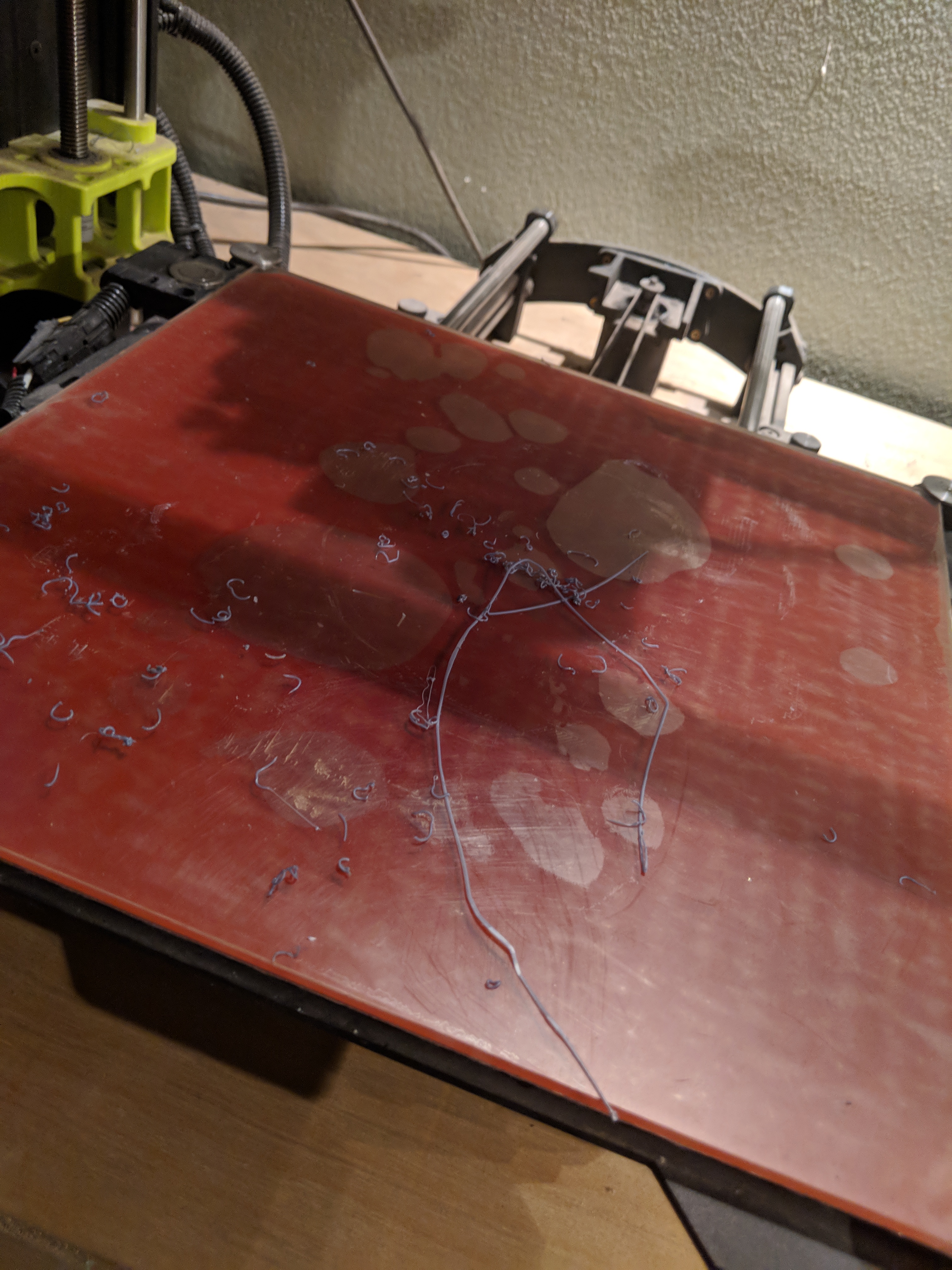

One last note it looks like my print bed is having issues and starting to bubble. I will probably have to replace this soon.

Time to pull off the support structure and get to playing!

Vi Out!

So, more pictures. I wrote about needing to re-print the Commando shoulder and I decided to do just that. Let me just preface that this thing is HUGE and I love it

This time I scaled it to max and then increased the width to I think 200mm. For reference its box dimensions are 200mm x 200mm x 250mm.

Time for pictures fresh off the bed.

Some printing defects like I had mentioned before:

Now size comparison:

as you can see this thing is much better, I'm just hoping it actually fits on my bicep piece!

One last note it looks like my print bed is having issues and starting to bubble. I will probably have to replace this soon.

Time to pull off the support structure and get to playing!

Vi Out!